吉林大学学报(工学版) ›› 2020, Vol. 50 ›› Issue (5): 1663-1668.doi: 10.13229/j.cnki.jdxbgxb20190580

• 材料科学与工程 • 上一篇

EP/EN模数对铝合金VP-CMT焊熔滴过渡及焊道成形的影响

- 1.天津大学 材料科学与工程学院,天津 300354

2.密歇根大学 机械工程系,安娜堡 48109

Effect of EP/EN Balance on droplet transfer and weld formation of Al alloy by VP⁃CMT

Yin-bao TIAN1,2( ),Jun-qi SHEN1(

),Jun-qi SHEN1( ),Sheng-sun HU1,Jian GOU1

),Sheng-sun HU1,Jian GOU1

- 1.School of Materials Science and Engineering, Tianjin University, Tianjin 300354, China

2.Department of Mechanical Engineering, University of Michigan, Ann Arbor 48109, USA

摘要:

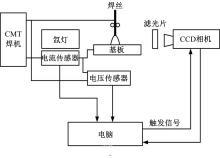

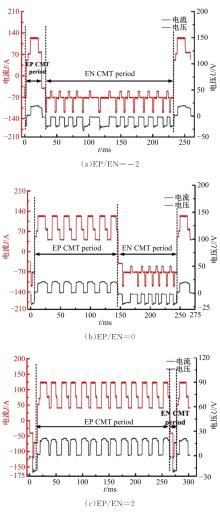

