吉林大学学报(工学版) ›› 2019, Vol. 49 ›› Issue (4): 1063-1071.doi: 10.13229/j.cnki.jdxbgxb20180530

• • 上一篇

高温老化对CFRP/铝合金粘接接头失效的影响

秦国锋1,2( ),那景新1(

),那景新1( ),慕文龙1,谭伟1,栾建泽1,申浩1

),慕文龙1,谭伟1,栾建泽1,申浩1

- 1. 吉林大学 汽车仿真与控制国家重点实验室,长春 130022

2. 广西师范大学 职业技术师范学院,广西 桂林 541004

Degradation failure of adhesively bonded CFRP/aluminum alloy subjected to high temperature environment

Guo⁃feng QIN1,2( ),Jing⁃xin NA1(

),Jing⁃xin NA1( ),Wen⁃long MU1,Wei TAN1,Jian⁃ze LUAN1,Hao SHEN1

),Wen⁃long MU1,Wei TAN1,Jian⁃ze LUAN1,Hao SHEN1

- 1. State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

2. Teachers College for Vocational and Technical Education, Guangxi Normal University, Guilin 541004,China

摘要:

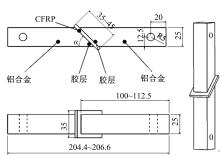

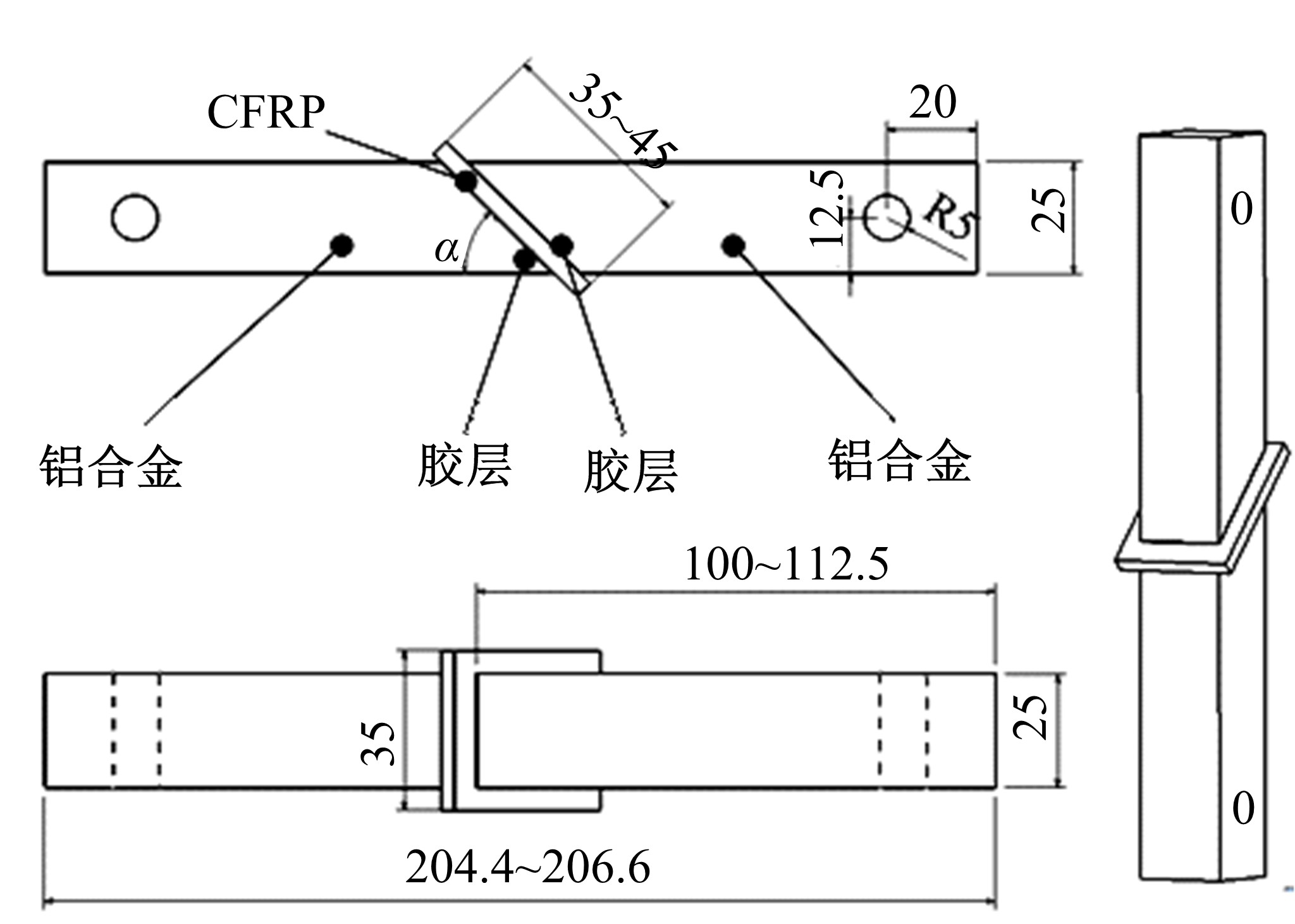

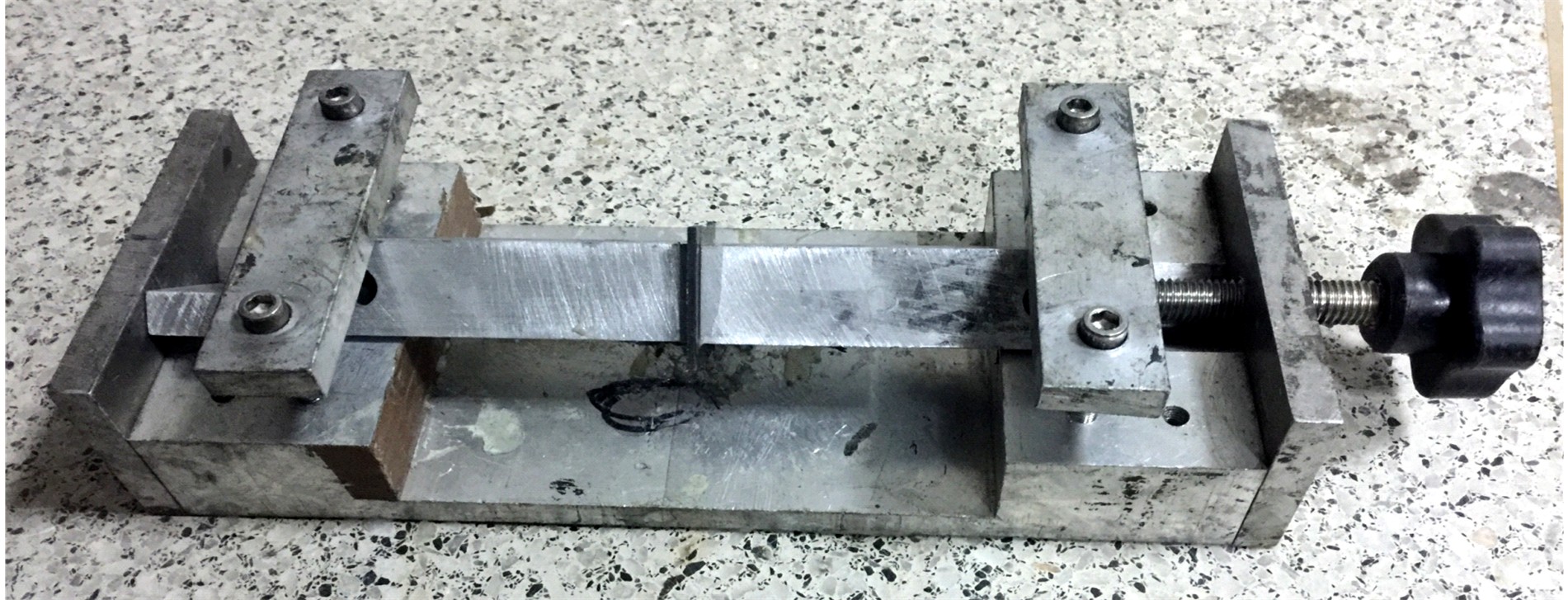

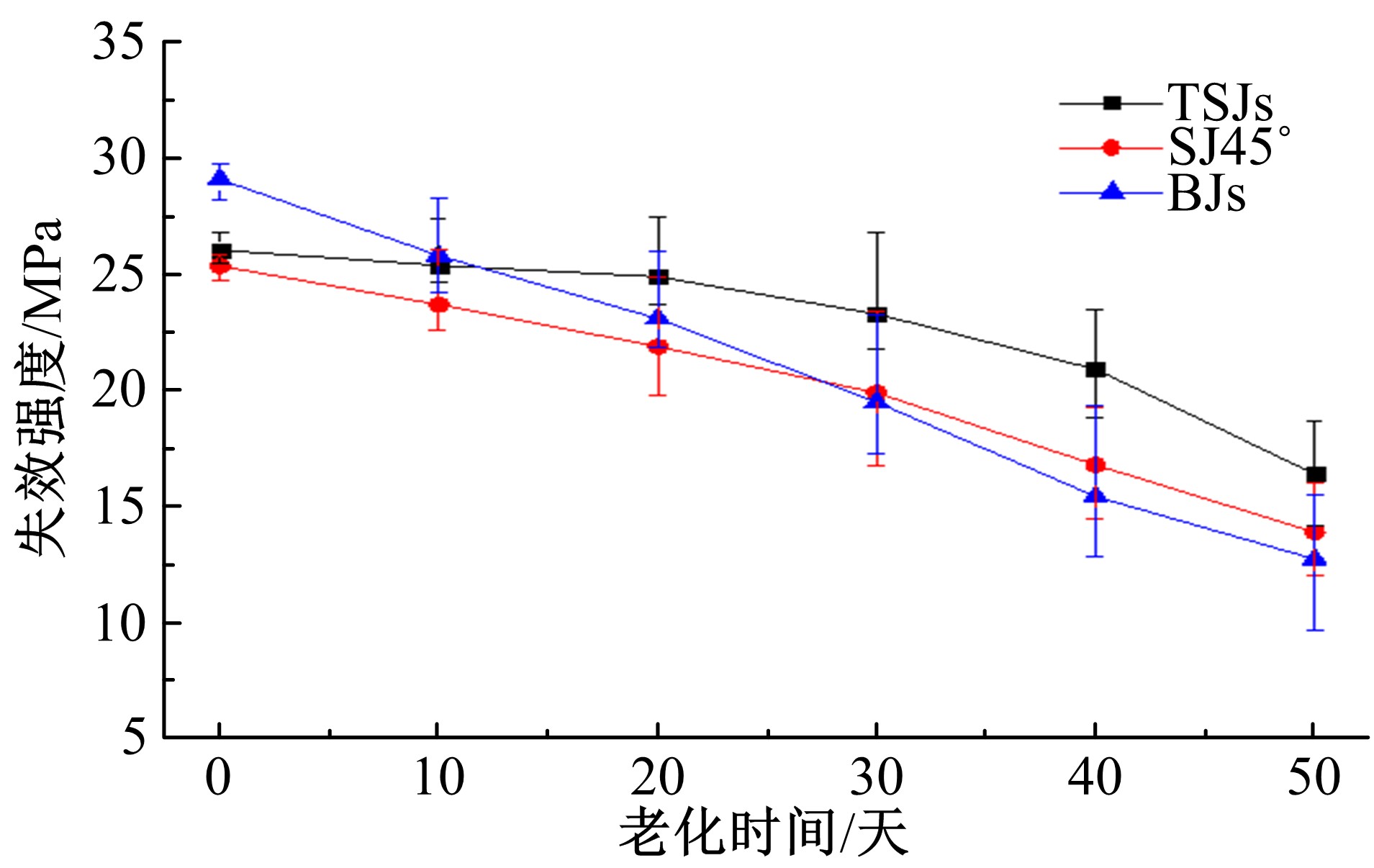

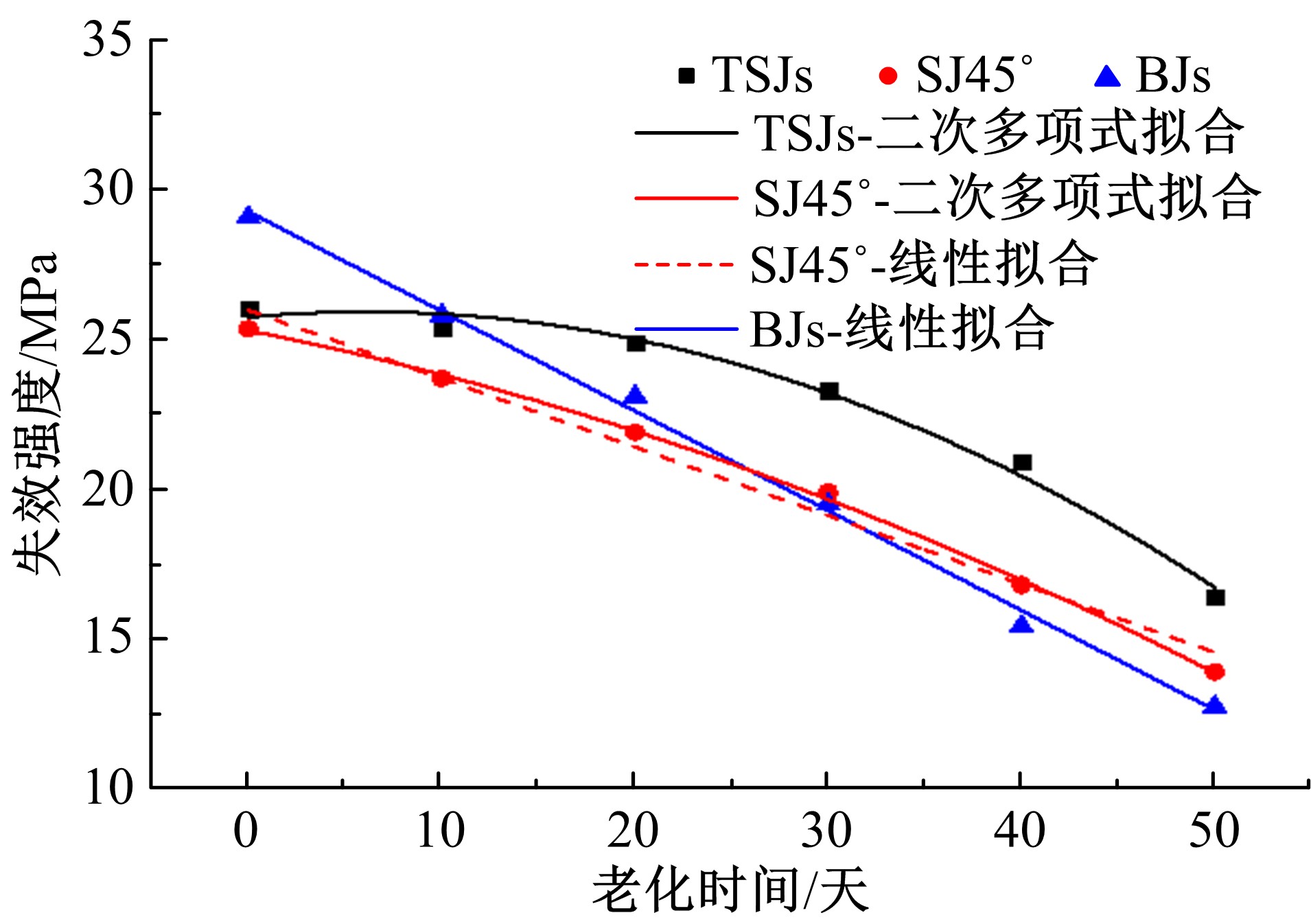

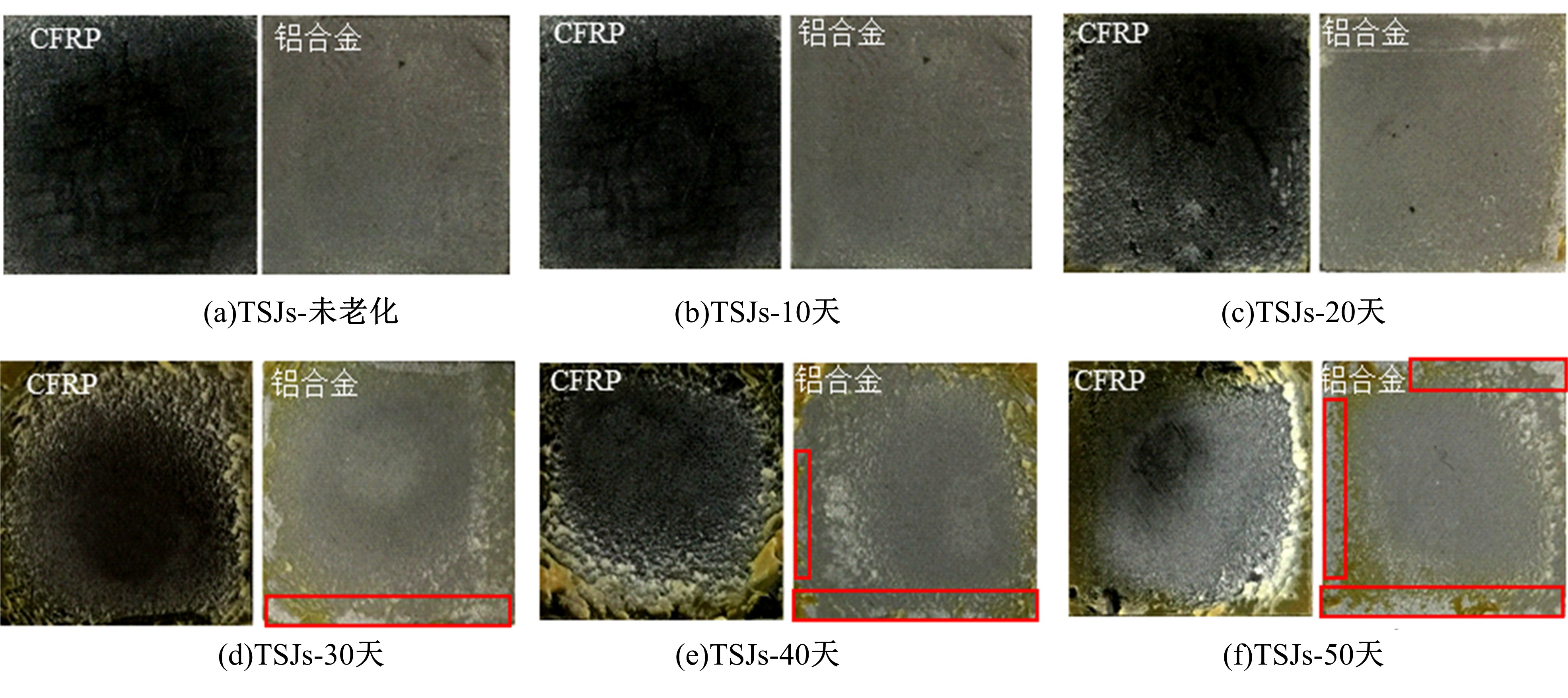

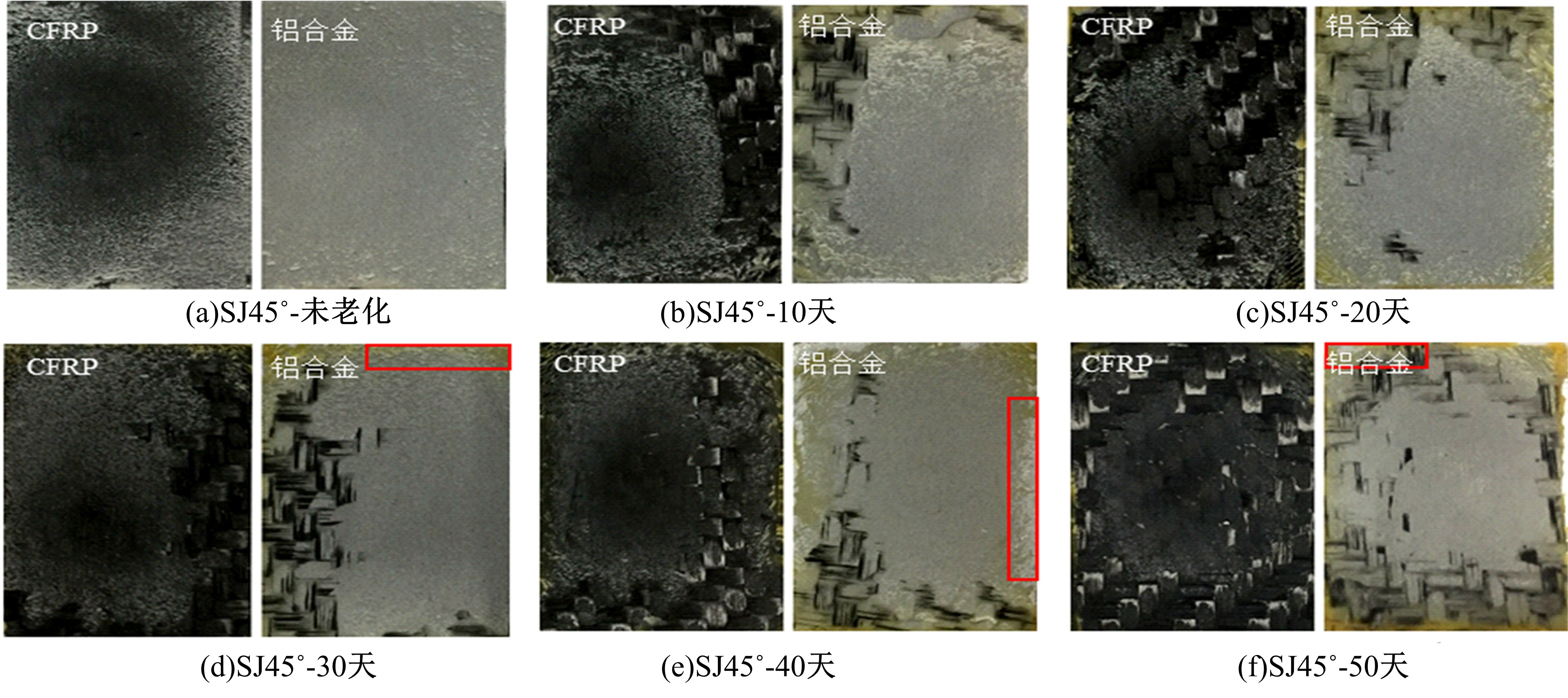

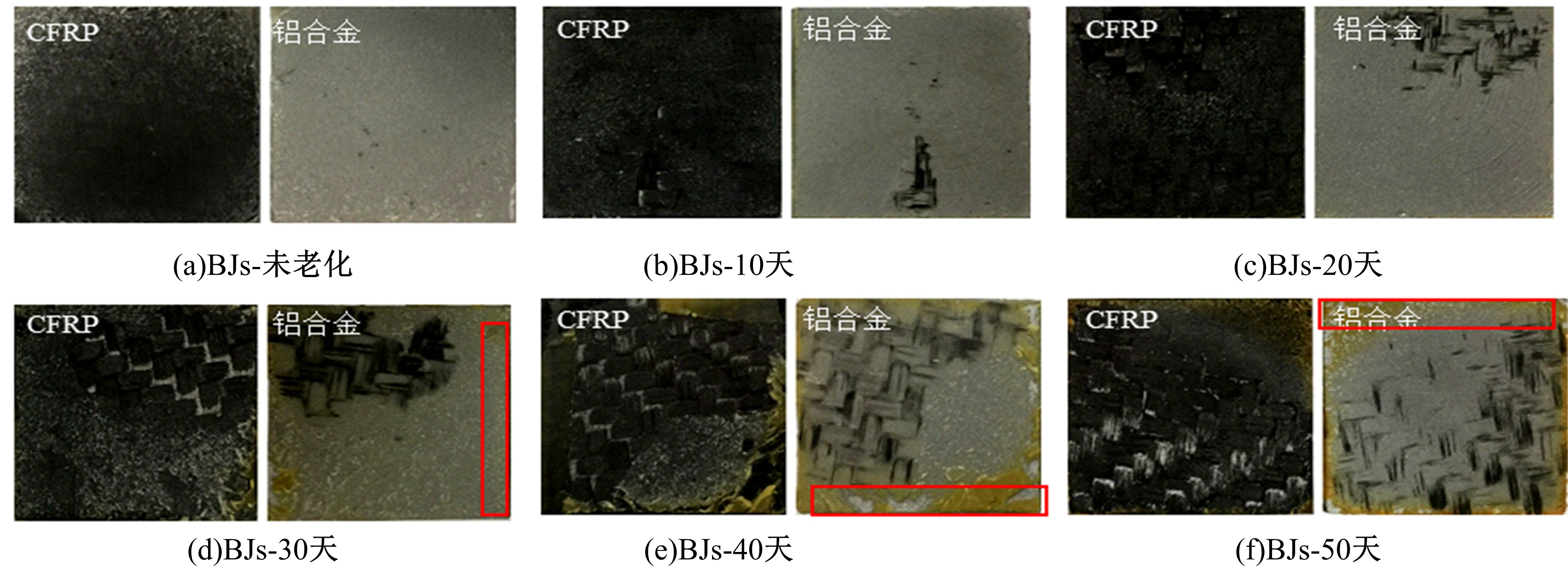

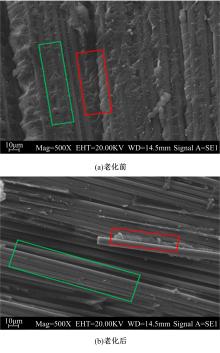

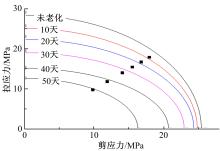

