吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (2): 761-771.doi: 10.13229/j.cnki.jdxbgxb20191186

• 农业工程·仿生工程 • 上一篇

玉米籽粒收获机清选筛堵塞规律及脱附试验

- 1.吉林大学 工程仿生教育部重点实验室,长春 130025

2.吉林大学 生物与农业工程学院,长春 130025

3.中国农业机械化科学研究院,北京 100083

Sieve blocking laws and stripping test of corn grain harvester

Chao CHENG1,2( ),Jun FU1,2(

),Jun FU1,2( ),Zhi CHEN2,3,Lu-quan REN1,2

),Zhi CHEN2,3,Lu-quan REN1,2

- 1.Key Laboratory of Bionic Engineering,Ministry of Education,Jilin University,Changchun 130022,China

2.College of Biological and Agricultural Engineering,Jilin University,Changchun 130022,China

3.Chinese Academy of Agricultural Mechanization Sciences,Beijing 100083,China

摘要:

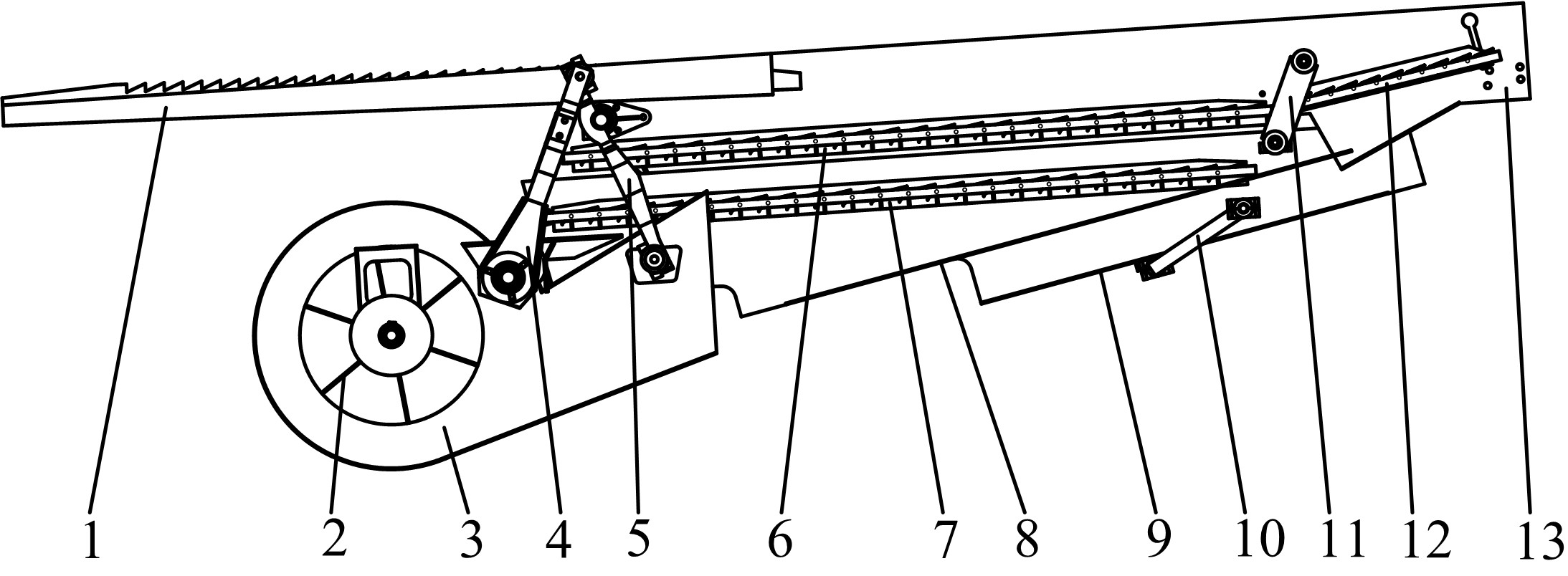

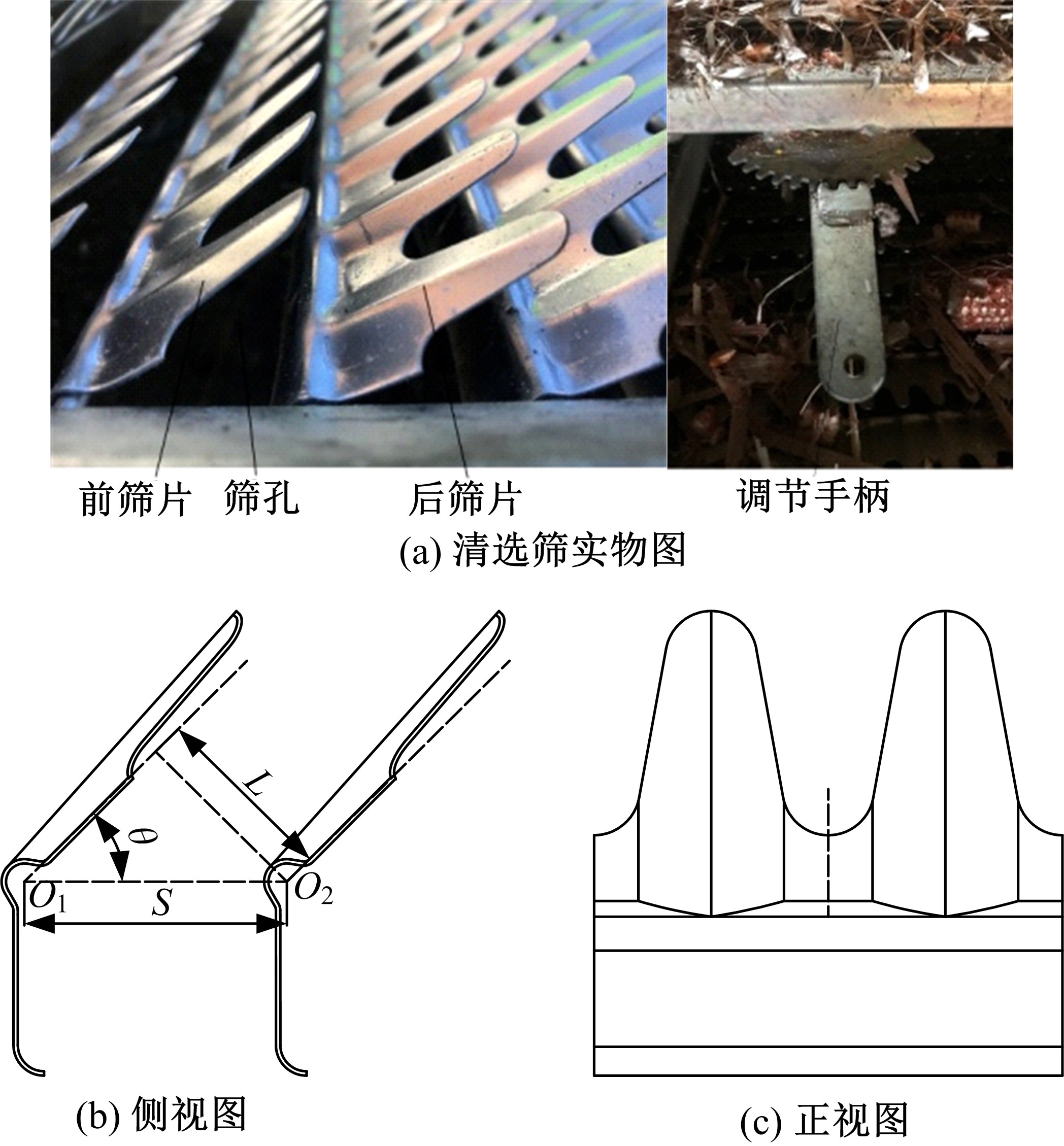

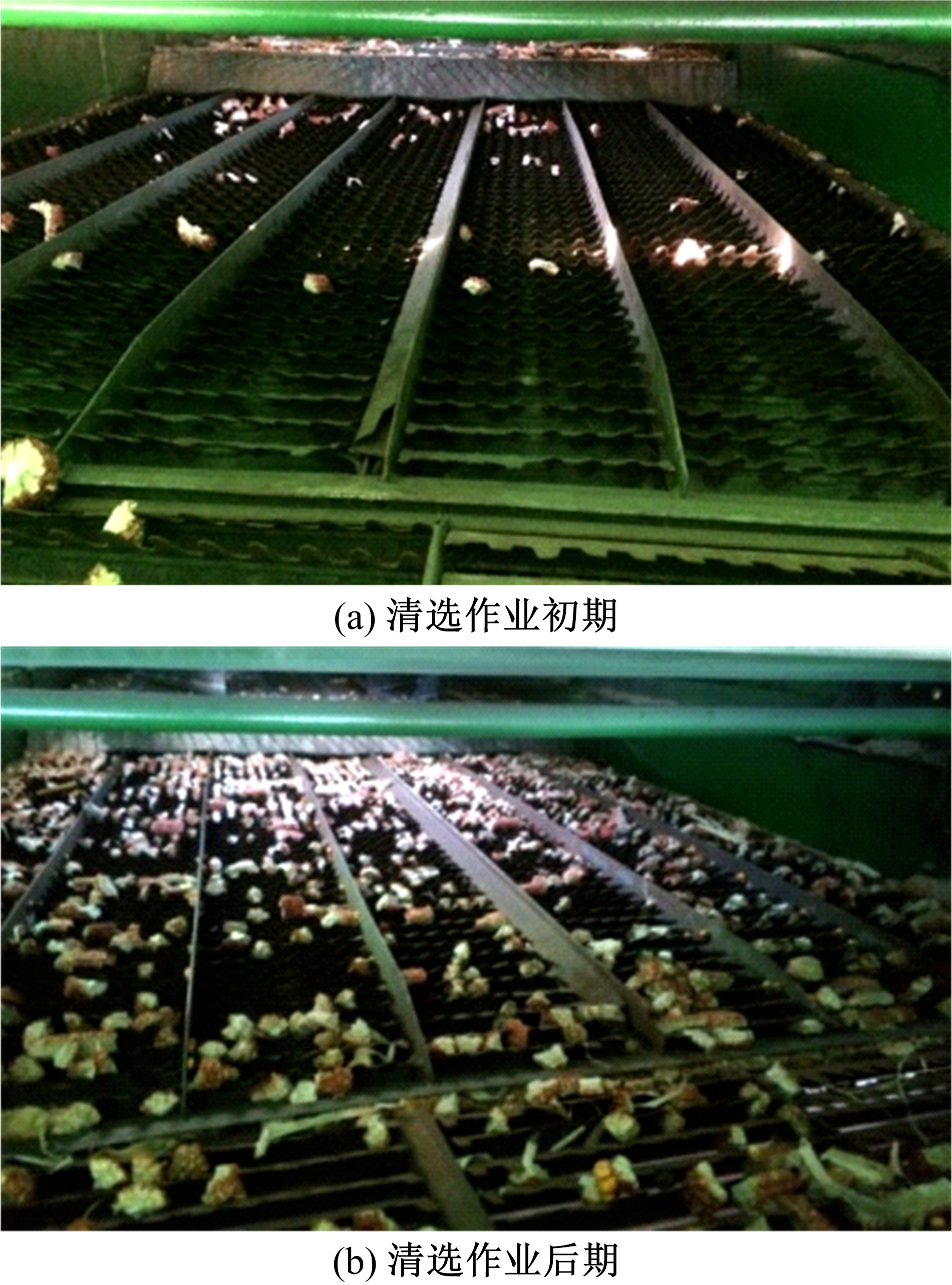

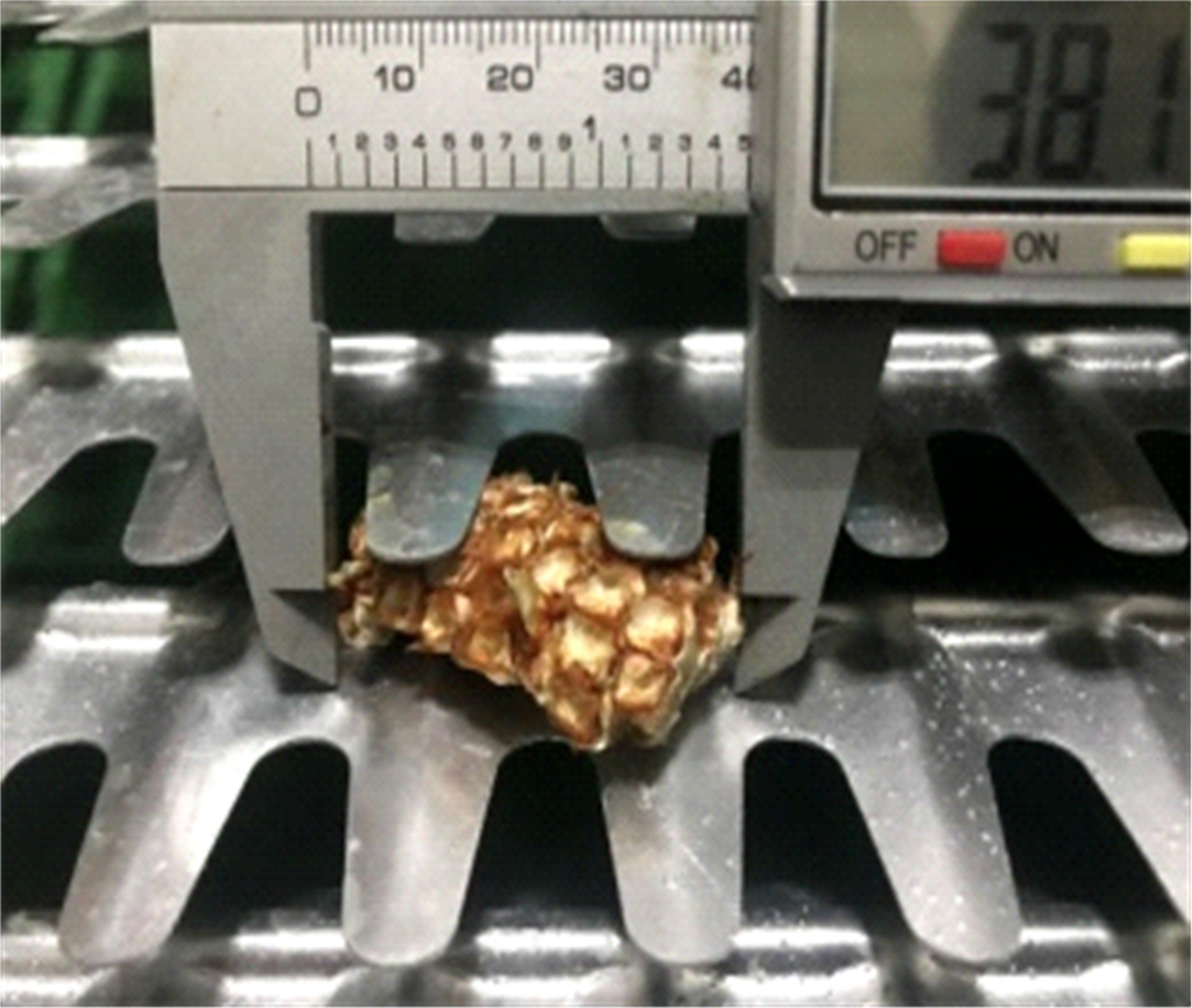

