吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (3): 1121-1130.doi: 10.13229/j.cnki.jdxbgxb20200199

• 农业工程·仿生工程 • 上一篇

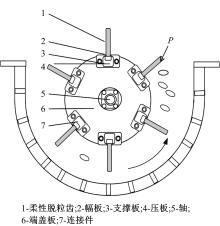

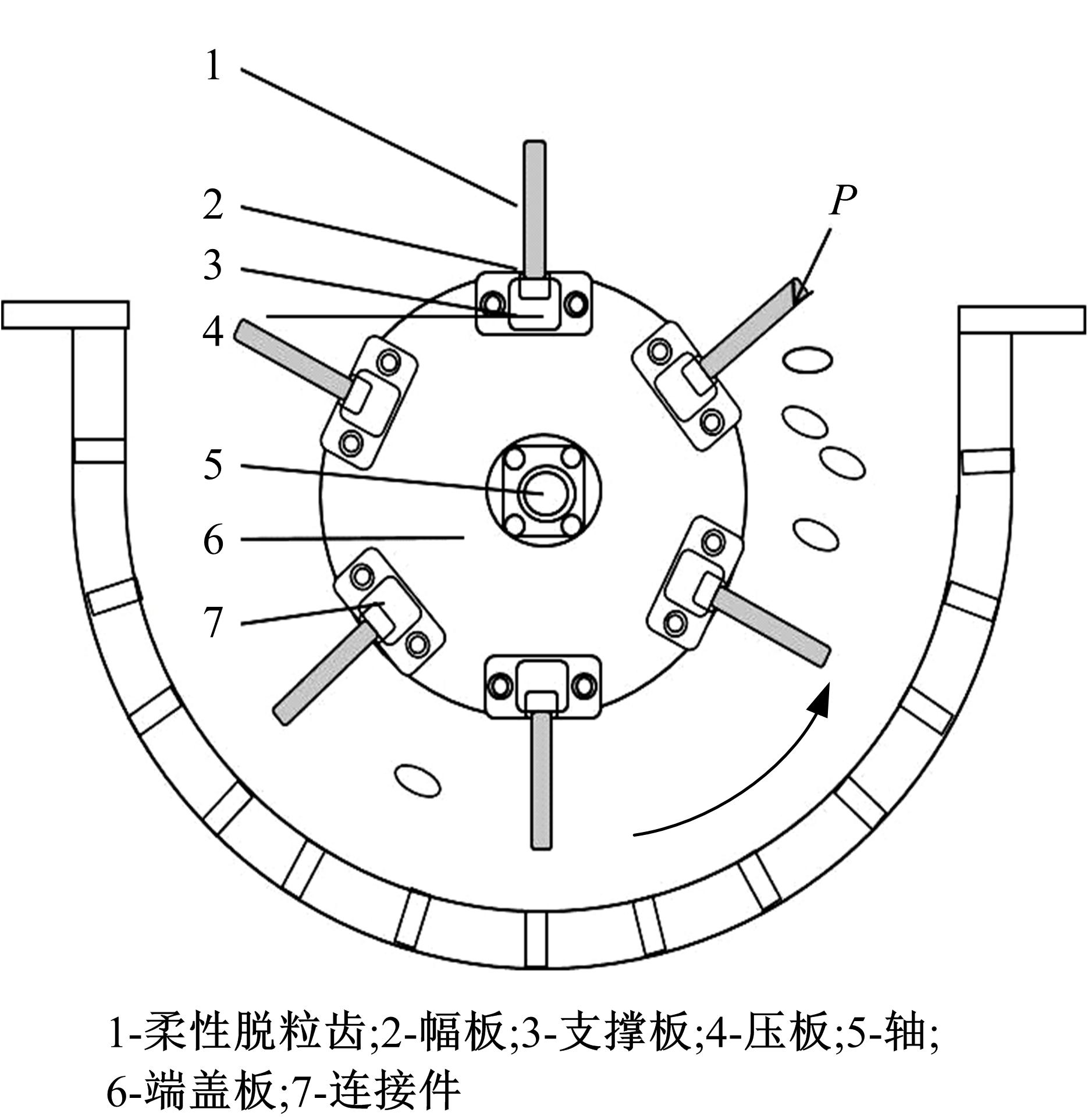

柔性脱粒齿杆与谷物含摩擦打击动力学模型

- 农业农村部 南京农业机械化研究所,南京 210014

Frictional impact dynamics model of threshing process between flexible teeth and grains

