吉林大学学报(工学版) ›› 2020, Vol. 50 ›› Issue (2): 417-425.doi: 10.13229/j.cnki.jdxbgxb20190202

• 车辆工程·机械工程 • 上一篇

纤维增强复合材料在汽车覆盖件中的应用

- 1.吉林大学 汽车仿真与控制国家重点实验室,长春 130022

2.陕西汽车控股集团有限公司 技术中心,西安 710200

Application of fiber reinforced composite in auto⁃body panel

Hui YE1( ),Chang LIU1,Kang-kang YAN2

),Chang LIU1,Kang-kang YAN2

- 1.State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

2.Technology Center,Shanxi Automobile Holding Group Co. LTD,Xi'an 710000, China

摘要:

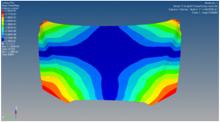

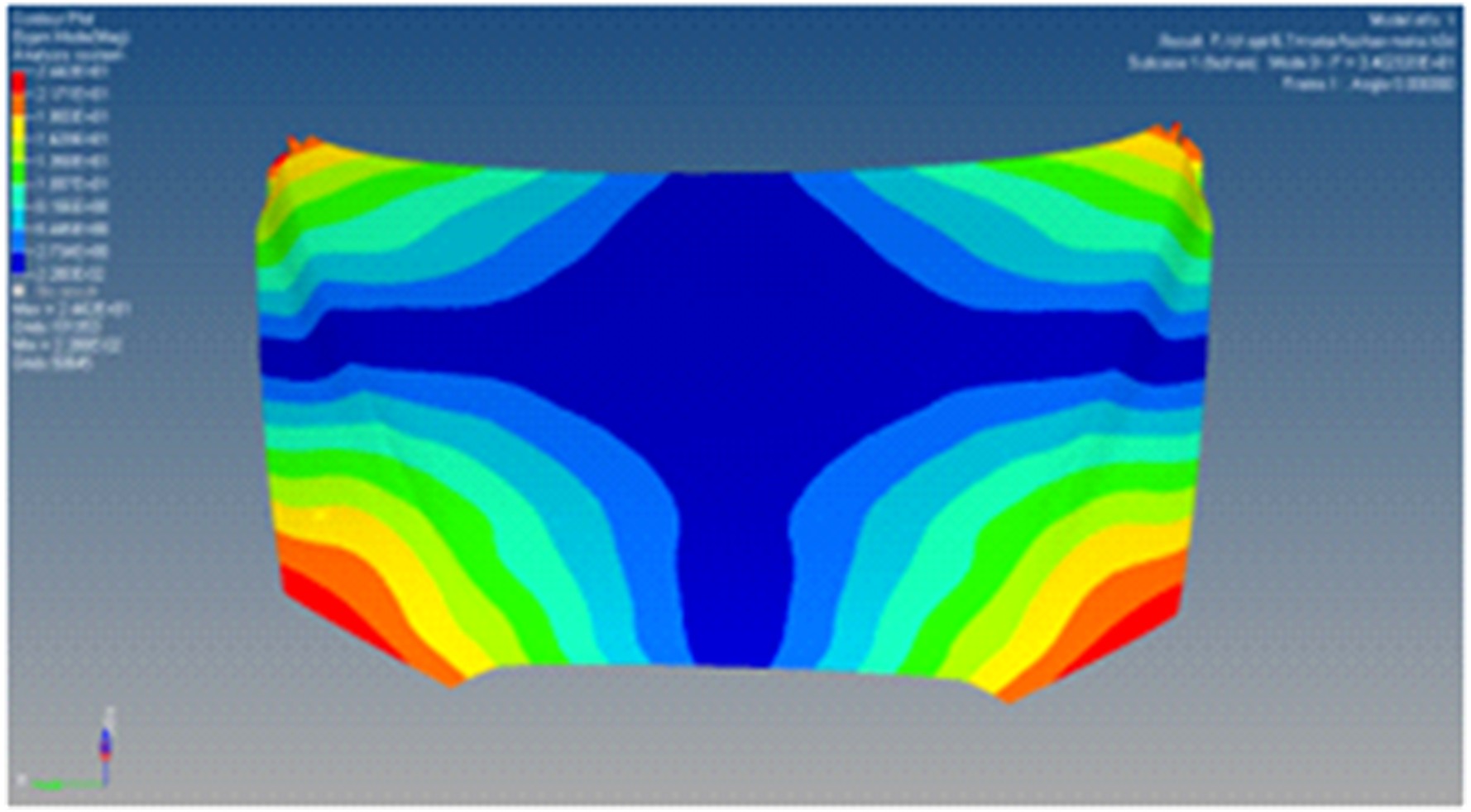

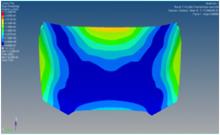

