吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (1): 172-180.doi: 10.13229/j.cnki.jdxbgxb20190869

• 材料科学与工程 • 上一篇

基于有限元计算的形状记忆合金⁃金属玻璃复合材料变形行为

- 1.西安交通大学 网络信息中心,西安 710049

2.西安交通大学 金属材料强度国家重点实验室,西安 710049

Deformation behavior of shape memory alloy-metallic glass matrix composites based on finite element calculations

Fan YANG1( ),Xu-dong ZHANG1(

),Xu-dong ZHANG1( ),Meng ZHAO2,Bo SHE1,Jun-kai DENG2

),Meng ZHAO2,Bo SHE1,Jun-kai DENG2

- 1.Network Information Center,Xi'an Jiaotong University,Xi'an 710049,China

2.State Key Laboratory for Mechanical Behavior of Materials,Xi'an Jiaotong University,Xi'an 710049,China

摘要:

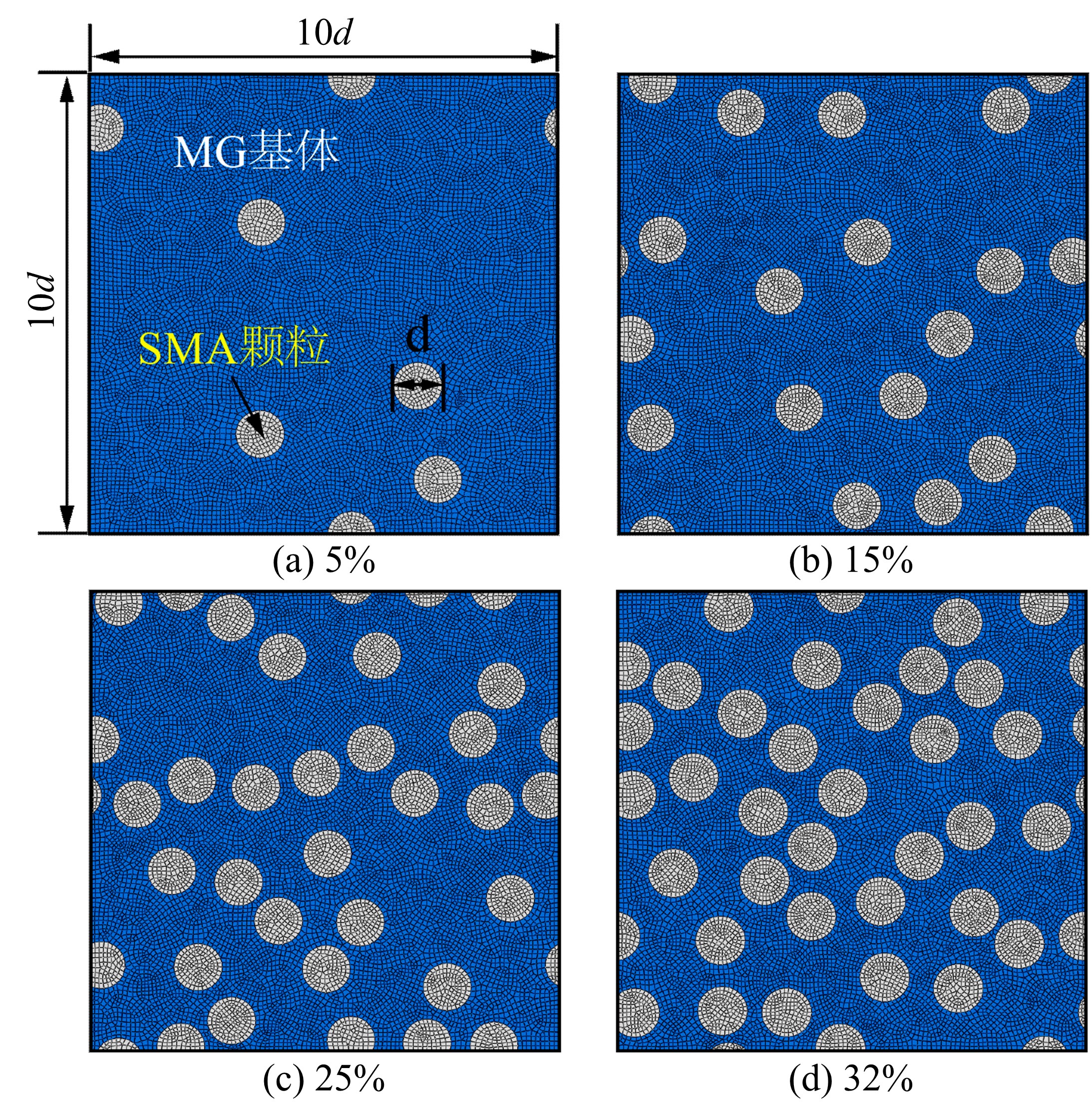

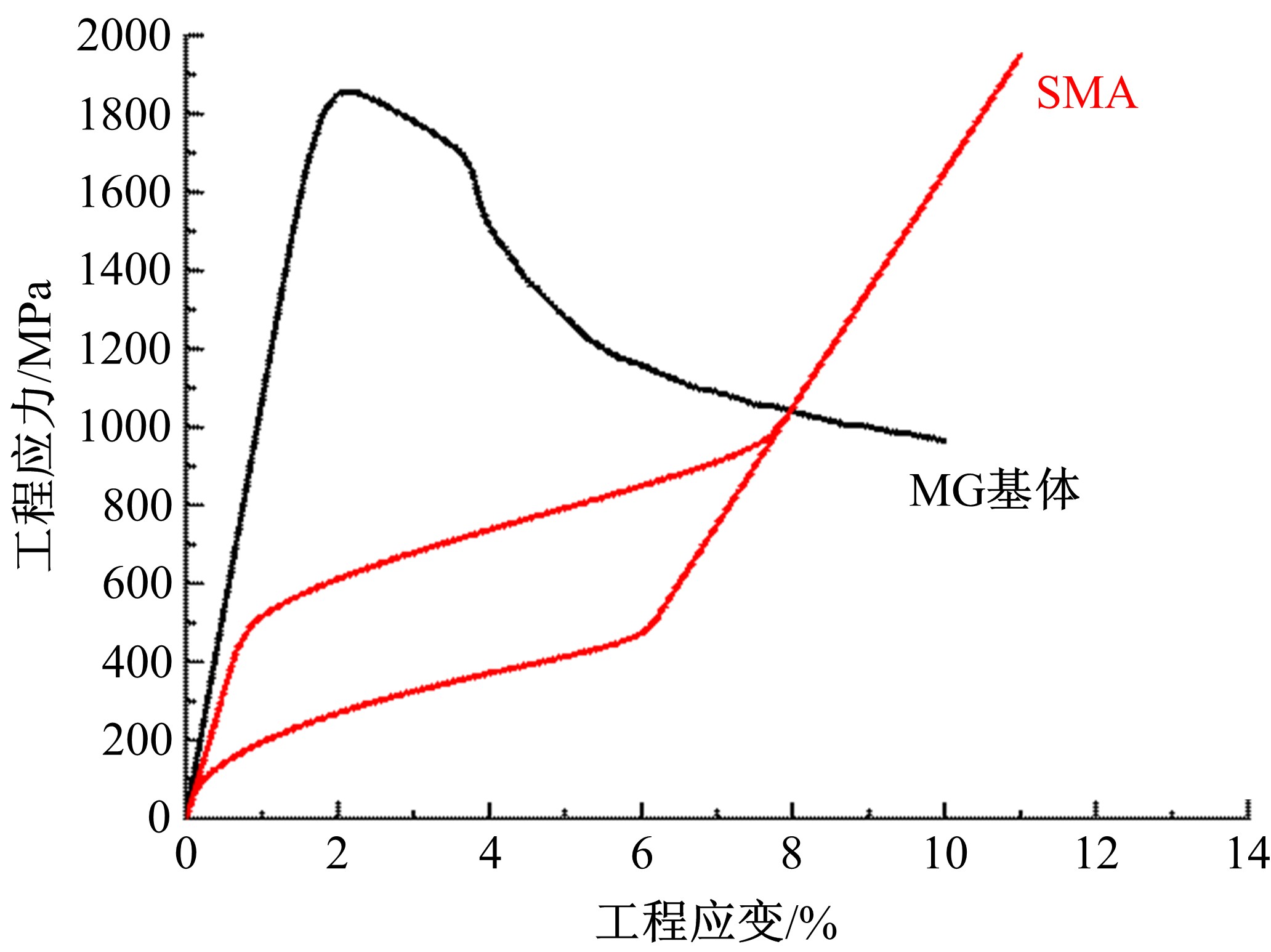

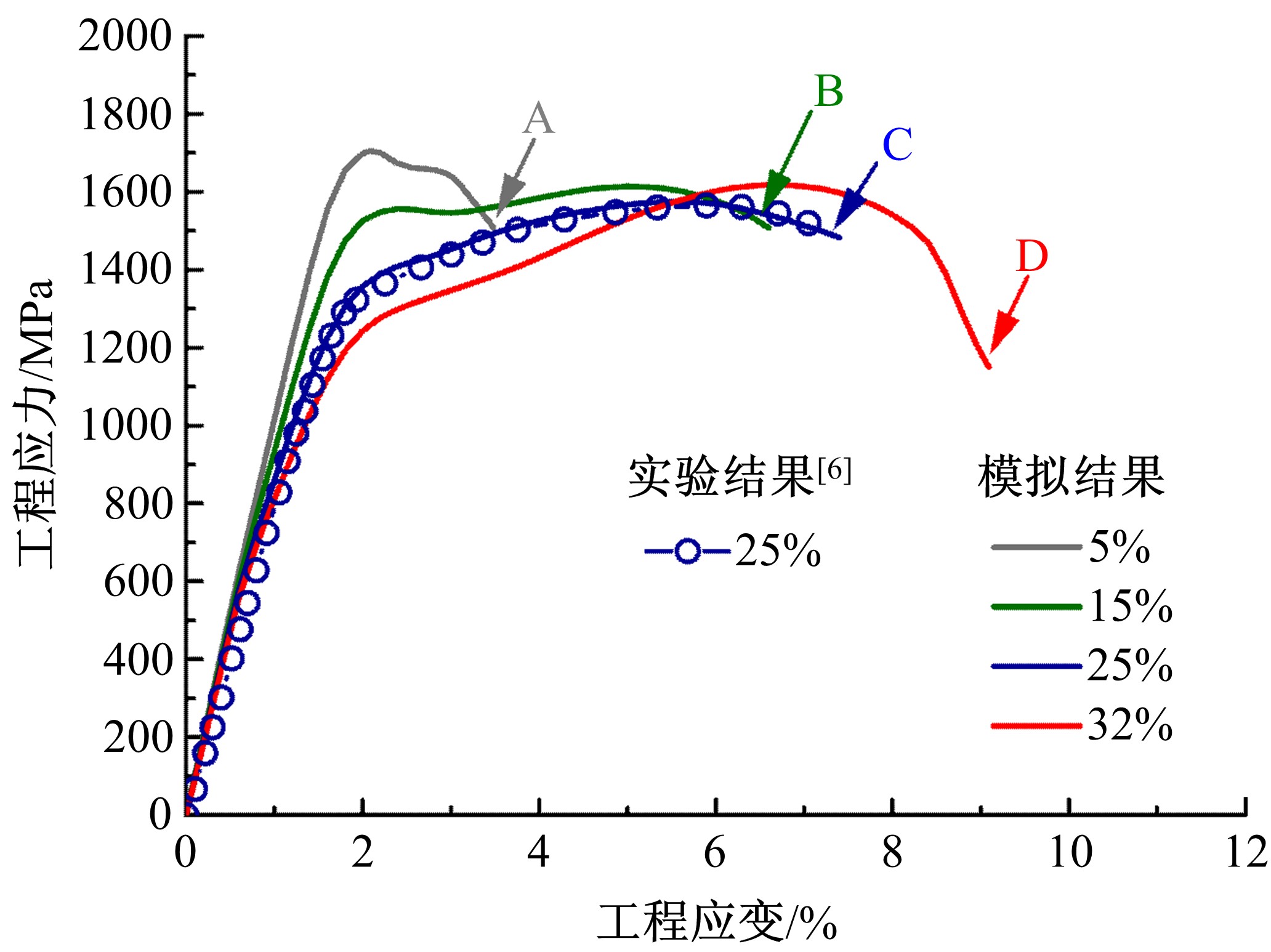

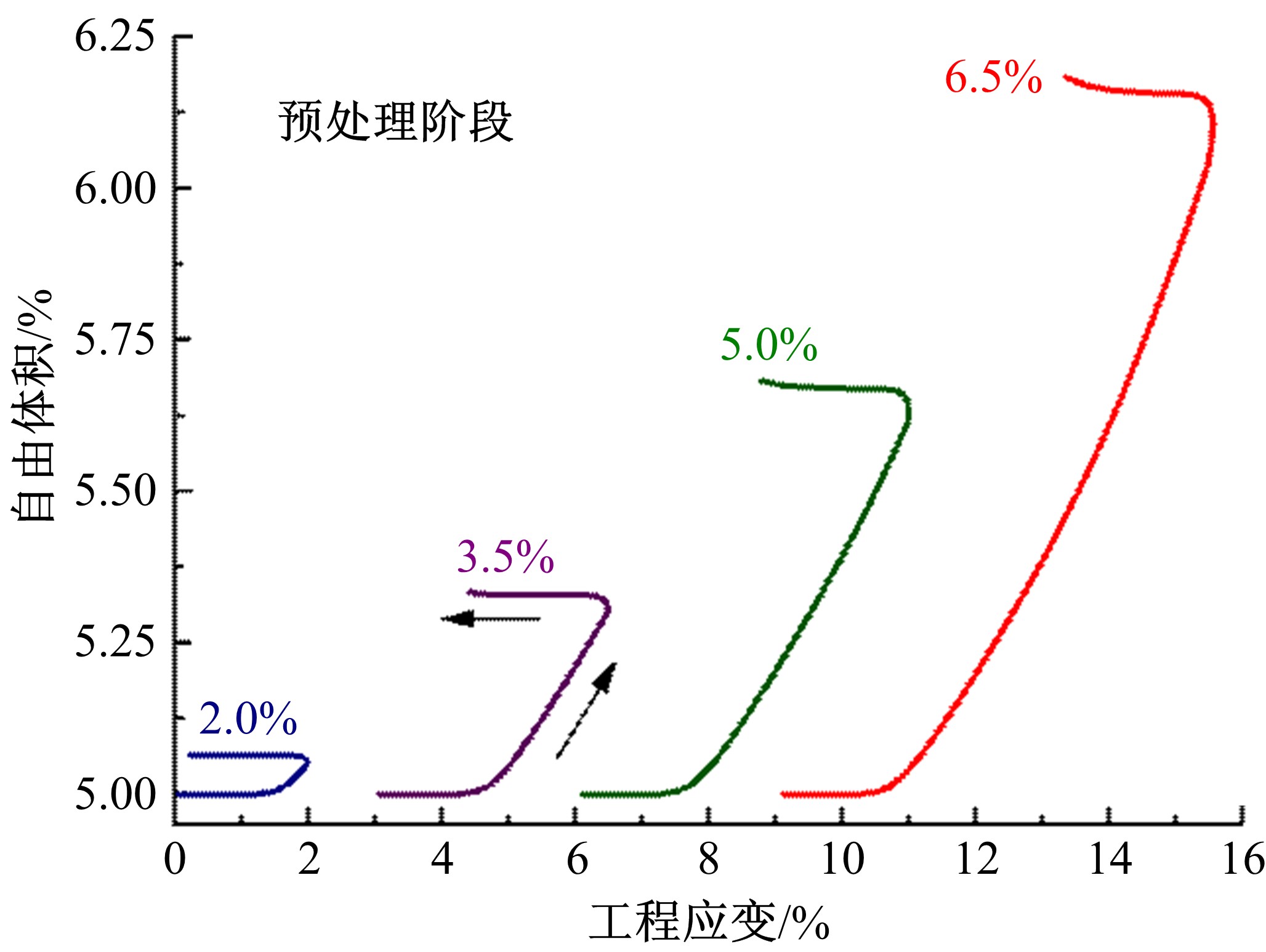

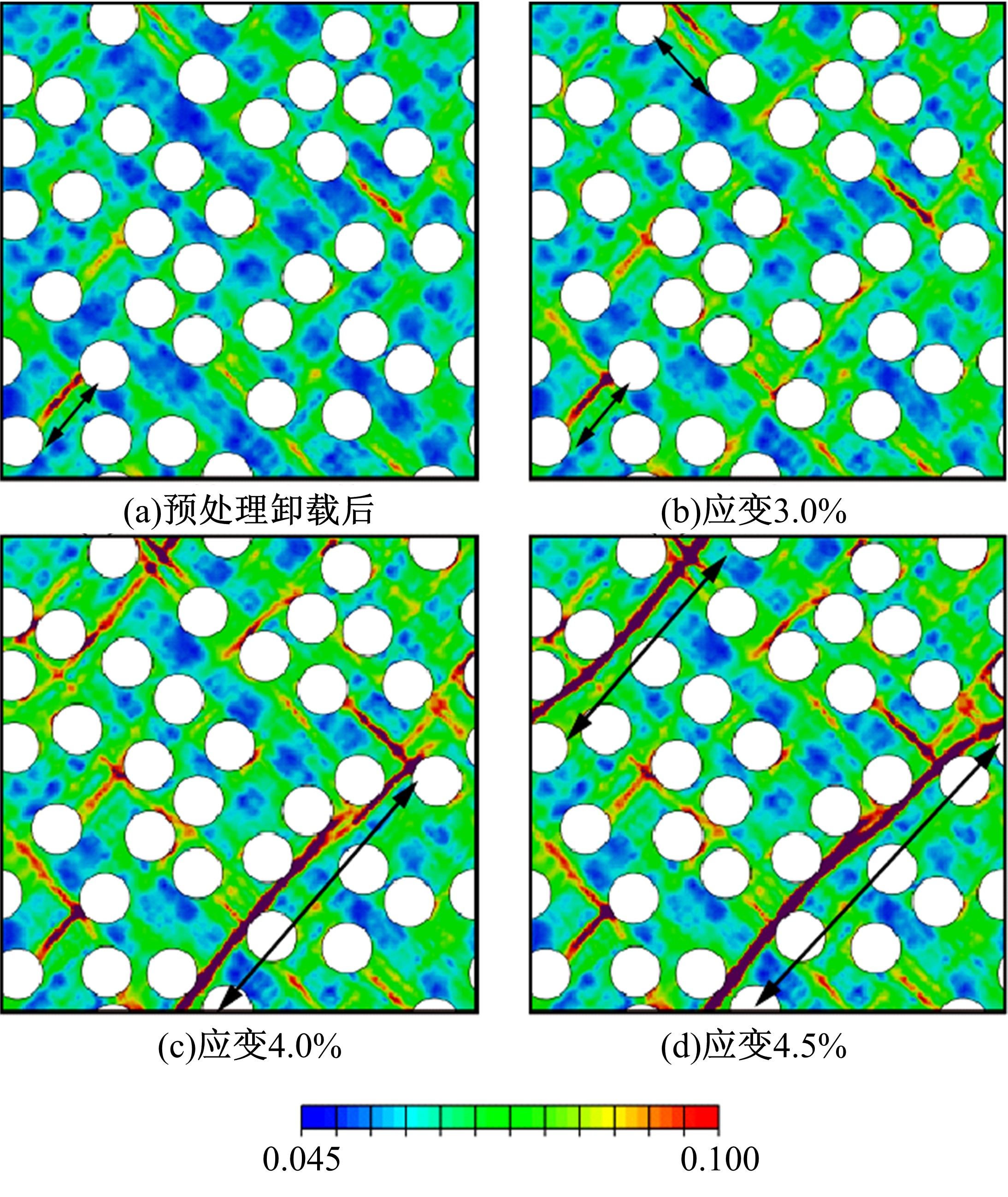

