吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (3): 693-702.doi: 10.13229/j.cnki.jdxbgxb20200812

• 农业工程·仿生工程 • 上一篇

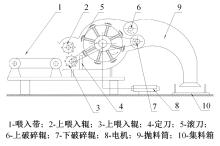

基于差速辊的青贮玉米籽粒破碎仿真试验及优化

耿端阳1( ),孙延成1,牟孝栋1,张国栋1,姜慧新2,朱俊科1

),孙延成1,牟孝栋1,张国栋1,姜慧新2,朱俊科1

- 1.山东理工大学 农业工程与食品科学学院,山东 淄博 255000

2.山东省畜牧总站,济南 250002

Simulation test and optimization of grain breakage of silage maize based on differential roller

Duan-yang GENG1( ),Yan-cheng SUN1,Xiao-dong MU1,Guo-dong ZHANG1,Hui-xin JIANG2,Jun-ke ZHU1

),Yan-cheng SUN1,Xiao-dong MU1,Guo-dong ZHANG1,Hui-xin JIANG2,Jun-ke ZHU1

- 1.School of Agricultural Engineering and Food Science,Shandong University of Technology,Zibo 255000,China

2.Shandong Animal Husbandry Terminus,Jinan 250002,China

摘要:

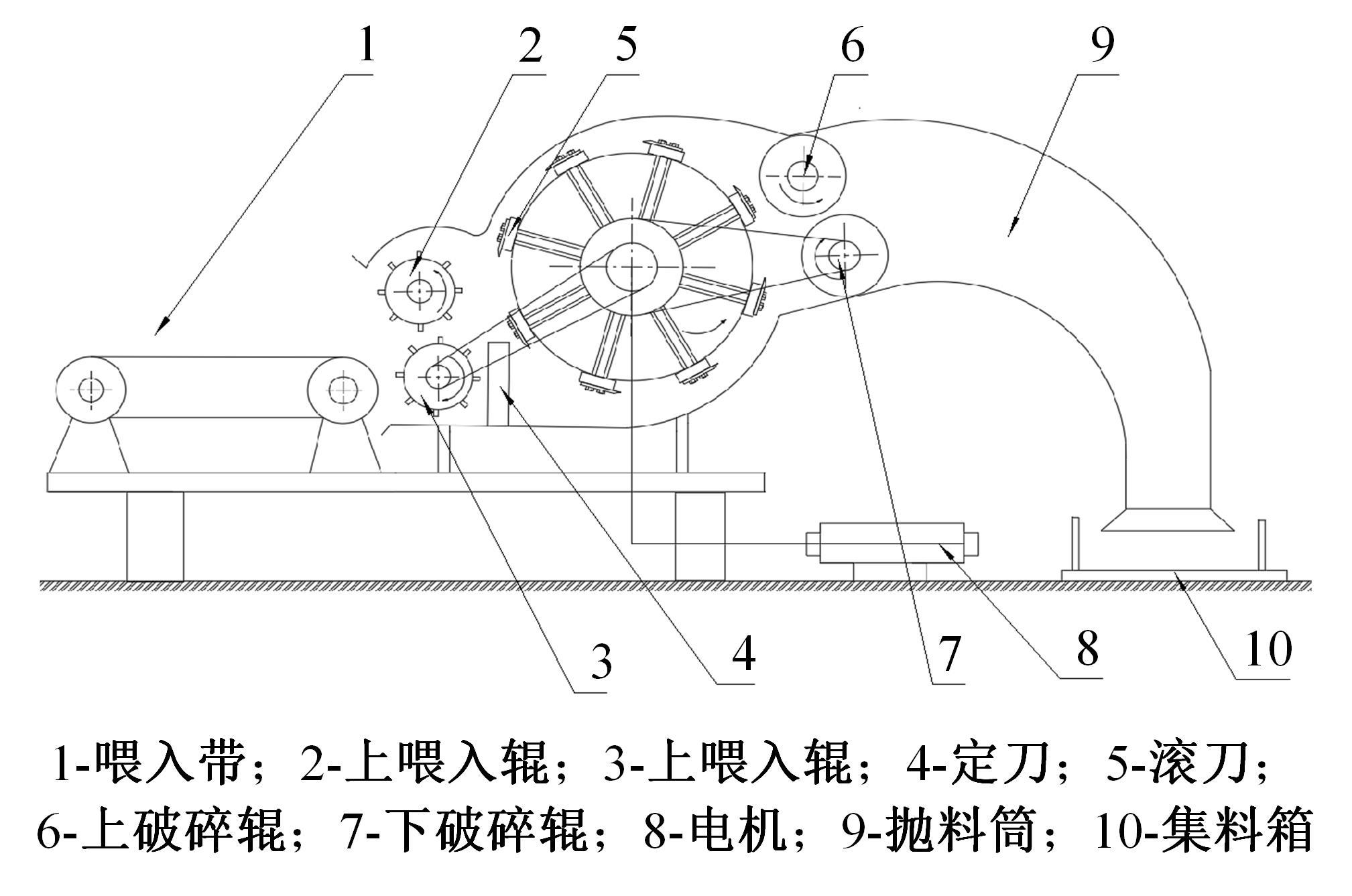

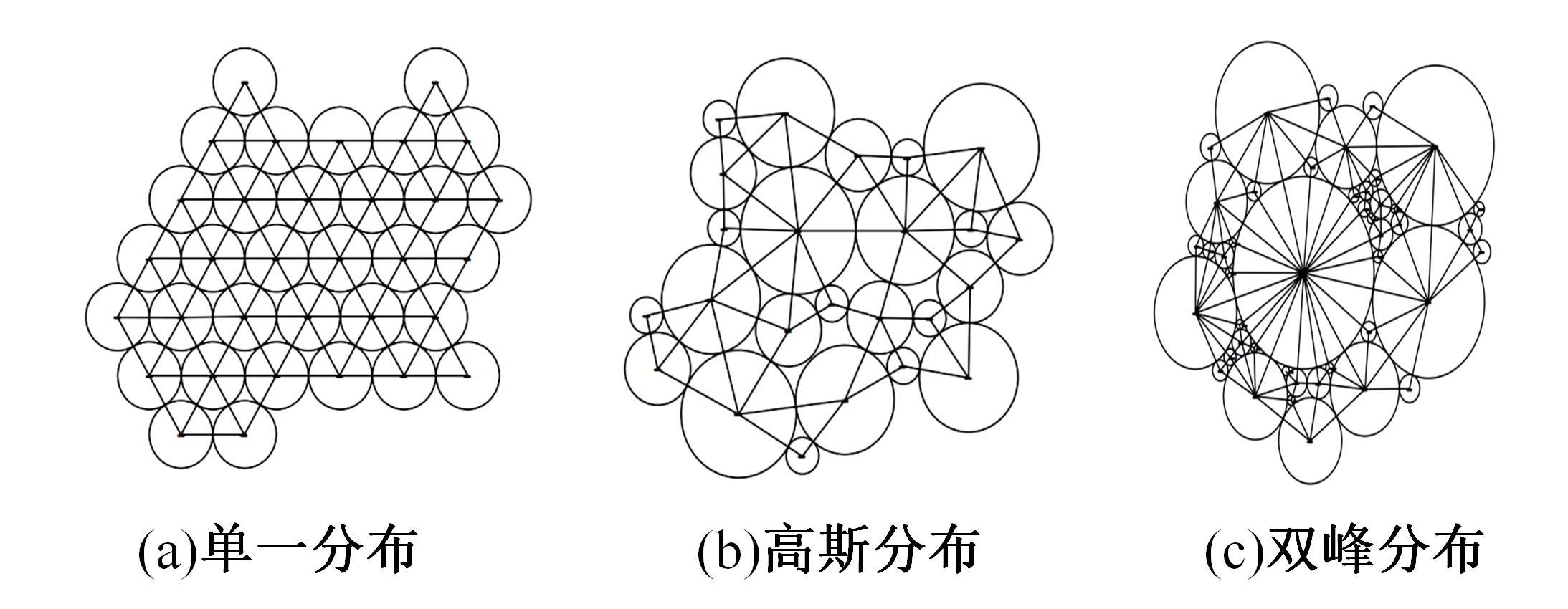

