吉林大学学报(工学版) ›› 2020, Vol. 50 ›› Issue (1): 36-43.doi: 10.13229/j.cnki.jdxbgxb20180966

基于极小值原理的燃料电池客车能量管理策略

- 1. 同济大学 汽车学院,上海 201804

2. 同济大学 新能源汽车工程中心,上海 201804

Energy management strategy of fuel cell bus based on Pontryagin′s minimum principle

Zhe WANG1,2( ),Yi XIE1,2,Peng-fei ZANG1,2,Yao WANG1,2

),Yi XIE1,2,Peng-fei ZANG1,2,Yao WANG1,2

- 1. School of Automotive Studies, Tongji University, Shanghai 201804, China

2. Clean Energy Automotive Engineering Center, Tongji University, Shanghai 201804, China

摘要:

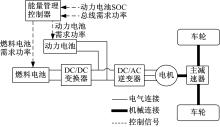

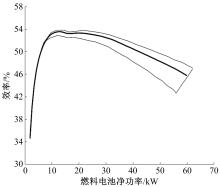

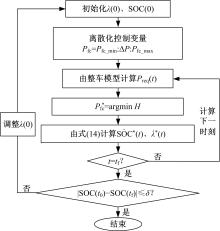

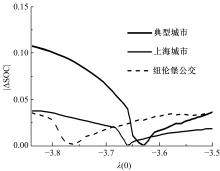

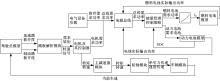

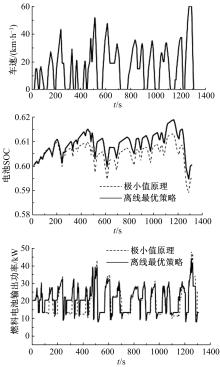

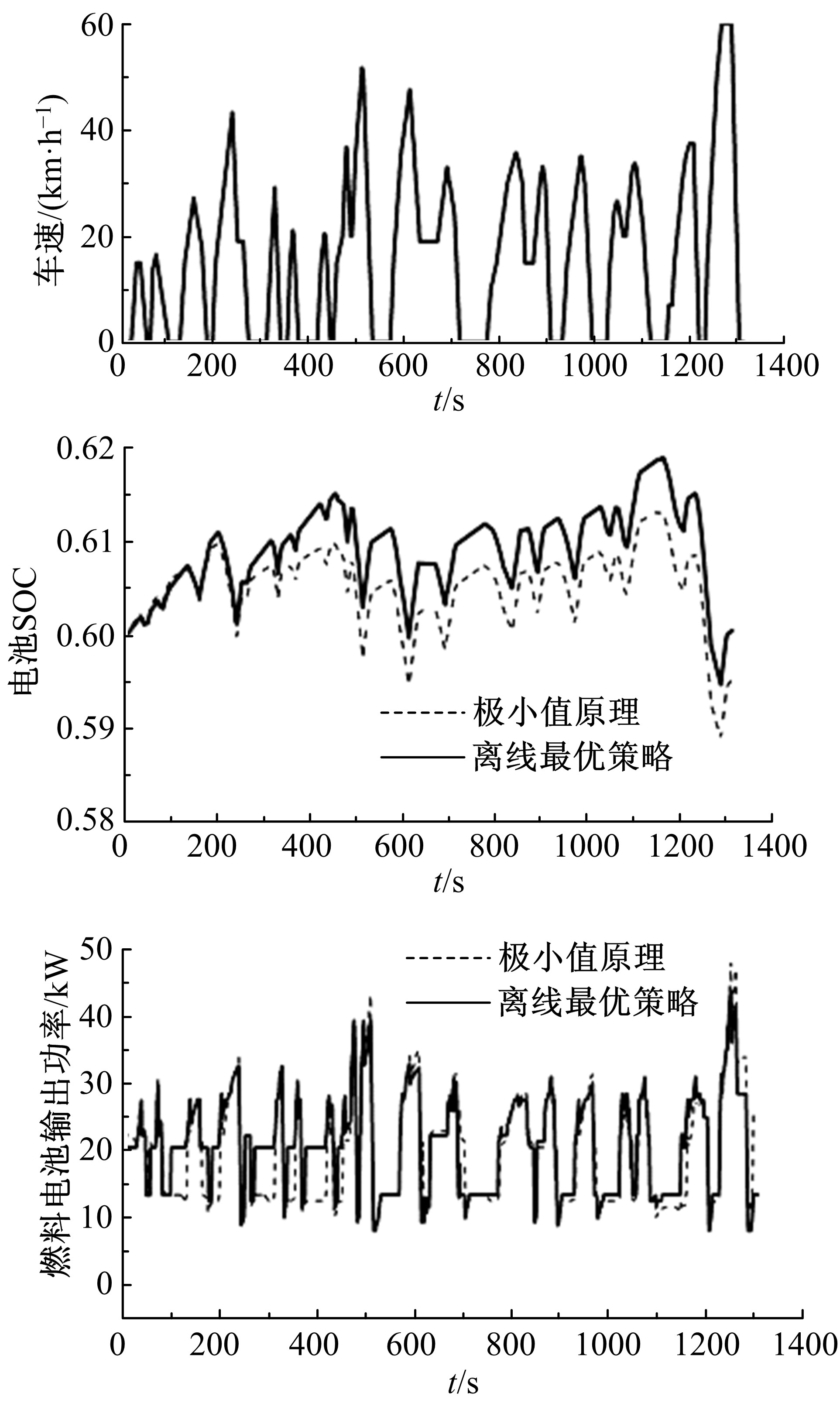

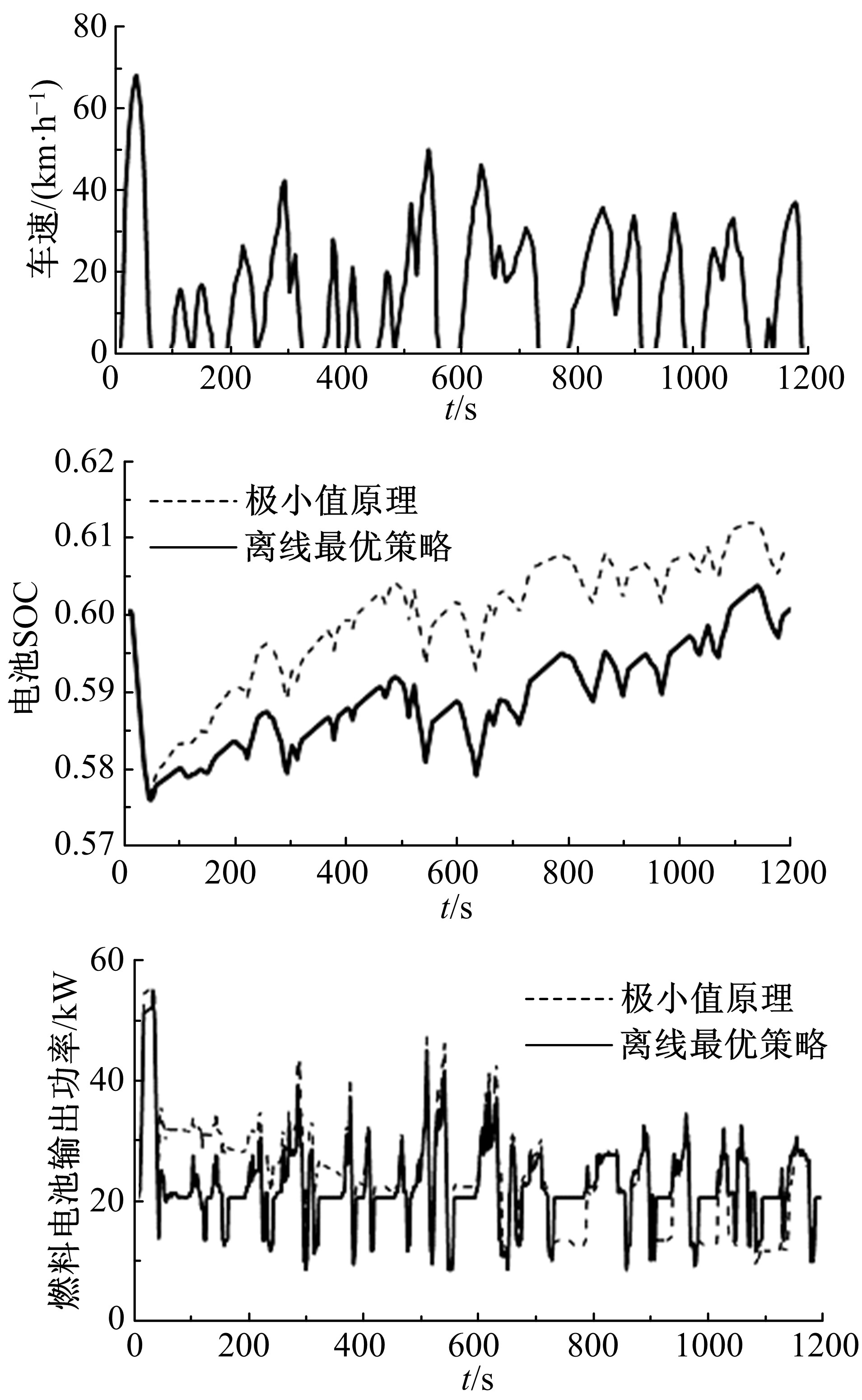

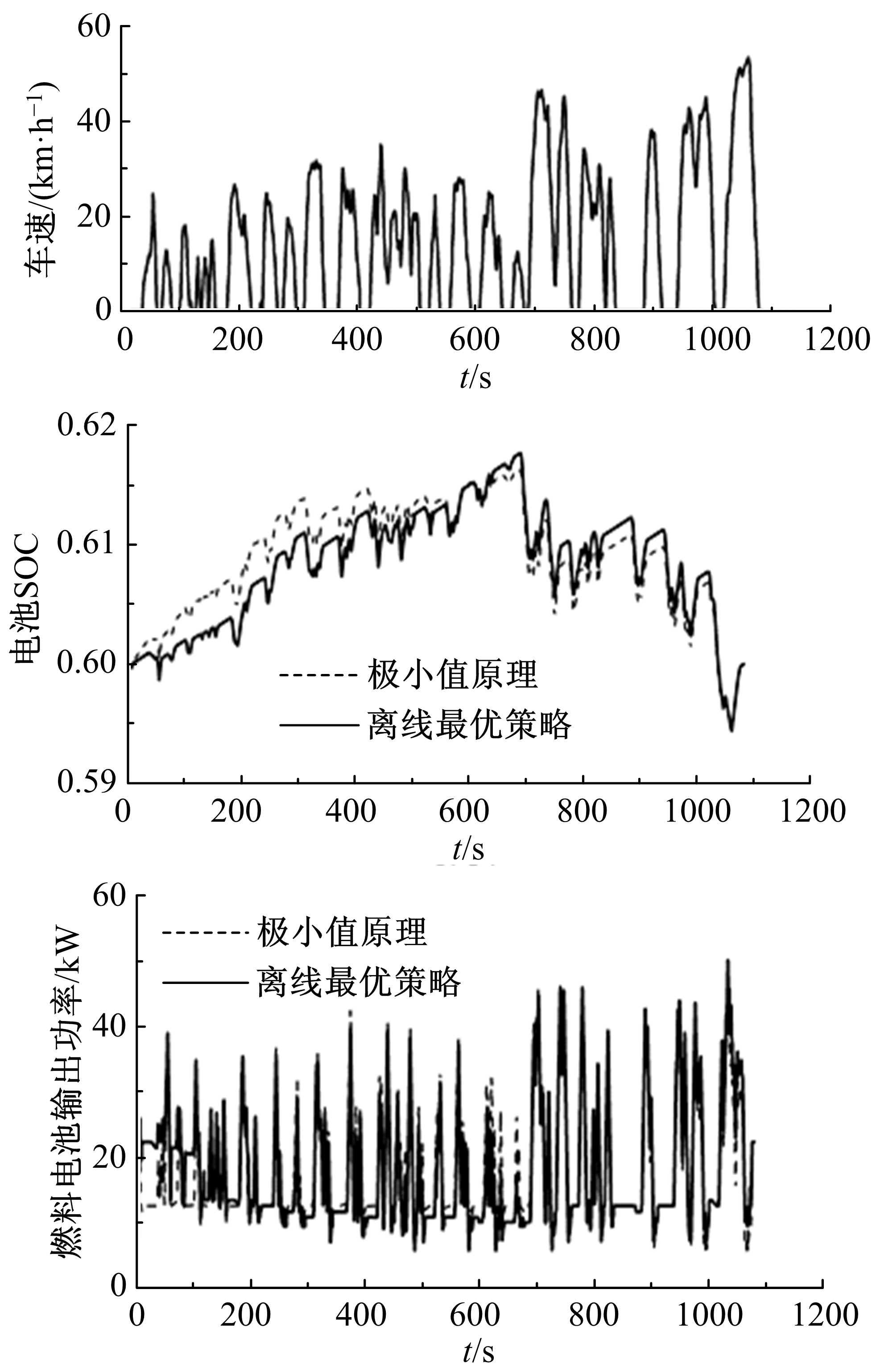

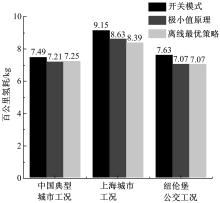

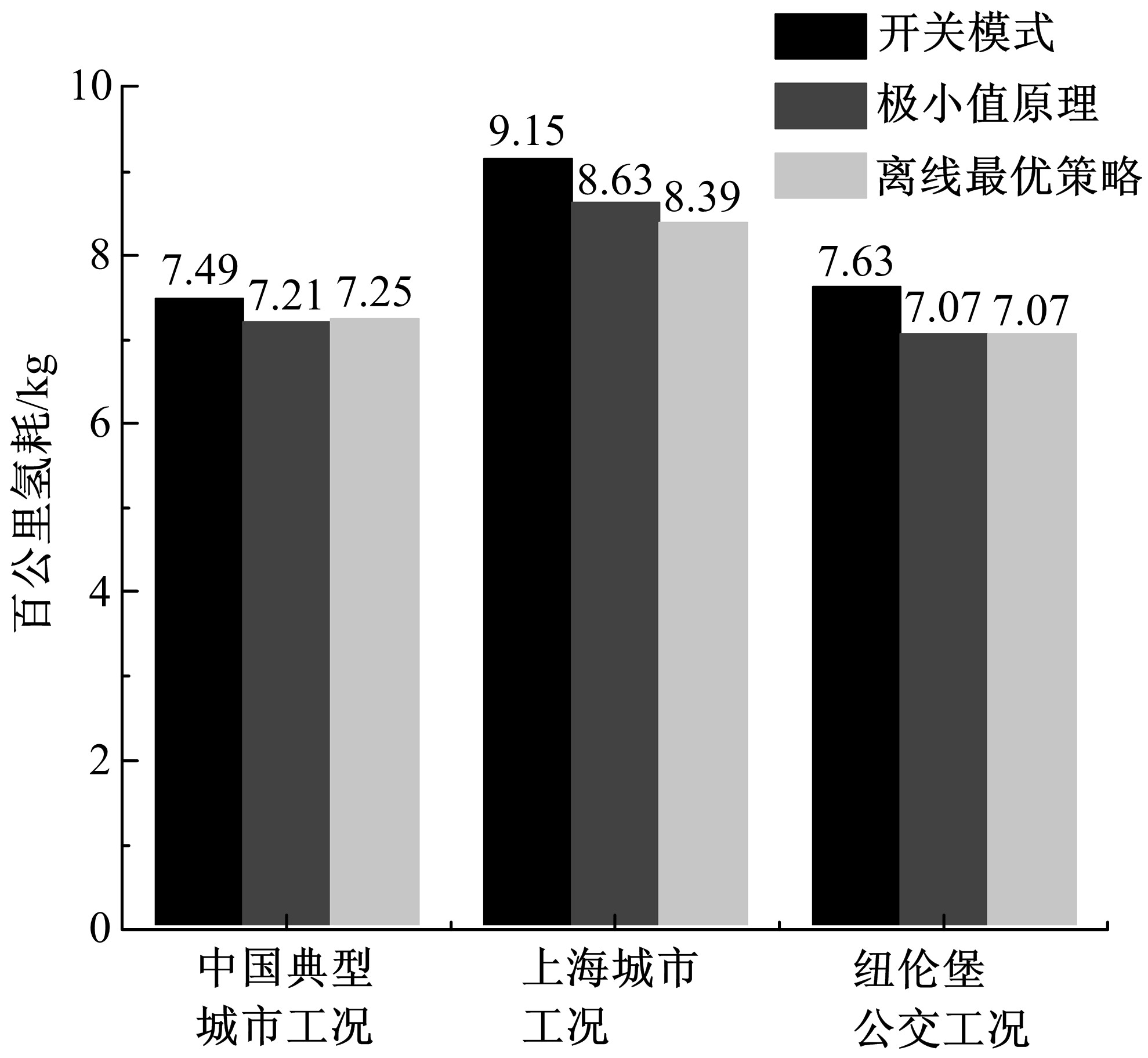

针对燃料电池客车动力系统,以氢耗最低为目标函数,以燃料电池输出功率为控制变量,并考虑燃料电池耐久性对控制变量进行约束,基于Pontryagin极小值原理设计能量管理策略。针对Pontryagin极小值原理仅适用于离线计算的缺点进行改进,设计了能适应不同工况的在线能量管理策略,并建立了燃料电池客车整车仿真模型。仿真结果表明:该能量管理策略在不同工况下具有较好的适应性,不同工况下燃料经济性和耐久性均优于传统开关模式能量管理策略。

中图分类号:

- U461.8

| 1 | 衣宝廉, 侯明. 车用燃料电池耐久性的解决策略[J]. 汽车安全与节能学报, 2011, 2(2): 91-100. |