Zhen-jie QIAN( ),Cheng-qian JIN(

),Cheng-qian JIN( ),Wen-sheng YUAN,You-liang NI,Guang-yue ZHANG

),Wen-sheng YUAN,You-liang NI,Guang-yue ZHANG

- Nanjing Institute of Agricultural Mechanization,Ministry of Agriculture and Rural Affairs,Nanjing 210014,China

摘要:

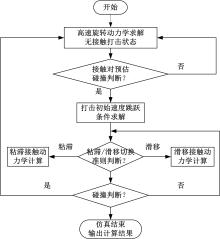

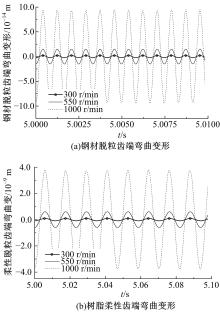

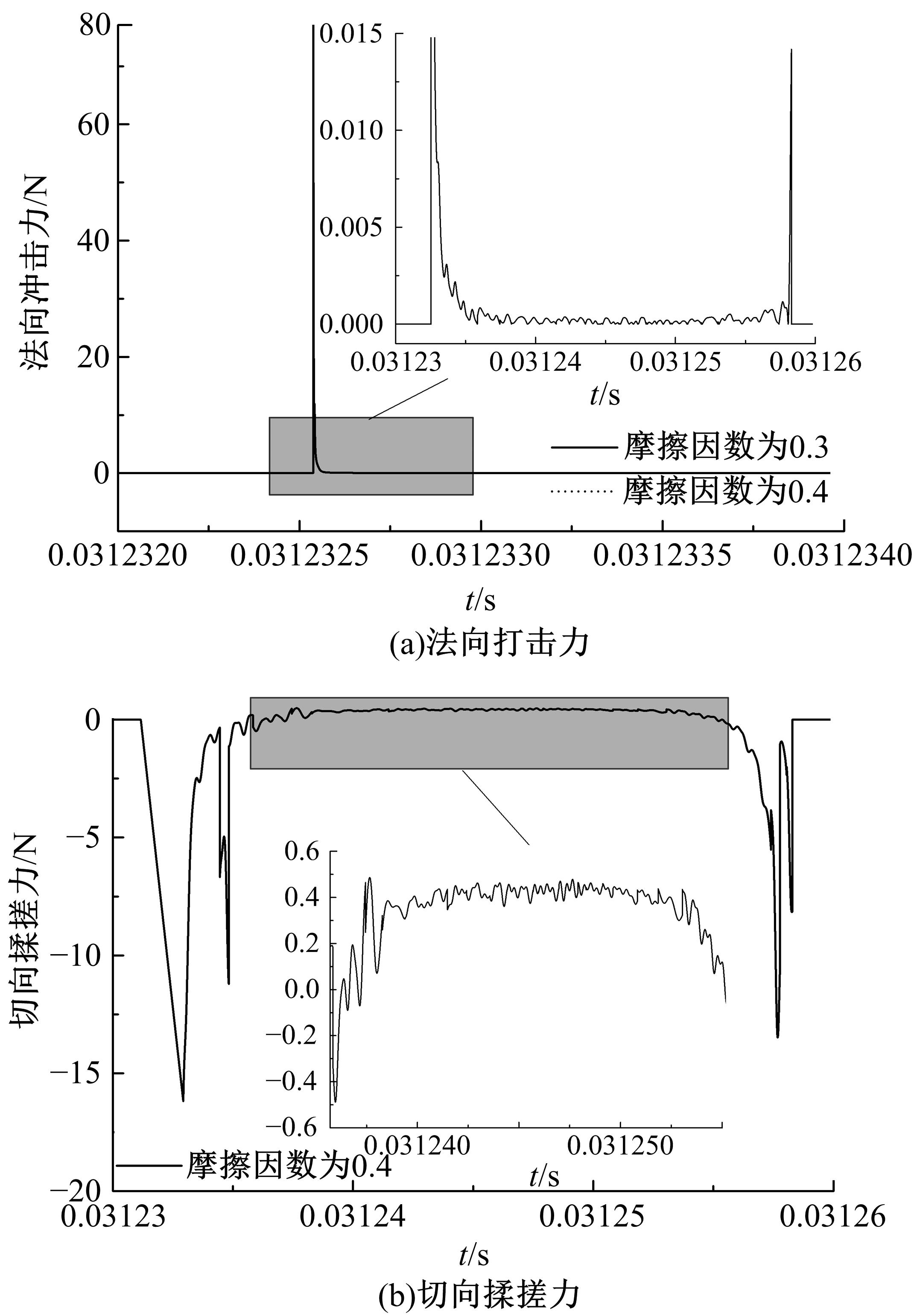

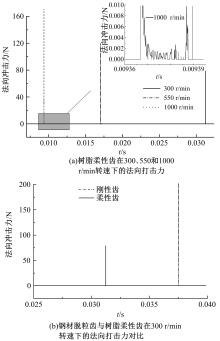

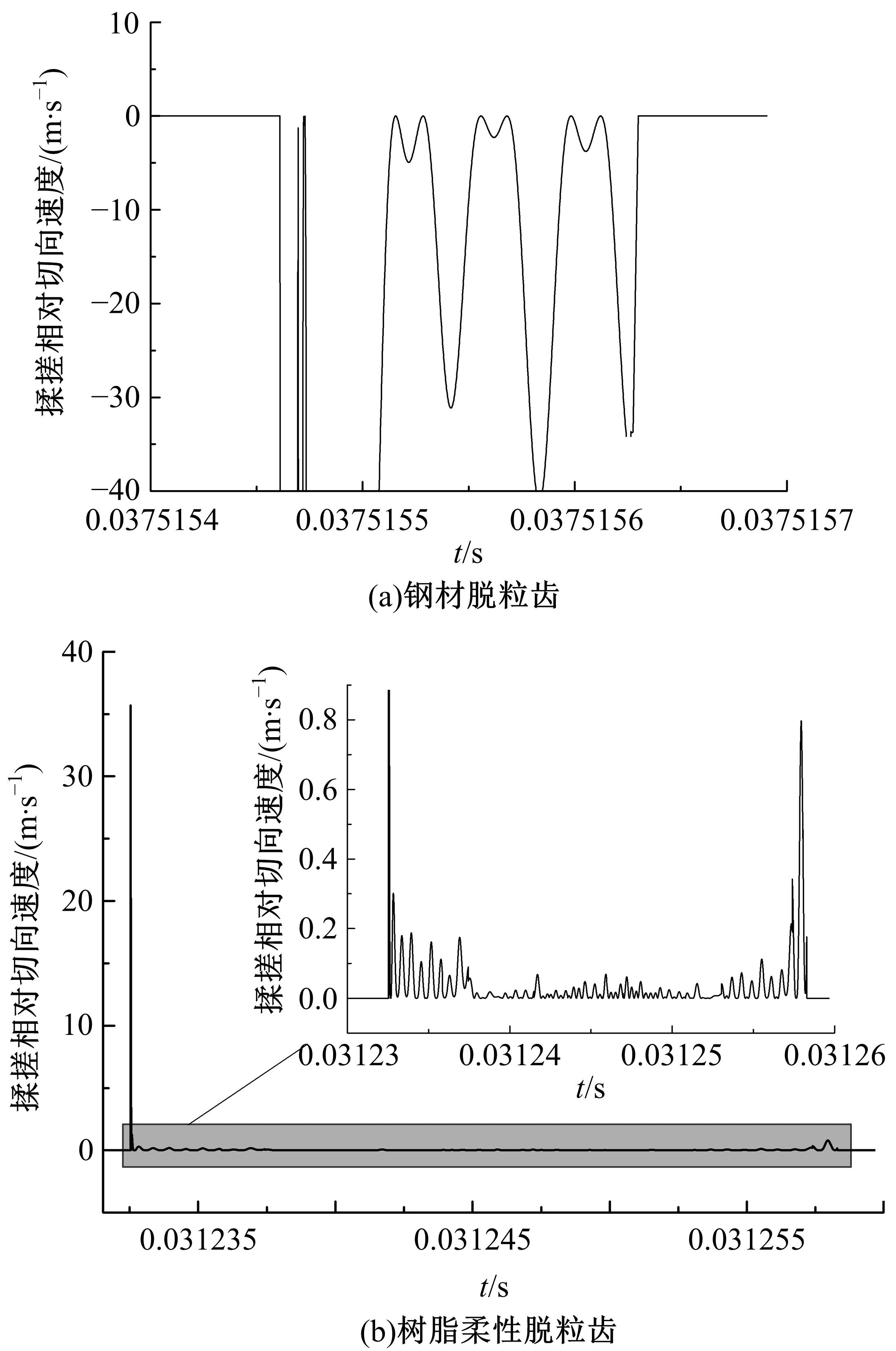

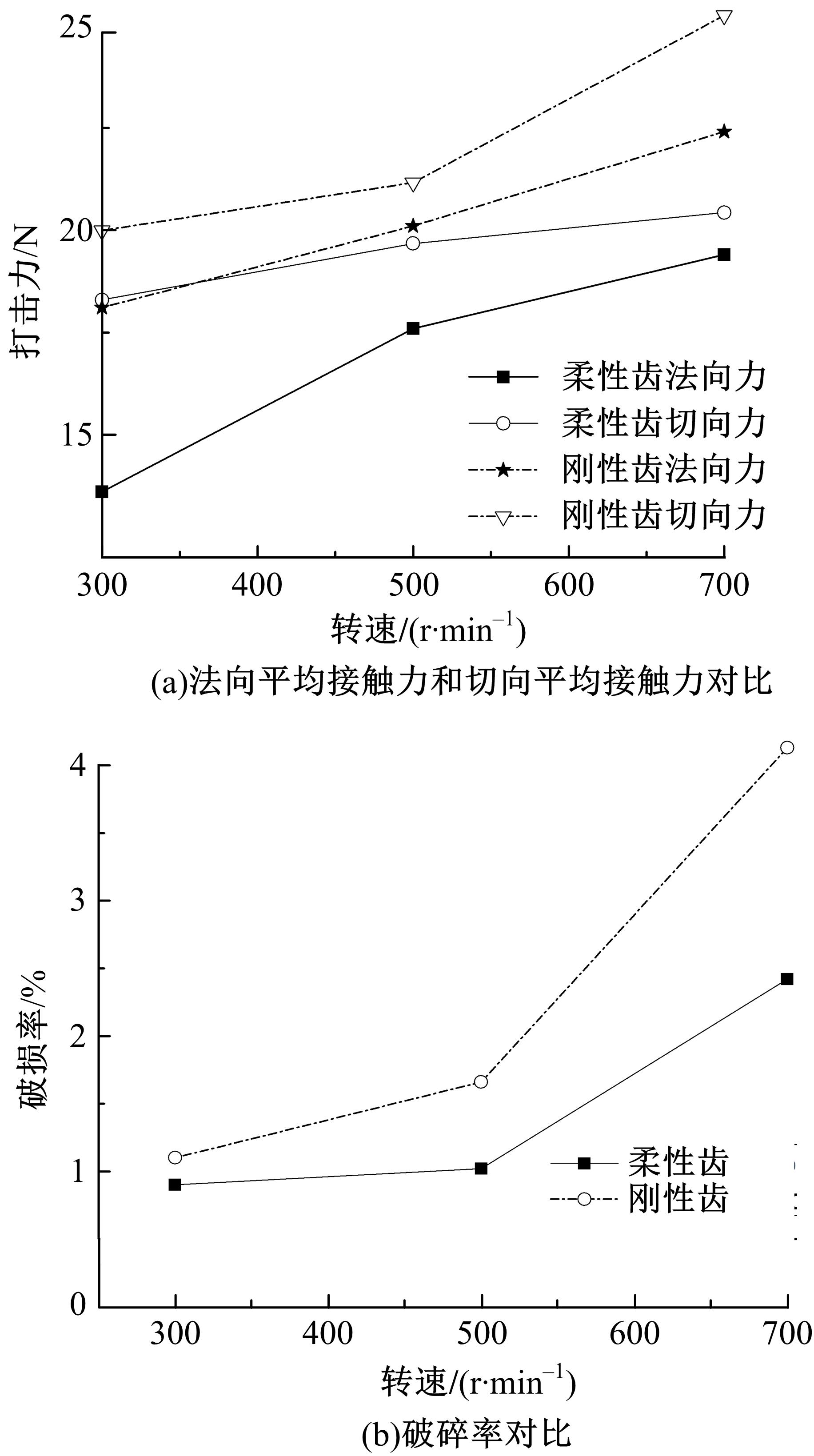

针对联合收割机脱粒过程,结合Lagrange乘子法和多体系统刚柔耦合理论,建立和分析了脱粒齿杆与谷物含摩擦接触的互作用机理的打击动力学模型。将脱粒过程描述为打击初始时刻、黏滞接触、滑移接触等阶段,引入增减接触约束法,分阶段建立动力学方程,并给出了碰撞搜索算法和状态切换准则。通过自行编制的C语言仿真程序,计算获得了不同脱粒滚筒转速下,脱粒齿打击谷物时的法向打击力、切向揉搓力以及在打击过程中脱粒齿的振动和变形。对纵轴流柔性脱粒滚筒模型进行了EDEM软件仿真和试验验证,结果表明:与普通刚性脱粒齿相比,柔性齿在打击中形成一系列持续的法向打击力和多次反复的微小切向揉搓力,有助于提高脱净率和降低籽粒损伤率。

