吉林大学学报(工学版) ›› 2020, Vol. 50 ›› Issue (1): 44-52.doi: 10.13229/j.cnki.jdxbgxb20181239

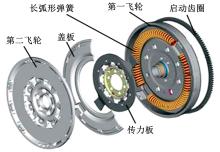

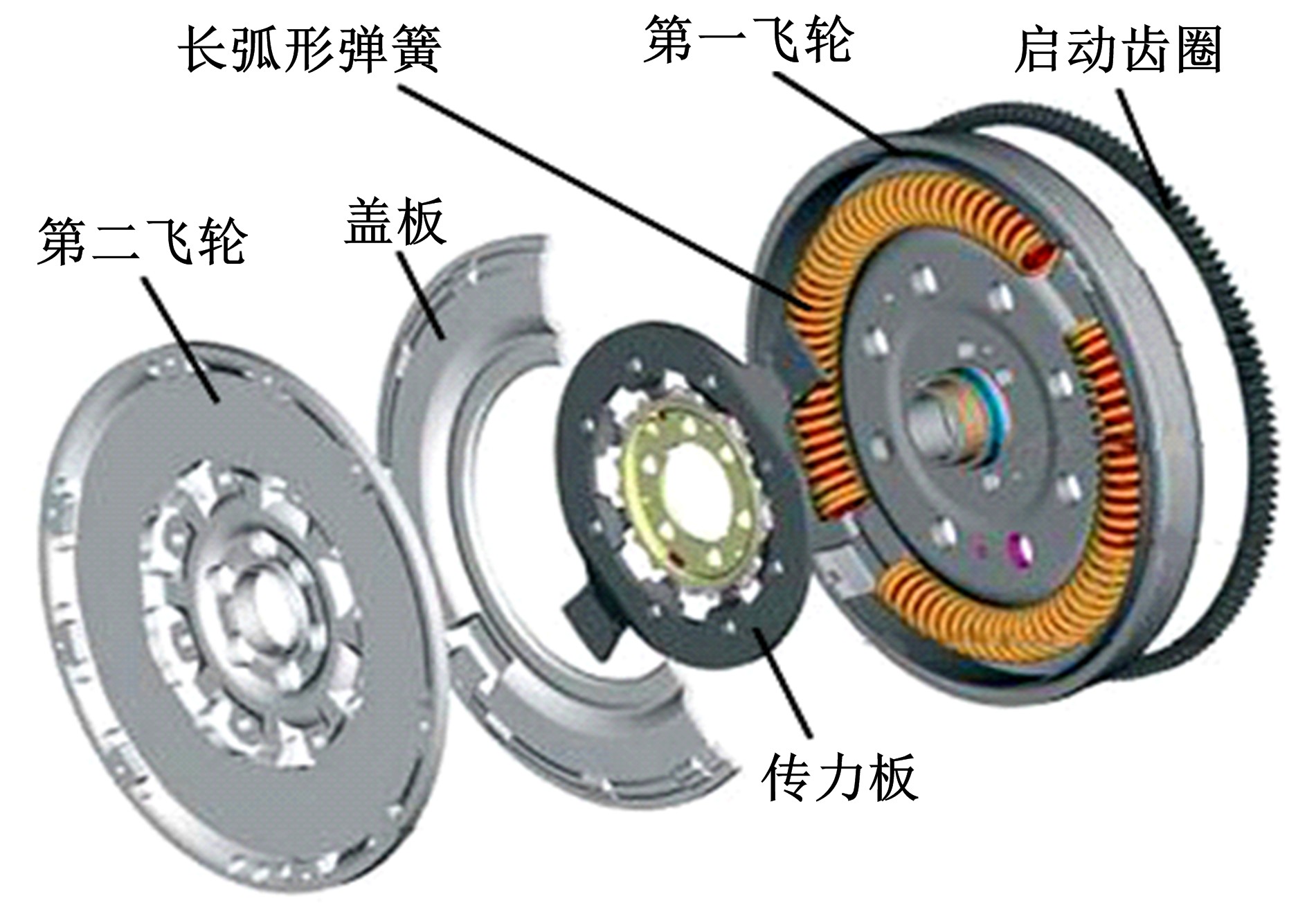

多级刚度双质量飞轮扭转特性建模与试验验证

- 1. 吉林大学 汽车仿真与控制国家重点实验室,长春 130022

2. 吉林大华机械制造有限公司,长春 130103

Modeling and tests for torsional characteristics of multi-stage stiffness dual mass flywheel torsional dampers

Wen-ku SHI1( ),Long CHEN1,Gui-hui ZHANG2,Zhi-yong CHEN1(

),Long CHEN1,Gui-hui ZHANG2,Zhi-yong CHEN1( )

)

- 1. State Key Laboratory of Automotive Simulation and Control, Jilin University, Changchun 130022, China

2. Dahua Machine Manufacturing Co. Ltd. , Changchun 130103, China

摘要:

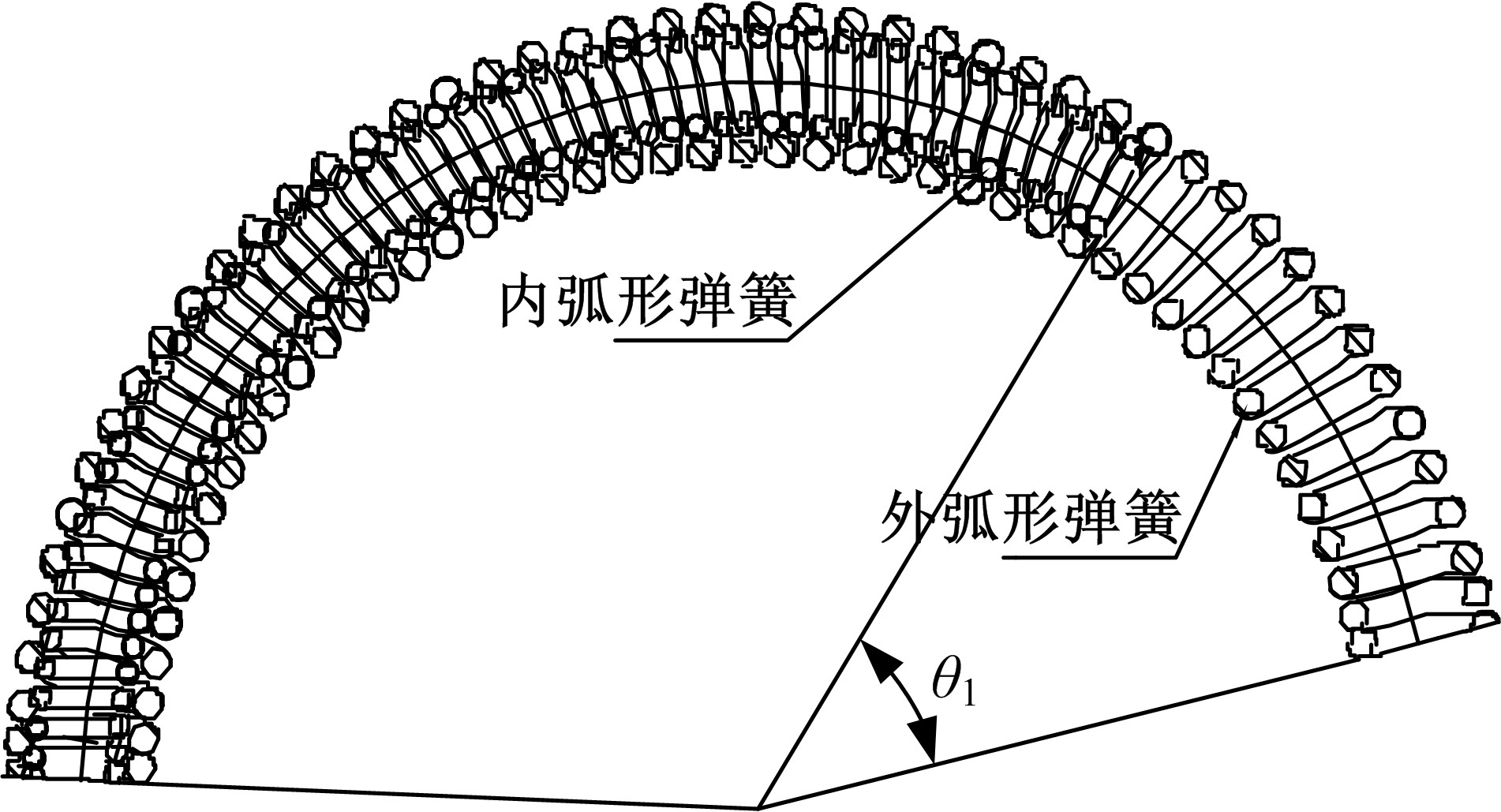

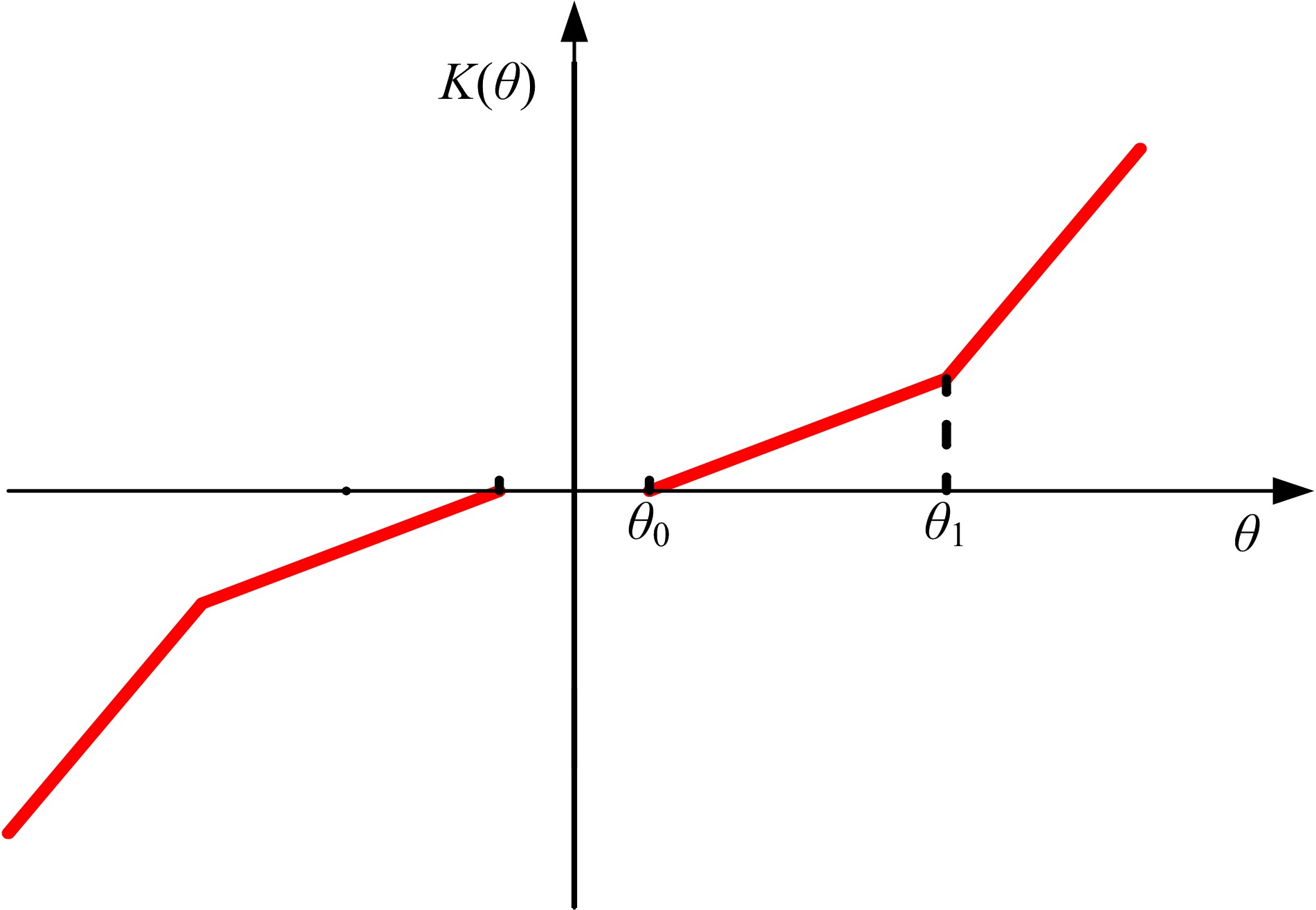

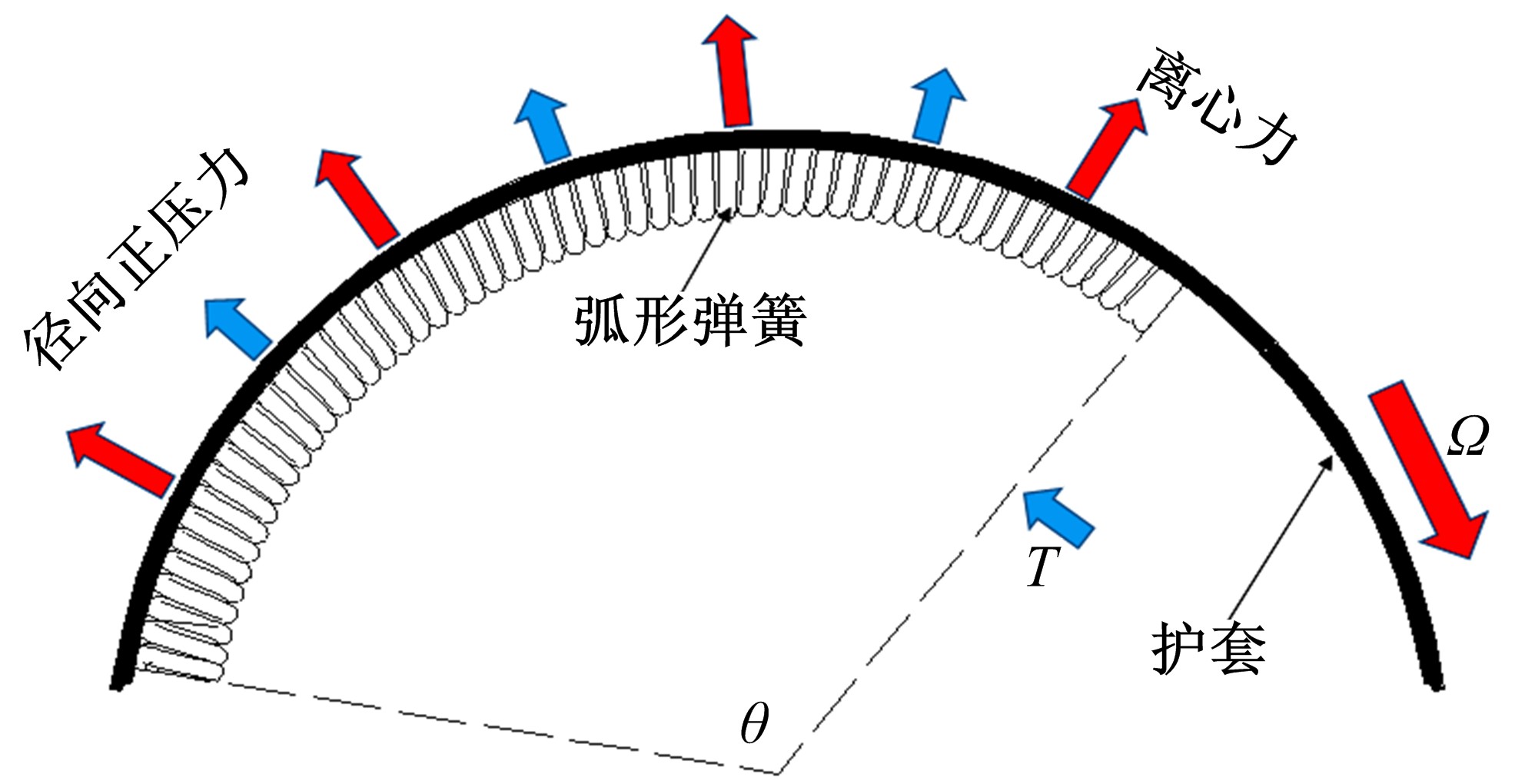

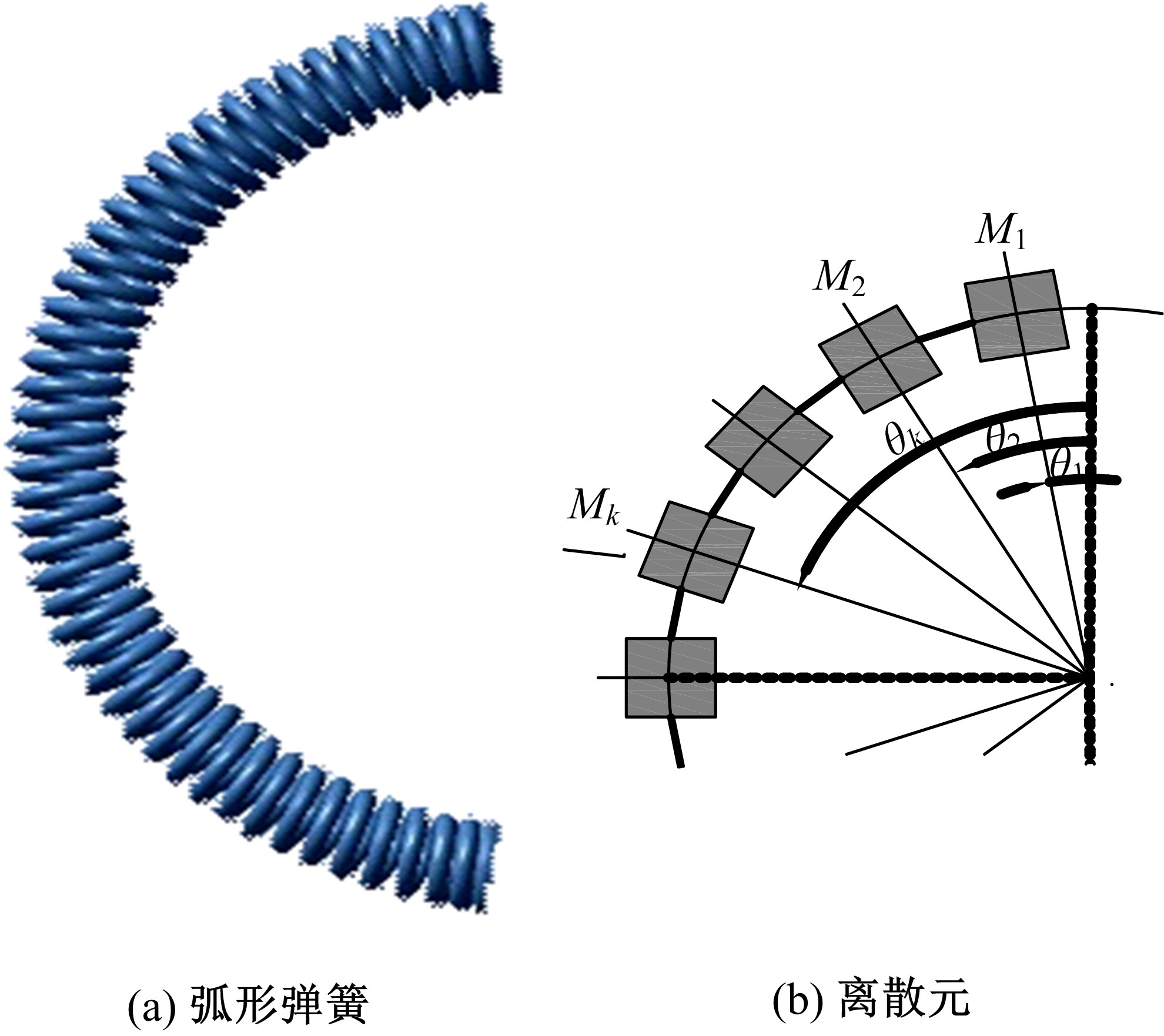

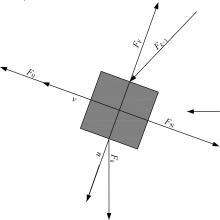

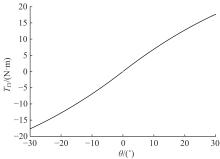

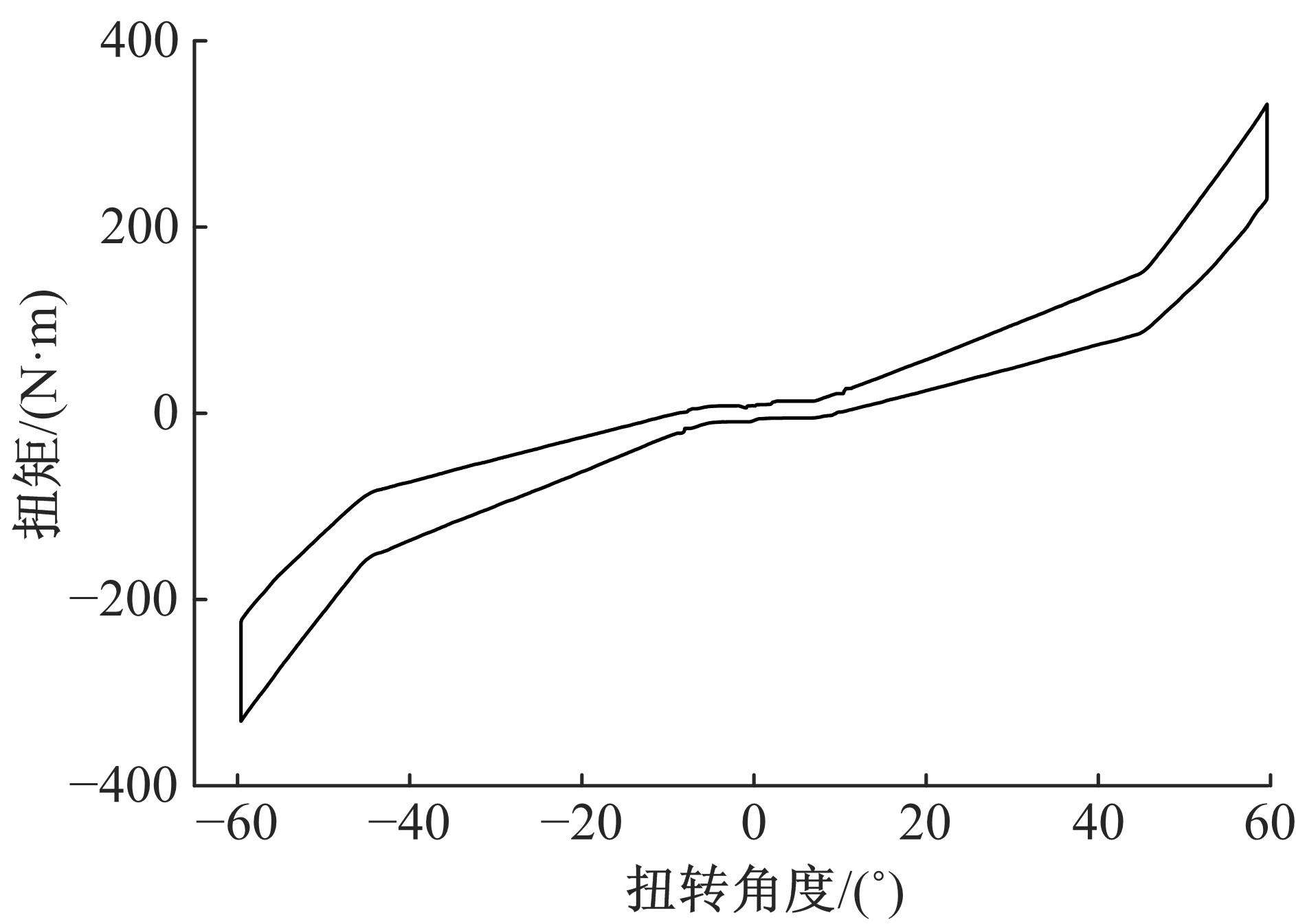

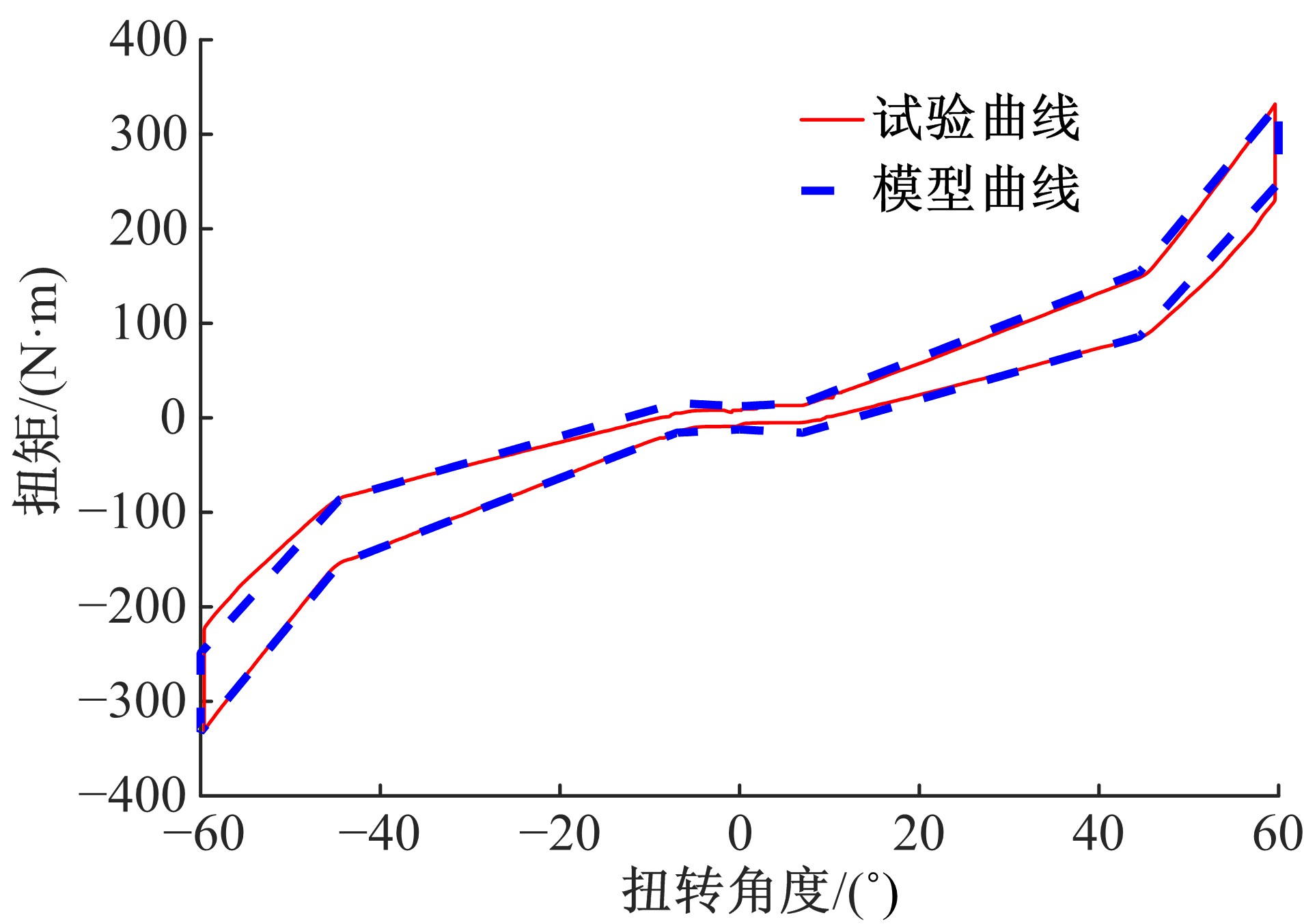

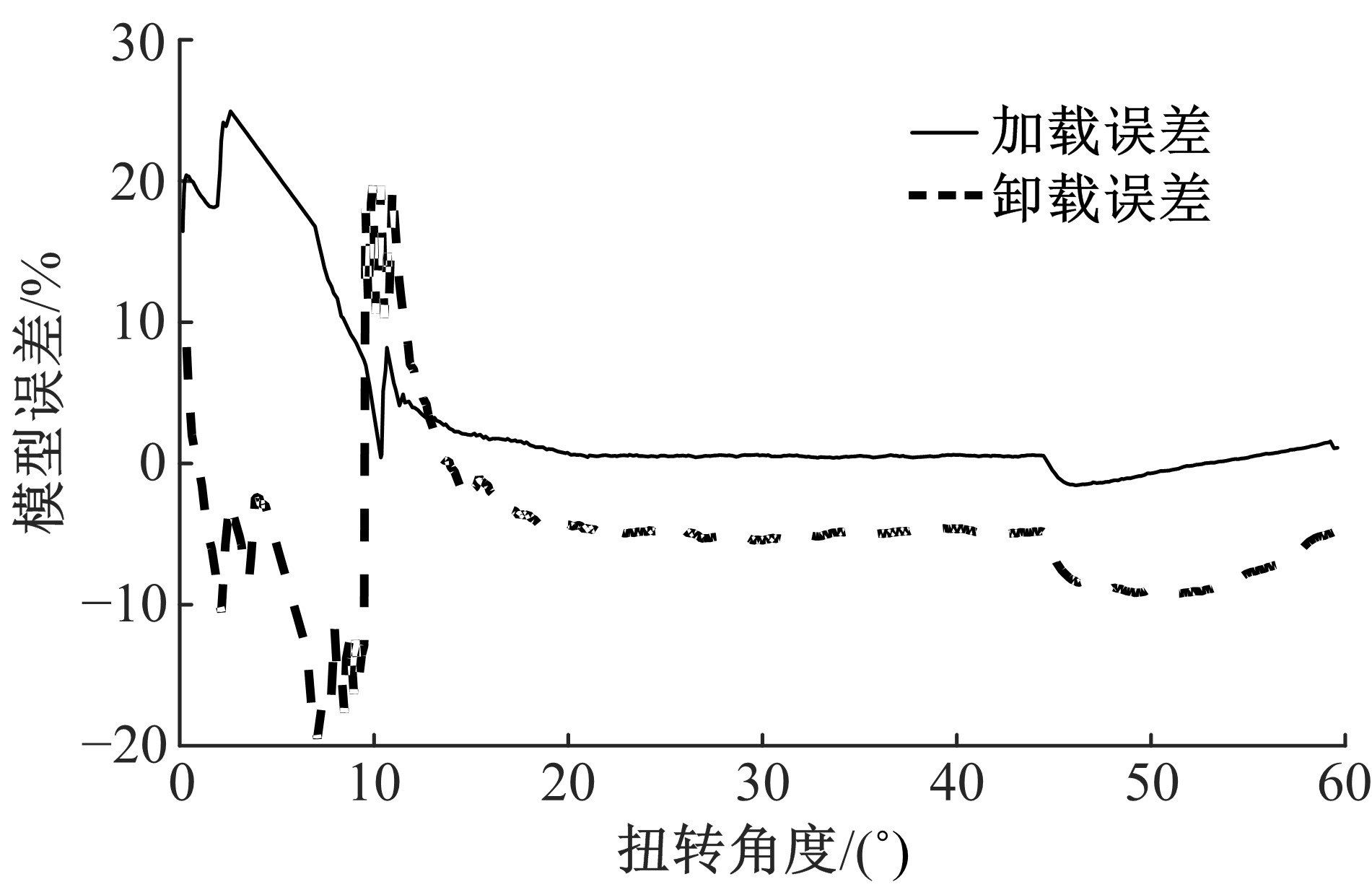

