吉林大学学报(工学版) ›› 2020, Vol. 50 ›› Issue (2): 512-519.doi: 10.13229/j.cnki.jdxbgxb20190241

• 材料科学与工程 • 上一篇

6082铝合金超厚板搅拌摩擦焊接头组织与性能

- 1.长春工业大学 先进结构材料教育部重点实验室,长春 130012

2.长春轨道客车股份有限公司,长春 130062

Microstructure and properties of 6082 aluminum alloyultra⁃thick plate preparated by friction stir weld

Wen-biao GONG1( ),Rui ZHU1,Xin-zhe QIE1,Heng CUI2,Ming-yue GONG2

),Rui ZHU1,Xin-zhe QIE1,Heng CUI2,Ming-yue GONG2

- 1.Key Laboratory of Advanced Structural Materials, Ministry of Education, Changchun University of Technology, Changchun 130012, China

2.Changchun Railway Vehicles Co. Ltd. , Changchun 130062, China

摘要:

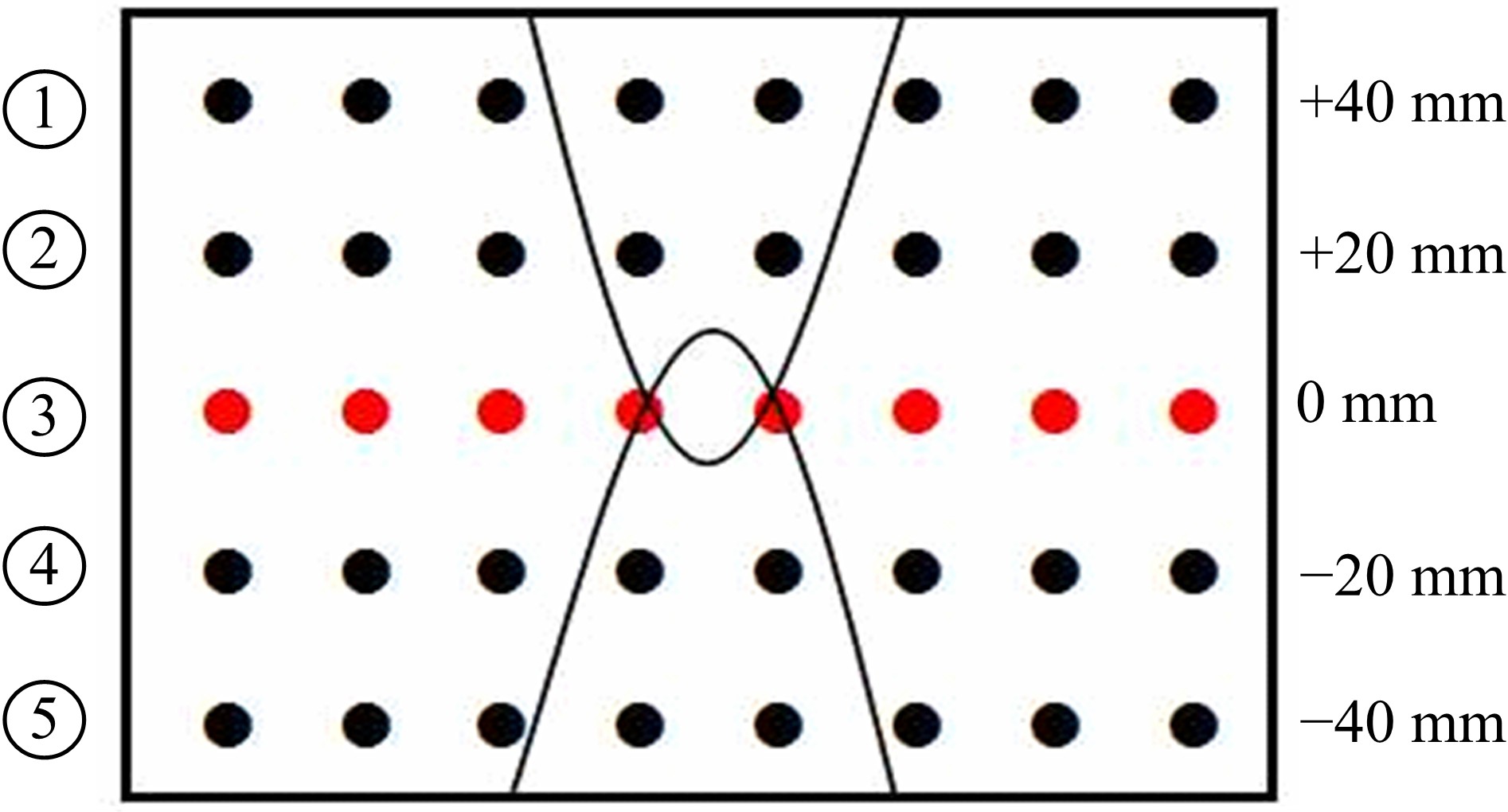

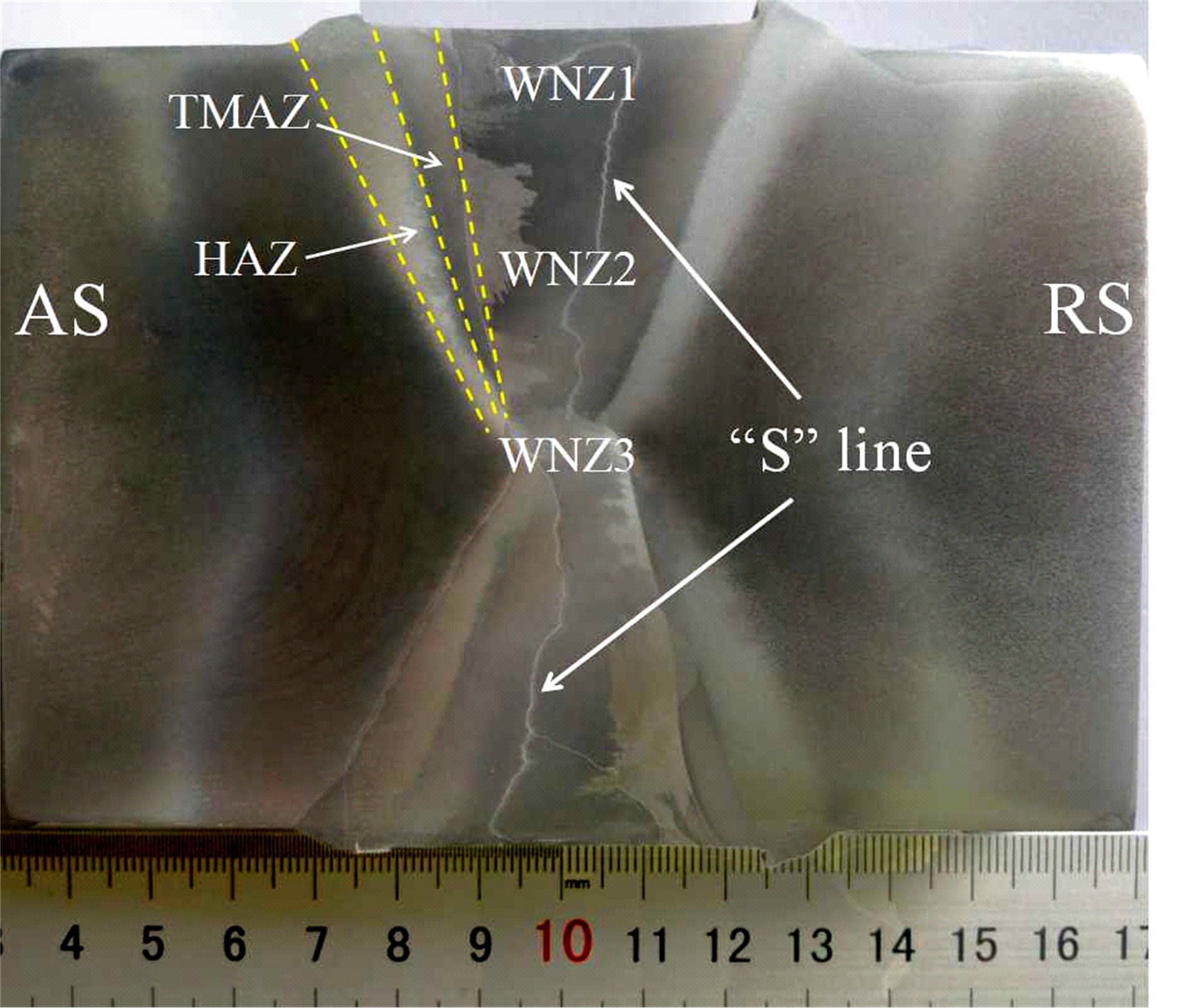

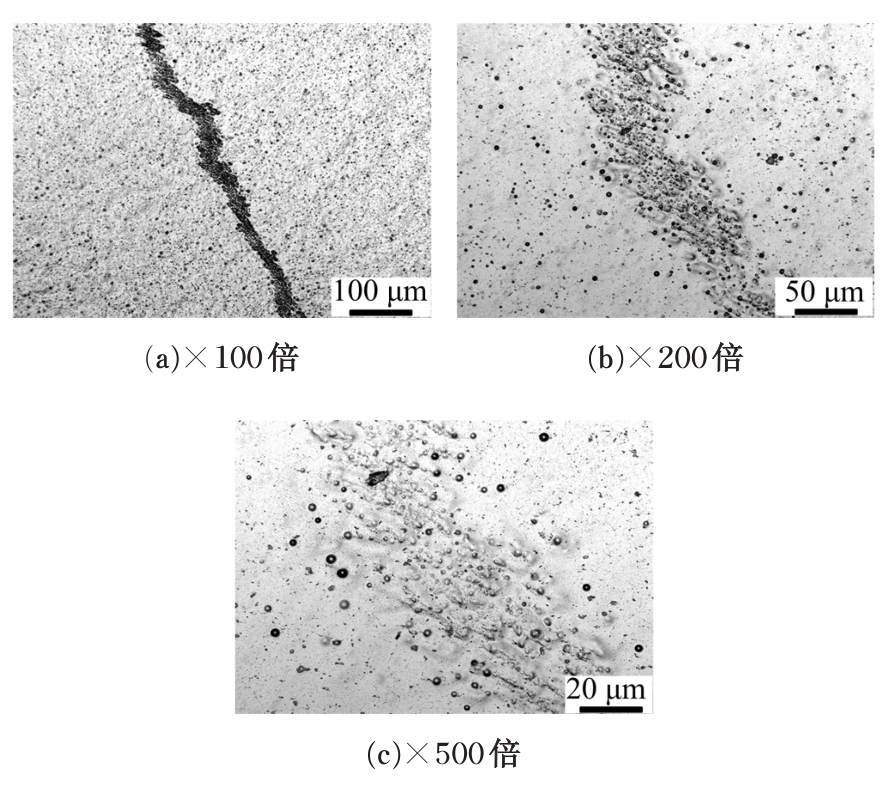

