吉林大学学报(工学版) ›› 2025, Vol. 55 ›› Issue (3): 974-985.doi: 10.13229/j.cnki.jdxbgxb.20230560

常规三轴压缩下高强混凝土能量演化和破坏准则

- 1.安徽理工大学 土木建筑学院,安徽 淮南 232001

2.安徽建筑大学 建筑结构与地下工程安徽省重点实验室,合肥 230601

3.安徽大学 资源与环境工程学院,合肥 230022

Energy evolution law and failure criterion of high strength concrete under conventional triaxial compression

Liang-liang ZHANG1( ),Hua CHENG1,2,3(

),Hua CHENG1,2,3( ),Xiao-jian WANG1

),Xiao-jian WANG1

- 1.School of Civil Engineering and Architecture,Anhui University of Science and Technology,Huainan 232001,China

2.Anhui Provincial Key Laboratory of Building Structure and Underground Engineering,Anhui Jianzhu University,Hefei 230601,China

3.School of Resources and Environmental Engineering,Anhui University,Hefei 230022,China

摘要:

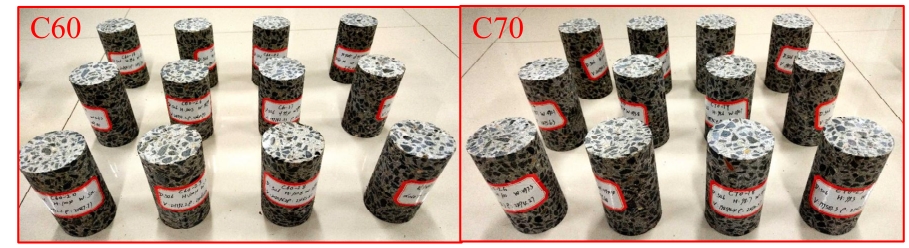

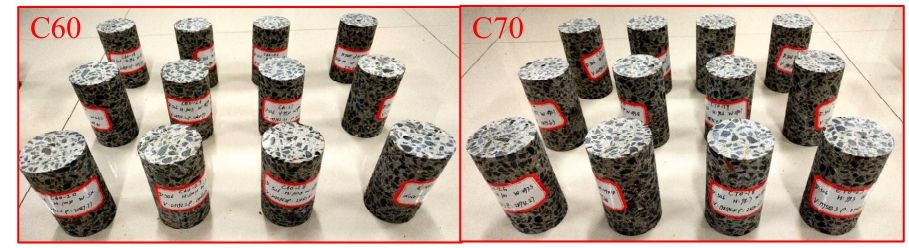

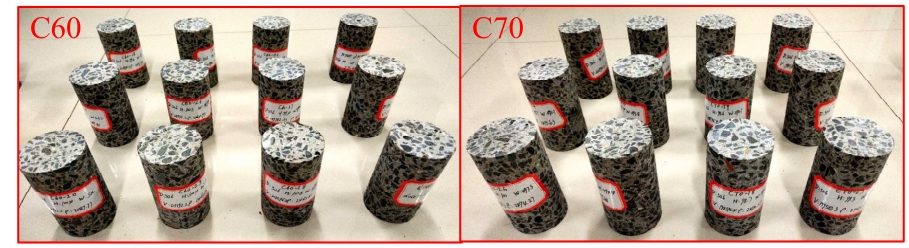

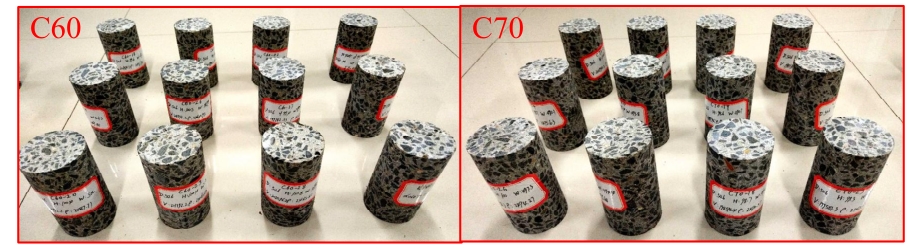

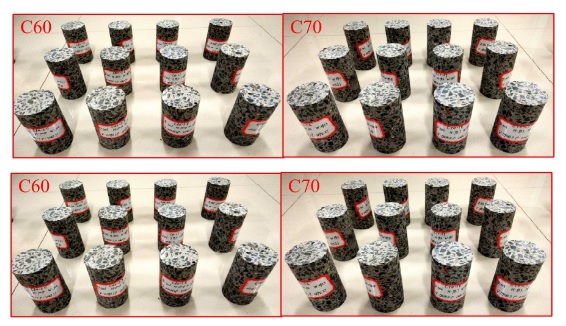

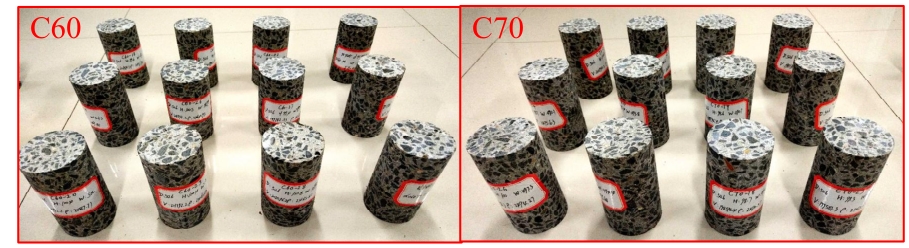

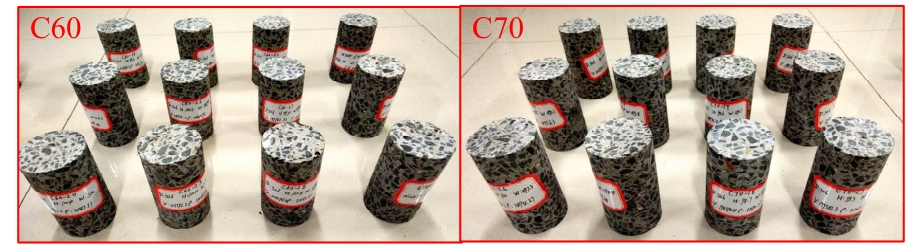

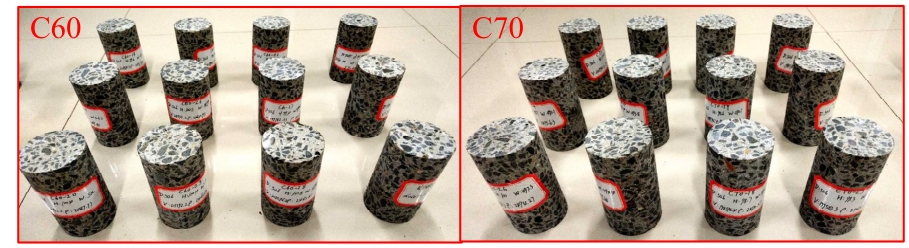