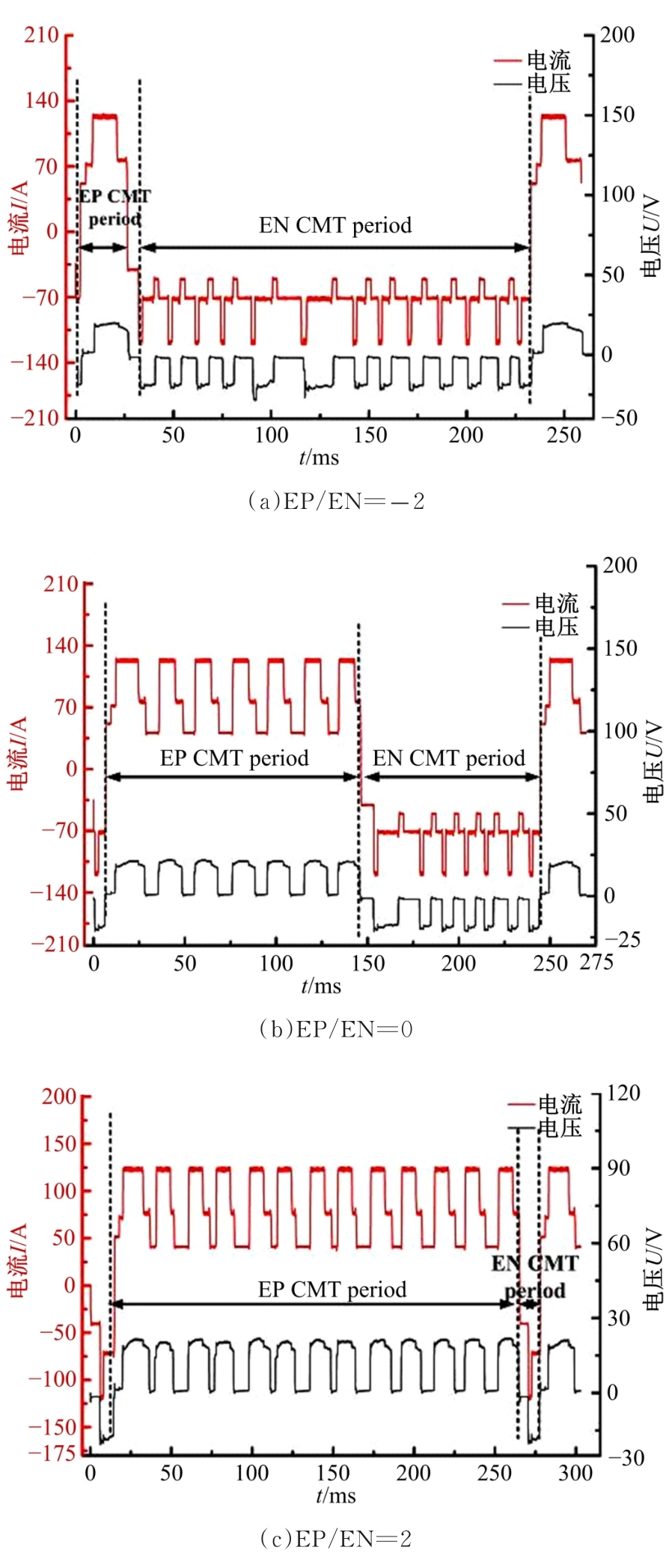

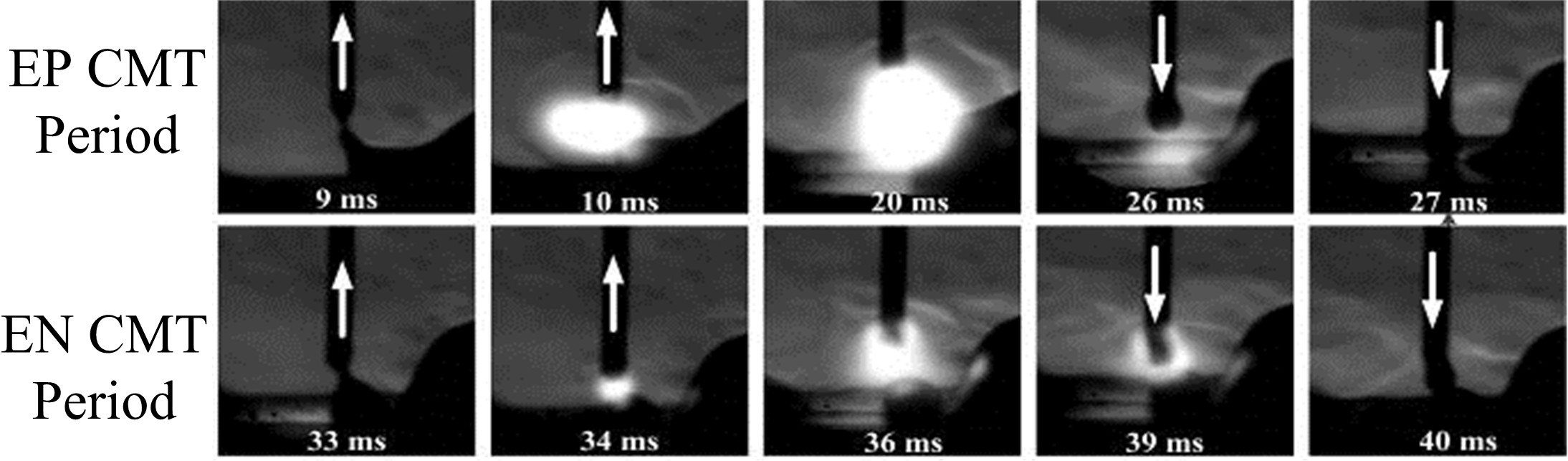

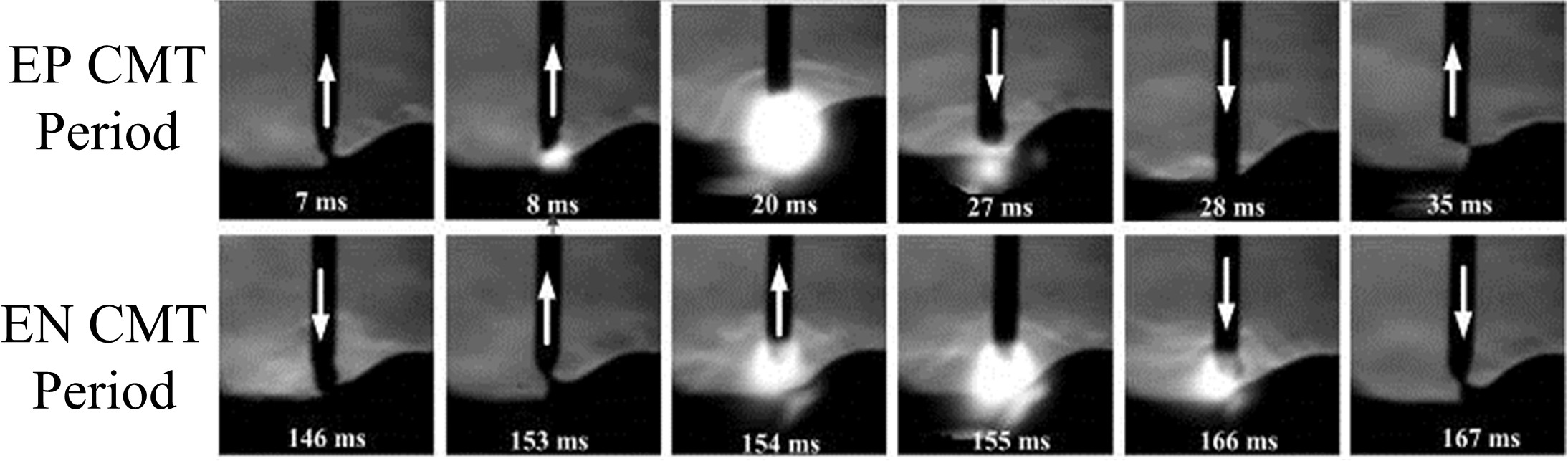

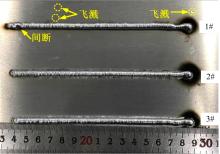

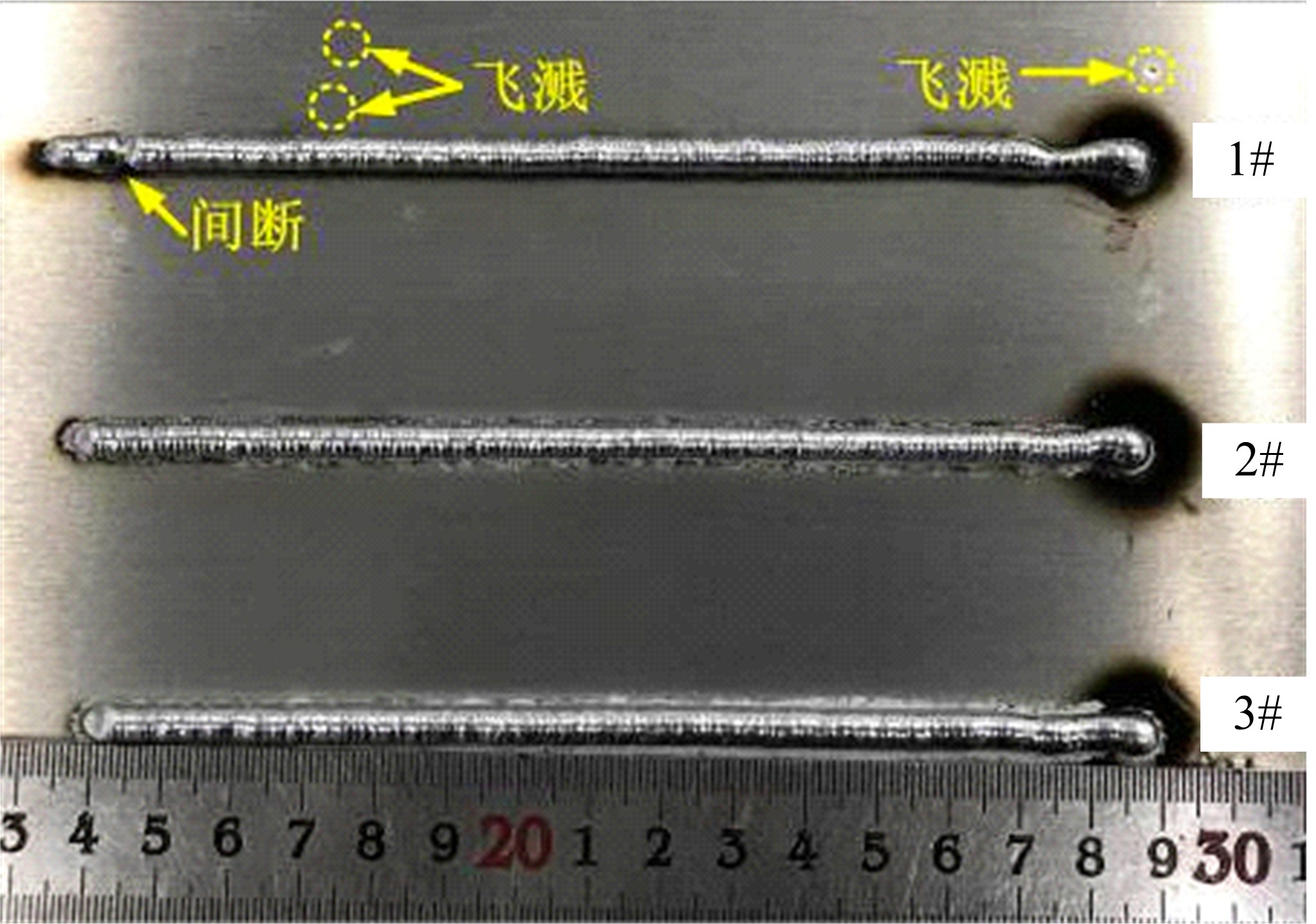