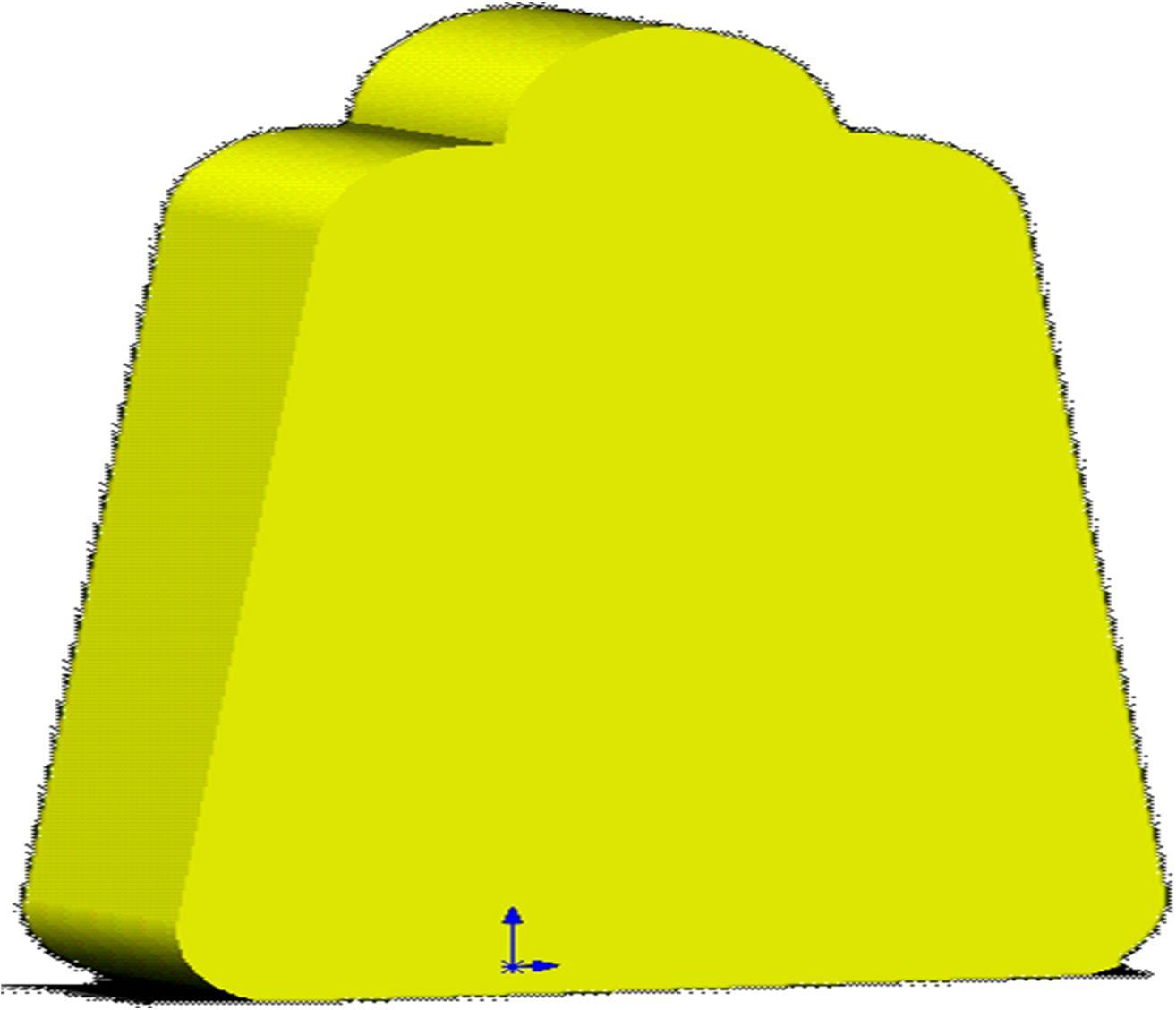

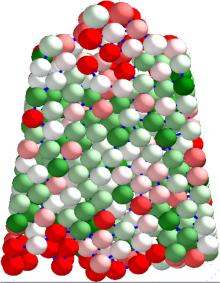

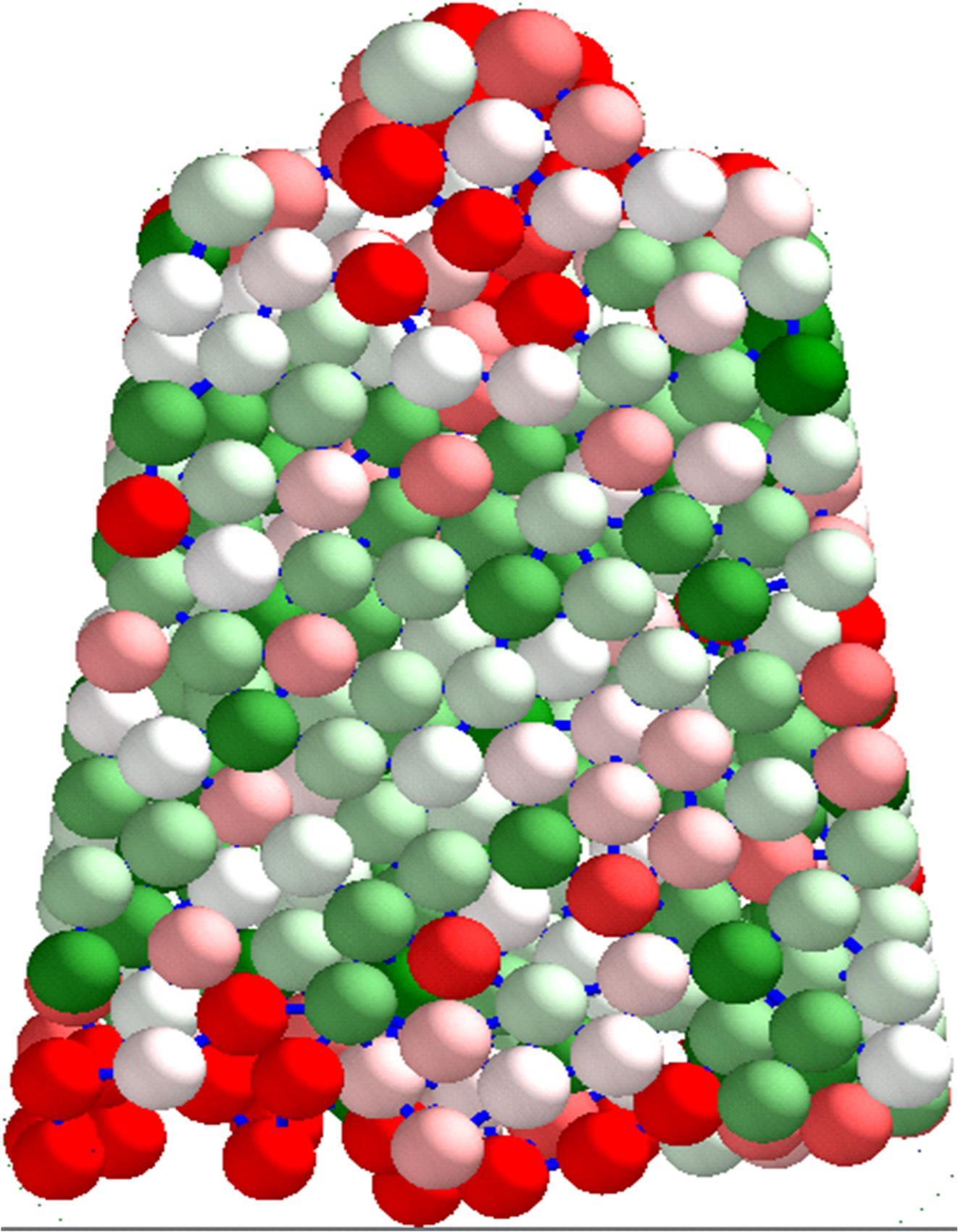

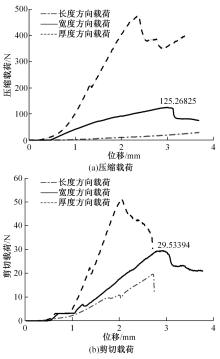

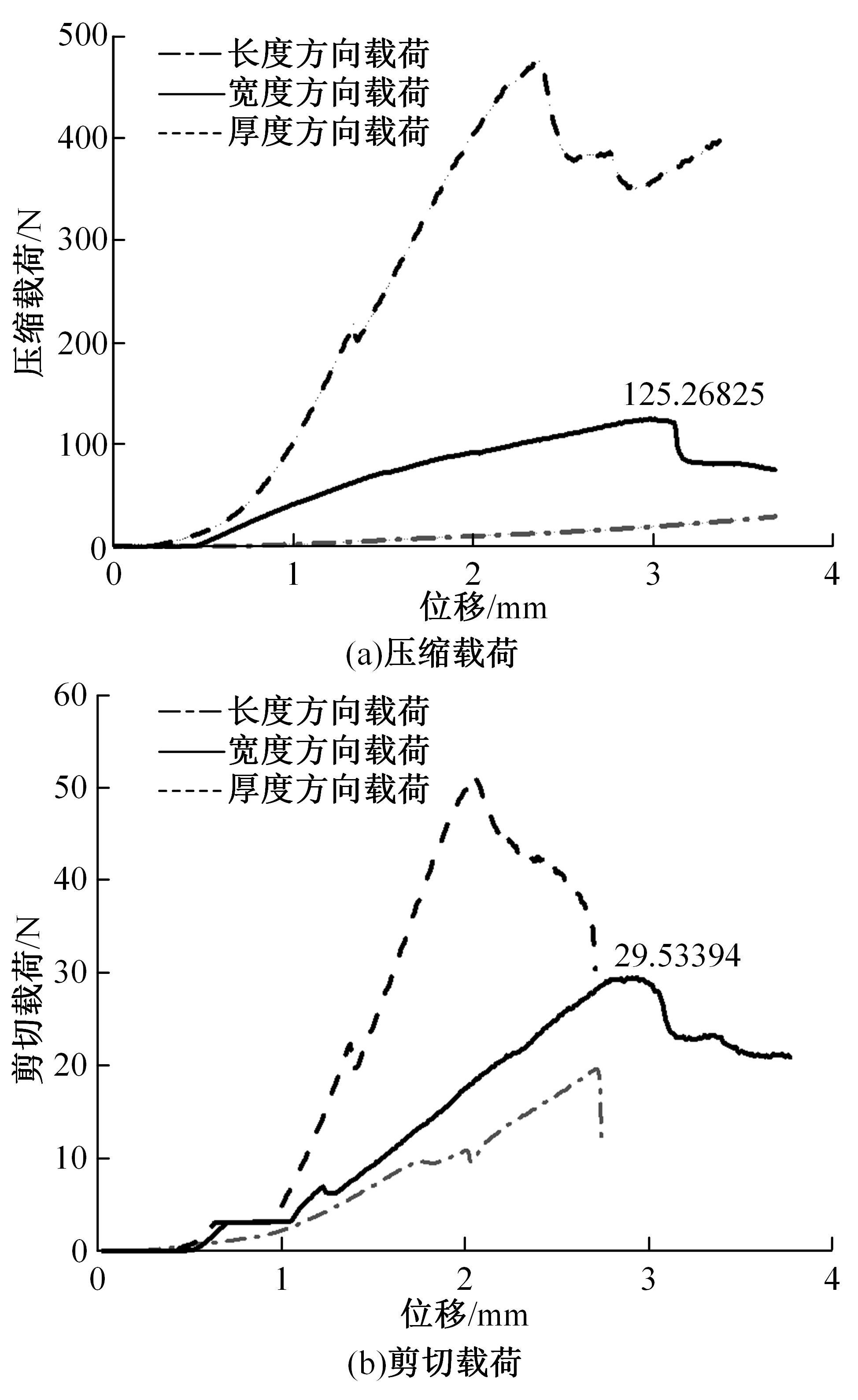

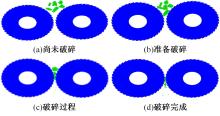

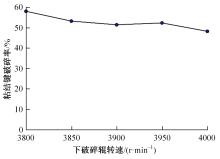

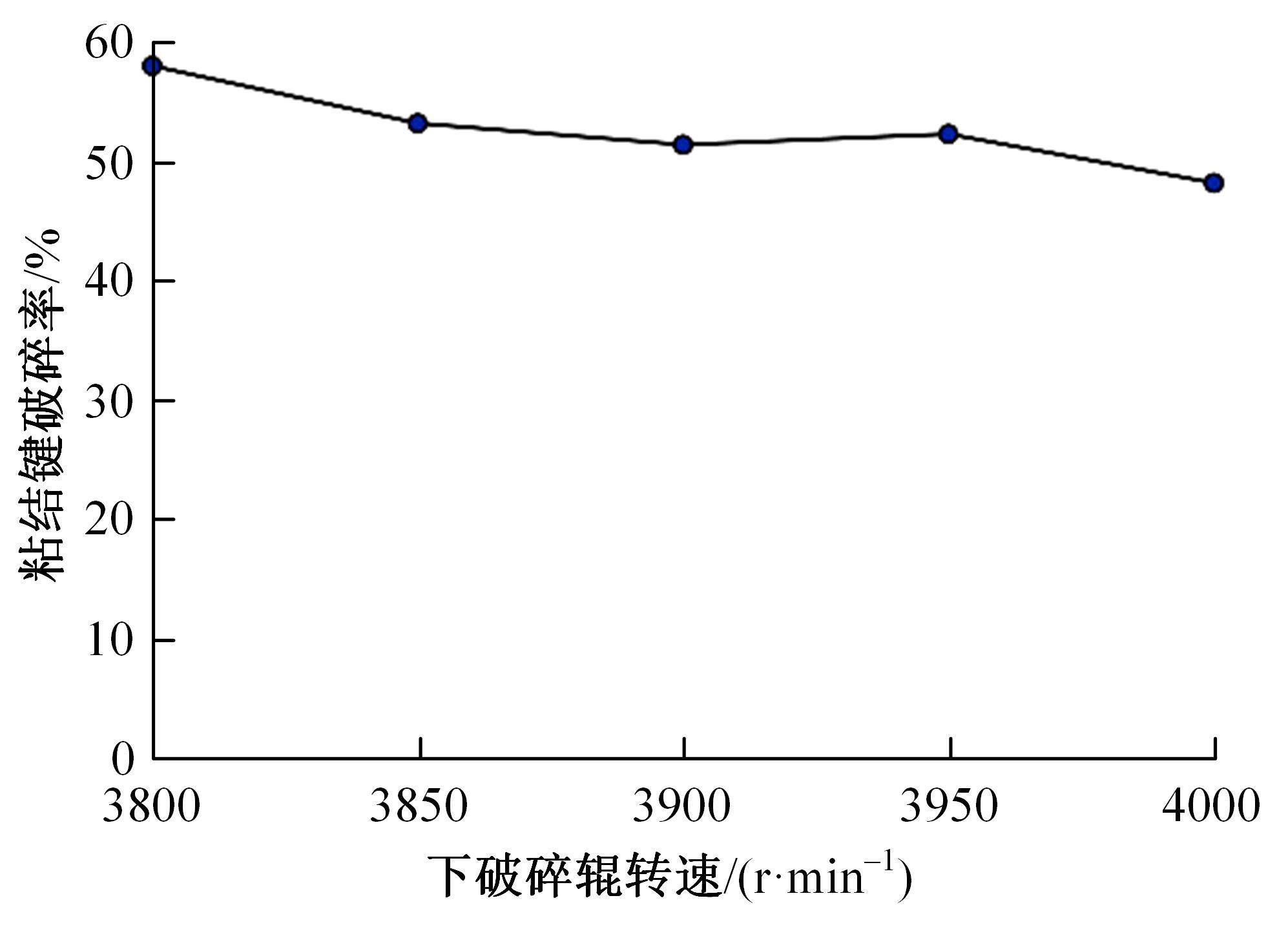

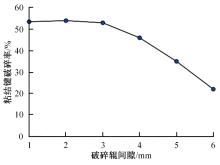