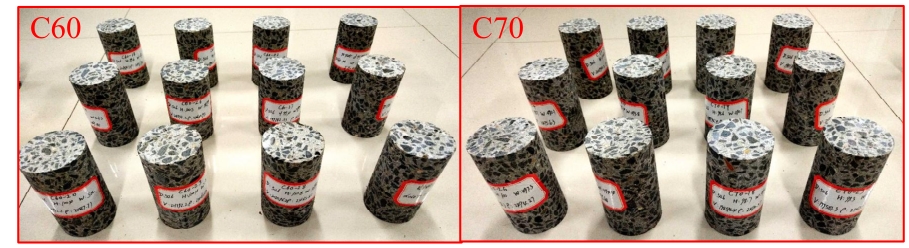

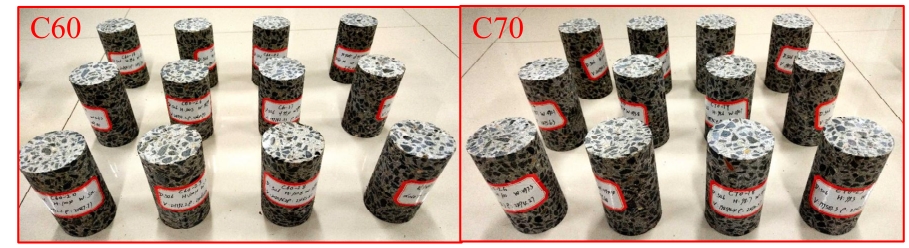

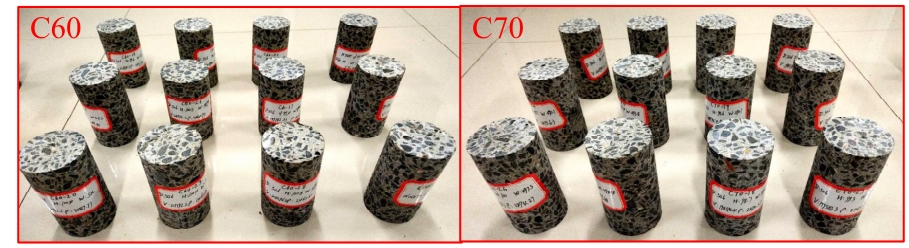

为研究高强混凝土在常规三轴压缩状态下的能量演化规律与整体破坏行为,开展了5组不同围压下C60和C70高强混凝土常规三轴压缩试验。基于试验结果和热力学能量守恒原理,得到高强混凝土输入能密度、弹性应变能密度和耗散能密度随轴向应变和围压的变化规律,并根据高强混凝土峰值应力对应的弹性应变能密度与围压成线性增长关系,建立了基于弹性应变能密度的高强混凝土破坏准则。研究结果表明:①高强混凝土输入能密度和耗散能密度均随轴向应变的增大而增大,弹性应变能密度在峰前阶段随轴向应变的增大而增大,峰后随之减小;②高强混凝土峰值应力对应输入能密度和耗散能密度均随围压的增大而增大,且同等围压条件下C70高强混凝土峰值应力对应的输入能密度和耗散能密度均大于C60高强混凝土;③基于弹性应变能密度的高强混凝土破坏准则精度高、所含参数少且物理意义明确,该准则表达形式与Hoek-Brown破坏准则相似,但其适用性更加广泛;④高强混凝土破坏准则在π平面为等边不等角的对称六边形,根据“化角为弧”的方法对破坏曲线奇异点进行了圆化处理。本文研究结果可为从能量角度研究混凝土材料变形破坏行为提供新的思路。

中图分类号:

- TU528

| 1 | Zhang L L, Cheng H, Wang X J, et al. Statistical damage constitutive model for high-strength concrete based on dissipation energy density[J]. Crystals, 2021, 11(7): No.800. |

| 2 | 李毅, 程桦, 张亮亮.不同围压下C60混凝土三轴压缩过程能量分析[J]. 应用力学学报, 2020, 37(5): 2086-2093. |

| Li Yi, Cheng Hua, Zhang Liang-liang. Energy analysis of C60 concrete under triaxial compression under different confining pressures[J]. Chinese Journal of Applied Mechanics, 2020, 37(5): 2086-2093. | |