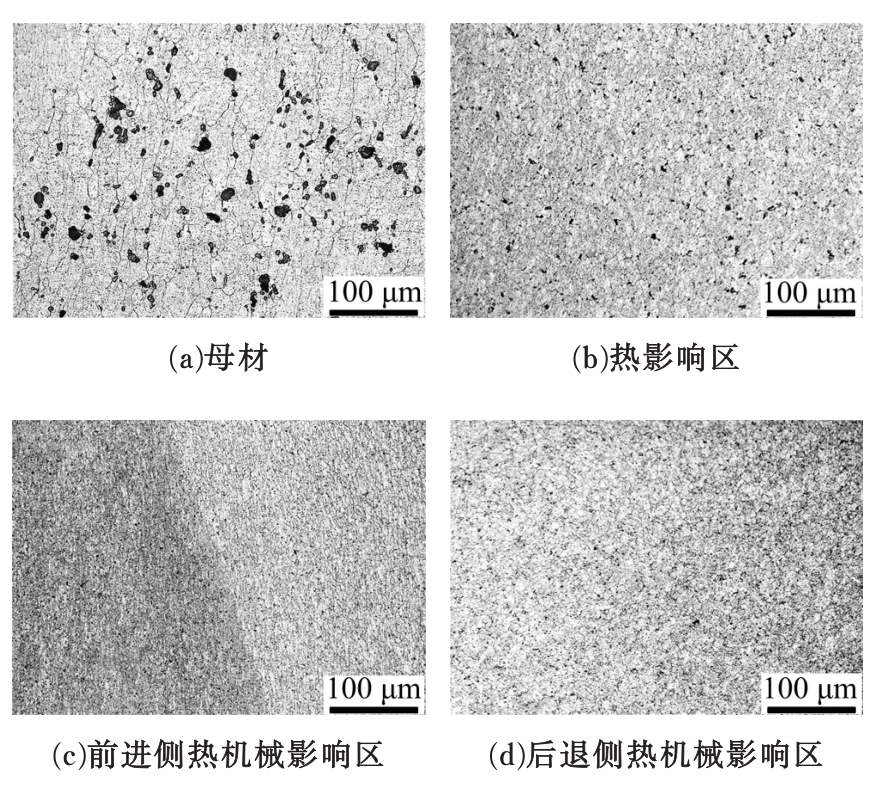

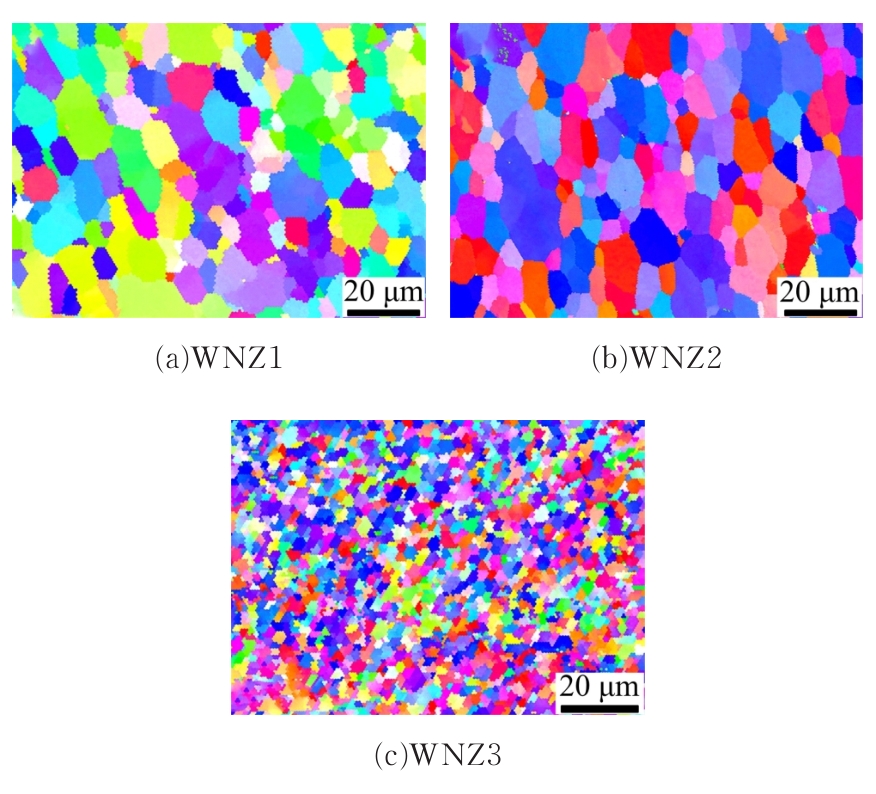

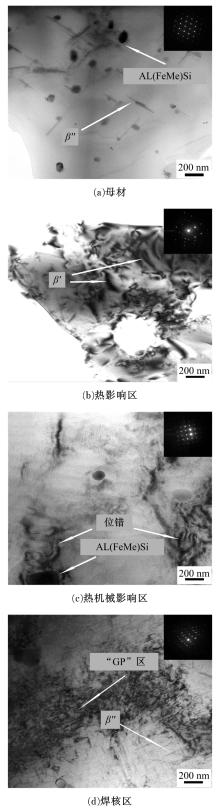

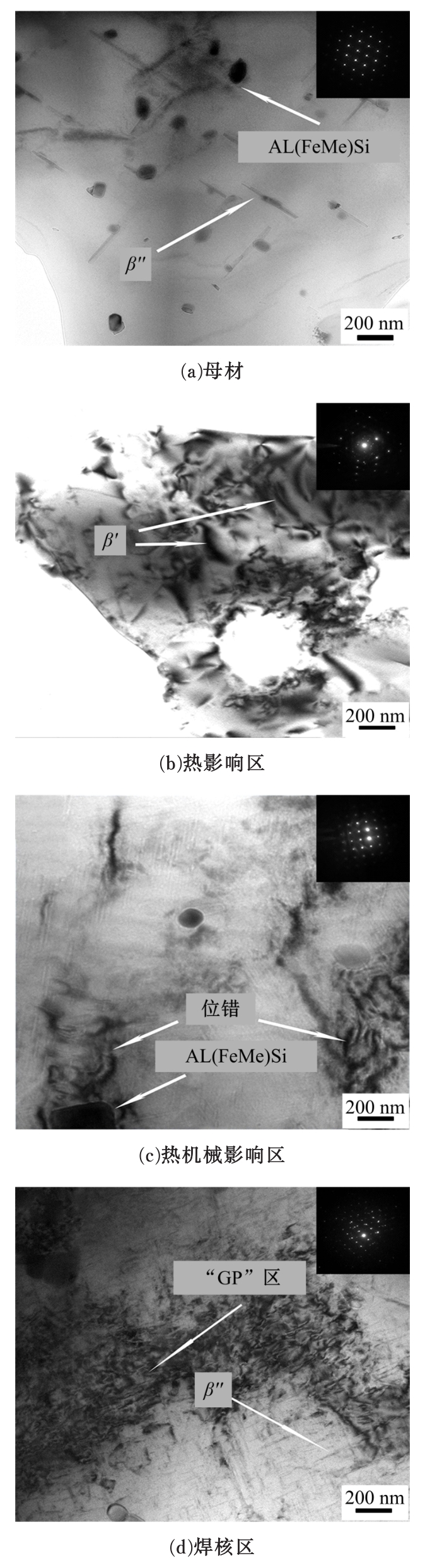

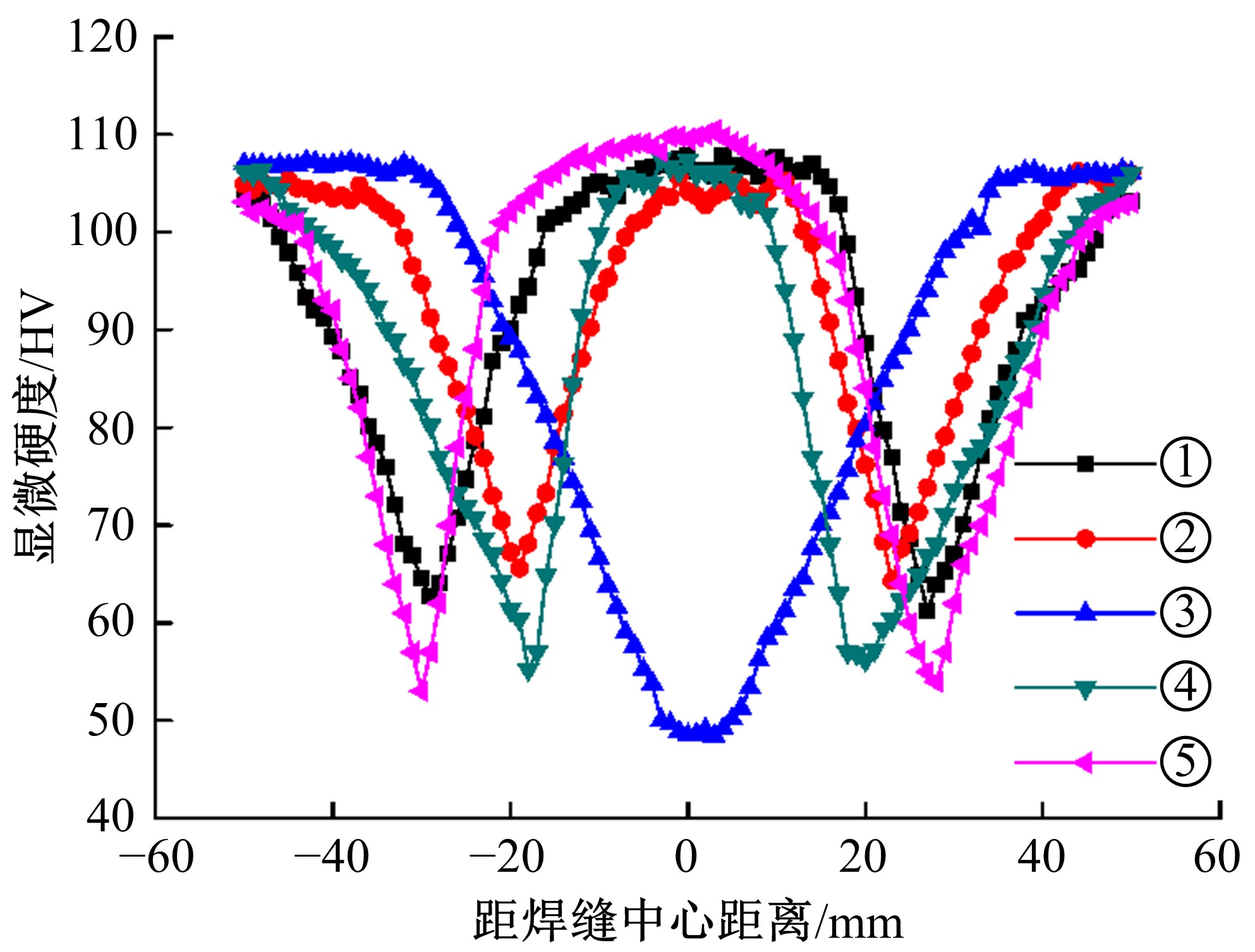

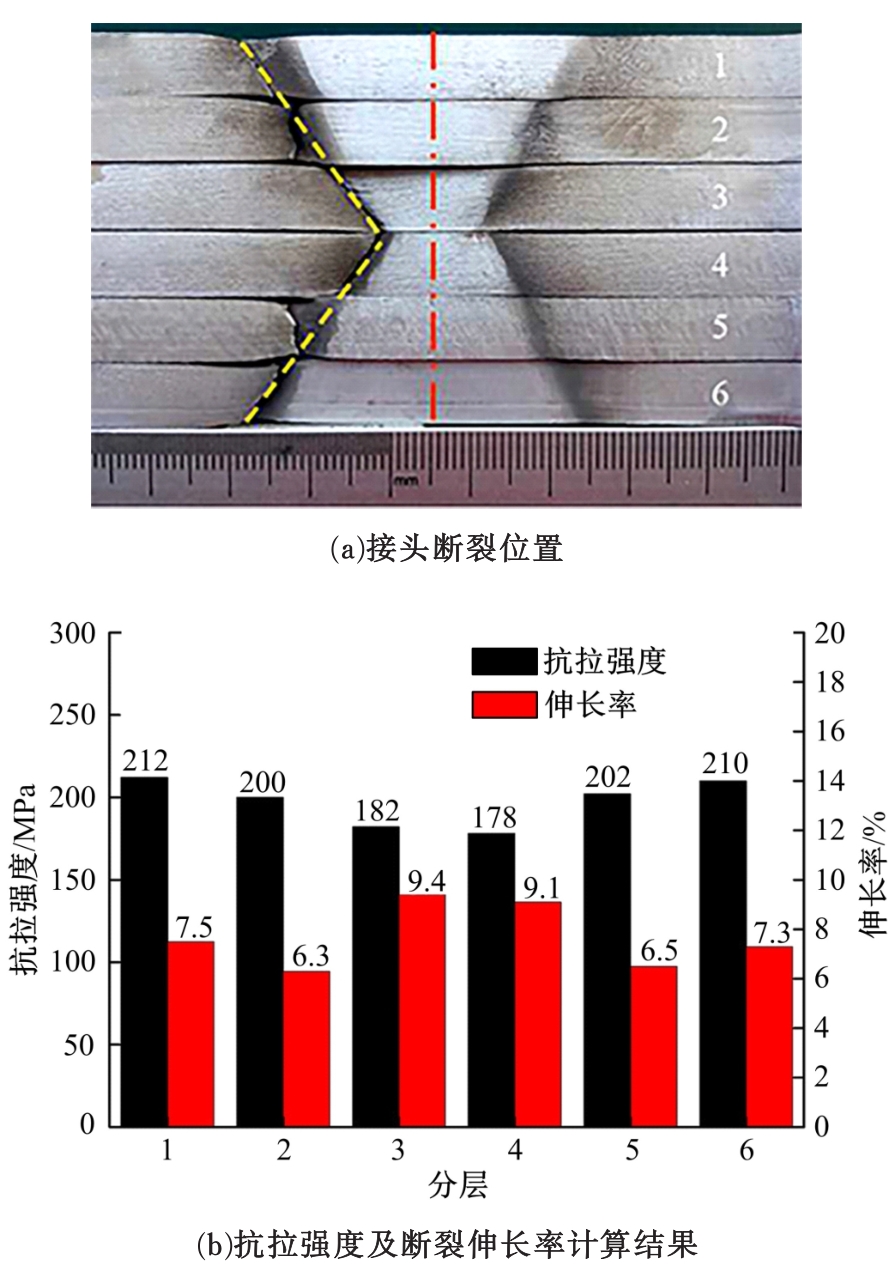