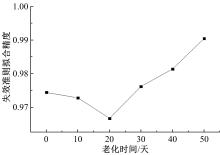

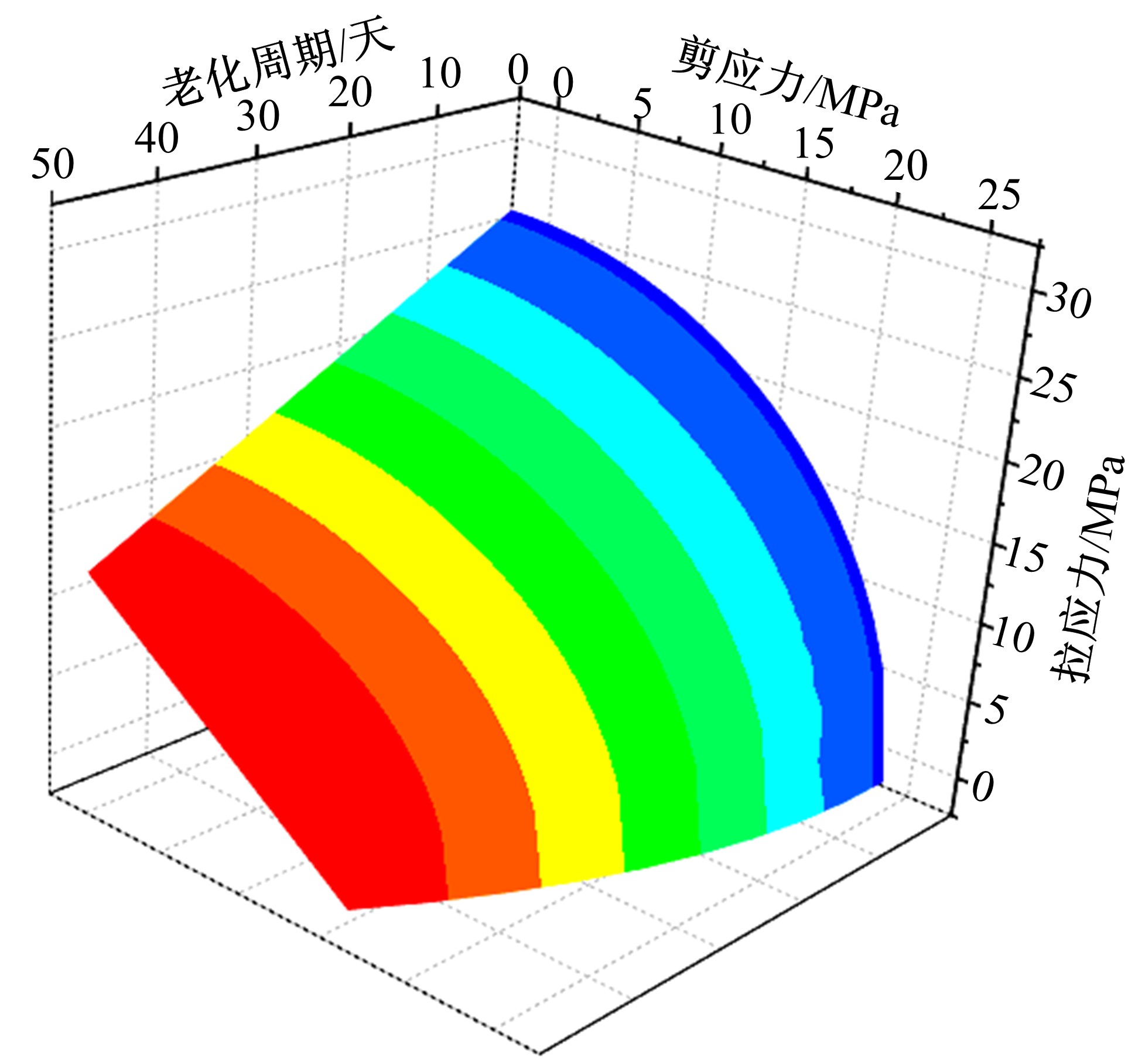

为了揭示碳纤维增强复合材料(CFRP)/铝合金粘接接头在高温环境中的老化失效规律,加工了处于剪应力、拉应力和拉剪组合应力状态的粘接接头,在高温(80 ℃)环境中分别进行了10、20、30、40、50天的老化测试,分析了失效强度、失效模式的变化规律,建立了失效准则响应面。结果表明:随着拉应力比例的增加,失效强度下降更明显,下降趋势由二次多项式向线性转变,失效模式由内聚失效转变为内聚、纤维撕裂和界面失效的混合失效模式,这主要是由CFRP老化引起的;失效准则响应面平均误差为3.0%,能够对不同应力状态下的接头进行失效预测。因此,在粘接结构中降低拉应力比例能够提高承载能力,同时在失效预测时需要考虑不同应力状态的影响。

中图分类号:

- U463.82

| 1 | 冯美斌. 汽车轻量化技术中新材料的发展及应用[J]. 汽车工程, 2006, 28(3): 213⁃220. |