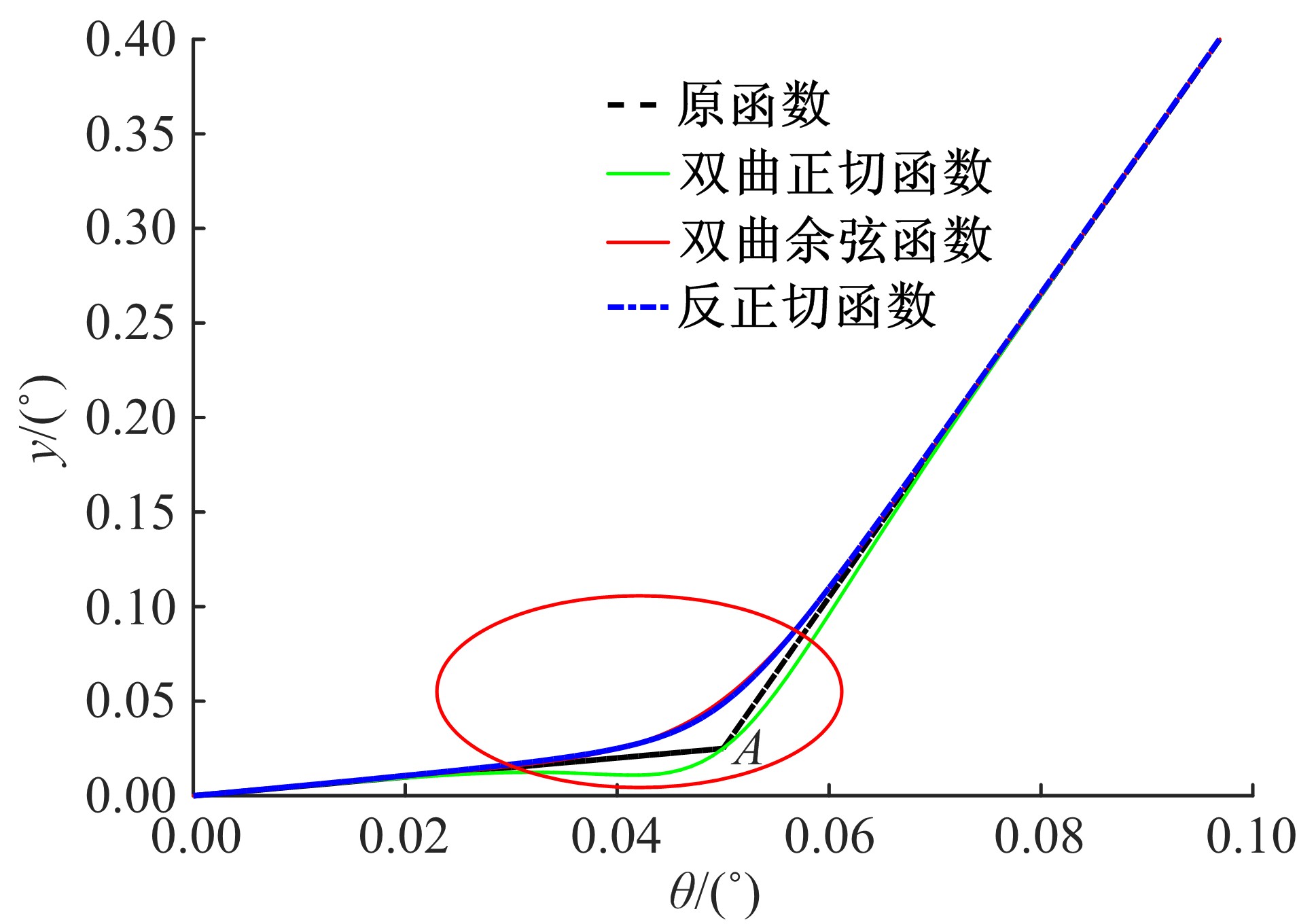

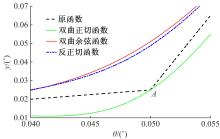

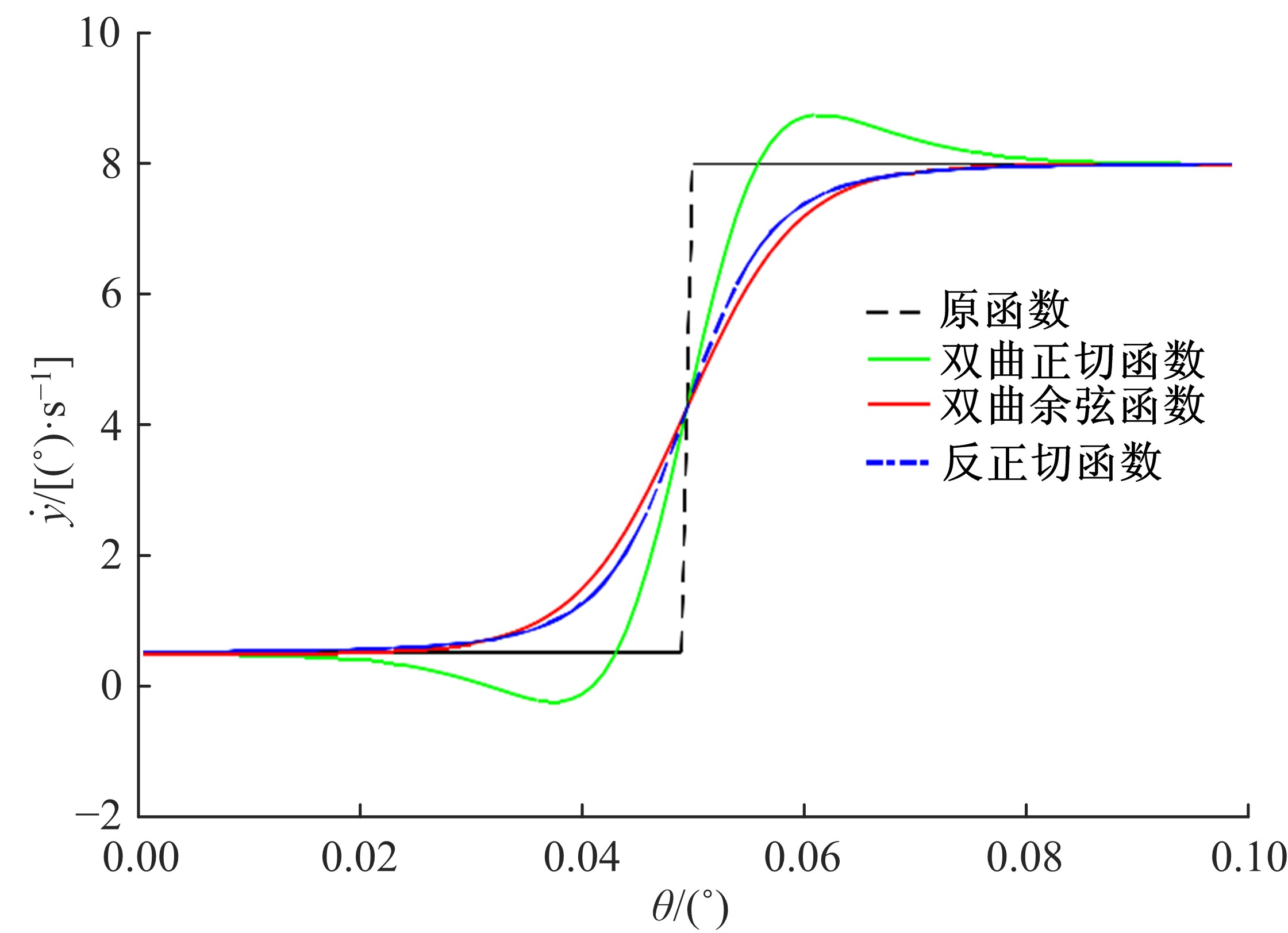

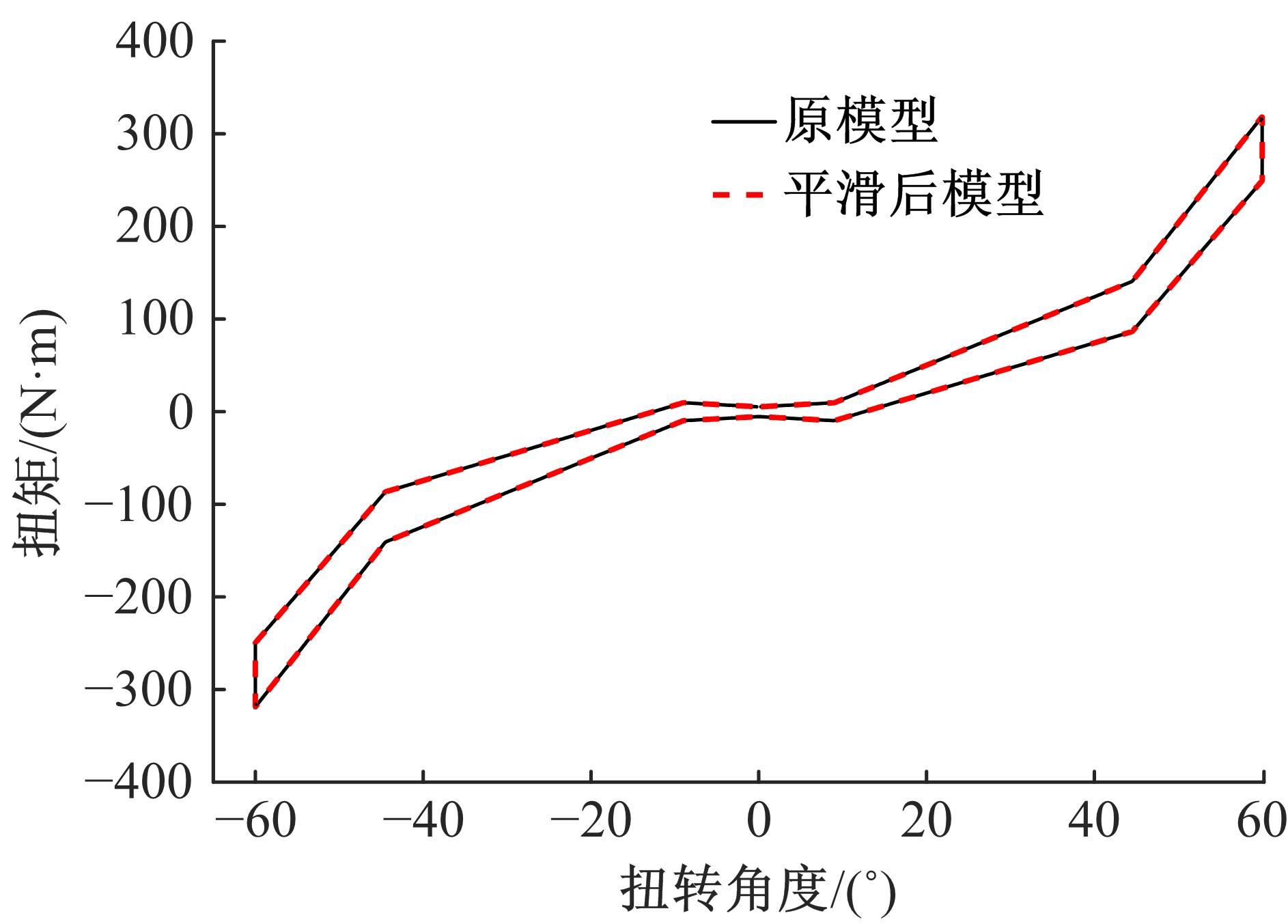

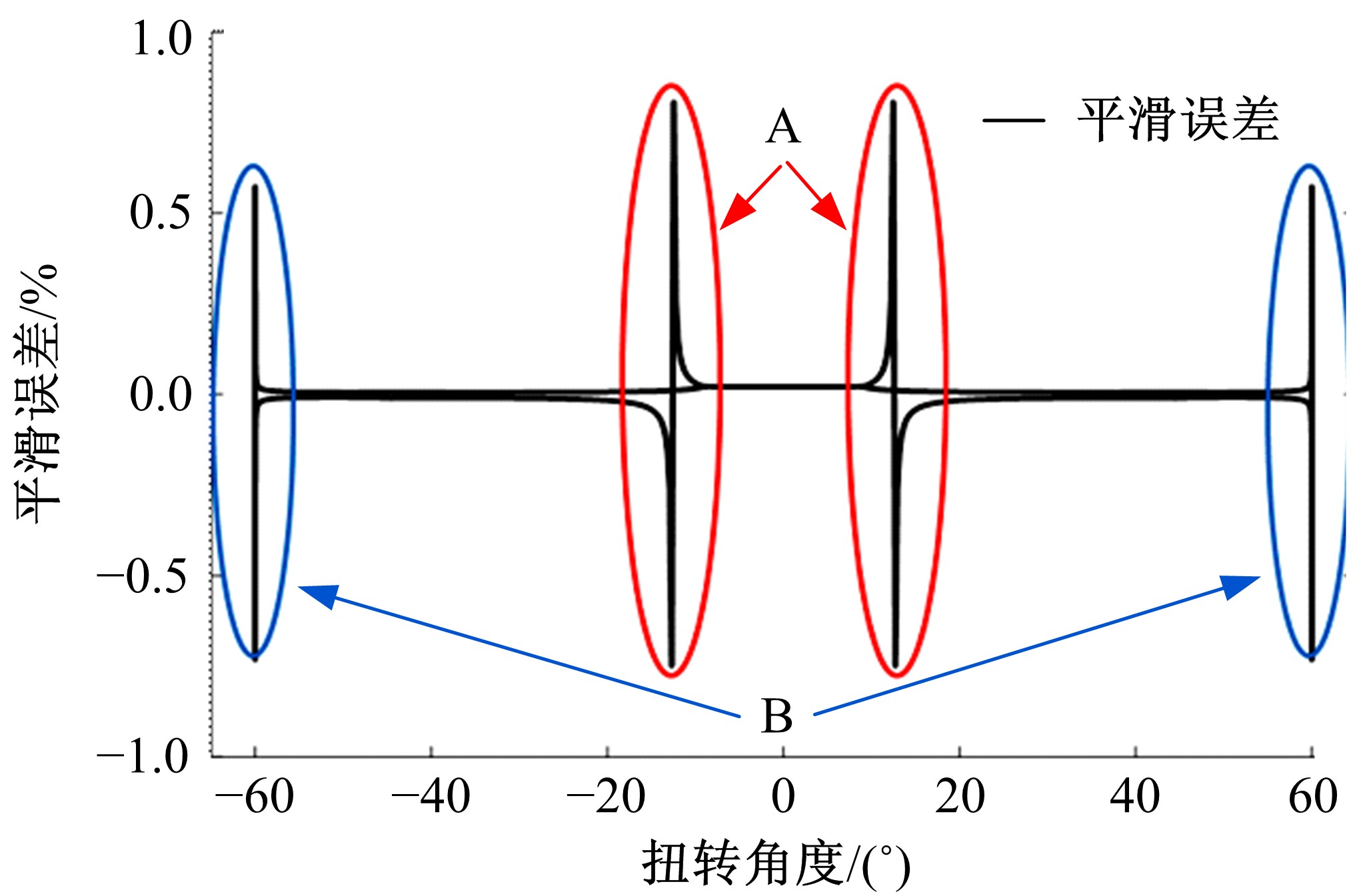

针对多级刚度双质量飞轮扭转特性建模和分段点平滑拟合展开了研究。首先,在分析多级刚度双质量飞轮工作原理基础上,建立了考虑分段刚度、阻尼非线性的双质量飞轮扭转特性数学模型,并通过台架试验验证模型准确性。