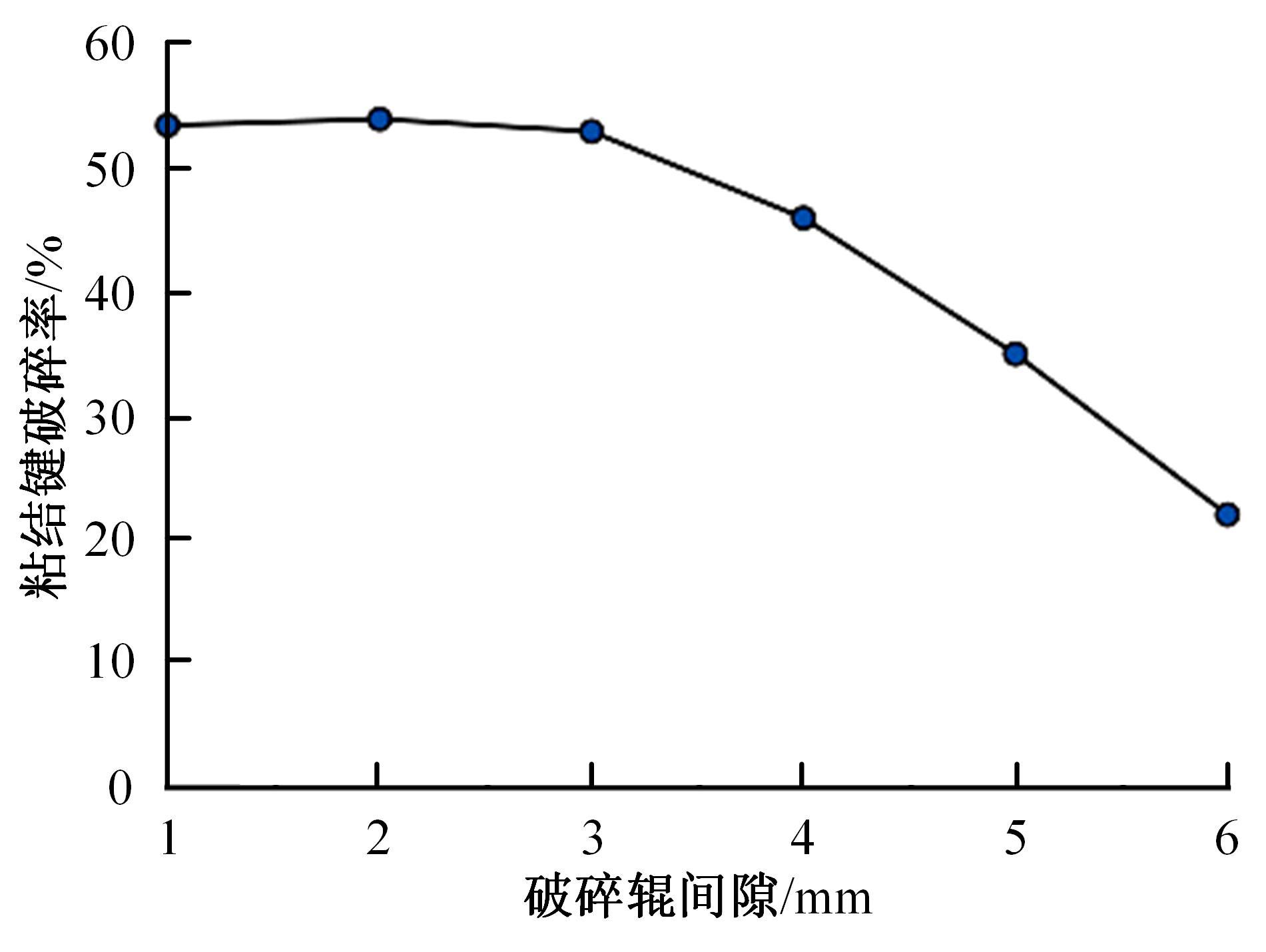

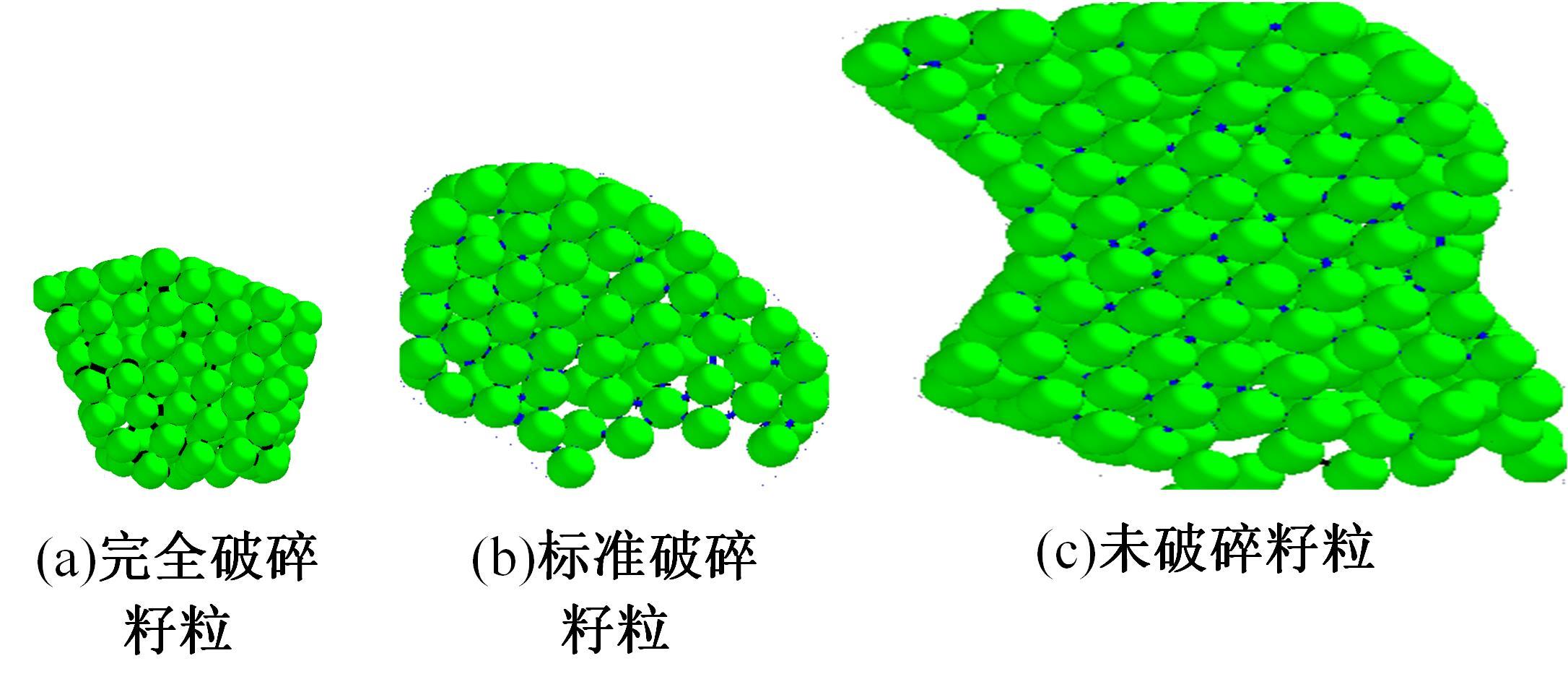

针对国内青贮玉米收获机籽粒破碎效果差、破碎率低,影响青贮饲料养分转化的问题,基于离散元法建立了玉米籽粒粘结接触模型,确定了其相应参数。结合差速籽粒破碎原理探索了破碎辊间隙、上下破碎辊转速对青贮玉米籽粒破碎率的影响规律,结果表明:上破碎辊转速为5197 r/min、下破碎辊转速(差速比)为3949 r/min、破碎辊间隙为3 mm时,玉米籽粒离散元模型粘结键的平均破碎率达到95.35%。在该上述试验条件下进行台架试验,结果表明,青贮玉米籽粒破碎率达到92.1%,其中75.3%的青贮玉米籽粒小于正常大小的1/4;19.5%的青贮玉米籽粒大于正常大小的1/4;仿真试验与台架试验相对误差为3.25%。试验符合青贮饲料的发酵和养分转化标准,为籽粒破碎技术和装备开发提供了一种新的研究方法。

中图分类号:

- S225.5

| 1 | 王永宏, 赵健, 沈强云, 等. 青贮玉米生物产量及营养积累规律研究[J]. 玉米科学, 2005, 13(4): 81-85. |

| Wang Yong-hong, Zhao Jian, Shen Qiang-yun, et al. Study on biological yield and nutrient accumulation of silage maize [J]. Journal of Maize Sciences, 2005, 13(4): 81-85. | |

| 2 | 王金龙. 青贮机籽粒破碎装置试验研究[D].秦皇岛:河北科技师范学院机电工程学院,2018. |

| Wang Jin-long. Experimental study on grain crushing device of silage machine[D]. Qinghuangdao:School of Mechanical and Electrical Engineering, Hebei Normal University of Science and Technology, 2018. | |

| 3 | 薛飞. 自走式青饲料收获机关键部件设计及仿真[D].秦皇岛:河北科技师范学院机电工程学院, 2017. |

| Xue Fei. Design and simulation of key components of self-propelled green feed harvester[D]. Qinghuangdao:School of Mechanical and Electrical Engineering, Hebei Normal University of Science and Technology, 2017. | |