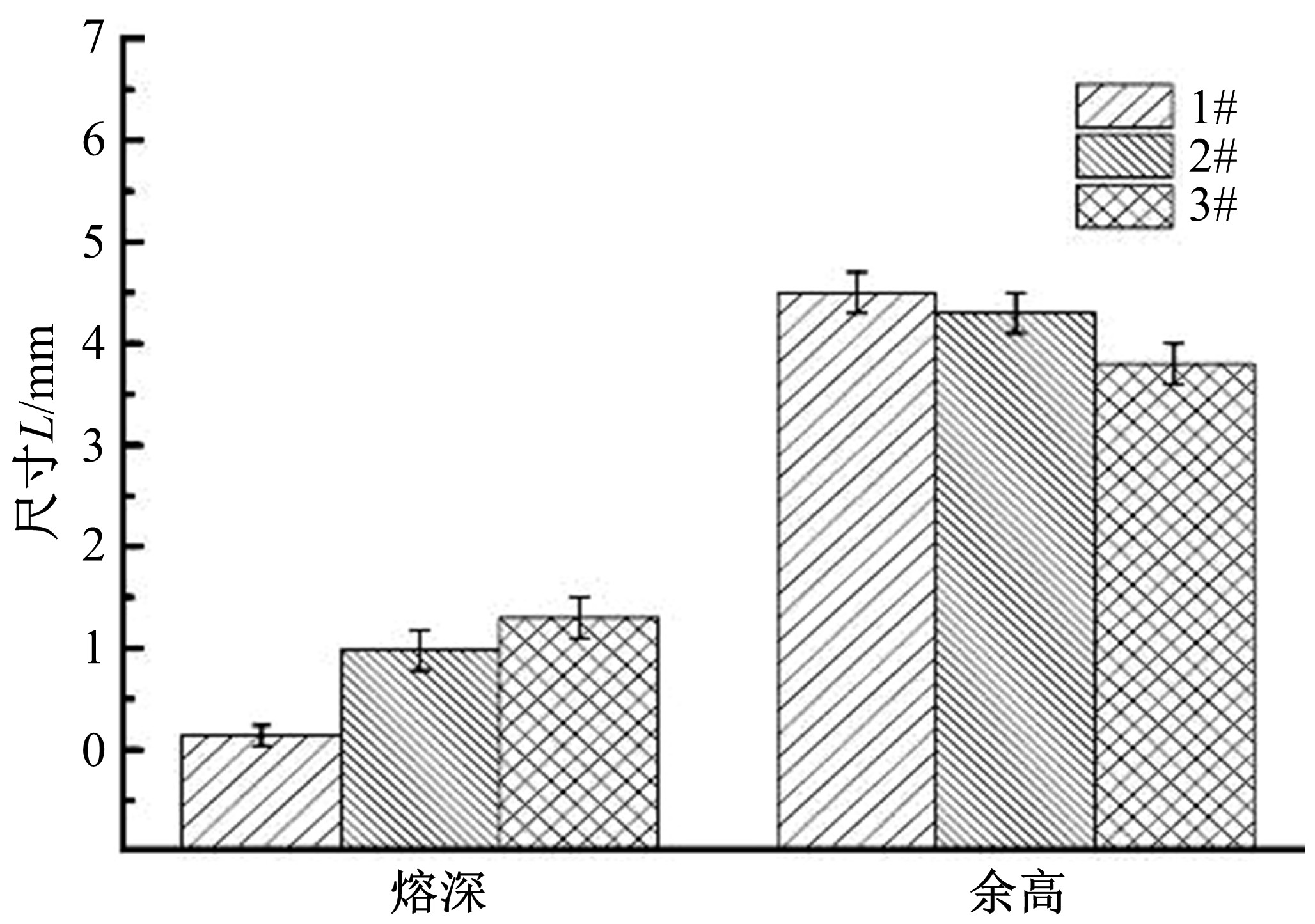

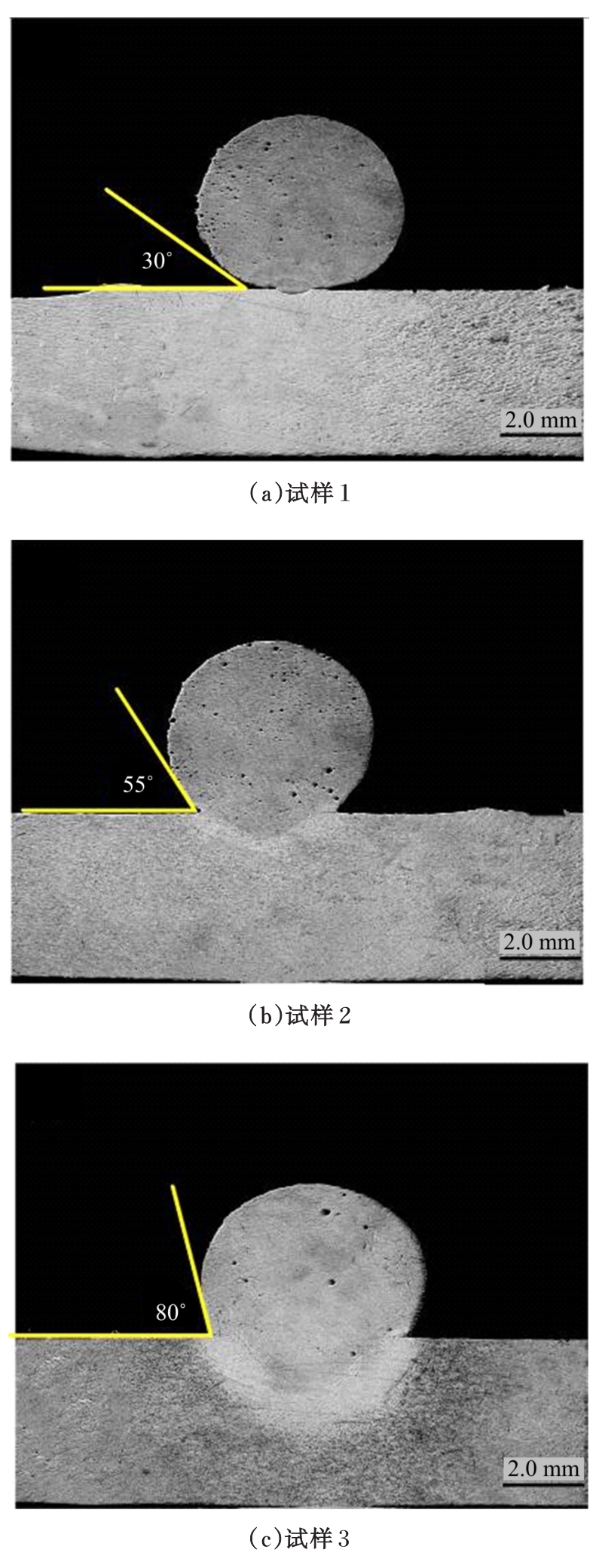

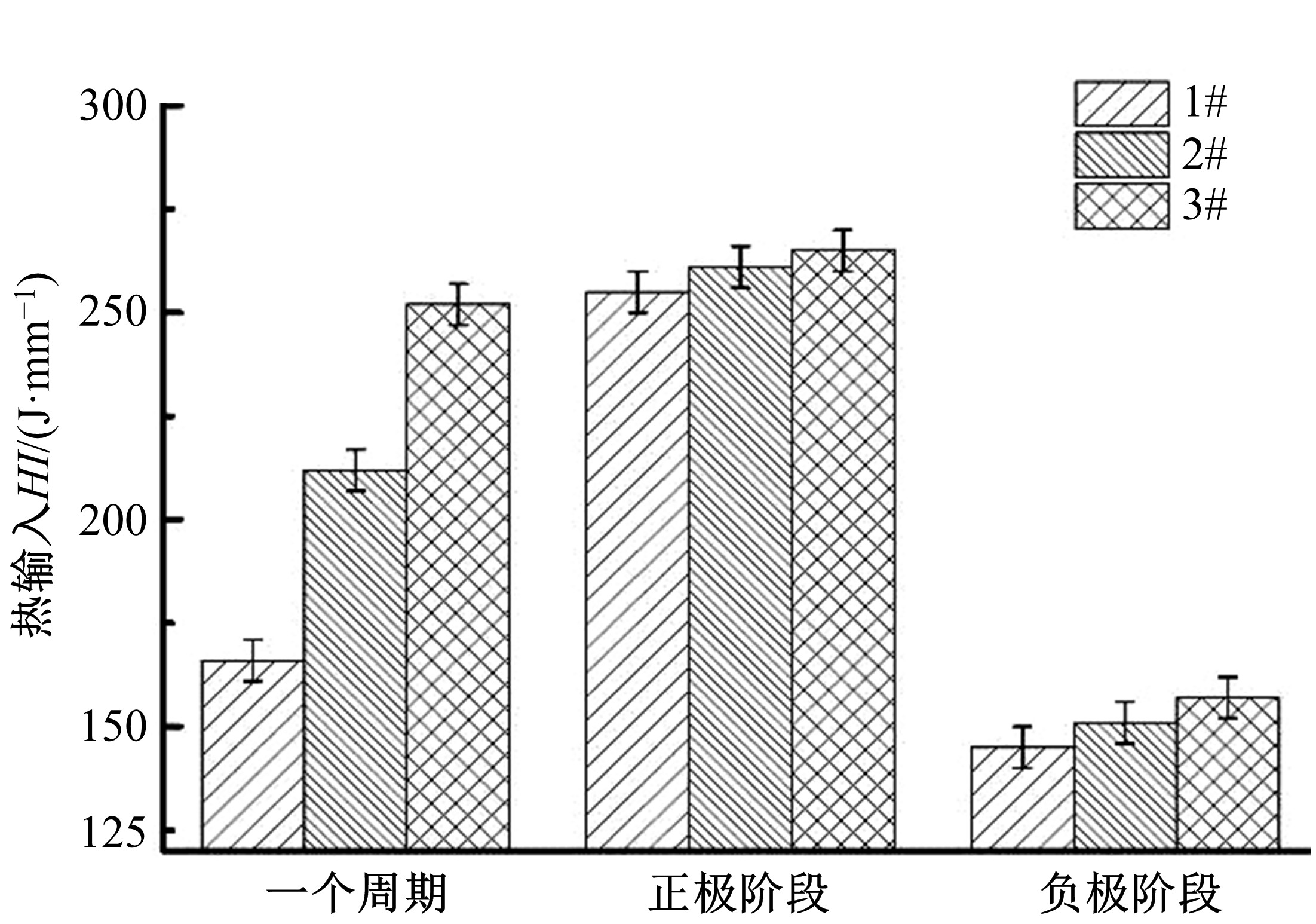

利用变极性冷金属过渡技术对铝合金进行平板堆焊,改变参数EP/EN Balance以调整正/负极性的比例。通过高速摄像及电信号采集系统对熔滴过渡过程和焊接过程电信号进行采集分析。通过金相分析,研究EP/EN Balance对焊道成形的影响。结果表明:变极性冷金属过渡堆焊过程中,正极阶段的热输入明显高于负极阶段,从而实现了“冷”和“热”的交替;通过调节EP/EN Balance参数,可以改变正/负极的比例,从而对焊接热输入进行调控;利用变极性冷金属过渡技术对铝合金进行堆焊,焊道外观成性良好;随着EP/EN Balance增加,熔深和接触角增大,余高降低。

中图分类号:

- TG455

| 1 | Zapico E P, Lutey A H A, Ascari A, et al. An improved model for cold metal transfer welding of aluminium alloys[J]. Journal of Thermal Analysis and Calorimetry, 2017, 131: 3003-3009. |

| 2 | 庞杰. 铝合金CMT+P焊接熔滴过渡行为研究[D]. 天津: 天津大学材料科学与工程学院, 2016. |

| Pang Jie. Study on metal transfer behavior of CMT+P welding for aluminum alloys[D]. Tianjin: School of Materials Science and Engineering, Tianjin University, 2016. | |

| 3 | 汪殿龙, 张志洋, 王波, 等. 铝锂合金交流CMT焊接高频脉冲复合电弧焊接技术研究进展[J]. 河北科技大学学报, 2013, 34(2): 91-96. |

| Wang Dian-long, Zhang Zhi-yang, Wang Bo, et al. Alternating current CMT and high frequency pulse composite arc on Al-Li alloys welding technique[J]. Journal of Hebei University of Science and Technology, 2013, 34(2): 91-96. | |

| 4 | Zhang C, Li Y F, Gao M, et al. Wire arc additive manufacturing of Al-6Mg alloy using variable polarity cold metal transfer arc as power source[J]. Materials Science & Engineering A, 2018, 711: 415-423. |

| 5 | Li G J, Zhang P L, Wu X, et al. Gap bridging of 6061 aluminum alloy joints welded by variable-polarity cold metal transfer[J]. Journal of Materials Processing Technology, 2018, 255: 927-935. |

| 6 | Wang P, Hu S S, Shen J Q, et al. Effects of electrode positive/negative ratio on microstructure and mechanical properties of Mg/Al dissimilar variable polarity cold metal transfer welded joints[J]. Materials Science & Engineering A, 2016, 652: 127-135. |

| 7 | Nie Y P, Zhang P L, Wu X, et al. Rapid prototyping of 4043 Al-alloy parts by cold metal transfer[J]. Science and Technology of Welding and Joining, 2018, 23(6): 527-535. |

| 8 | Tian Y B, Shen J Q, Hu S S, et al. Effects of ultrasonic vibration in the CMT process on welded joints of Al alloy [J]. Journal of Materials Processing Technology, 2018, 259: 282-291. |

| 9 | Feng J C, Zhang H T, He P. The CMT short-circuiting metal transfer process and its use in thin aluminium sheets welding[J]. Materials and Design, 2009, 30(5): 1850-1852. |

| 10 | 汪殿龙, 张志洋, 梁志敏, 等. 交流CMT动态电弧特征及熔滴过渡行为分析[J]. 焊接学报, 2014, 35(3): 6-10. |

| Wang Dian-long, Zhang Zhi-yiang, Liang Zhi-min, et al. Analysis of dynamic arc characteristics and melt transfer behavior of AC CMT[J]. Transactions of the China Welding Institution, 2014, 35(3): 6-10. | |

| 11 | 王鹏. 基于CMT焊接能量输入过程控制的镁/铝异种金属焊接研究[D]. 天津: 天津大学材料科学与工程学院, 2017. |

| Wang Peng. Study on CMT welding process of Mg/Al dissimilar metals based on the control of energy input process[D]. Tianjin: School of Materials Science and Engineering, Tianjin University, 2017. | |

| 12 | 张瑞英,穆森,王军. 铝合金薄板交流CMT焊接过程能量分配研究[J]. 电焊机, 2013, 43(6): 22-26. |

| Zhang Rui-ying, Mu Sen, Wang Jun. Research on energy distribution of AD CMT advanced welding with aluminum alloy sheet[J]. Electric Welding Machine, 2013, 43(6): 22-26. | |

| 13 | Niu S, Chen S, Dong H G, et al. Microstructure and properties of lap joint between aluminum alloy and galvanized steel by CMT[J]. Journal of Materials Engineering and Performance, 2016, 25(5): 1839-1847. |

| 14 | 谷晓燕, 刘东锋, 刘婧, 等. 焊接能量对Cu/Al超声波焊接接头组织与性能的影响[J]. 吉林大学学报: 工学版, 2019, 49(5): 1600-1607. |