其次,针对所建模型存在跳跃间断点以及仿真过程中可能出错的问题,采用反正切函数对模型进行平滑拟合,得到基于反正切拟合函数的双质量飞轮非线性模型。最后,对平滑拟合前、后模型进行对比分析,结果表明:采用反正切函数平滑拟合对模型精度影响较小,使模型分段点和临界点平滑过渡,提升了模型仿真稳定性。

中图分类号:

- U461.1

| 1 | Mahl T , Sawodny O . Modelling of an automotive dual mass flywheel[C]∥IFAC Proceedings Volumes, 2010, 43(18): 517-523. |

| 2 | Theodossiades S , Gnanakumarr M , Rahnejat H , et al . Effect of a dual-mass flywheel on the impact-induced noise in vehicular powertrain systems[J]. Institution of Mechanical Engineers Part D Journal of Automobile Engineering, 2006, 220(6): 747-761. |

| 3 | Gupta K , Choudhary A , Bidre R . NVH performance improvement study using a dual mass flywheel(DMF) , inertia ring type tuned torsional vibration damper(TVD) and single mass flywheel(SMF) in a front engine and rear wheel driveline architecture[C]∥SAE Paper, 2017-01-1752. |

| 4 | 宋立权, 周建东, 吴荣华, 等 . 摩擦式双级分段变刚度汽车双质量飞轮设计理论研究及应用[J]. 机械工程学报, 2012, 48(15): 150-157. |

| Song Li-quan , Zhou Jian-dong , Wu Rong-hua , et al . Research and application on design theory of friction dual mass flywheel with double-stage piecewise variable stiffness[J]. Journal of Mechanical Engineering, 2012, 48(15): 150-157. | |

| 5 | 李伟, 史文库, 龙岩, 等 . DMF-CS型扭振减振器刚度匹配设计[J]. 吉林大学学报:工学版, 2009, 39(增刊1):62-67. |

| Li Wei , Shi Wen-ku , Long Yan , et al . Match and design of torsional stiffness of the DMF-CS torsional damper[J] Journal of Jilin University(Engineering and Technology Edition), 2009, 39(Sup.1): 62-67. | |