| 4 | Cundall P A, Strack O D L. Discussion: a discrete numerical model for granular assemblies[J]. Geotechnique, 1980, 30(3): 331-336. |

| 5 | Potyondy D O, Cundall P A. A bonded-particle model for rock[J]. International Journal of Rock Mechanics and Mining Sciences, 2004, 41(8): 1329-1364. |

| 6 | Cho N, Martin C D, Sego D C. A clumped particle model for rock[J]. International Journal of Rock Mechanics and Mining Sciences, 2007, 44(7): 997-1010. |

| 7 | Metzger M J, Glasser B J. Simulation of the breakage of bonded agglomerates in a ball mill[J]. Powder Technology, 2013, 237: 286-302. |

| 8 | Jiménez-Herrera N, Barrios G K P, Tavares L M. Comparison of breakage models in DEM in simulating impact on particle beds[J]. Advanced Powder Technology, 2018, 29(3): 692-706. |

| 9 | 王扬,王晓梅,陈泽仁,等. 基于离散元法的玉米籽粒建模[J]. 吉林大学学报: 工学版, 2018, 48(5): 1537-1547. |

| Wang Yang, Wang Xiao-mei, Chen Ze-ren, et al. Modeling method of maize kernels based on discrete element method[J]. Journal of Jilin University (Engineering and Technology Edition), 2018, 48(5): 1537-1547. | |

| 10 | Matsushima T, Saomoto H, Matsumoto M, et al. Discrete element simulation of an assembly of irregularly shaped grains:quantitative comparison with experiments[C]∥16th ASCE Engineering Mechanics Conference, Seattle, 2003: 16-18. |

| 11 | Quist Johannes. Cone crusher modeling and simulation [D]. Sweden: Chalmers University of Technology, 2012. |

| 12 | Quist J, Evertsson C M. Cone crusher modelling and simulation using DEM[J]. Minerals Engineering, 2016, 85: 92-105. |

| 13 | 王笑丹, 王洪美, 韩云秀, 等. 基于离散元法的牛肉咀嚼破碎模型构建[J]. 农业工程学报, 2016, 32(4):228-234. |

| Wang Xiao-dan, Wang Hong-mei, Han Yun-xiu, et al. Structure of beef chewing model based on discrete element method[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(4): 228-234. | |

| 14 | 赖庆辉, 袁海阔, 胡子武, 等. 滚筒板齿式三七种苗分离装置结构设计与试验[J]. 农业机械学报, 2018, 49(4): 121-129. |

| Lai Qing-hui, Yuan Hai-kuo, Hu Zi-wu, et al. Design and experiment on seedling separation device of Panax notoginseng seedlings based on roller zigzag mechanism[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(4): 121-129. | |

| 15 | 刘凡一, 张舰, 李博, 等. 基于堆积试验的小麦离散元参数分析及标定[J]. 农业工程学报, 2016, 32(12): 247-253. |

| Liu Fan-yi, Zhang Jian, Li Bo, et al. Calibration of parameters of wheat required in discrete element method simulation based on repose angle of particle heap[J]. Journal of Agricultural Engineering, 2016, 32(12): 247-253. | |

| 16 | 史嵩, 张东兴, 杨丽, 等. 基于 EDEM 软件的气压组合孔式排种器充种性能模拟与验证[J]. 农业工程学报, 2015, 31(3): 62-69. |

| Shi Song, Zhang Dong-xing, Yang Li, et al. Simulation and verification of seed filling performance of pneumatic combined hole seed metering device based on EDEM software[J]. Journal of Agricultural Engineering, 2015, 31(3): 62-69. | |

| 17 | 于亚军, 于建群, 陈仲, 等. 三维离散元法边界建模软件设计[J].农业机械学报, 2011, 42(8): 99-103, 98. |

| Yu Ya-jun, Yu Jian-qun, Chen Zhong, et al. Design of 3-D DEM boundary modeling software[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(8): 99-103, 98. | |

| 18 | Coetzee C J, Els D N. Calibration of discrete element parameters and the modelling of silo discharge and bucket filling[J]. Computers and Electronics in Agriculture, 2009, 65(2): 198-212. |

| 19 | Bin R. CFD-DEM simulation of spouting of corn-shaped particles[J]. China Particuology, 2012, 10(5): 562-572. |

| 20 | 蔡鹏. 基于离散元的双齿辊破碎机破碎性能分析与齿形优化[D]. 长沙:湖南大学机械与运载工程学院, 2014. |

| Cai Peng. Analysis of crushing performance and optimization of tooth shape of a two-tooth roll crusher based on discrete element[D]. Changsha: School of Mechanical and Transport Engineering, Hunan University, 2014. | |

| 21 | 张锋伟, 宋学锋, 张雪坤, 等. 玉米秸秆揉丝破碎过程力学特性仿真与试验[J]. 农业工程报, 2019, 35(9): 58-65. |

| Zhang Feng-wei, Song Xue-feng, Zhang Xue-kun, et al. Simulation and test of mechanical properties of corn straw crushing process[J]. Chinese Journal of Agricultural Engineering, 2019, 35(9): 58-65. | |

| 22 | Weerasekara N S, Powell M S, Cleary P W, et al. The contribution of DEM to the science of comminution[J]. Powder Technology, 2013, 248: 3-24. |

| 23 | ASABE—S368. Compression test of food material of convex shape [S]. |

| 24 | Coşkun M B, Yalçin I, Özarslan C. Physical properties of sweet corn seed (zea mays saccharata sturt) [J]. Journal of Food Engineering, 2006, 74(4): 523-528. |

| 25 | ASAE—2002. American society of agricultural engineers. compression test of food materials of convex shape [S]. |