| 3 | 岳健广, 夏月飞, 方华. 钢纤维混凝土断裂破坏机理及受拉损伤本构试验研究[J].土木工程学报, 2021, 54(2): 93-106. |

| Yue Jian-guang, Xia Yue-fei, Fang Hua. Experimental study on fracture mechanism and tension damage constitutive relationship of steel fiber reinforced concrete[J]. China Civil Engineering Journal, 2021, 54(2): 93-106. | |

| 4 | Zhang Z Z, Gao F. Experimental investigation on the energy evolution of dry and water-saturated red sandstones[J]. International Journal of Mining Science and Technology, 2015, 25: 383-388. |

| 5 | 王四巍, 王忠福, 潘旭威, 等. 多轴应力下塑性混凝土峰值后变形特征[J]. 建筑材料学报, 2014, 17(4): 654-658. |

| Wang Si-wei, Wang Zhong-fu, Pan Xu-wei, et al. Post peak deformation characteristics of plastic concrete under multiaxial stress state[J]. Journal of Building Materials, 2014, 17(4): 654-658. | |

| 6 | 郭寅川, 谢波, 周利超, 等. 动态疲劳荷载下玄武岩纤维混凝土抗渗性衰减及机理研究[J]. 硅酸盐通报, 2022, 41(3): 810-817. |

| Guo Yin-chuan, Xie Bo, Zhou Li-chao, et al. Impermeability attenuation and mechanism of basalt fiber reinforced concrete under dynamic fatigue load[J]. Bulletin of the Chinese Ceramic Society, 2022, 41(3): 810-817. | |