| Yi Bao-lian, Hou Ming. Solutions for the durability of fuel cells in vehicle applications[J]. Journal of Automotive Safety and Energy, 2011, 2(2): 91-100. | |

| 2 | 张来云. 增程式燃料电池汽车动力系统匹配及能量管理策略研究[D]. 上海:华东理工大学机械与动力工程学院, 2016. |

| Zhang Lai-yun. The power system matching and energy management strategy research of fuel cell range extender electric vehicle[D]. Shanghai: College of Mechanical and Power Engineering,East China University of Science and Technology, 2016. | |

| 3 | 谢星, 周苏, 王廷宏, 等. 基于Cruise/Simulink的车用燃料电池/蓄电池混合动力的能量管理策略仿真[J]. 汽车工程, 2010, 32(5): 373-378. |

| Xie Xing, Zhou Su, Wang Ting-hong, et, al. A Simulation on energy management strategy for the power system of a fuel cell/battery HEV based on Cruise/Simulink[J]. Automotive Engineering, 2010, 32(5): 373-378. | |

| 4 | 李熙, 谢勇波, 宋超,等. 基于T-S模糊控制的燃料电池客车能量管理策略及仿真分析[J]. 客车技术与研究, 2017, 39(4): 5-8, 39. |

| Li Xi, Xie Yong-bo, Song Chao, et al. Management strategy and simulation analysis on fuel cell bus energy based on T-S fuzzy control[J]. Bus & Coach Technology and Research, 2017, 39(4): 5-8, 39. | |

| 5 | Ahn H S, Lee N S. Power distribution control law for FCHEV-a fuzzy logic-based approach[C]∥International Conference on Control and Automation, Budapest, Hungary, 2005. |

| 6 | 徐陈锋. 基于自适应模糊策略的燃料电池车混合动力系统控制[D]. 杭州:浙江大学控制科学与工程学院, 2017.Xu Chen-feng. Adaptive fuzzy control for power management of fuel-cell-battery hybrid vehicles[D]. Hangzhou:College of Control Science and Engineering, Zhejiang University, 2017. |

| 7 | Fletcher T, Thring R, Watkinson M. An energy management strategy to concurrently optimise fuel consumption & PEM fuel cell lifetime in a hybrid vehicle[J]. International Journal of Hydrogen Energy, 2016, 41(46): 21503-21515. |

| 8 | 张炳力, 代康伟, 赵韩, 等. 基于随机动态规划的燃料电池城市客车能量管理策略优化[J]. 系统仿真学报, 2008, 20(17): 4664-4667. |

| Zhang Bing-li, Dai Kang-wei, Zhao Han, et al. Optimized energy management strategy for fuel cell city bus based on stochastic dynamic programming[J]. Journal of System Simulation, 2008, 20(17): 4664-4667. | |