| 26 | Molenda M, Montross M D, Ross I J, et al. Mechanical properties of corn and soy bean meal[J]. Transactions of the ASAE, 2002,45(6): 1929-1936. |

| 27 | 石博, 卢妍妍. 约翰迪尔7380型自走式青贮收获机[J].现代化农业, 2015, 36(9): 43. |

| Shi-Bo, Lu Yan-yan. John deere 7380 self-propelled silage harvester[J]. Modern Agriculture, 2015, 36(9): 43. | |

| 28 | 卢妍妍, 杨帆. 约翰迪尔8400型自走式青贮收获机(一)[J]. 现代化农业, 2016, 37(6): 44. |

| Lu Yan-yan, Yang Fan. John deere 8400 self-propelled silage harvester(I)[J]. Modern Agriculture, 2016, 37(6): 44. | |

| 29 | Ferraretto L F, Shaver R D. Meta-analysis:impact of corn silage harvest practice on intake,digestion and milk production by dairy cows[J]. The Professional Animal Scientist, 2012, 28(2):141-149. |

| 30 | 张乐. 基于离散元法的矿石高压辊磨破碎研究[D].湘潭:湘潭大学机械工程学院, 2016. |

| Zhang Le. Study on ore crushing by high pressure roller mill based on discrete element method[D]. Xiangtan: School of Mechanical Engineering, Xiangtan University, 2016. | |

| 31 | 陈阳, 胡志超, 吴惠昌, 等. 基于EDEM的单粒式谷物水分仪采样机构仿真研究[J]. 农机化研究, 2016, 38(7): 239-244, 262. |

| Chen Yang, Hu Zhi-chao, Wu Hui-chang, et al. Simulation study on sampling mechanism of grain moisture meter based on edem [J]. Agricultural Mechanization Research, 2016, 38(7): 239-244, 262. | |

| 32 | 付宏, 吕游, 李艳双, 等. 基于离散元法的玉米脱粒过程分析[J].吉林大学学报:工学版, 2012, 42(4): 997-1002. |

| Fu Hong, Lyu You, Li Yan-shuang, et al. Analysis for corn threshing process based DEM[J]. Journal of Jilin University(Engineering and Technology Edition), 2012, 42(4): 997-1002. | |

| 33 | . 玉米青贮收获机作业质量 [S]. |

| [1] | 梁方,王德成,尤泳,王光辉,王宇兵,张晓明,冯金奎. 草地切根施肥补播复式改良机设计与试验[J]. 吉林大学学报(工学版), 2022, 52(1): 231-241. |

| [2] | 王国伟,朱庆辉,于海业,黄东岩. 基于数字化农机装备的青贮饲料可追溯系统[J]. 吉林大学学报(工学版), 2022, 52(1): 242-252. |

| [3] | 耿端阳,牟孝栋,张国栋,王宗源,朱俊科,徐海刚. 小麦联合收获机清选机理分析与优化试验[J]. 吉林大学学报(工学版), 2022, 52(1): 219-230. |

| [4] | 王新彦,江泉,吕峰,易政洋. 基于参数化模型的零转弯半径割草机侧翻稳定性[J]. 吉林大学学报(工学版), 2021, 51(5): 1908-1918. |

| [5] | 钱震杰,金诚谦,袁文胜,倪有亮,张光跃. 柔性脱粒齿杆与谷物含摩擦打击动力学模型[J]. 吉林大学学报(工学版), 2021, 51(3): 1121-1130. |

| [6] | 程超,付君,陈志,任露泉. 玉米籽粒收获机清选筛堵塞规律及脱附试验[J]. 吉林大学学报(工学版), 2021, 51(2): 761-771. |

| [7] | 丛茜,徐金,马博帅,张晓超,陈廷坤. 基于虚拟仿真的拖拉机后悬挂检测装置设计与实验[J]. 吉林大学学报(工学版), 2021, 51(2): 754-760. |

| [8] | 陈学深,黄柱健,马旭,齐龙,方贵进. 水稻机械除草避苗控制系统设计与试验[J]. 吉林大学学报(工学版), 2021, 51(1): 386-396. |

| [9] | 耿端阳,谭德蕾,于兴瑞,苏国粱,王骞,鹿秀凤,金诚谦. 玉米柔性脱粒滚筒脱粒元件设计与试验[J]. 吉林大学学报(工学版), 2020, 50(5): 1923-1933. |

| [10] | 高锐涛,单建,杨洲,文晟,兰玉彬,张泉勇,汪洋. 植保无人机变量喷雾处方图实时解译系统的设计与试验[J]. 吉林大学学报(工学版), 2020, 50(1): 361-374. |

| [11] | 刘恩泽,吴文福. 基于综合指标品质评价算法的单色水果生长状态检测互联网架构[J]. 吉林大学学报(工学版), 2019, 49(6): 2019-2026. |

| [12] | 秦嘉浩,李臻,光岡宗司,井上英二,宋正河,朱忠祥. 基于模型实验的拖拉机配置对稳定性的影响差异[J]. 吉林大学学报(工学版), 2019, 49(4): 1236-1245. |

| [13] | 梁方,尤泳,王德成,王光辉,贺长彬,李帅. 运动参数对草地切根刀具与土壤作用关系的影响[J]. 吉林大学学报(工学版), 2019, 49(3): 903-911. |

| [14] | 王扬, 王晓梅, 陈泽仁, 于建群. 基于离散元法的玉米籽粒建模[J]. 吉林大学学报(工学版), 2018, 48(5): 1537-1547. |

| [15] | 陈东辉, 吕建华, 龙刚, 张宇晨, 常志勇. 基于ADAMS的半悬挂式农业机组静侧翻稳定性[J]. 吉林大学学报(工学版), 2018, 48(4): 1176-1183. |

|

||