中图分类号:

- S225.3

| 1 | Mesquita C M, Hanna M A. Soya bean threshing mechanics 1: frictional rubbing by flat belts[J]. Transactions of the ASAE, 1993, 36(2):275-279. |

| 2 | Ukatu A C. A modified threshing unit for soya beans[J]. Biosystems Engineering, 2006, 95(3):371-377. |

| 3 | 师清翔, 刘师多, 姬江涛, 等. 水稻的控速喂入柔性脱粒试验研究[J]. 农业机械学报, 1996, 27(1):41-46. |

| Shi Qing-xiang, Liu Shi-duo, Ji Jiang-tao, et a1. Research on speed-controlled feed and soft threshing for rice[J]. Transactions of the Chinese Society of Agricultural Engineering, 1996, 27(1):41-46. | |

| 4 | 任述光, 谢方平, 罗锡文, 等. 柔性齿与刚性齿脱粒水稻功耗比较分析与试验[J]. 农业工程学报, 2013,29(5):12-18. |

| Ren Shu-guang, Xie Fang-ping, Luo Xi-wen, et a1. Analysis and test of power consumption in paddy threshing using flexible and rigid teeth[J]. Transactions of the Chinese Society of Agricultural Engineering, 2013,29(5):12-18. | |

| 5 | 李耀明, 王显仁, 徐立章, 等. 水稻谷粒的挤压力学性能研究[J]. 农业机械学报, 2007, 38(11):56-59. |

| Li Yao-ming, Wang Xian-ren, Xu Li-zhang, et a1. Study on compression properties of rice grains[J]. Transactions of the Chinese Society of Agricultural Engineering, 2007, 38(11):56-59. | |

| 6 | Xu L Z, Li Y M, Ma Z, et al. Theoretical analysis and finite element simulation of a rice kernel obliquely impacted by a threshing tooth[J]. Biosystems Engineering, 2013, 114(2):146-156. |

| 7 | 耿端阳,谭德蕾,于兴瑞,等.玉米柔性脱粒滚筒脱粒元件设计与试验[J].吉林大学学报:工学版,2020,50(5):1923-1933. |

| Geng Duan-yang, Tan De-lei, Yu Xing-rui, et al. Design and test of corn flexible threshing cylinder element[J]. Journal of Jilin University (Engineering and Technology Edition), 2020,50(5):1923-1933. | |

| 8 | 付君,张屹晨,程超,等. 刚柔耦合式小麦脱粒弓齿设计及试验[J]. 吉林大学学报:工学版,2020,50(2):730-738. |

| Fu Jun, Zhang Yi-chen, Cheng Chao, et al. Design and experiment of bow tooth of rigid flexible coupling for wheat threshing[J]. Journal of Jilin University (Engineering and Technology Edition), 2020,50(2):730-738. | |

| 9 | 付宏,吕游,李艳双,等. 基于离散元法的玉米脱粒过程分析[J]. 吉林大学学报:工学版,2012, 42(4):997-1002. |

| Fu Hong, Lyu You, Li Yan-shuang, et a1. Analysis for corn threshing process based DEM[J]. Journal of Jilin University (Engineering and Technology Edition), 2012, 42(4):997-1002. | |