| FengMei⁃bin. Development and applications of new materials in automotive light weighting technologies[J]. Automotive Engineering, 2006, 28(3): 66⁃72. | |

| 2 | ElmarakbiA. Advanced Composite Materials for Automotive Applications: Structural Integrity and Crashworthiness[M]. New York: Wiley, 2013. |

| 3 | SakundariniN, TahaZ, Abdul⁃RashidS H, et al. Optimal multi/material selection for lightweight design of automotive body assembly incorporating recyclability[J]. Materials and Design, 2013, 50:846⁃857. |

| 4 | SilvaL F M D, ÖchsnerA, AdamsR D. Handbook of Adhesion Technology NOVA[M]. Newcastle: The University of Newcastle's Digital Repository, 2011. |

| 5 | VianaG, CostaM, BaneaM D, et al. A review on the temperature and moisture degradation of adhesive joints[J]. Journal of Materials: Design and Applications, 2017, 231(5): 488⁃501. |

| 6 | MarquesE A S, Da SilvaL F M, BaneaM D, et al. Adhesive joints for low⁃ and high⁃temperature use: an overview[J]. Journal of Adhesion, 2014, 91(7): 556⁃585. |

| 7 | PlazekD J, FrundZ N, FrundJ Z N, et al. Epoxy resins (DGEBA): the curing and physical aging process[J]. Journal of Polymer Science Part A: Polymer Chemistry, 1990, 28(4): 431⁃448 |

| 8 | BuchX, ShanahanM E R. Influence of the gaseous environment on the thermal degradation of a structural epoxy adhesive[J]. Journal of Applied Polymer Science, 2000, 76(7): 987⁃992. |

| 9 | HancoxN L. Thermal effects on polymer matrix composites: part 2. thermal degradation[J]. Materials and Design, 1998, 19(3): 93⁃97. |

| 10 | LiM. Temperature and moisture effects on composite materials for wind turbine blades[D]. Bozeman: Montana State University, 2000. |

| 11 | SkourlisT P, McculloughR L. The effect of temperature on the behavior of the interphase in polymeric composites[J]. Composites Science and Technology, 1993, 49(4): 363⁃368. |

| 12 | NgS J, CramerR J, MehrkamP. Characterization of IM 7/8552 polymer composites subjected to heat damage[C]∥International SAMPE Technical Conference, London, UK, 1997, 29: 776⁃786. |

| 13 | WolfrumJ, EiblS, LietchL. Rapid evaluation of long⁃term thermal degradation of carbon fibre epoxy composites[J]. Composites Science and Technology, 2009, 69(3): 523⁃530. |