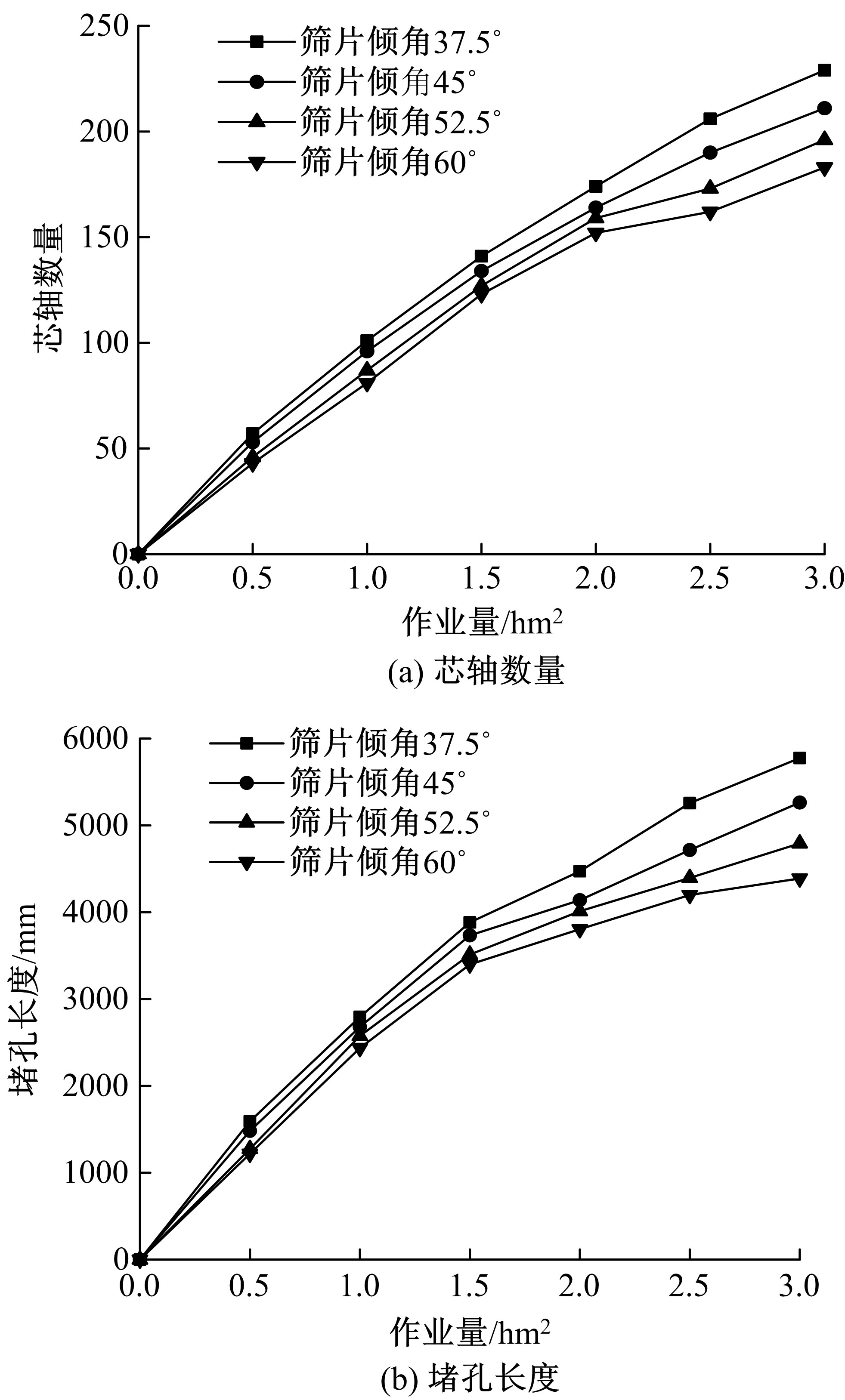

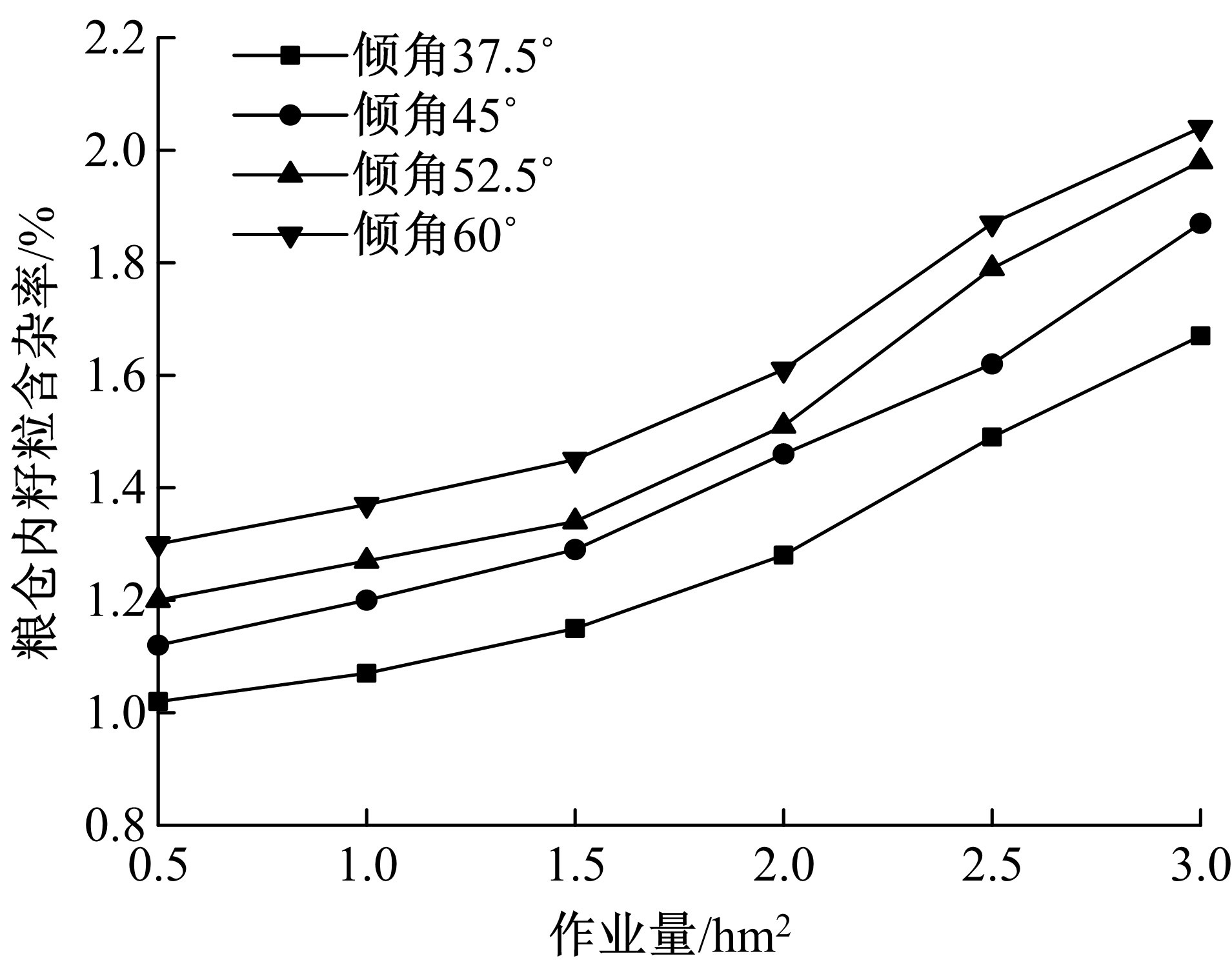

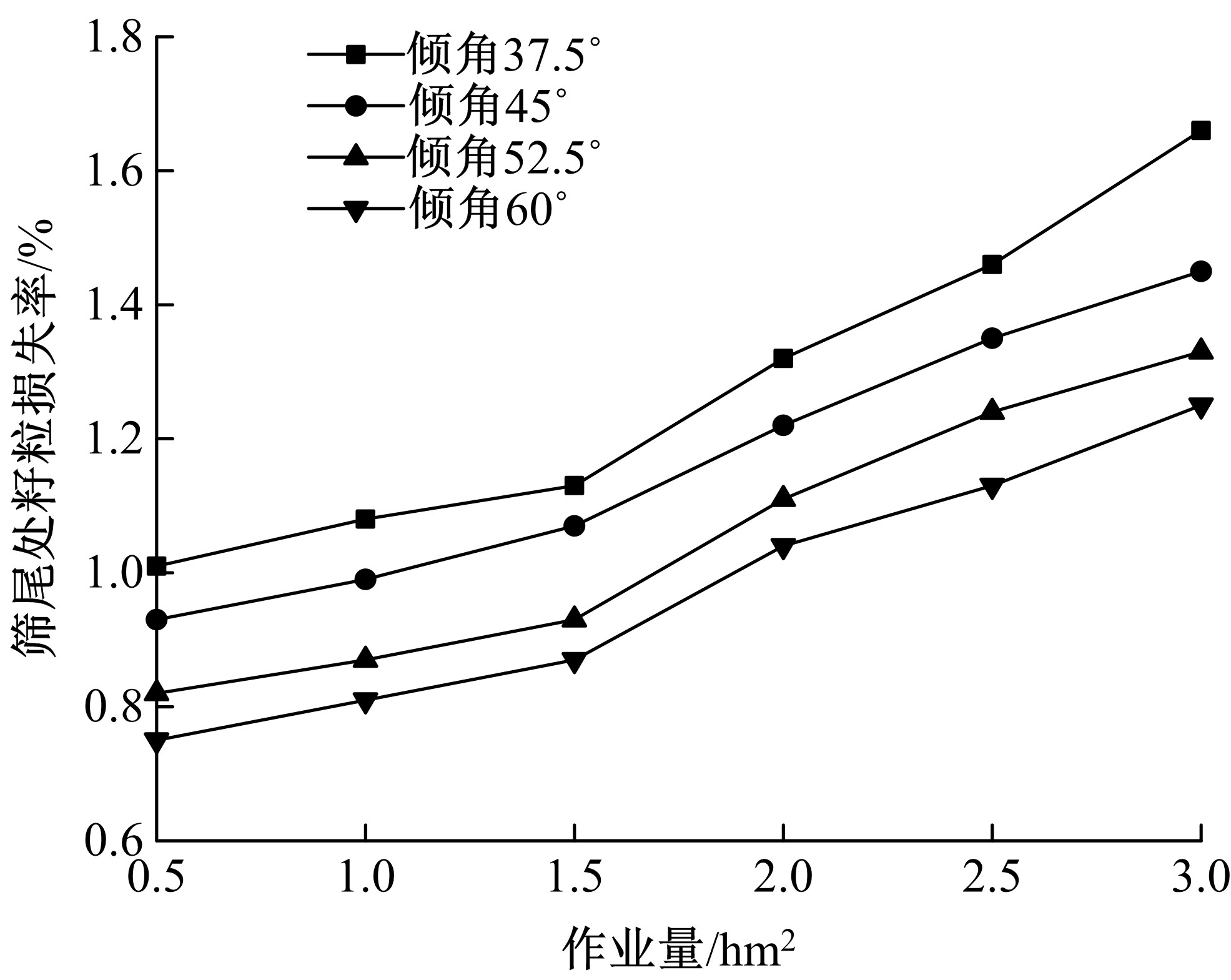

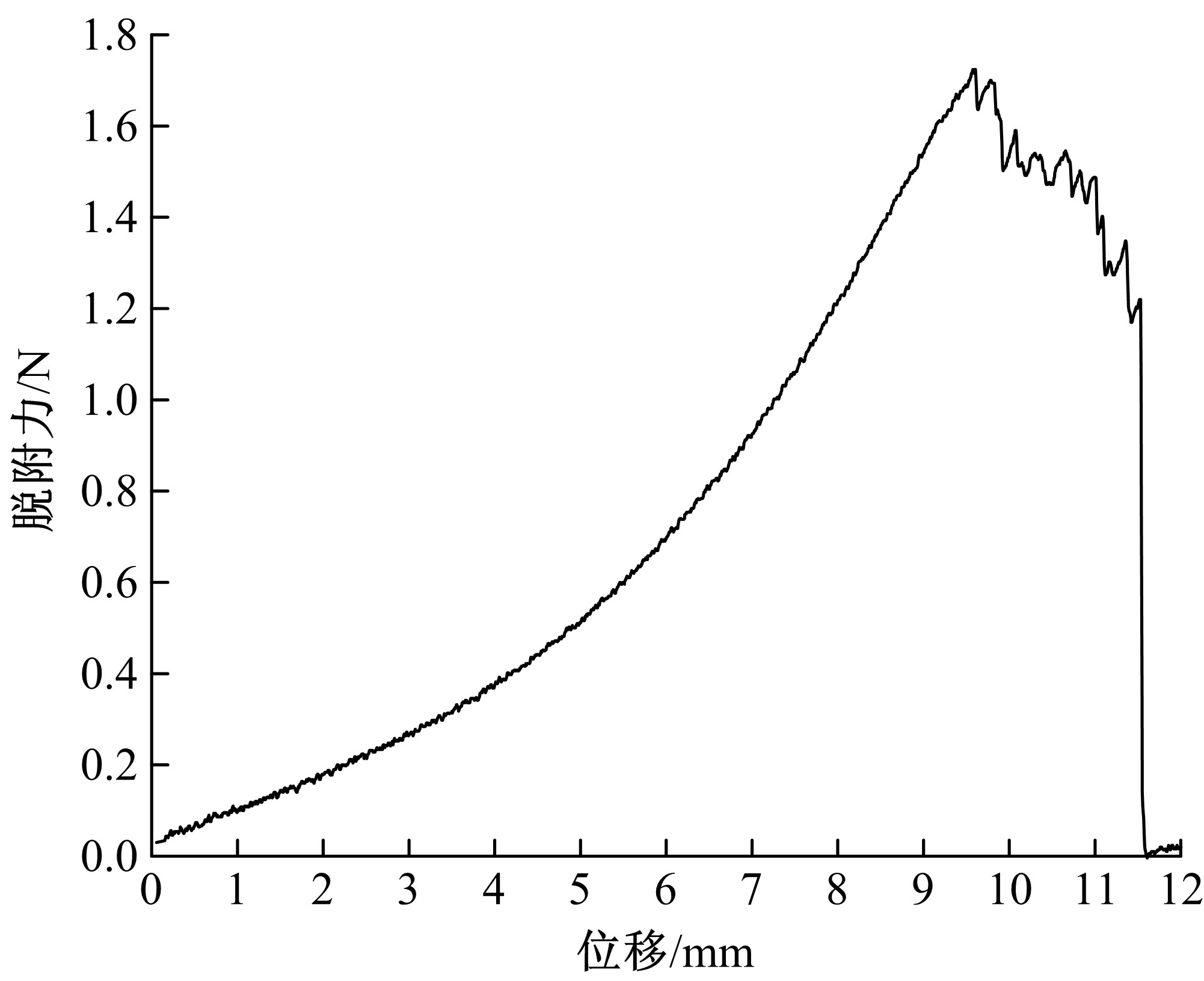