| 10 | 段玥晨,章定国,洪嘉振. 作大范围运动柔性梁的一种碰撞动力学求解方法[J]. 机械工程学报, 2012, 48(19):95-102. |

| Duan Yue-chen, Zhang Ding-guo, Hong Jia-zhen. Method for solving the impact problem of a flexible beam with large overall motion[J]. Journal of Mechanical Engineering, 2012, 48(19):95-102. | |

| 11 | Pfister J, Eberhard P. Frictional contact of flexible and rigid bodies[J]. Granular Matter, 2002, 4(1):25-36. |

| 12 | 任祖方,许乔沼,吴杰,等. 稻谷的机械力学特性试验[J]. 湖北农业科学,2012,51(21):4880-4883. |

| Ren Zu-fang, Xu Qiao-ming, Wu Jie, et al. Research on the mechanical properties of rice kernel [J]. Hubei Agricultural Sciences, 2012,51(21):4880-4883. | |

| 13 | 李耀明,周金芝,徐立章,等. 水稻复脱分离系统脱粒分离性能的试验[J]. 江苏大学学报:自然科学版,2005,26(1):1-4. |

| Li Yao-ming, Zhou Jin-zhi, Xu Li-zhang, et al. Experimental test of grain threshing and separating unit[J]. Journal of Jiangsu University (Natural Science Edition), 2005,26(1):1-4. | |

| 14 | 李耀明,孙夕龙,徐立章. 水稻穗头连接力的试验与分析[J]. 江苏大学学报:自然科学版,2008,29(2):97-100, 105. |

| Li Yao-ming, Sun Xi-long, Xu Li-zhang. Test and analysis on connection force of rice spike[J]. Journal of Jiangsu University (Natural Science Edition), 2008,29(2):97-100, 105. | |

| 15 | 李杰,阎楚良,杨方飞. 纵向轴流脱粒装置的理论模型与仿真[J]. 江苏大学学报:自然科学版,2006,27(4):299-302. |

| Li Jie, Yan Chu-liang, Yang Fang-fei. Theoretical model and simulation of threshing of axial unit with axial feeding[J]. Journal of Jiangsu University (Natural Science Edition), 2006,27(4):299-302. | |

| 16 | Leine R I, Campen D H V, Glocker C H. Nonlinear dynamics and modeling of various wooden toys with impact and friction[J]. Journal of Vibration and Control, 2003, 9(1/2):25-78. |

| 17 | Qian Zhen-jie, Zhang Ding-guo, Jin Cheng-qian. A regularized approach for frictional impact dynamics of flexible multi-link manipulator arms considering the dynamic stiffening effect[J]. Multibody System Dynamics, 2017, 17(4):229-255. |

| 18 | 张烨, 李长友, 李建民,等. 稻谷摩擦特性研究[J]. 广东农业科学, 2011, 38(13):15-17. |

| Zhang Ye, Li Chang-you, Li Jian-min, et al. Experimental study on frictional characteristic of grain[J]. Guangdong Agricultural Sciences, 2011, 38(13):15-17. | |

| 19 | 冯家畅, 程绪铎, 严晓婕. 大豆与仓壁材料摩擦因数的研究[J]. 大豆科学, 2014, 33(5): 787-794. |

| Feng Jia-chang, Cheng Xu-duo, Yan Xiao-jie. Research on the coefficient of friction between soybean and silo wall material[J]. Soybean Science, 2014, 33(5):787-794. | |

| 20 | 杨明芳. 基于离散元法的玉米排种器的数字化设计方法研究[D]. 长春: 吉林大学生物与农业工程学院, 2009. |

| Yang Ming-fang. Study on digital design method of corn seed-metering device based on DEM[D]. Changchun:College of Biological and Agricultural Engineering, Jilin University, 2009. | |

| 21 | 崔涛,刘佳,杨丽, 等. 基于高速摄像的玉米种子滚动摩擦特性试验与仿真[J]. 农业工程学报,2013, 29(15):34-41. |

| Cui Tao, Liu Jia, Yang Li, et al. Experiment and simulation of rolling friction characteristic of corn seed based on high-speed photography[J]. Transactions of the Chinese Society of Agricultural Engineering, 2013, 29(15):34-41. | |