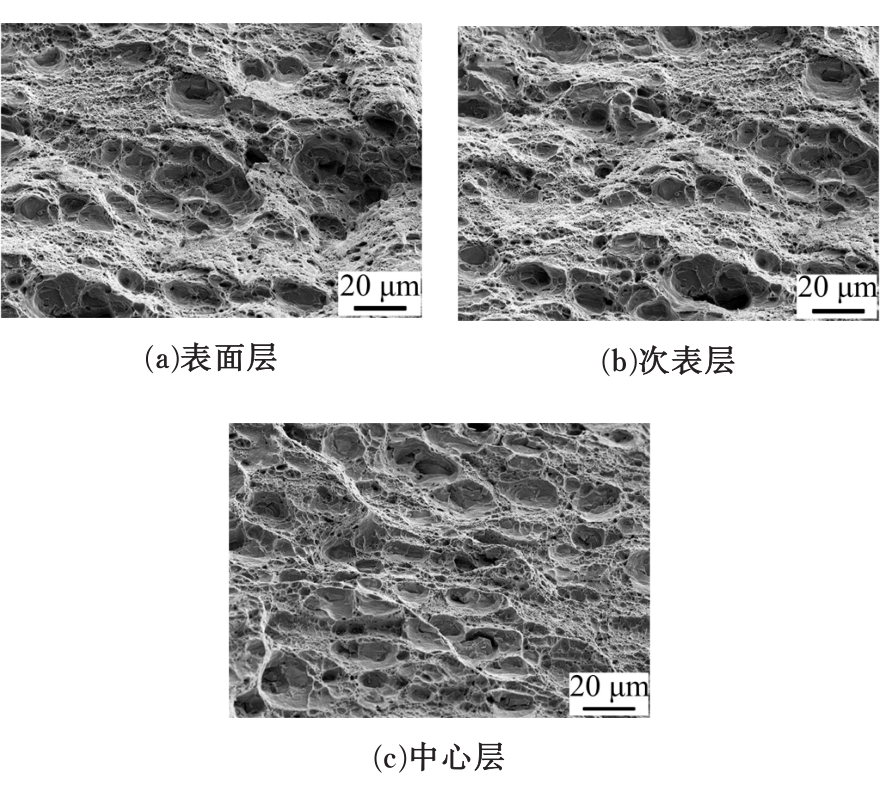

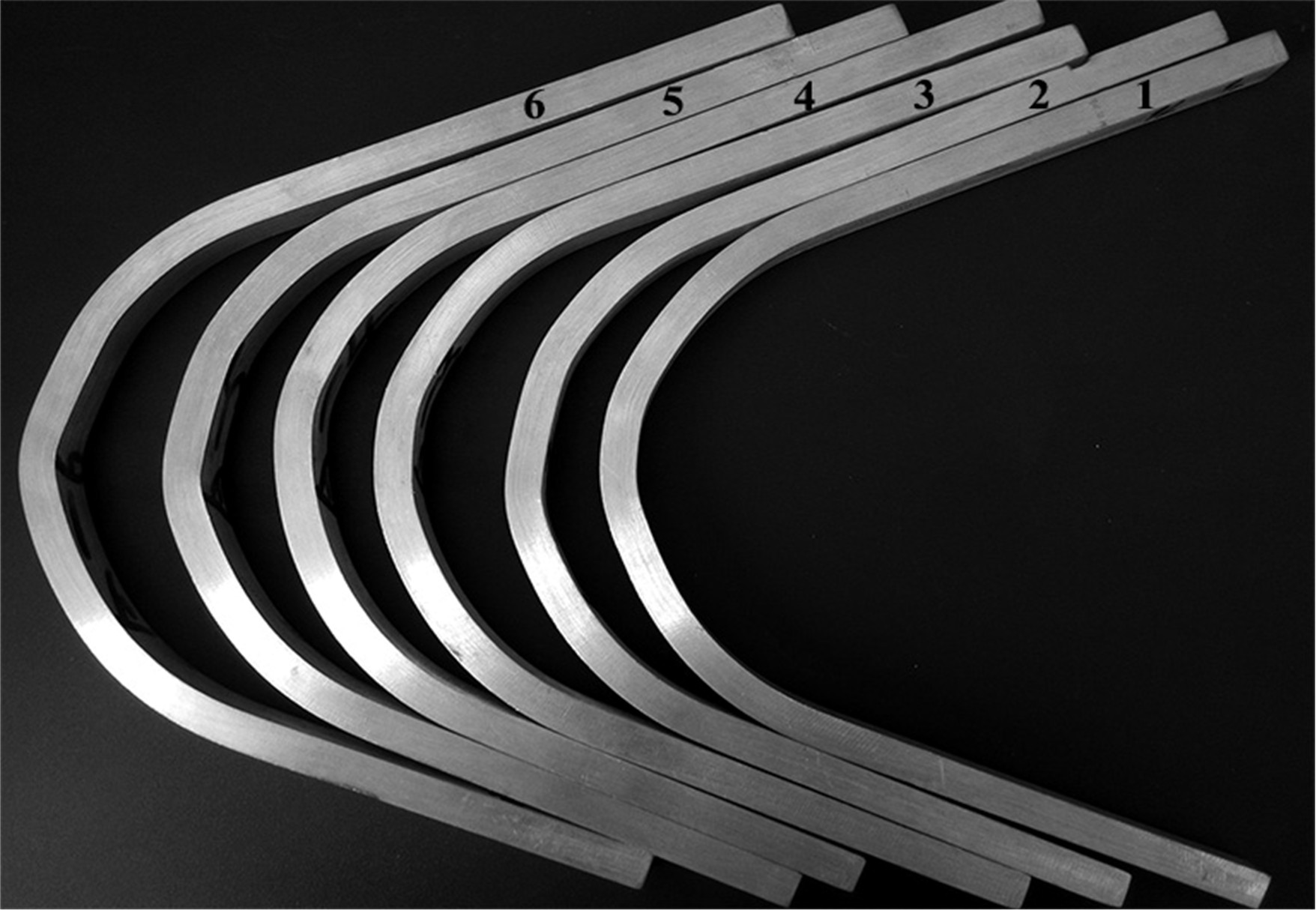

采用搅拌摩擦焊对84 mm厚的6082-T4铝合金进行双面对接焊接,焊后进行人工时效(180 ℃×5 h)处理。研究了沿板厚方向焊接接头的微观组织与力学性能变化。结果表明:焊核区组织为细小的等轴晶粒,从表面至焊缝的中心,晶粒尺寸分别为16、13、5 μm,高角度晶界所占比例分别为77.2%、76.3%、72.5%;焊核区的强化相主要为“GP区”及β″相;热机械影响区晶粒沿搅拌头旋转方向被拉长,组织中存在较高密度位错;焊缝中心层区域硬度分布呈“V”型,硬度最低值出现在双面焊重叠区,其他位置硬度曲线呈“W”型分布;正、反面两道焊缝发生断裂的位置均为TMAZ与HAZ交汇的区域,接头平均抗拉强度沿厚度方向从表面至中心分别为211、201、180 MPa,呈逐渐降低趋势;中心层抗拉强度最低,但其断裂伸长率最高,约为母材的69%;断口为大小不同的韧窝,接头表现为韧性断裂。