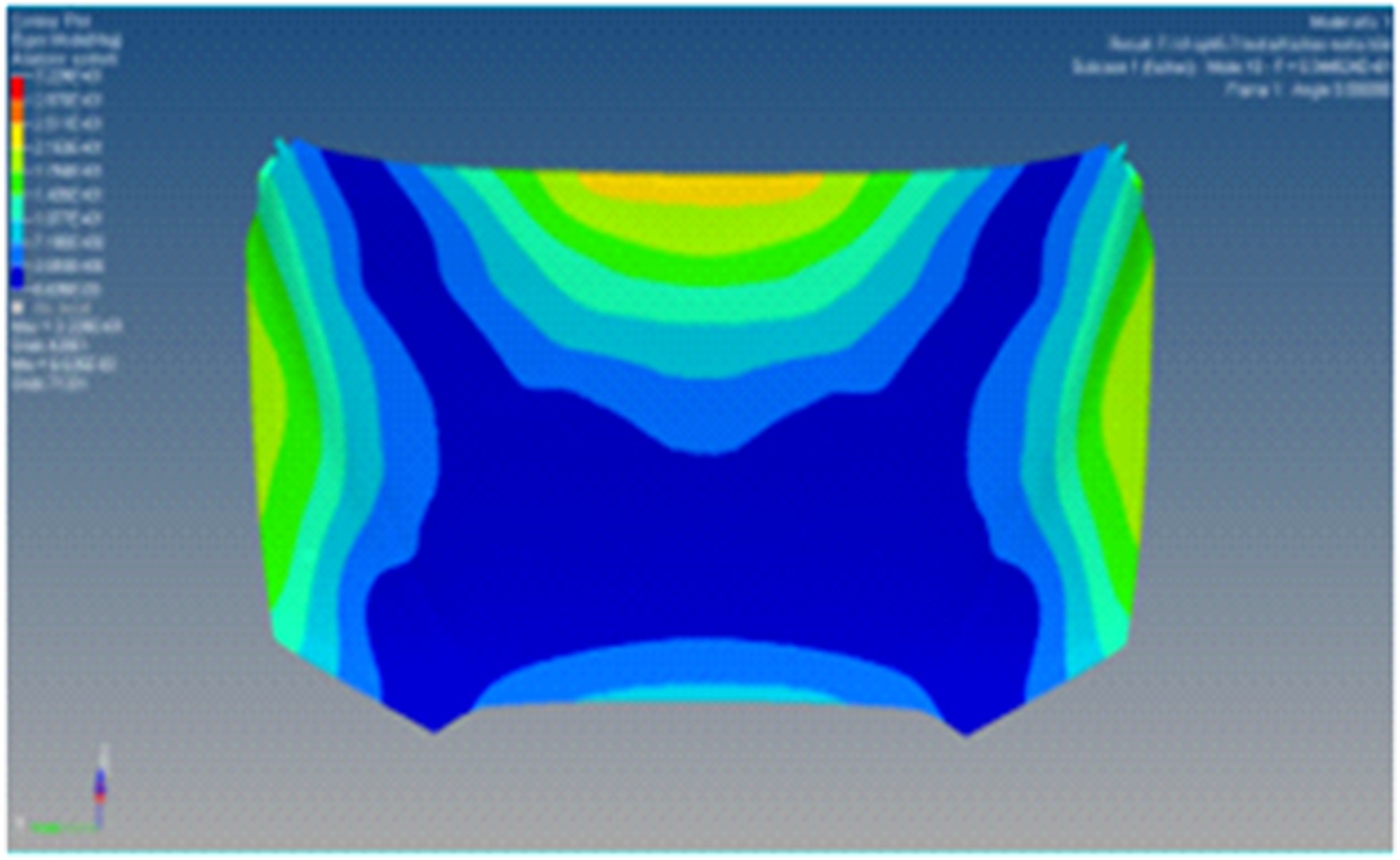

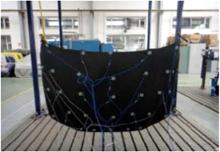

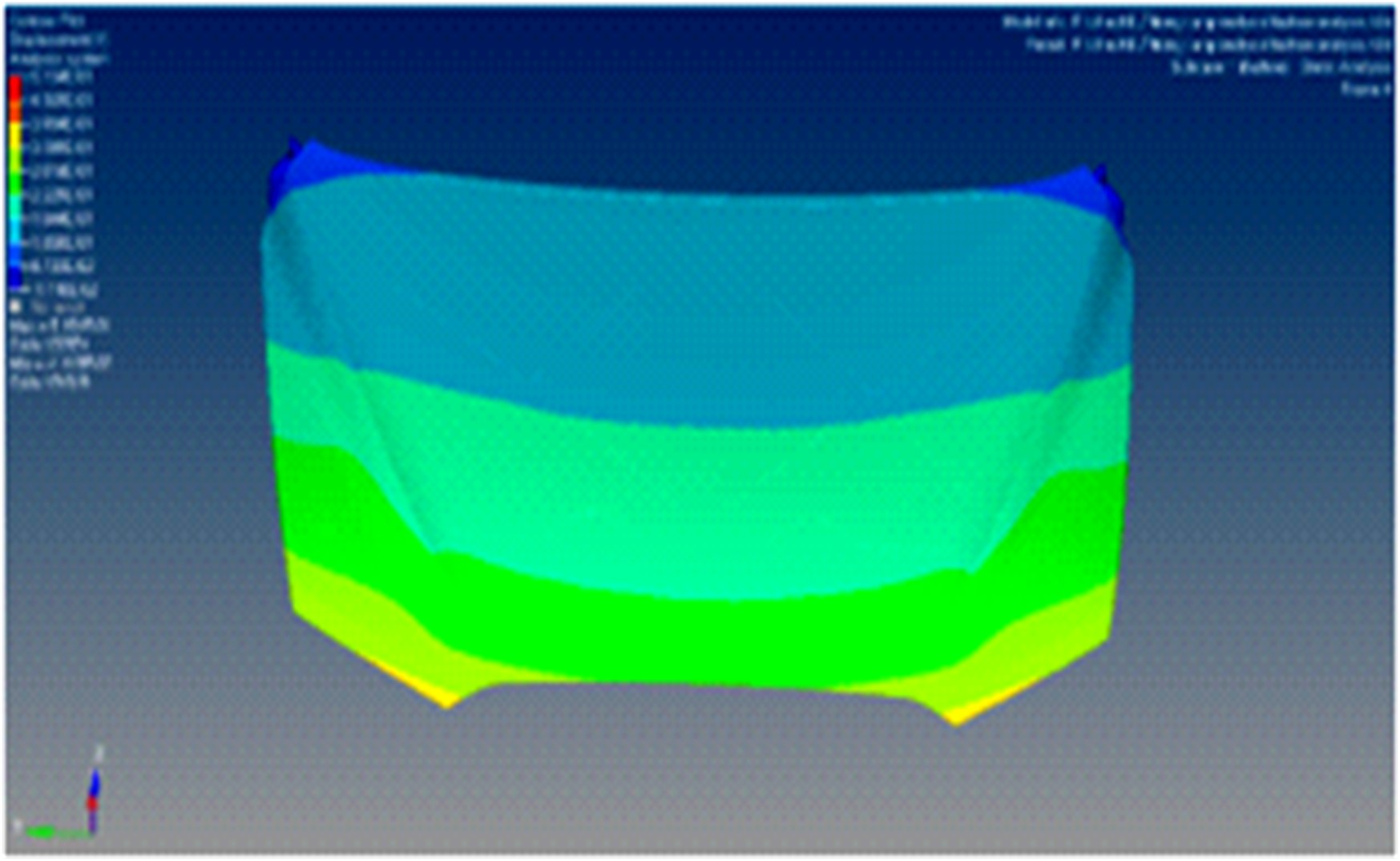

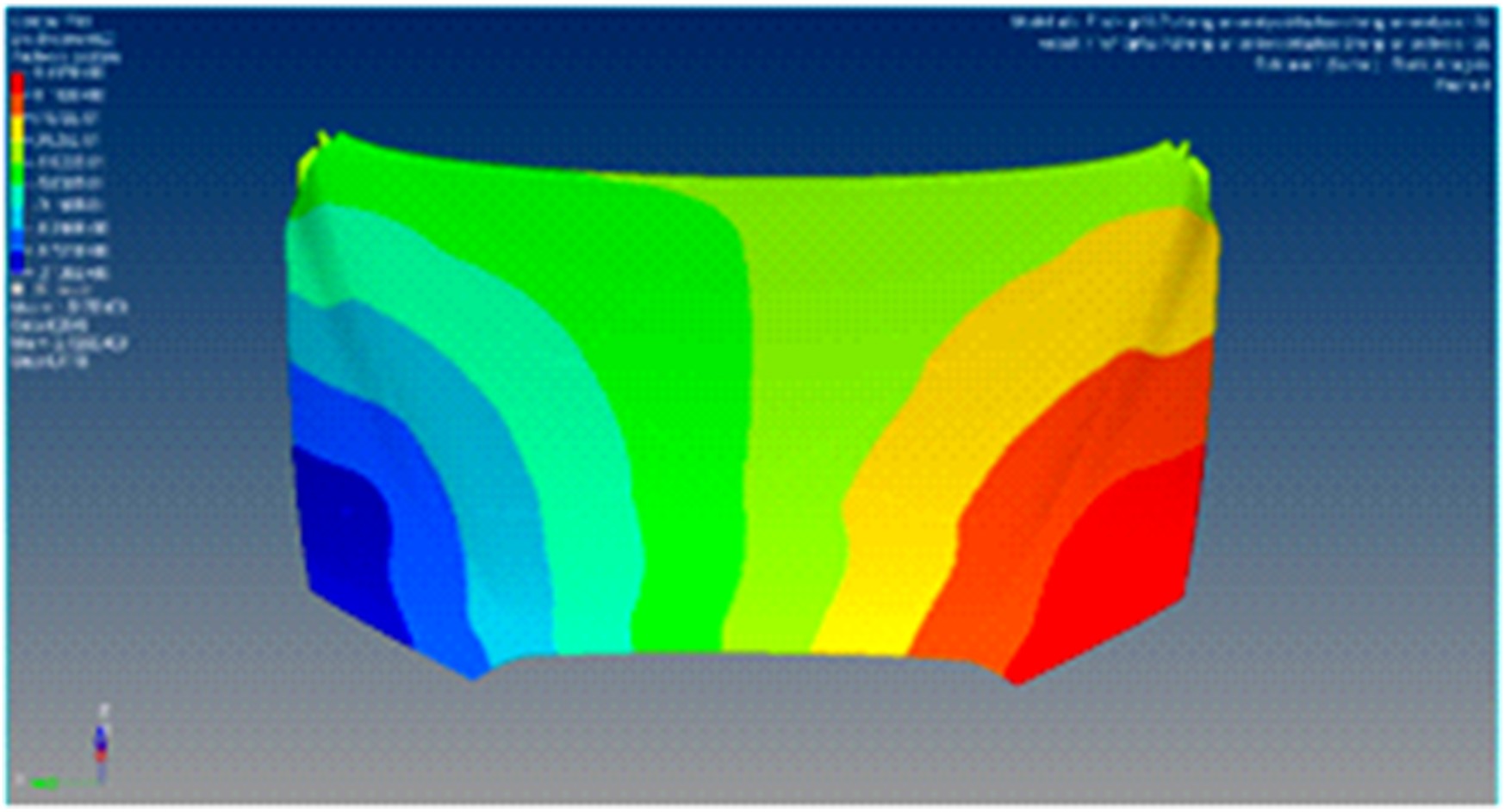

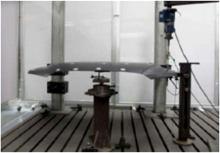