| 22 | Yu Y, Fu H, Yu J. Dem-based simulation of the corn threshing process[J]. Advanced Powder Technology, 2015, 26(5):1400-1409. |

| 23 | 陈艳普,康艳,王廷恩,等.大豆收获机纵轴流柔性脱粒装置脱出物分布规律[J]. 中国农业大学学报, 2020,25(9):104-111. |

| Chen Yan-pu, Kang Yan, Wang Ting-en, et al. Distribution regularities of the threshed mixtures in longitudinal axial flow flexible thresher of soybean harvester[J]. Journal of China Agricultural University, 2020, 25(9):104-111. |

| [1] | 丛茜,徐金,马博帅,张晓超,陈廷坤. 基于虚拟仿真的拖拉机后悬挂检测装置设计与实验[J]. 吉林大学学报(工学版), 2021, 51(2): 754-760. |

| [2] | 程超,付君,陈志,任露泉. 玉米籽粒收获机清选筛堵塞规律及脱附试验[J]. 吉林大学学报(工学版), 2021, 51(2): 761-771. |

| [3] | 陈学深,黄柱健,马旭,齐龙,方贵进. 水稻机械除草避苗控制系统设计与试验[J]. 吉林大学学报(工学版), 2021, 51(1): 386-396. |

| [4] | 耿端阳,谭德蕾,于兴瑞,苏国粱,王骞,鹿秀凤,金诚谦. 玉米柔性脱粒滚筒脱粒元件设计与试验[J]. 吉林大学学报(工学版), 2020, 50(5): 1923-1933. |

| [5] | 高锐涛,单建,杨洲,文晟,兰玉彬,张泉勇,汪洋. 植保无人机变量喷雾处方图实时解译系统的设计与试验[J]. 吉林大学学报(工学版), 2020, 50(1): 361-374. |

| [6] | 刘恩泽,吴文福. 基于综合指标品质评价算法的单色水果生长状态检测互联网架构[J]. 吉林大学学报(工学版), 2019, 49(6): 2019-2026. |

| [7] | 秦嘉浩,李臻,光岡宗司,井上英二,宋正河,朱忠祥. 基于模型实验的拖拉机配置对稳定性的影响差异[J]. 吉林大学学报(工学版), 2019, 49(4): 1236-1245. |

| [8] | 梁方,尤泳,王德成,王光辉,贺长彬,李帅. 运动参数对草地切根刀具与土壤作用关系的影响[J]. 吉林大学学报(工学版), 2019, 49(3): 903-911. |

| [9] | 王扬, 王晓梅, 陈泽仁, 于建群. 基于离散元法的玉米籽粒建模[J]. 吉林大学学报(工学版), 2018, 48(5): 1537-1547. |

| [10] | 陈东辉, 吕建华, 龙刚, 张宇晨, 常志勇. 基于ADAMS的半悬挂式农业机组静侧翻稳定性[J]. 吉林大学学报(工学版), 2018, 48(4): 1176-1183. |

| [11] | 贾洪雷, 王万鹏, 陈志, 庄健, 王文君, 刘慧力. 基于土壤坚实度的仿形弹性镇压辊镇压力实时测量方法[J]. 吉林大学学报(工学版), 2018, 48(4): 1169-1175. |

| [12] | 王扬, 吕凤妍, 徐天月, 于建群. 大豆籽粒形状和尺寸分析及其建模[J]. 吉林大学学报(工学版), 2018, 48(2): 507-517. |

| [13] | 贾洪雷, 郑嘉鑫, 袁洪方, 郭明卓, 王文君, 于路路. 大豆播种机双V型筑沟器设计与试验[J]. 吉林大学学报(工学版), 2017, 47(1): 323-331. |

| [14] | 肖志锋, 乐建波, 吴南星, 刘相东. 操作压力对过热蒸汽流化床干燥的影响[J]. 吉林大学学报(工学版), 2015, 45(4): 1375-1380. |

| [15] | 张金波,佟金,马云海. 仿生肋条结构表面深松铲刃的磨料磨损特性[J]. 吉林大学学报(工学版), 2015, 45(1): 174-180. |

|

||