| 7 | 王怀亮. 钢纤维高性能轻骨料混凝土多轴强度和变形特性研究[J]. 工程力学, 2019, 36(8): 122-132. |

| Wang Huai-liang. Strength and deformation properties of high performance steel fiber reinforced lightweight concrete under multiaxial compression[J]. Engineering Mechanics, 2019, 36(8): 122-132. | |

| 8 | 徐福卫, 田斌, 徐港. 界面过渡区厚度对再生混凝土损伤性能的影响分析[J]. 材料导报, 2022, 36(4): 122-128. |

| Xu Fu-wei, Tian Bin, Xu Gang. Influence analysis of interface transition zone thickness on the damage performance of recycled concrete[J]. Materials Reports, 2022, 36(4): 122-128. | |

| 9 | 刘誉宏, 罗威, 叶永. 沥青混凝土级配曲线的数值设计方法与对有效弹性模量影响的研究[J]. 固体力学学报, 2021, 42(6): 736-745. |

| Liu Yu-hong, Luo Wei, Ye Yong. Research on the numerical design method of asphalt concrete gradation curve and its influence on the effective elastic modulus[J]. Chinese Journal of Solid Mechanics, 2021, 42(6): 736-745. | |

| 10 | 李松, 焦楚杰, 何松松, 等. CFRP约束钢管高强混凝土轴压短柱承载力的极限分析[J].工程科学与技术, 2022, 54(2): 162-169. |

| Li Song, Jiao Chu-jie, He Song-song, et al. Limit analysis of bearing capacity of CFRP confined high strength concrete filled steel tube stub columns under axial compression[J]. Advanced Engineering Sciences, 2022, 54(2): 162-169. | |

| 11 | 李传习, 张宇, 聂洁, 等. UHPC局压性能试验研究与承载力计算公式[J]. 土木工程学报, 2022, 55(3): 36-46. |

| Li Chuan-xi, Zhang Yu, Nie Jie, et al. Experimental research on local compression performance and bearing capacity calculation formula of UHPC[J]. China Civil Engineering Journal, 2022, 55(3): 36-46. | |

| 12 | 何越骁, 黄维蓉, 郭江川, 等. 共聚甲醛纤维超高性能混凝土高温后残余力学性能[J]. 硅酸盐学报, 2022, 50(3): 839-848. |

| He Yue-xiao, Huang Wei-rong, Guo Jiang-chuan, et al. Residual mechanical properties of ultra-high performance concrete doped with copolymer formaldehyde fiber exposed to high temperature[J]. Journal of the Chinese Ceramic Society, 2022, 50(3): 839-848. | |

| 13 | 谢剑, 刘洋, 严加宝, 等. 极地低温环境下混凝土断裂性能试验研究[J]. 建筑结构学报, 2021, 42(): 341-350 . |

| Xie Jian, Liu Yang, Yan Jia-bao, et al. Experimental study on fracture properties of concrete in polar temperature environments[J]. Journal of Building Structures, 2021, 42(Sup.1): 341-350. | |

| 14 | 黄灵芝, 柯梅尉, 司政, 等. 冻融损伤混凝土单轴压缩细观破坏研究[J]. 应用力学学报, 2021, 38(4): 1400-1407. |

| Huang Ling-zhi, Ke Mei-wei, Si Zheng, et al. Research on meso failure of concrete subjected to freeze-thaw damage under uniaxial compression[J]. Chinese Journal of Applied Mechanics, 2021, 38(4): 1400-1407. | |

| 15 | 甘磊, 吴健, 沈振中, 等. 硫酸盐和干湿循环作用下玄武岩纤维混凝土劣化规律[J]. 土木工程学报, 2021, 54(11): 37-46. |

| Gan Lei, Wu Jian, Shen Zhen-zhong, et al. Deterioration law of basalt fiber reinforced concrete under sulfate attack and dry-wet cycle[J]. Journal of the Chinese Ceramic Society, 2021, 54(11): 37-46. | |

| 16 | Zhou D Y, Xie Q, Wang X. A concrete sandwich wallboard damage identification method based on strain energy density increment[J]. Canadian Journal of Civil Engineering. 2022, 50(5): 349-361. |