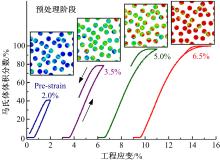

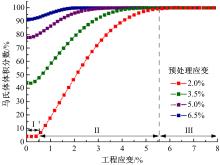

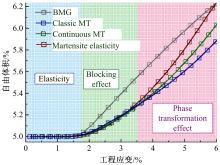

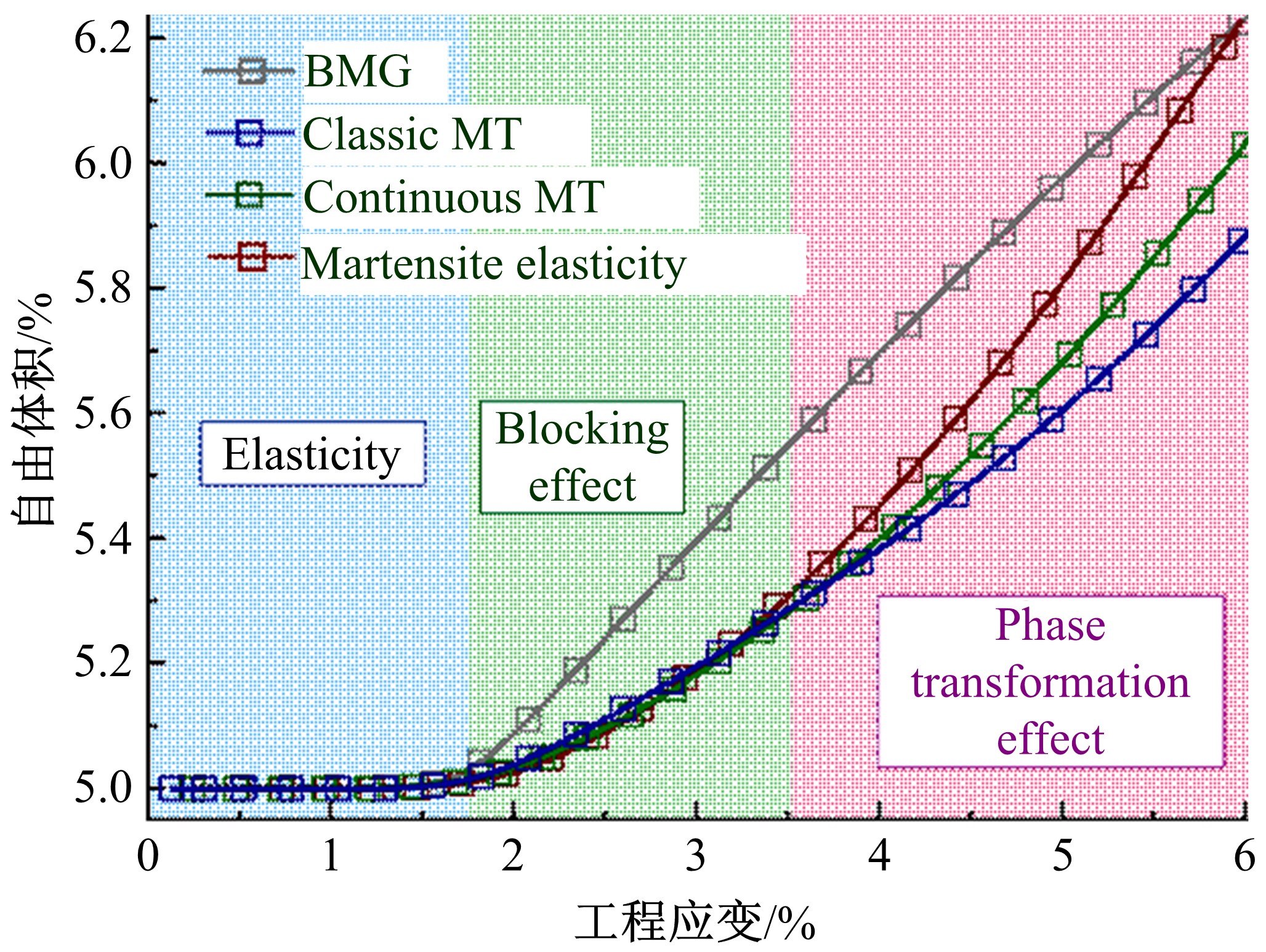

利用有限元模拟方法,研究了拉伸-卸载预应变对形状记忆合金-金属玻璃复合材料力学行为的影响及其内在机理。结果表明:预处理应变增加,形状记忆合金-金属玻璃复合材料的屈服强度及弹性应变极限均提高,但拉伸延展性急剧下降。预应变增加导致形状记忆合金颗粒第二次加载时的变形行为由典型的马氏体相变过渡为连续的马氏体相变,甚至表现为纯马氏体相的弹性变形。这一“相变效应”的减弱甚至消失,是形状记忆合金-金属玻璃复合材料经拉伸-卸载预处理后拉伸性能退化的直接原因。

中图分类号:

- TB331

| 1 | Pauly S, Gorantla S, Wang G, et al. Transformation-mediated ductility in CuZr-based bulk metallic glasses[J]. Nature Materials, 2010, 9(6): 473-477. |

| 2 | Hofmann D C, Suh J Y, Wiest A, et al. Designing metallic glass matrix composites with high toughness and tensile ductility[J]. Nature, 2008, 451(7182): 1085-1089. |

| 3 | Baran Sarac, Jan Schroers. Designing tensile ductility in metallic glasses[J]. Nature Communications, 2013, 4: 2158. |

| 4 | Wang Y, Li M, Xu J. Toughen and harden metallic glass through designing statistical heterogeneity[J]. Scripta Materialia, 2016, 113: 10-13. |

| 5 | Gargarella P, Pauly S, Song K K, et al. Ti-Cu-Ni shape memory bulk metallic glass composites[J]. Acta Materialia, 2013, 61 (1): 151-162. |

| 6 | Wu Y, Xiao Y, Chen G, et al. Bulk metallic glass composites with transformation-mediated work-hardening and ductility[J]. Advanced Materials, 2010, 22(25): 2770-2773. |

| 7 | Hofmann D C. Shape memory bulk metallic glass composites[J]. Science, 2010, 329(5997): 1294-1295. |

| 8 | Qiao J. In-situ dendrite/metallic glass matrix composites: a review[J]. Journal of Materials Science & Technology, 2013, 29(8): 685-701. |

| 9 | Hao S, Cui L, Jiang D, et al. A transforming metal nanocomposite with large elastic strain, low modulus, and high strength[J]. Science, 2013, 339(6124): 1191-1194. |

| 10 | Wu F F, Chan K C, Jiang S, et al. Bulk metallic glass composite with good tensile ductility, high strength and large elastic strain limit[J]. Scientific Reports, 2014, 4: 5302. |

| 11 | Wei R, Chang Y, Li Y F, et al. Effect of lateral pre-compression on the compressive behavior of a CuZr-based bulk metallic glass composite containing B2-CuZr phase[J]. Materials Science and Engineering: A, 2013, 587: 233-239. |

| 12 | Jiang Y, Shi X, Qiu K. Numerical study of shear banding evolution in bulk metallic glass composites[J]. Materials & design, 2015, 77: 32-40. |

| 13 | Sarac B, Wilmers J, Bargmann S. Property optimization of porous metallic glasses via structural design[J]. Materials Letters, 2014, 134: 306-310. |

| 14 | Jiang Y, Qiu K. Computational micromechanics analysis of toughening mechanisms of particle-reinforced bulk metallic glass composites[J]. Materials & Design, 2015, 65: 410-416. |

| 15 | Wang Y, Li M, Xu J. Mechanical properties of spinodal decomposed metallic glass composites[J]. Scripta Materialia, 2017, 135: 41-45. |

| 16 | Zhang X, Ren J, Ding X. Synergistic effects among the structure, martensite transformation and shear band in a shape memory alloy-metallic glass composite[J]. Applied Composite Materials, 2019, 26: 455-467. |

| 17 | Rao W, Kang G, Zhang J, et al. Numerical study on toughening mechanism of bulk metallic glass composites from martensite transformation of toughening phase[J]. Journal of Non Crystalline Solids, 2019, 506: 88-97. |

| 18 | Wu Y, Wang H, Wu H H, et al. Formation of Cu-Zr-Al bulk metallic glass composites with improved tensile properties[J]. Acta Materialia, 2011, 59: 2928-2936. |

| 19 | Jiang Y, Sun L, Wu Q, et al. Enhanced tensile ductility of metallic glass matrix composites with novel microstructure[J]. Journal of Non Crystalline Solids, 2017, 459: 26-31. |

| 20 | Jiang Y. Numerical modeling of cyclic deformation in bulk metallic glasses[J]. Metals, 2016, 6(9): 217. |

| 21 | Pauly S, Liu G, Wang G, et al. Modeling deformation behavior of Cu-Zr-Al bulk metallic glass matrix composites[J]. Applied Physics Letters, 2009, 95(10): 101906. |

| 22 | Auricchio F, Taylor R. Shape-memory alloys: modelling and numerical simulations of the finite-strain superelastic behavior[J]. Computer Methods in Applied Mechanics and Engineering, 1997, 143(1/2): 175-194. |

| 23 | Lei H, Wang Z, Zhou B, et al. Simulation and analysis of shape memory alloy fiber reinforced composite based on cohesive zone model[J]. Materials & Design, 2012, 40: 138-147. |

| 24 | Lei H, Wang Z, Tong L, et al. Experimental and numerical investigation on the macroscopic mechanical behavior of shape memory alloy hybrid composite with weak interface[J]. Composite Structures, 2013, 101: 301-312. |