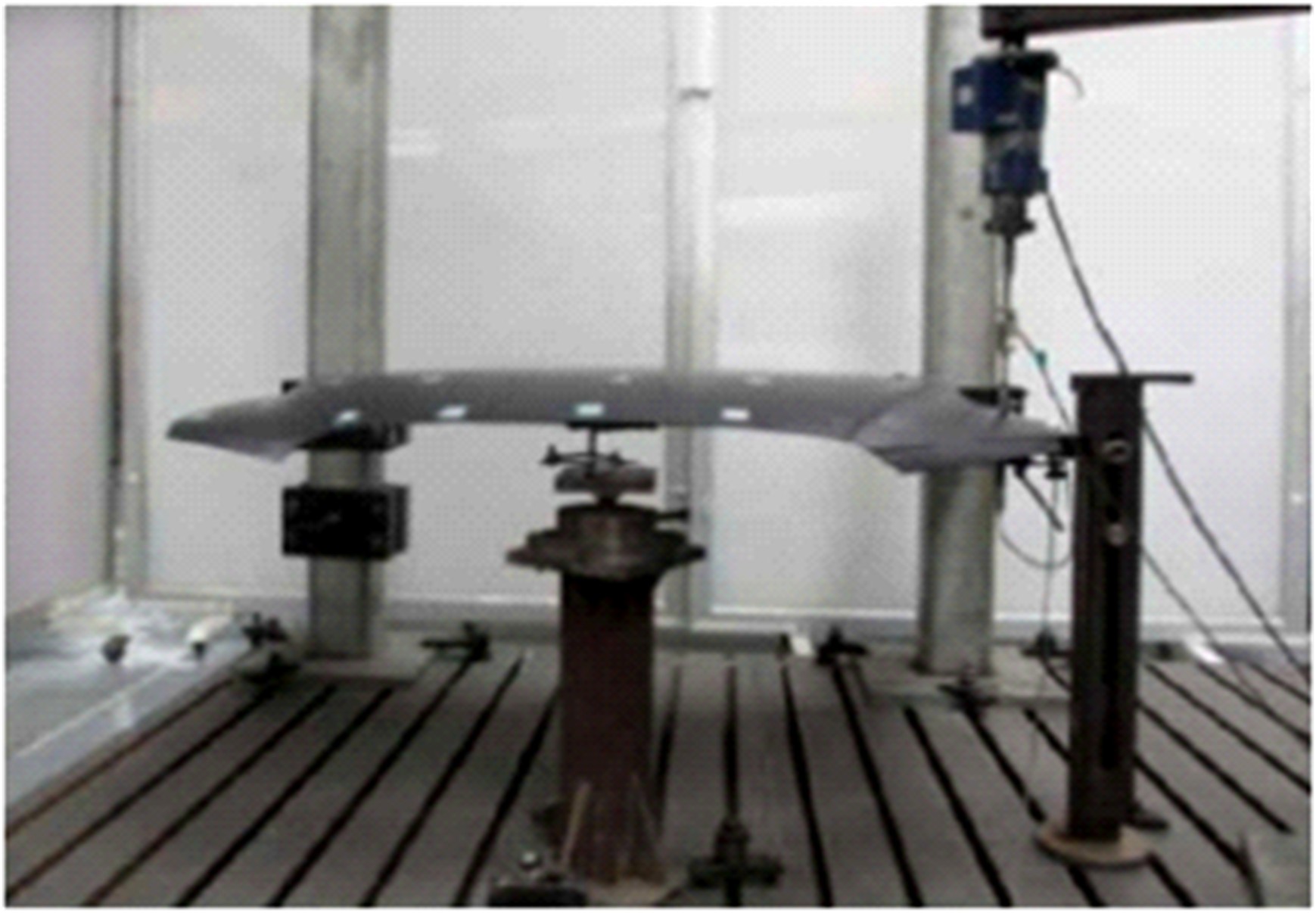

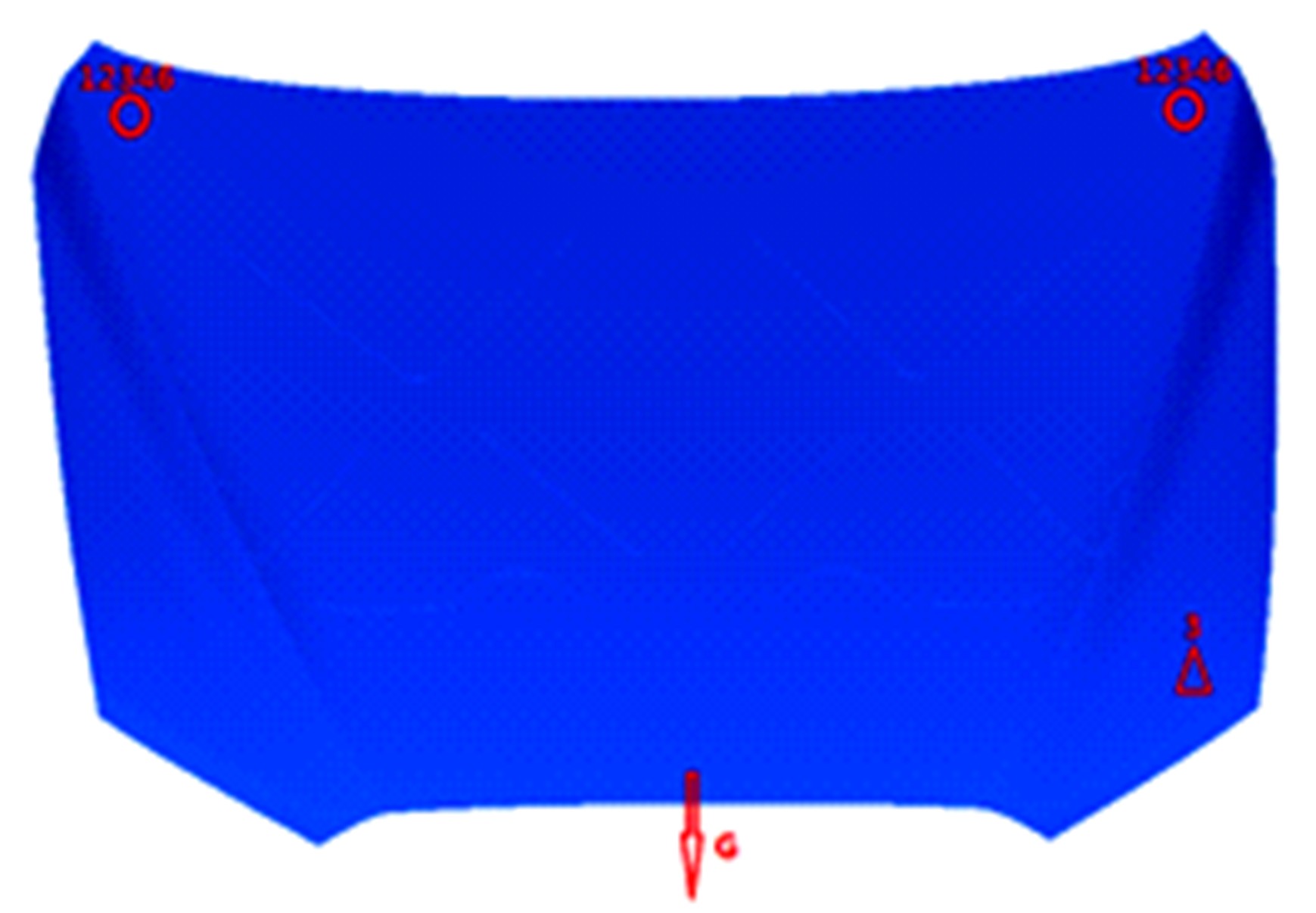

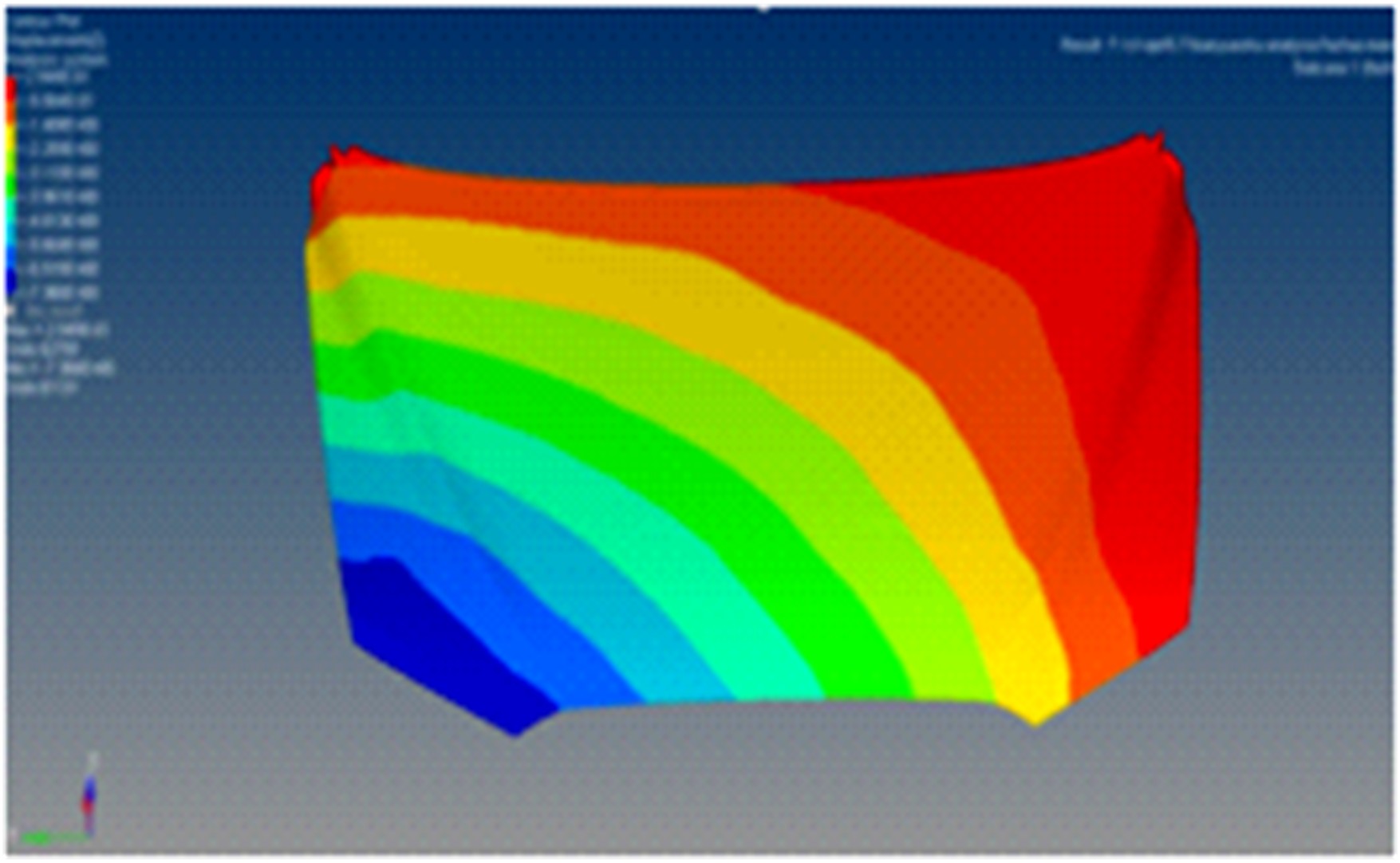

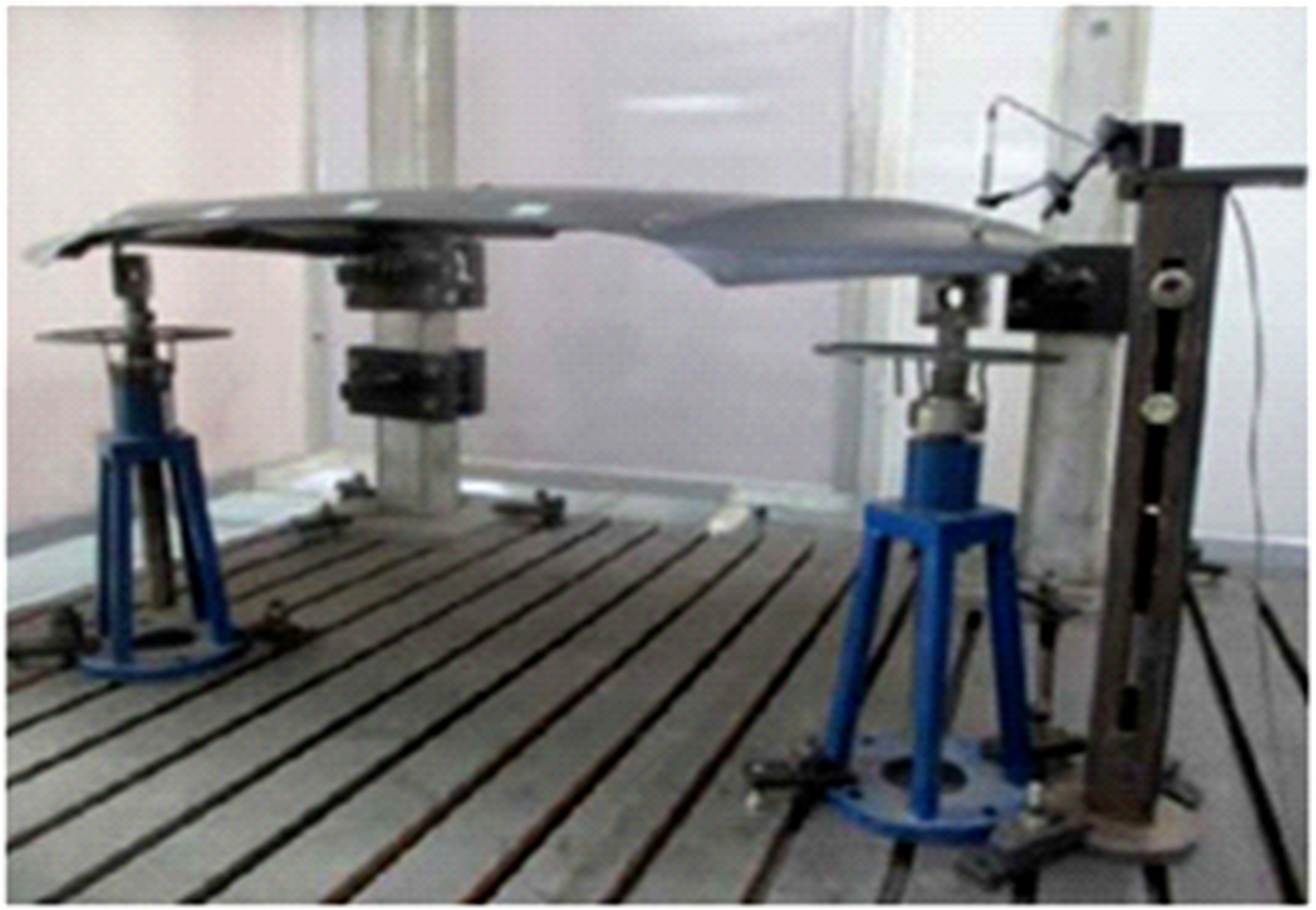

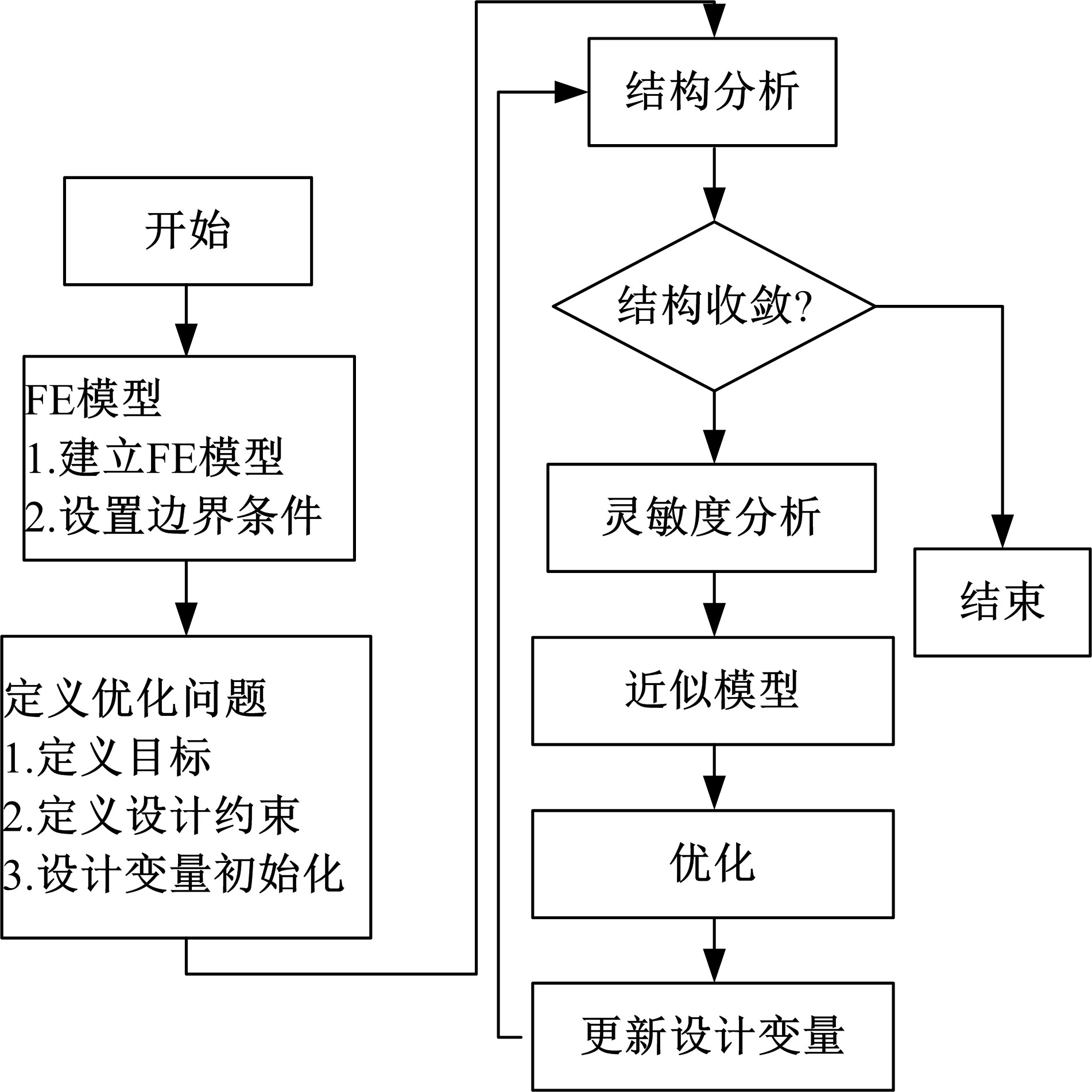