| 6 | 曾荣, 左厅, 江征风, 等 . 周向长弧形弹簧式双质量飞轮迟滞非线性扭转特性模型研究[J]. 中国机械工程, 2015, 26(16): 2148-2153. |

| Zeng Rong , Zuo Ting , Jiang Zheng-feng , et al . Hysteresus torsion characteristic model of circumferential arc spring dual mass flywheel[J] . China Mechanical Engineering, 2015, 26(16): 2148-2153. | |

| 7 | Kim T H , Song H L , Hwang S H , et al . Analysis of dual mass flywheel using discrete arcspring model[J]. Key Engineering Materials, 2006, 326-328: 1607-1610. |

| 8 | 宋立权, 周建东, 吴荣华, 等 . 摩擦式双级分段变刚度汽车双质量飞轮设计理论研究及应用[J]. 机械工程学报, 2012, 48(15): 150-157. |

| Song Li-quan , Zhou Jian-dong , Wu Rong-hua , et al . Research and application on design theory of friction dual mass flywheel with double-stage piecewise variable stiffness[J]. Journal of Mechanical Engineering, 2012, 48(15): 150-157. | |

| 9 | 曾礼平, 陈齐平, 袁星星, 等 . 汽车三级分段变刚度双质量飞轮非线性振动研究[J]. 中国机械工程, 2018, 29(20): 2453-2459. |

| Zeng Li-ping , Chen Qi-ping , Yuan Xing-xing , et al . Study on nonlinear vibration of vehicle dual mass flywheel with three-stage piecewise stiffnesses[J]. China Mechanical Engineering, 2018, 29(20): 2453-2459. | |

| 10 | Kim T C , Rook T E , Singh R . Effect of smoothening functions on the frequency response of an oscillator with clearance non-linearity[J]. Journal of Sound & Vibration, 2003, 263(3): 665-678. |

| 11 | 吴虎威, 吴光强, 陈祥, 等 . 考虑迟滞特性的多级刚度扭转减振器建模及试验验证[J]. 振动与冲击, 2017, 36(2): 170-176. |

| Wu Hu-wei , Wu Guang-qiang , Chen Xiang , et al . Numerical and experimental analysis on multi-staged stiffness clutch dampers considering hysteresis characteristics[J]. Journal of Vibration and Shock, 2017, 36(2): 170-176. | |

| 12 | 刘圣田 . 双质量飞轮式扭振减振器对振动的控制分析[J]. 农业机械学报, 2004, 35(3): 16-19. |

| Liu Sheng-tian . Influences of a dual-mass flywheel damper on idling vibration[J] Transactions of the Chinese Society for Agricultural Machinery, 2004, 35(3): 16-19. | |

| 13 | 史文库, 龙岩, 卢玉东 . 多级非线性双质量飞轮参数设计和优化[J]. 振动与冲击, 2009, 28(5): 92-96. |

| Shi Wen-ku , Long Yan , Lu Yu-dong . Study on multistage non-linear dual mass flywheel damper[J]. Journal of Vibration and Shock, 2009, 28(5): 92-96. | |

| 14 | 赵光明, 江征风, 陈雷, 等 . 周向长弧形弹簧双质量飞轮阻尼特性研究及其试验验证[J]. 内燃机工程, 2012, 33(1): 81-86. |

| Zhao Guang-ming , Jiang Zheng-feng , Chen Lei , et al . Research and experiment verification on damping characteristics of circumferential arc spring dual mass flywheel[J]. Chinese Internal Combustion Engine Engineering, 2012, 33(1): 81-86. | |

| 15 | 丁千, 翟红梅 . 机械系统摩擦动力学研究进展[J]. 力学进展, 2013, 43(1): 112-131. |

| Ding Qian , Zhai Hong-mei . The advance in researches of friction dynamics in mechanics system[J]. Advances in Mechanics, 2013, 43(1): 112-131. |

| [1] | 马芳武,梁鸿宇,赵颖,杨猛,蒲永锋. 内凹三角形负泊松比结构耐撞性多目标优化设计[J]. 吉林大学学报(工学版), 2020, 50(1): 29-35. |

| [2] | 郭孔辉,黄世庆,吴海东. 适用于高频激励的面内轮胎动态模型[J]. 吉林大学学报(工学版), 2020, 50(1): 19-28. |

| [3] | 王哲,谢怡,臧鹏飞,王耀. 基于极小值原理的燃料电池客车能量管理策略[J]. 吉林大学学报(工学版), 2020, 50(1): 36-43. |

| [4] | 陈鑫,阮新建,李铭,王宁,王佳宁,潘凯旋. 基于大涡模拟的离散格式改进方法及应用[J]. 吉林大学学报(工学版), 2019, 49(6): 1756-1763. |

| [5] | 马芳武,倪利伟,吴量,聂家弘,徐广健. 轮腿式全地形移动机器人位姿闭环控制[J]. 吉林大学学报(工学版), 2019, 49(6): 1745-1755. |

| [6] | 靳立强, 田端洋, 田浩, 刘蒙蒙. 汽车电子稳定系统制动增力辅助技术[J]. 吉林大学学报(工学版), 2019, 49(6): 1764-1776. |

| [7] | 王杨,宋占帅,郭孔辉,庄晔. 转动惯量试验台的惯性参数测量[J]. 吉林大学学报(工学版), 2019, 49(6): 1795-1801. |

| [8] | 庄蔚敏,刘洋,王鹏跃,施宏达,徐纪栓. 钢铝异质自冲铆接头剥离失效仿真[J]. 吉林大学学报(工学版), 2019, 49(6): 1826-1835. |

| [9] | 李杰, 郭文翠, 赵旗, 谷盛丰. 基于车辆响应的路面不平度识别方法[J]. 吉林大学学报(工学版), 2019, 49(6): 1810-1817. |

| [10] | 陈百超,邹猛,党兆龙,黄晗,贾阳,石睿杨,李建桥. CE-3月球车筛网轮月面沉陷行为试验[J]. 吉林大学学报(工学版), 2019, 49(6): 1836-1843. |

| [11] | 何仁,涂琨. 基于温度补偿气隙宽度的电磁制动器[J]. 吉林大学学报(工学版), 2019, 49(6): 1777-1785. |

| [12] | 刘巧斌,史文库,陈志勇,骆联盟,苏志勇,黄开军. 混合可靠性模型参数的核密度和引力搜索估计[J]. 吉林大学学报(工学版), 2019, 49(6): 1818-1825. |

| [13] | 管欣,金号,段春光,卢萍萍. 汽车行驶道路侧向坡度估计[J]. 吉林大学学报(工学版), 2019, 49(6): 1802-1809. |

| [14] | 鄢挺,杨林,陈亮. AMT换挡执行机构自适应智能控制策略[J]. 吉林大学学报(工学版), 2019, 49(5): 1441-1450. |

| [15] | 马芳武,韩露,周阳,王世英,蒲永锋. 采用聚乳酸复合材料的汽车零件多材料优化设计[J]. 吉林大学学报(工学版), 2019, 49(5): 1385-1391. |

|

||