| 17 | Bakhshi M, Dalalbashi A, Soheili H. Energy dissipation capacity of an optimized structural lightweight perlite concrete[J]. Construction and Building Materials, 2023, 389:No. 131765. |

| 18 | Mai A D, Sheikh M N, Hadi M N S. Strain model for discretely FRP confined concrete based on energy balance principle[J]. Engineering Structures, 2021,241:No.112489. |

| 19 | Jawed M, Saeed A, Mohsen S. Loading phase change material in a concrete based wall to enhance concrete thermal properties[J]. Journal of Building Engineering, 2022, 56:No.104765. |

| 20 | 赵海增, 余自若, 王月. 混凝土三轴压力学性能研究现状[J]. 混凝土, 2014(12): 25-31. |

| Zhao Hai-zeng, Yu Zi-ruo, Wang Yue. Review on the mechanical properties of concrete under triaxial compression[J]. Concrete, 2014 (12): 25-31. | |

| 21 | 金浏, 李健, 余文轩, 等. 混凝土动态双轴拉压破坏准则细观数值模拟研究[J]. 力学学报, 2022, 54(3): 800-809. |

| Jin Liu, Li Jian, Yu Wen-xuan, et al. Mesoscopic numerical simulation on dynamic biaxial tension- compression failure criterion of concrete[J]. Chinese Journal of Theoretical and Applied Mechanics, 2022, 54(3): 800-809. | |

| 22 | 朱贺, 胡昱, 李庆斌. 基于应力与变形的混凝土破坏准则[J]. 水力发电学报, 2018, 37(12): 1-10. |

| Zhu He, Hu Yu, Li Qing-bin. Stress-and-strain based failure criterion for concrete[J]. Journal of Hydroelectric Engineering, 2018, 37(12): 1-10. | |

| 23 | 俞茂宏. 强度理论新体系: 理论发展和应用[M]. 西安:西安交通大学出版社, 2011. |

| 24 | 俞茂宏, 杨松岩, 范寿昌, 等. 双剪统一弹塑性本构模型及其工程应用[J]. 岩土工程学报, 1997(6): 2-10. |

| Yu Mao-hong, Yang Song-yan, Fan Shou-chang, et al. Twin shear unified elasto-plastic constitutive model and its applications[J]. Chinese Journal of Geotechnical Engineering, 1997(6): 2-10. | |

| 25 | .普通混凝土配合比设计规程 [S]. |

| 26 | .工程岩体试验方法标准 [S]. |

| 27 | Liu X S, Ning J G, Tan Y L, et al. Damage constitutive model based on energy dissipation for intact rock subjected to cyclic loading[J]. International Journal of Rock Mechanics & Mining Sciences, 2016, 85:27-32. |

| 28 | Peng R D, Ju Y, Wang J G, et al. Energy dissipation and release during coal failure under conventional triaxial compression[J]. Rock Mechanics and Rock Engineering, 2015, 48: 509-526. |

| 29 | Song D Z, Wang E Y, Li Z H, et al. Energy dissipation of coal and rock during damage and failure process based on EMR[J]. International Journal of Mining Science and Technology, 2015, 25: 787-795. |

| 30 | 谢和平, 鞠杨, 黎立云. 基于能量耗散与释放原理的岩石强度与整体破坏准则[J]. 岩石力学与工程学报, 2005, 24(17): 3003-3010. |

| Xie He-ping, Ju Yang, Li Li-yun. Criteria for strength and structural failure of rocks based on energy dissipation and energy release principles[J]. Chinese Journal of Rock Mechanics and Engineering, 2005, 24(17): 3003-3010. | |

| 31 | 郭建强. 基于弹性应变能盐岩屈服准则及其工程应用研究[D]. 重庆: 重庆大学土木工程学院, 2014. |

| Guo Jian-qiang. Study on the criterion of rock salt based on energy principles and its application in engineering[D]. Chongqing: School of Civil Engineering, Chongqing University, 2014. | |

| 32 | 崔建锋, 王卫军. Hoek-Brown破坏准则下深埋硐室围岩抗震稳定性分析[J].采矿与安全工程学报, 2021, 38(2): 260-268. |