| 9 | Zheng C H, Xu G Q, Park Y I, et al. Prolonging fuel cell stack lifetime based on Pontryagin's minimum principle in fuel cell hybrid vehicles and its economic influence evaluation[J]. Journal of Power Sources, 2014, 248: 533-544. |

| 10 | Chen H, Pei P, Song M. Lifetime prediction and the economic lifetime of proton exchange membrane fuel cells[J]. Applied Energy, 2015, 142: 154-163. |

| 11 | Pei P, Chang Q, Tang T. A quick evaluating method for automotive fuel cell lifetime[J]. International Journal of Hydrogen Energy, 2008, 33(14): 3829-3836. |

| 12 | Pei P, Yuan X, Li P, et al. Lifetime evaluating and the effects of operation conditions on automotive fuel cells[J]. Chinese Journal of Mechanical Engineering, 2010, 23(1): 66-71. |

| 13 | Pei P, Chen H. Main factors affecting the lifetime of proton exchange membrane fuel cells in vehicle applications: a review[J]. Applied Energy, 2014, 125: 60-75. |

| [1] | 马芳武,梁鸿宇,赵颖,杨猛,蒲永锋. 内凹三角形负泊松比结构耐撞性多目标优化设计[J]. 吉林大学学报(工学版), 2020, 50(1): 29-35. |

| [2] | 郭孔辉,黄世庆,吴海东. 适用于高频激励的面内轮胎动态模型[J]. 吉林大学学报(工学版), 2020, 50(1): 19-28. |

| [3] | 陈鑫,阮新建,李铭,王宁,王佳宁,潘凯旋. 基于大涡模拟的离散格式改进方法及应用[J]. 吉林大学学报(工学版), 2019, 49(6): 1756-1763. |

| [4] | 马芳武,倪利伟,吴量,聂家弘,徐广健. 轮腿式全地形移动机器人位姿闭环控制[J]. 吉林大学学报(工学版), 2019, 49(6): 1745-1755. |

| [5] | 靳立强, 田端洋, 田浩, 刘蒙蒙. 汽车电子稳定系统制动增力辅助技术[J]. 吉林大学学报(工学版), 2019, 49(6): 1764-1776. |

| [6] | 王杨,宋占帅,郭孔辉,庄晔. 转动惯量试验台的惯性参数测量[J]. 吉林大学学报(工学版), 2019, 49(6): 1795-1801. |

| [7] | 庄蔚敏,刘洋,王鹏跃,施宏达,徐纪栓. 钢铝异质自冲铆接头剥离失效仿真[J]. 吉林大学学报(工学版), 2019, 49(6): 1826-1835. |

| [8] | 李杰, 郭文翠, 赵旗, 谷盛丰. 基于车辆响应的路面不平度识别方法[J]. 吉林大学学报(工学版), 2019, 49(6): 1810-1817. |

| [9] | 陈百超,邹猛,党兆龙,黄晗,贾阳,石睿杨,李建桥. CE-3月球车筛网轮月面沉陷行为试验[J]. 吉林大学学报(工学版), 2019, 49(6): 1836-1843. |

| [10] | 何仁,涂琨. 基于温度补偿气隙宽度的电磁制动器[J]. 吉林大学学报(工学版), 2019, 49(6): 1777-1785. |

| [11] | 刘巧斌,史文库,陈志勇,骆联盟,苏志勇,黄开军. 混合可靠性模型参数的核密度和引力搜索估计[J]. 吉林大学学报(工学版), 2019, 49(6): 1818-1825. |

| [12] | 管欣,金号,段春光,卢萍萍. 汽车行驶道路侧向坡度估计[J]. 吉林大学学报(工学版), 2019, 49(6): 1802-1809. |

| [13] | 鄢挺,杨林,陈亮. AMT换挡执行机构自适应智能控制策略[J]. 吉林大学学报(工学版), 2019, 49(5): 1441-1450. |

| [14] | 马芳武,韩露,周阳,王世英,蒲永锋. 采用聚乳酸复合材料的汽车零件多材料优化设计[J]. 吉林大学学报(工学版), 2019, 49(5): 1385-1391. |

| [15] | 张博,张建伟,郭孔辉,丁海涛,褚洪庆. 路感模拟用永磁同步电机电流控制[J]. 吉林大学学报(工学版), 2019, 49(5): 1405-1413. |

|

||