| 14 | MarquesE A S, Da SilvaL F M, BaneaM D, et al. Adhesive joints for low⁃and high⁃temperature use: an overview[J]. The Journal of Adhesion, 2015, 91(7): 556⁃585. |

| 15 | KhaliliS M R, SharafiM, Eslami⁃FarsaniR, et al. Effect of thermal cycling on tensile properties of degraded FML to metal hybrid joints exposed to sea water[J]. International Journal of Adhesion and Adhesives, 2017, 79(2): 95⁃101. |

| 16 | BaneaM D, DaS L F M. The effect of temperature on the mechanical properties of adhesives for the automotive industry[J]. Journal of Materials: Design and Applications, 2010, 224(2): 51⁃62. |

| 17 | QinGuo⁃feng, NaJing⁃xin, MuWen⁃long, et al. Effect of continuous high temperature exposure on the adhesive strength of epoxy adhesive, CFRP and adhesively bonded CFRP⁃aluminum alloy joints[J]. Composites Part B: Engineering, 2018, 154: 43⁃55. |

| 18 | DaS L F M, AdamsR D. Joint strength predictions for adhesive joints to be used over a wide temperature range [J]. International Journal of Adhesion and Adhesives 2007, 27(5): 362⁃379. |

| 19 | LeeM, YeoE, Black LockM, et al. Predicting the strength of adhesively bonded joints of variable thickness using a cohesive element approach[J]. International Journal of Adhesion and Adhesives, 2015, 58(1): 44⁃52. |

| [1] | 李静,石求军,刘鹏,户亚威. 基于纵向车速估算的商用车ABS神经网络滑模控制[J]. 吉林大学学报(工学版), 2019, 49(4): 1017-1025. |

| [2] | 杨顺,蒋渊德,吴坚,刘海贞. 基于多类型传感数据的自动驾驶深度强化学习方法[J]. 吉林大学学报(工学版), 2019, 49(4): 1026-1033. |

| [3] | 陈鑫,李铭,阮新建,王宁,王佳宁. 基于浸入单元法和延迟分离涡模型的Ahmed车模尾流涡旋结构[J]. 吉林大学学报(工学版), 2019, 49(4): 1034-1042. |

| [4] | 周华,杨志刚,朱晖. 基于整车风洞试验的MIRA车型数值计算[J]. 吉林大学学报(工学版), 2019, 49(4): 1043-1053. |

| [5] | 柳润东,毛军,郗艳红,张宏宇,彭飞. 横风下高速列车会车压力波对风障的气动冲击[J]. 吉林大学学报(工学版), 2019, 49(4): 1054-1062. |

| [6] | 常成,宋传学,张雅歌,邵玉龙,周放. 双馈电机驱动电动汽车变频器容量最小化[J]. 吉林大学学报(工学版), 2018, 48(6): 1629-1635. |

| [7] | 席利贺,张欣,孙传扬,王泽兴,姜涛. 增程式电动汽车自适应能量管理策略[J]. 吉林大学学报(工学版), 2018, 48(6): 1636-1644. |

| [8] | 何仁,杨柳,胡东海. 冷藏运输车太阳能辅助供电制冷系统设计及分析[J]. 吉林大学学报(工学版), 2018, 48(6): 1645-1652. |

| [9] | 那景新,慕文龙,范以撒,谭伟,杨佳宙. 车身钢-铝粘接接头湿热老化性能[J]. 吉林大学学报(工学版), 2018, 48(6): 1653-1660. |

| [10] | 刘玉梅,刘丽,曹晓宁,熊明烨,庄娇娇. 转向架动态模拟试验台避撞模型的构建[J]. 吉林大学学报(工学版), 2018, 48(6): 1661-1668. |

| [11] | 赵伟强, 高恪, 王文彬. 基于电液耦合转向系统的商用车防失稳控制[J]. 吉林大学学报(工学版), 2018, 48(5): 1305-1312. |

| [12] | 宋大凤, 吴西涛, 曾小华, 杨南南, 李文远. 基于理论油耗模型的轻混重卡全生命周期成本分析[J]. 吉林大学学报(工学版), 2018, 48(5): 1313-1323. |

| [13] | 朱剑峰, 张君媛, 陈潇凯, 洪光辉, 宋正超, 曹杰. 基于座椅拉拽安全性能的车身结构改进设计[J]. 吉林大学学报(工学版), 2018, 48(5): 1324-1330. |

| [14] | 那景新, 浦磊鑫, 范以撒, 沈传亮. 湿热环境对Sikaflex-265铝合金粘接接头失效强度的影响[J]. 吉林大学学报(工学版), 2018, 48(5): 1331-1338. |

| [15] | 王炎, 高青, 王国华, 张天时, 苑盟. 混流集成式电池组热管理温均特性增效仿真[J]. 吉林大学学报(工学版), 2018, 48(5): 1339-1348. |

|

||