| Cui Jian-feng, Wang Wei-jun. Seismic stability analysis of surrounding rocks in deep buried chamber based on Hoek-Brown failure criterion[J]. Journal of Mining & Safety Engineering, 2021, 38(2): 260-268. | |

| 33 | 尤涛, 戴自航, 卢才金, 等. Hoek-Brown准则奇异屈服面的圆化方法及其强度折减技术与应用[J]. 岩石力学与工程报, 2017, 36(7): 1659-1669. |

| You Tao, Dai Zi-hang, Lu Cai-jin, et al. A rounding approach the singular surface of Hoek-Brown criterion and its strength reduction technique[J]. Chinese Journal of Rock Mechanics and Engineering, 2017, 36(7): 1659-1669. | |

| 34 | Chen W, Konietzky H, Tan X, et al. Pre-failure damage analysis for brittle rocks under triaxial compression[J]. Computers and Geotechnics, 2016, 74 :45-55. |

| [1] | 周宇,李萌,狄生奎,石贤增,陈东. 变截面两铰拱推力影响线解析解及损伤识别应用[J]. 吉林大学学报(工学版), 2025, 55(2): 664-672. |

| [2] | 王羽岱,王斌,苗福生,马楠. 水热耦合变化下衬砌渠道冻胀响应[J]. 吉林大学学报(工学版), 2025, 55(1): 256-268. |

| [3] | 姜浩,赵正文. 玄武岩纤维网格水泥基复合材料加固RC梁抗剪性能试验[J]. 吉林大学学报(工学版), 2025, 55(1): 211-220. |

| [4] | 韦芳芳,李丽萍,徐庆鹏,赵有正,杨晶晶. 受火双钢板-混凝土组合剪力墙加固后抗震性能试验[J]. 吉林大学学报(工学版), 2025, 55(1): 230-244. |

| [5] | 赵金全,周龙,丁永刚,朱熔基. 螺旋箍筋-波纹管浆锚连接锚固性能试验[J]. 吉林大学学报(工学版), 2024, 54(9): 2484-2494. |

| [6] | 杨伟松,张安,许卫晓,李海生,杜轲. 刚度增强型金属连梁阻尼器的抗震性能[J]. 吉林大学学报(工学版), 2024, 54(9): 2469-2483. |

| [7] | 阎奇武,邹忠亮. 减震结构阻尼器优化布置混合算法[J]. 吉林大学学报(工学版), 2024, 54(8): 2267-2274. |

| [8] | 姜封国,周玉明,白丽丽,梁爽. 改进磷虾群算法及其在结构优化中的应用[J]. 吉林大学学报(工学版), 2024, 54(8): 2256-2266. |

| [9] | 张广泰,周乘孝,刘诗拓. 盐渍土环境下纤维锂渣混凝土柱恢复力模型[J]. 吉林大学学报(工学版), 2024, 54(7): 1944-1957. |

| [10] | 刁延松,任义建,杨元强,赵凌云,刘秀丽,刘芸. 带有摩擦耗能组件的可更换钢梁柱拼接节点抗震性能试验[J]. 吉林大学学报(工学版), 2024, 54(6): 1643-1656. |

| [11] | 樊学平,刘月飞. 基于改进高斯混合粒子滤波新算法的桥梁极值应力动态预测[J]. 吉林大学学报(工学版), 2024, 54(4): 1038-1044. |

| [12] | 刘一凡,缪志伟,申晨,耿祥东. 基于蒙特卡罗法的不均匀锈蚀钢筋力学性能评估[J]. 吉林大学学报(工学版), 2024, 54(4): 1007-1015. |

| [13] | 樊学平,周衡,刘月飞. 基于Gaussian Copula-贝叶斯动态模型的桥梁构件时变可靠性分析[J]. 吉林大学学报(工学版), 2024, 54(2): 485-493. |

| [14] | 杨海旭,郭悦,王海飙,胡宜. 冷弯薄壁型钢-胶合木组合梁受弯性能[J]. 吉林大学学报(工学版), 2024, 54(12): 3513-3525. |

| [15] | 于跟社,邓宗才. 钢纤维与细非金属纤维混杂UHPC双向板弯曲特性[J]. 吉林大学学报(工学版), 2024, 54(11): 3265-3273. |

|

||