| Gu Xiao-yan, Liu Dong-feng, Liu Jing, et al. Effect of welding energy on microstructure and mechanical properties of Cu/Al joints welded by ultrasonic welding [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1600-1607. | |

| 15 | 宫文彪, 朱芮, 郄新哲, 等. 6082铝合金超厚板搅拌摩擦焊接头组织与性能[J]. 吉林大学学报: 工学版, 2020, 50(2): 512-519. |

| Gong Wen-biao, Zhu Rui, Xin-zhe Qie, et al. Microstructure and properties of 6082 aluminum alloy ultra-thick plate prepared by friction stir weld [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 512-519. |

| [1] | 王金国,王志强,任帅,闫瑞芳,黄恺,郭劲. Ti添加量对球墨铸铁组织及力学性能的影响[J]. 吉林大学学报(工学版), 2020, 50(5): 1653-1662. |

| [2] | 宫文彪,朱芮,郄新哲,崔恒,宫明月. 6082铝合金超厚板搅拌摩擦焊接头组织与性能[J]. 吉林大学学报(工学版), 2020, 50(2): 512-519. |

| [3] | 修文翠,吴化,韩英,刘云旭. 等温热处理温度对超级贝氏体组织与性能的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 520-525. |

| [4] | 陈学文,王继业,杨喜晴,皇涛,宋克兴. Cr8合金钢热变形行为及位错密度演变规律[J]. 吉林大学学报(工学版), 2020, 50(1): 91-99. |

| [5] | 王金国,任帅,闫瑞芳,黄恺,王志强. TiC颗粒对铸态球墨铸铁组织和力学性能的影响[J]. 吉林大学学报(工学版), 2019, 49(6): 2010-2018. |

| [6] | 刘义伦,王卿,刘驰,李松柏,何军,赵先琼. 蠕变和人工时效对2524铝合金疲劳裂纹扩展性能的影响[J]. 吉林大学学报(工学版), 2019, 49(5): 1636-1643. |

| [7] | 徐戊矫,刘承尚,鲁鑫垚. 喷丸处理后6061铝合金工件表面粗糙度的模拟计算及预测[J]. 吉林大学学报(工学版), 2019, 49(4): 1280-1287. |

| [8] | 鲁金忠,周婉婷,张圣洋,邵亦锴,王长雨,罗开玉. 激光冲击强化层数对6061⁃T6铝合金抗腐蚀性能的影响[J]. 吉林大学学报(工学版), 2019, 49(3): 842-849. |

| [9] | 李于朋,孙大千,宫文彪. 6082⁃T6铝合金薄板双轴肩搅拌摩擦焊温度场[J]. 吉林大学学报(工学版), 2019, 49(3): 836-841. |

| [10] | 关庆丰,张福涛,彭韬,吕鹏,李姚君,许亮,丁佐军. 含硼、钴9%Cr耐热钢的热变形行为[J]. 吉林大学学报(工学版), 2018, 48(6): 1799-1805. |

| [11] | 胡志清, 颜庭旭, 李洪杰, 吕振华, 廖伟, 刘庚. 深冷处理对铝合金薄板冲剪成形性能的影响[J]. 吉林大学学报(工学版), 2018, 48(5): 1524-1530. |

| [12] | 关庆丰, 董书恒, 郑欢欢, 李晨, 张从林, 吕鹏. 强流脉冲电子束作用下45#钢表面Cr合金化[J]. 吉林大学学报(工学版), 2018, 48(4): 1161-1168. |

| [13] | 胡志清, 郑会会, 徐亚男, 张春玲, 党停停. 表面微沟槽对Al/CFRP胶结性能的影响[J]. 吉林大学学报(工学版), 2018, 48(1): 229-235. |

| [14] | 赵宇光, 杨雪慧, 徐晓峰, 张阳阳, 宁玉恒. Al-10Sr变质剂状态、变质温度及变质时间对ZL114A合金组织的影响[J]. 吉林大学学报(工学版), 2018, 48(1): 212-220. |

| [15] | 付文智, 刘晓东, 王洪波, 闫德俊, 刘晓莉, 李明哲, 董玉其, 曾振华, 刘桂彬. 关于1561铝合金曲面件的多点成形工艺[J]. 吉林大学学报(工学版), 2017, 47(6): 1822-1828. |

|

||