中图分类号:

- TG456.9

| 1 | 牛得田. 铝合金车体在轨道车辆上的应用及展望[J]. 机车车辆工艺, 2003(3): 1-2. |

| Niu De-tian. Application of Al alloy carbody to railway vehicles and its prospects[J]. Locomotive & Rolling Stock Technology, 2003(3): 1-2. | |

| 2 | 盛建辉, 彭家仁, 李光, 等. 搅拌摩擦焊工艺及其在地铁铝合金车体上的应用[J]. 电力机车与城轨车辆, 2009, 32(3): 28-31. |

| Sheng Jian-hui,Peng Jia-ren, Li Guang, et al. Friction stir welding technology and its application on metro aluminum alloy car body[J]. Electric Locomotive and the Urban Rail Vehicles, 2009, 32(3): 28-31. | |

| 3 | 杨悦, 周磊磊. 微弧氧化对铝合金搅拌摩擦焊缝耐蚀性能的影响[J]. 吉林大学学报: 工学版, 2016, 46(2): 511-515. |

| Yang Yue,Zhou Lei-lei. Effect of micro-arc oxidation treatment on corrosion resistance of aluminum friction stir welding welds[J]. Journal of Jilin University (Engineering and Technology Edition), 2016, 46(2): 511-515. | |

| 4 | 黎俊初, 周德生, 刘大海, 等. 2A12铝合金筋板件T型搅拌摩擦焊工艺及焊后热处理[J]. 材料科学与工艺, 2011, 19(2): 80-85, 91. |

| Li Jun-chun, Zhou De-sheng, Liu Da-hai, et al. Friction stir welding and successive heat treatment of T-shaped rib-web parts of 2A12 aluminium alloy[J]. Materials Science &Technology, 2011, 19(2): 80-85, 91. | |

| 5 | 杨模聪, 孙中刚, 马锐, 等. 2060搅拌摩擦焊对接接头显微组织与析出相分析[J]. 材料科学与工艺, 2014, 22(5): 119-123. |

| Yang Mo-cong, Sun Zhong-gang, Ma Rui, et al. Analysis for microstricture and precipitation phase evolution of friction stir welding 2060 butt jiont[J]. Materials Science and Technology, 2014, 22(5): 119-123. | |

| 6 | 张秋征, 宫文彪, 刘杰. 6005A-T6铝合金厚板单面与双面搅拌摩擦焊的性能比较[J]. 材料热处理学报, 2014, 35(6): 75-79. |

| Zhang Qiu-zheng, Gong Wen-biao, Liu Jie. Property comparison of aluminum alloy 6005A-T6 thick plate by single-sided and double-sided processes of friction stir welding[J]. Transactions of Materials and Heat Treatment, 2014, 35(6): 75-79. | |

| 7 | 罗维, 贺地求, 邬红光, 等. 22 mm 6061-T6铝合金板的搅拌摩擦焊接[J]. 金属铸锻焊技术, 2010, 39(15): 130-132. |

| Luo Wei, He Di-qiu, Wu Hong-guang, et al. Friction stir welding of 22 mm plate of 6061-T6 aluminum alloy plate[J]. Casting Forging Welding, 2010, 39(15): 130-132. | |

| 8 | Ma Z, Chen D, Liu H, et al. Microstructure and properties of welding joints of 30 mm thickness 7A52 aluminum alloy plate by friction stir welding[J]. Ordnance Material Science & Engineering, 2014, 37(2): 63-65. |

| 9 | He D, Luo W, Wu H. Microstructure and mechanical property analysis on double-sided friction stir welding joints of 60 mm 6061-T6 aluminum alloy plate[J]. Journal of Materials Engineering, 2011, 1(9): 20-24. |

| 10 | Zhang Z, Xiao B L, Ma Z Y. Effect of segregation of secondary phase particles and “S” line on tensile fracture behavior of friction stir-welded 2024Al-T351 joints[J]. Metallurgical & Materials Transactions A, 2013, 44(9): 4081-4097. |

| 11 | Di S, Yang X, Fang D, et al. The influence of zigzag-curve defect on the fatigue properties of friction stir welds in 7075-T6 Al alloy[J]. Materials Chemistry & Physics, 2007, 104(2/3): 244-248. |

| 12 | Okamura H, Aota K, Sakamoto M, et al. Behavior of oxides during friction stir welding of aluminum alloy and their effect on its mechanical properties[J]. Welding International, 2002, 16(4): 266-275. |

| 13 | Scialpi A, Filippis L A C D, Cavaliere P. Influence of shoulder geometry on microstructure and mechanical properties of friction stir welded 6082 aluminum alloy[J]. Material & Design, 2007, 28(4): 1124-1129. |

| 14 | Adamowski J, Szkodo M. Friction stir welds(FSW) of aluminum alloy AW6082-T6[J]. Journal of Achievements in Materials and Manufacturing Engineering, 2007, 20(1/2): 403-406. |

| 15 | Xu W F, Liu J H. Microstructure evolution along thickness in double-side friction stir welded 7085 Al alloy[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(10): 3212-3222. |