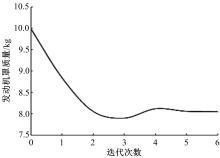

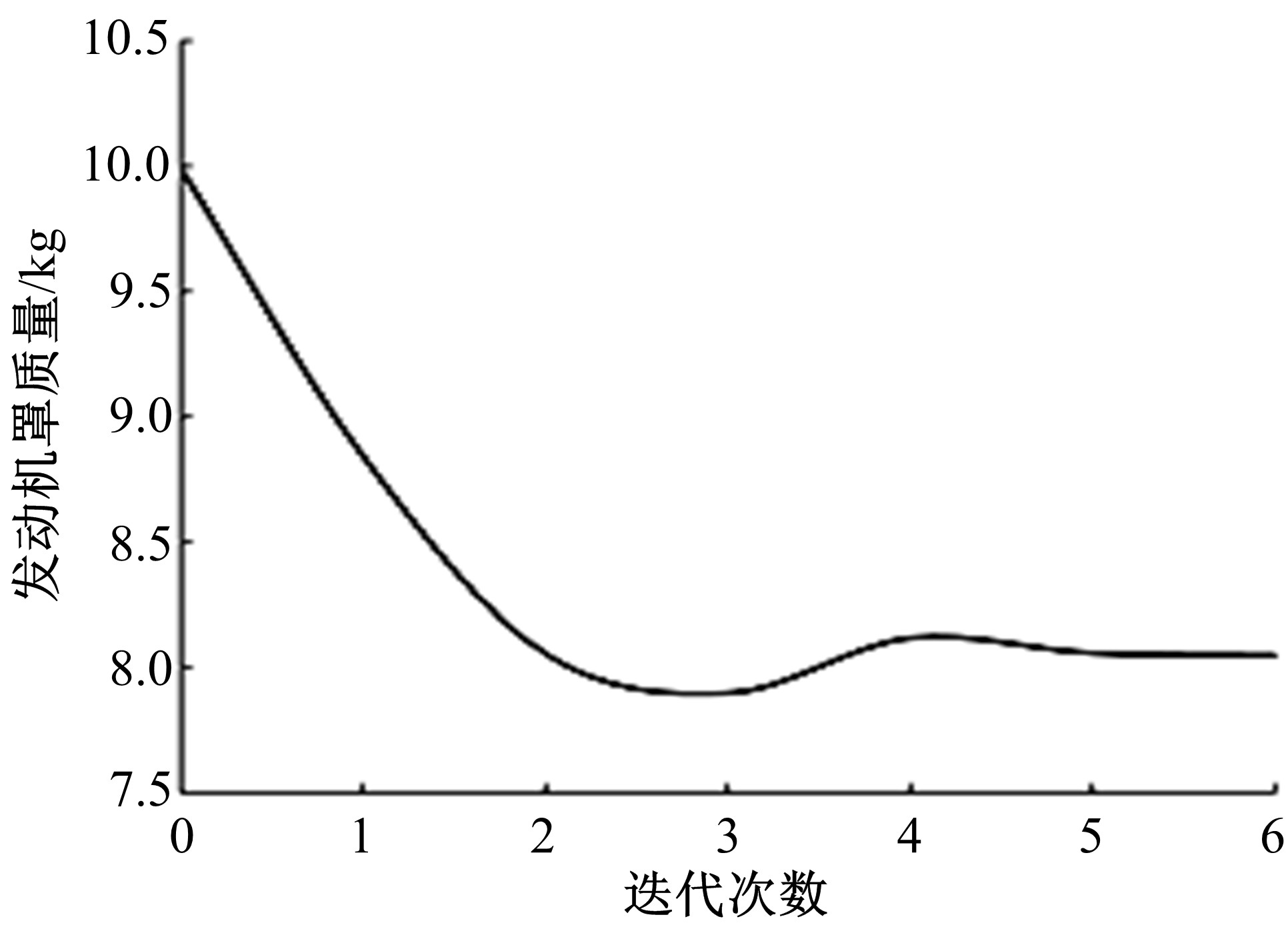

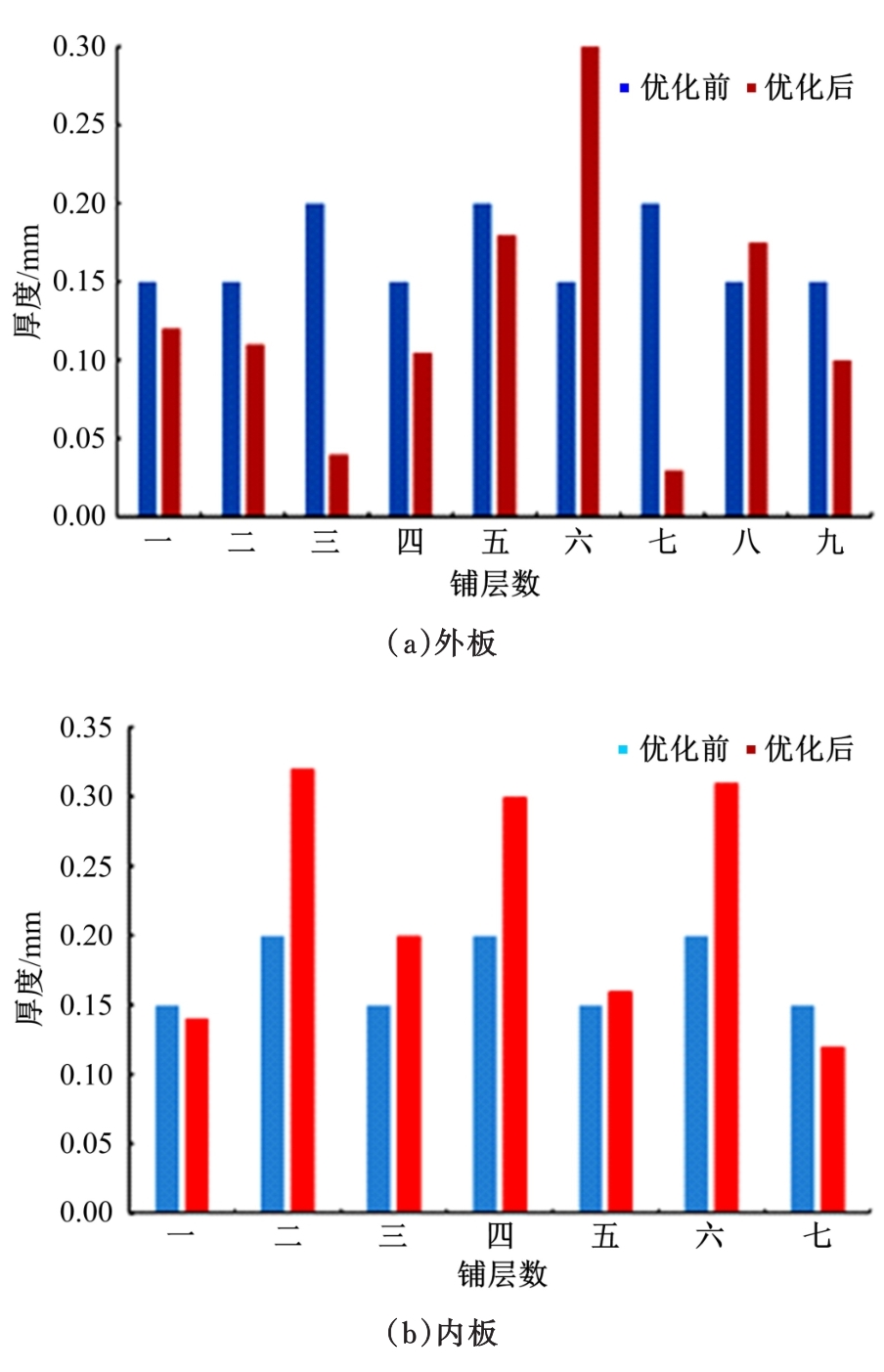

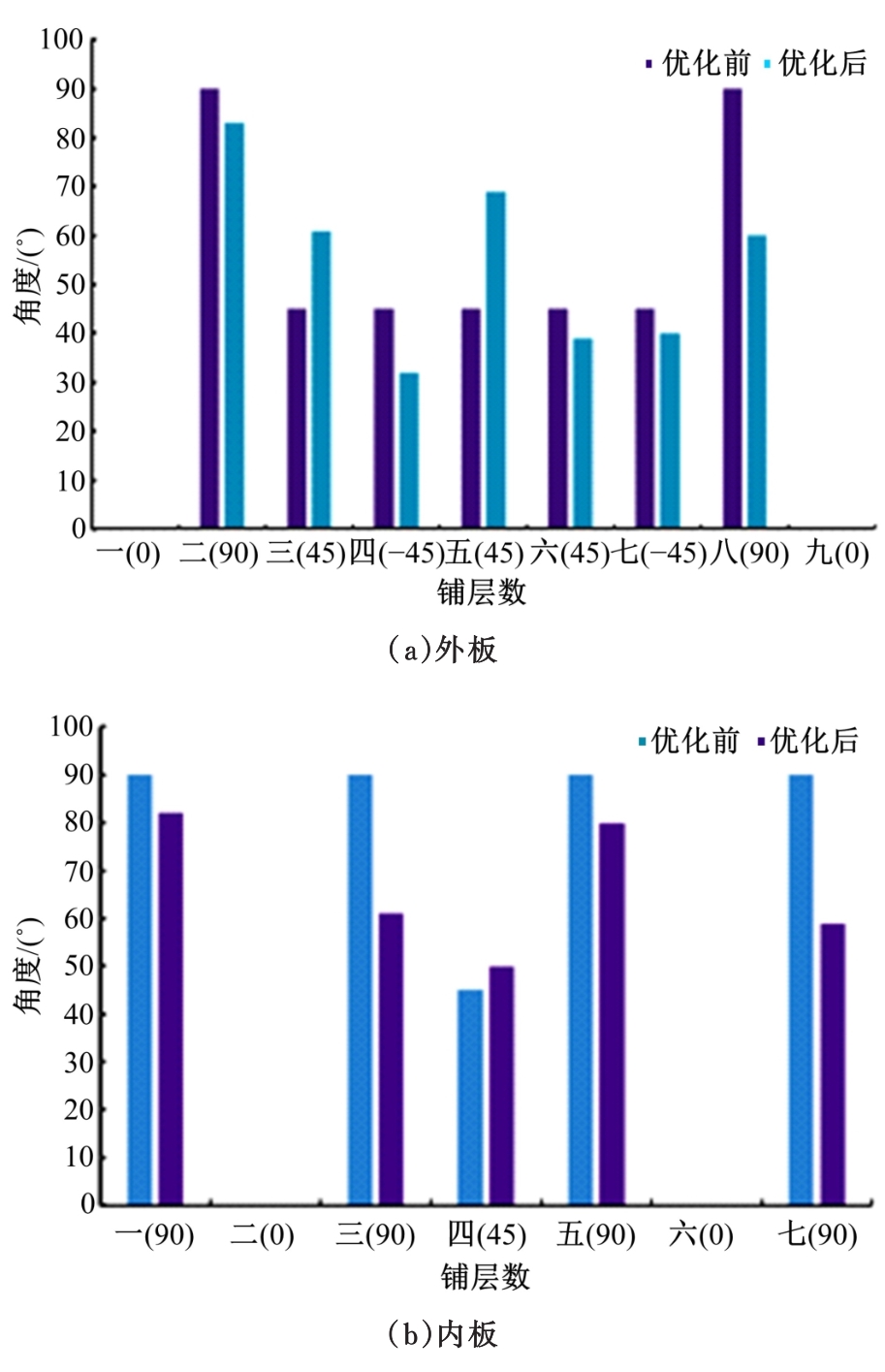

采用碳纤维和玻璃纤维两种增强材料与环氧树脂基体材料,对汽车发动机罩进行了铺层结构设计、样件制造和性能对比分析。研究表明:纤维增强发动机罩在满足刚度、模态要求的同时能有效减轻质量,实现发动机罩减重51.2%。在不同工况下,将发动机罩自由模态、横向弯曲刚度、扭转刚度的仿真结果与试验结果和原钢制件发动机罩性能进行了对比,验证了设计的有效性。对复合材料发动机罩铺层优化设计进行了研究,通过优化发动机罩质量相对于初始设计减重9.7%,充分发挥了纤维复合材料在汽车轻量化方面的优势。

中图分类号:

- U465.6

| 1 | 王登峰, 卢放. 基于多学科优化设计方法的白车身轻量化[J]. 吉林大学学报: 工学版, 2015, 45 (1): 29-37. |

| Wang Deng-feng, Lu Fang. Body-in-white lightweight based on multidisciplinary design optimization[J]. Journal of Jilin University (Engineering and Technology Edition), 2015, 45(1): 29-37. | |

| 2 | 杨天云, 张晴朗, 杨兵. CAE在汽车座椅轻量化设计中的应用[J]. 精密成形工程, 2012, 4(1): 73-77. |

| Yang Tian-yun, Zhang Qing-lang, Yang Bing, et al. Application of CAE to automotive seat back for weight reduction[J]. Journal of Netshape Forming Engineering, 2012, 4(1): 73-77. | |

| 3 | Lee S L, Lee D C, Lee J I, et al. Integrated process for structural-topological configuration design of weight-reduced vehicle components[J]. Finite Elements in Analysis and Design, 2007, 43(8): 620-629. |

| 4 | Ghiasi H, Pasini D, Lessard L. Optimum stacking sequence design of composite materials Part I: constant stiffness design[J]. Composite Structures, 2009, 90(1): 1-11. |

| 5 | Ghiasi H, Fayazbakhsh K, Pasini D, et al. Optimum stacking sequence design of composite materials Part II: variable stiffness design[J]. Composite Structures, 2010, 93(1): 1-13. |

| 6 | 沙云东, 贾秋月, 骆丽. 纤维增强复合材料轴结构铺层方案优化设计[J]. 航空动力学报, 2016, 31(12): 2933-2940. |

| Sha Yun-dong, Jia Qiu-yue, Luo Li, et al. Optimization design for laminate scheme of fiber reinforced composite shaft[J]. Journal of Aerospace Power, 2016, 31(12): 2933-2940. | |

| 7 | 陆振玉, 张恩阳, 刘波. 基于改进自适应遗传算法的复合材料铺层优化设计[J]. 玻璃钢/复合材料, 2016(2): 53-56. |

| Lu Zhen-yu, Zhang En-Yang, Liu Bo, et al. Ply optimization of composite laminate based on improved adaptive genetic algorithm[J]. Fiber Reinforced Plastics/Composites, 2016(2): 53-56. | |

| 8 | 段尊义. 纤维增强复合材料框架结构拓扑与纤维铺角一体化优化设计[D]. 大连: 大连理工大学运载工程与力学学部, 2016. |

| Duan Zun-yi. Integrated optimization design of structural topology and laying angle of fiber reinforced composite frame[D]. Dalian: Facully of Vehicle Engineering and Mechanics, Dalian University of Technology, 2016. | |

| 9 | 洪清泉, 赵康, 张攀. OptiStruct&HyperStudy理论基础与工程应用[M]. 北京: 机械工业出版社, 2013. |

| 10 | 潘玲玲. 碳纤维复合材料典型车身覆盖件设计开发与试制[D]. 上海: 同济大学汽车学院, 2006. |

| Pan Ling-ling. Design and trial production of typical body covers of carbon fiber composites[D]. Shanghai: College of Automotive Studies,Tongji University, 2006. | |

| 11 | 陈绍杰. 先进复合材料在汽车领域的应用[J]. 高科技纤维与应用, 2011, 36(1): 11-17, 23. |

| Chen Shao-jie. Application of advanced composites on automotive filed[J]. Hi-Tech Fiber and Application, 2011, 36(1): 11-17, 23. | |

| 12 | Black S. Innovative composite design may replace aluminum chassis[J]. Composites Technology, 2006(1): 44-46. |

| 13 | 刘念, 徐涛, 徐天爽, 等. 基于差厚技术的汽车仪表板管梁轻量化设计[J].吉林大学学报: 工学版, 2018, 48(1): 199-204. |

| Liu Nian, Xu Tao, Xu Tian-shuang, et al. Lightweight design of TRB dashboard cross beam[J]. Journal of Jilin University (Engineering and Technology Edition), 2018, 48(1): 199-204. | |

| 14 | 孙鸿昌, 张欣然. 碳纤维复合材料汽车零部件开发与应用前景[J]. 化工设计通讯, 2018, 44(12): 74. |

| Sun Hong-chang, Zhang Xin-ran. Research on development and prospect of carbon fiber composite automotive parts[J]. Chemical Engineering Design Communications, 2018, 44(12): 74. |

| [1] | 赖晨光,王擎宇,胡博,文凯平,陈彦宇. 静气动弹性影响下带小翼汽车尾翼的设计与优化[J]. 吉林大学学报(工学版), 2020, 50(2): 399-407. |

| [2] | 李小雨,许男,仇韬,郭孔辉. 各向异性刚度对轮胎力学特性及车辆操纵性的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 389-398. |

| [3] | 马芳武,梁鸿宇,赵颖,杨猛,蒲永锋. 内凹三角形负泊松比结构耐撞性多目标优化设计[J]. 吉林大学学报(工学版), 2020, 50(1): 29-35. |

| [4] | 郭孔辉,黄世庆,吴海东. 适用于高频激励的面内轮胎动态模型[J]. 吉林大学学报(工学版), 2020, 50(1): 19-28. |

| [5] | 王哲,谢怡,臧鹏飞,王耀. 基于极小值原理的燃料电池客车能量管理策略[J]. 吉林大学学报(工学版), 2020, 50(1): 36-43. |

| [6] | 史文库,陈龙,张贵辉,陈志勇. 多级刚度双质量飞轮扭转特性建模与试验验证[J]. 吉林大学学报(工学版), 2020, 50(1): 44-52. |

| [7] | 管欣,金号,段春光,卢萍萍. 汽车行驶道路侧向坡度估计[J]. 吉林大学学报(工学版), 2019, 49(6): 1802-1809. |

| [8] | 陈鑫,阮新建,李铭,王宁,王佳宁,潘凯旋. 基于大涡模拟的离散格式改进方法及应用[J]. 吉林大学学报(工学版), 2019, 49(6): 1756-1763. |

| [9] | 马芳武,倪利伟,吴量,聂家弘,徐广健. 轮腿式全地形移动机器人位姿闭环控制[J]. 吉林大学学报(工学版), 2019, 49(6): 1745-1755. |

| [10] | 靳立强, 田端洋, 田浩, 刘蒙蒙. 汽车电子稳定系统制动增力辅助技术[J]. 吉林大学学报(工学版), 2019, 49(6): 1764-1776. |

| [11] | 王杨,宋占帅,郭孔辉,庄晔. 转动惯量试验台的惯性参数测量[J]. 吉林大学学报(工学版), 2019, 49(6): 1795-1801. |

| [12] | 庄蔚敏,刘洋,王鹏跃,施宏达,徐纪栓. 钢铝异质自冲铆接头剥离失效仿真[J]. 吉林大学学报(工学版), 2019, 49(6): 1826-1835. |

| [13] | 何仁,涂琨. 基于温度补偿气隙宽度的电磁制动器[J]. 吉林大学学报(工学版), 2019, 49(6): 1777-1785. |

| [14] | 刘巧斌,史文库,陈志勇,骆联盟,苏志勇,黄开军. 混合可靠性模型参数的核密度和引力搜索估计[J]. 吉林大学学报(工学版), 2019, 49(6): 1818-1825. |

| [15] | 李杰, 郭文翠, 赵旗, 谷盛丰. 基于车辆响应的路面不平度识别方法[J]. 吉林大学学报(工学版), 2019, 49(6): 1810-1817. |

|

||