| 25 | Şopu D, Soyarslan C, Sarac B, et al. Structure-property relationships in nanoporous metallic glasses[J]. Acta Materialia, 2016, 106: 199-207. |

| 26 | Kumar G, Rector D, Conner R D, et al. Embrittlement of Zr-based bulk metallic glasses[J]. Acta Materialia, 2009, 57 (12): 3572-3583. |

| 27 | Chen L Y, Fu Z D, Zhang G Q, et al. New class of plastic bulk metallic glass[J]. Physical Review Letters, 2008, 100 (7): 075501. |

| 28 | Gao Y F. An implicit finite element method for simulating inhomogeneous deformation and shear bands of amorphous alloys based on the free-volume model[J]. Modelling and Simulation in Materials Science and Engineering, 2006, 14(8): 1329-1345. |

| [1] | 慕文龙,那景新,谭伟,王广彬,申浩,栾建泽. 基于FTIR分析的CFRP-铝合金粘接接头剩余强度预测[J]. 吉林大学学报(工学版), 2021, 51(1): 139-146. |

| [2] | 叶辉,刘畅,闫康康. 纤维增强复合材料在汽车覆盖件中的应用[J]. 吉林大学学报(工学版), 2020, 50(2): 417-425. |

| [3] | 李欣,孙延朋,王丹,陈军绪,谷诤巍,徐虹. 汽车前地板成形有限元数值模拟[J]. 吉林大学学报(工学版), 2019, 49(5): 1608-1614. |

| [4] | 叶辉,朱艳荣,蒲永锋. 纤维增强复合材料应变率效应的数值仿真[J]. 吉林大学学报(工学版), 2019, 49(5): 1622-1629. |

| [5] | 马芳武,韩露,周阳,王世英,蒲永锋. 采用聚乳酸复合材料的汽车零件多材料优化设计[J]. 吉林大学学报(工学版), 2019, 49(5): 1385-1391. |

| [6] | 李碧雄,廖桥,章一萍,周练,隗萍,刘侃. 超高强钢筋工程用水泥基复合材料梁受弯计算理论[J]. 吉林大学学报(工学版), 2019, 49(4): 1153-1161. |

| [7] | 胡志清, 郑会会, 徐亚男, 张春玲, 党停停. 表面微沟槽对Al/CFRP胶结性能的影响[J]. 吉林大学学报(工学版), 2018, 48(1): 229-235. |

| [8] | 王靖宇, 于旭涛, 胡兴军, 郭鹏, 辛俐, 郭峰, 张扬辉. 汽车外后视镜流致振特性及其流动机理[J]. 吉林大学学报(工学版), 2017, 47(6): 1669-1676. |

| [9] | 刘耀辉, 陈乔旭, 宋雨来, 沈艳东. 火山灰-SBS、胶粉-SBS和SBS改性沥青压缩变形行为及机理[J]. 吉林大学学报(工学版), 2017, 47(6): 1861-1867. |

| [10] | 李静, 王哲. 真三轴加载条件下混凝土的力学特性[J]. 吉林大学学报(工学版), 2017, 47(3): 771-777. |

| [11] | 杨悦, 李雪, 徐晓丹. Ti-B-C-N粉末烧结的微观组织及其性能[J]. 吉林大学学报(工学版), 2017, 47(2): 552-556. |

| [12] | 陈江义, 刘保元. 纤维断裂损伤对复合材料板中导波频散特性的影响[J]. 吉林大学学报(工学版), 2017, 47(1): 180-184. |

| [13] | 关庆丰, 黄尉, 李怀福, 龚晓花, 张从林, 吕鹏. 强流脉冲电子束诱发的Cu-C扩散合金化[J]. 吉林大学学报(工学版), 2016, 46(6): 1967-1973. |

| [14] | 彭爱东, 刘贺男. 基于水包油微乳液法的方形苝纳米颗粒的合成与荧光性能[J]. 吉林大学学报(工学版), 2016, 46(5): 1583-1586. |

| [15] | 刘晓波, 周德坤, 赵宇光. 不同等温热处理条件下半固态挤压Mg2Si/Al复合材料的组织和性能[J]. 吉林大学学报(工学版), 2016, 46(5): 1577-1582. |

|

||