| 16 | Yadav D, Bauri R. Effect of friction stir processing on microstructure and mechanical properties of aluminium[J]. Materials Science & Engineering A, 2012, 539: 85-92. |

| 17 | Denquin A, Allehaux D, Campagnac M H, et al. Relationship between microstructural variations and properties of a friction stir welded 6056 aluminum alloy[J]. Welding in the World, 2002, 46(11/12): 14-19. |

| 18 | 李于朋, 孙大千, 宫文彪. 6082-T6铝合金薄板双轴肩搅拌摩擦焊温度场[J]. 吉林大学学报: 工学版, 2019, 49(3): 836-841. |

| Li Yu-peng, Sun Da-qian, Gong Wen-biao. Temperature fields in bobbin-tool friction stir welding for 6082-t6 aluminum alloy sheet[J]. Journal of Jilin University (Engineering and Technology Edition), 2019, 49(3): 836-841. | |

| 19 | Andersen S J, Zandbergen H W, Jansen J, et al. The crystal structure of the β'' phase in Al-Mg-Si alloys[J]. Acta Materialia, 2007, 46(9): 3283-3298. |

| 20 | 王冰. 6082-T6铝合金搅拌摩擦焊接头微观组织及力学性能的研究[D]. 长春: 吉林大学材料科学与工程学院, 2015. |

| Wang Bing. Study on microstructures and mechanical properties of friction stir welding joints of 6082-T6 aluminum alloy[D]. Changchun: College of Materials Science and Engineering, Jilin University, 2015. | |

| 21 | Murayama M, Hono K. Pre-precipitate clusters and precipitation processes in Al-Mg-Si alloys[J]. Acta Materialia, 1999, 47(5): 1537-1548. |

| 22 | 王希靖, 魏学玲, 张亮亮. 6082-T6铝合金搅拌摩擦焊组织演变与力学性能[J]. 焊接学报, 2018, 39(3): 1-5. |

| Wang Xi-jing, Wei Xue-ling, Zhang Liang-liang. Microstructure evolution and mechanical properties of 6082-T6 Al alloy friction stir welding[J]. Transactions of the China Welding Institution, 2018, 39(3): 1-5. |

| [1] | 李银平,靳添絮,刘立. 纯电动铲运机弓网续能系统设计与动态特性仿真[J]. 吉林大学学报(工学版), 2020, 50(2): 454-463. |

| [2] | 陈学文,王继业,杨喜晴,皇涛,宋克兴. Cr8合金钢热变形行为及位错密度演变规律[J]. 吉林大学学报(工学版), 2020, 50(1): 91-99. |

| [3] | 张淼,钱永久,张方,朱守芹. 基于增大截面法的混凝土加固石拱桥空间受力性能试验分析[J]. 吉林大学学报(工学版), 2020, 50(1): 210-215. |

| [4] | 邓钧忆,刘衍珩,冯时,赵荣村,王健. 基于GSPN的Ad⁃hoc网络性能和安全平衡[J]. 吉林大学学报(工学版), 2020, 50(1): 255-261. |

| [5] | 朱春凤,程永春,梁春雨,肖波. 硅藻土⁃玄武岩纤维复合改性沥青混合料路用性能试验[J]. 吉林大学学报(工学版), 2020, 50(1): 165-173. |

| [6] | 杨德磊,童乐为. 支管受轴向受拉工况下CHS-CFSHS T型节点应力集中系数计算公式[J]. 吉林大学学报(工学版), 2019, 49(6): 1891-1899. |

| [7] | 王金国,任帅,闫瑞芳,黄恺,王志强. TiC颗粒对铸态球墨铸铁组织和力学性能的影响[J]. 吉林大学学报(工学版), 2019, 49(6): 2010-2018. |

| [8] | 石舟,寇淑清. 36MnVS4裂解连杆性能分析及轻量化设计[J]. 吉林大学学报(工学版), 2019, 49(6): 1992-2001. |

| [9] | 佟鑫,张雅娇,黄玉山,胡正正,王庆,张志辉. 选区激光熔化304L不锈钢的组织结构及力学性能分析[J]. 吉林大学学报(工学版), 2019, 49(5): 1615-1621. |

| [10] | 李明,王浩然,赵唯坚. 带抗剪键叠合板的力学性能[J]. 吉林大学学报(工学版), 2019, 49(5): 1509-1520. |

| [11] | 万世成,黄侨,关健,郭赵元. 预应力碳纤维板加固钢⁃混凝土组合连续梁负弯矩区试验[J]. 吉林大学学报(工学版), 2019, 49(4): 1114-1123. |

| [12] | 徐戊矫,刘承尚,鲁鑫垚. 喷丸处理后6061铝合金工件表面粗糙度的模拟计算及预测[J]. 吉林大学学报(工学版), 2019, 49(4): 1280-1287. |

| [13] | 鲁金忠,周婉婷,张圣洋,邵亦锴,王长雨,罗开玉. 激光冲击强化层数对6061⁃T6铝合金抗腐蚀性能的影响[J]. 吉林大学学报(工学版), 2019, 49(3): 842-849. |

| [14] | 王露,刘玉雯,陈红. 侧风下峡谷桥隧连接段汽车的行驶特性[J]. 吉林大学学报(工学版), 2019, 49(3): 736-748. |

| [15] | 李于朋,孙大千,宫文彪. 6082⁃T6铝合金薄板双轴肩搅拌摩擦焊温度场[J]. 吉林大学学报(工学版), 2019, 49(3): 836-841. |

|

||