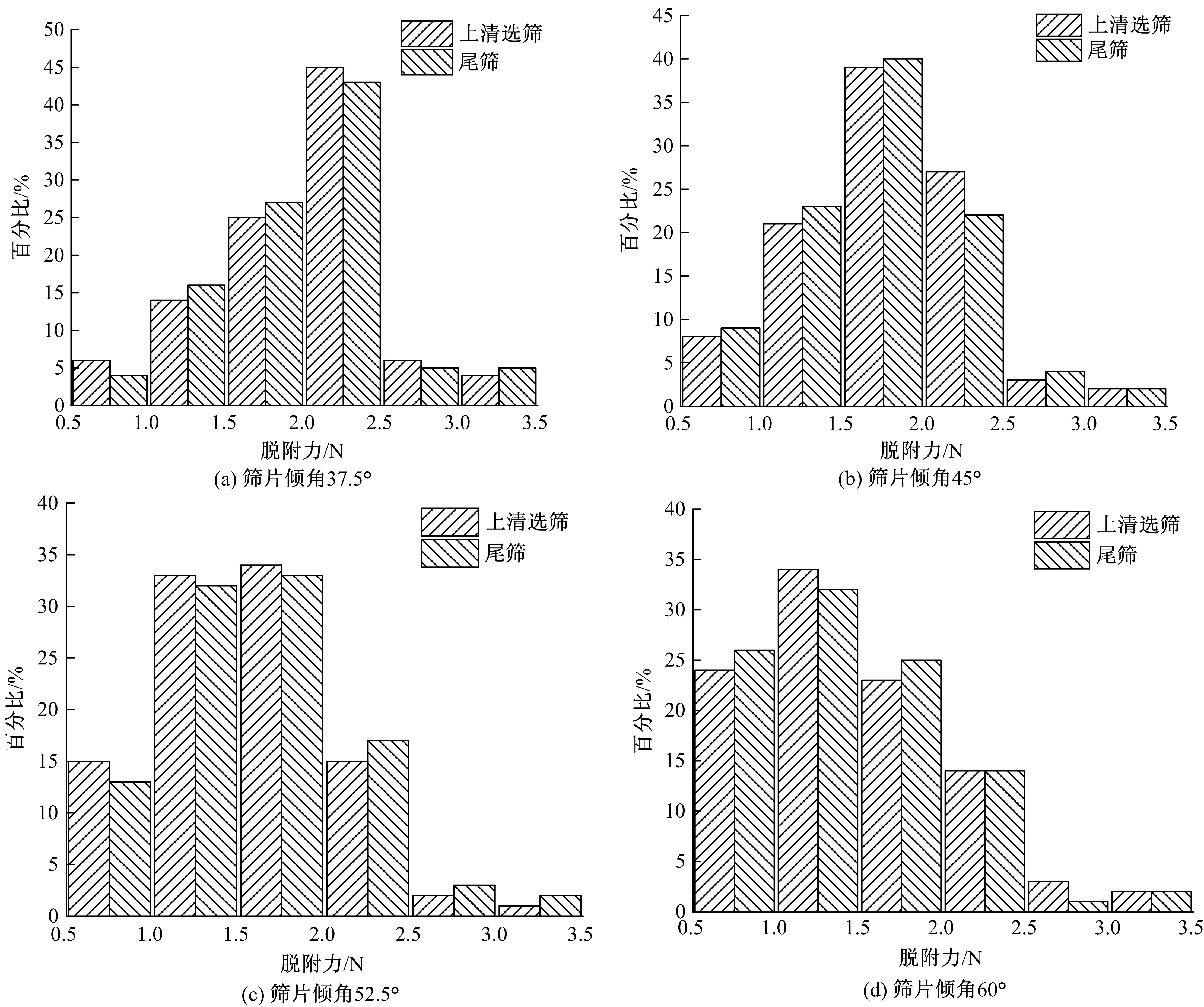

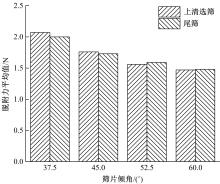

针对玉米籽粒收获机清选筛堵塞引发清选作业质量降低的问题,选取筛片倾角37.5°、45°、52.5°、60°四组筛孔开度的鱼鳞筛,开展清选筛堵塞规律和脱附田间试验。作业量为1.5 hm2时,上清选筛的堵孔比例分别为7.89%、7.59%、7.14%、6.91%,尾筛的堵孔比例分别为8.07%、7.81%、7.49%、6.78%,粮仓内籽粒含杂率分别为1.15%、1.29%、1.34%、1.45%,筛尾处籽粒损失率分别为1.13%、1.07%、0.93%、0.87%;上清选筛堵塞玉米芯轴的脱附力平均值分别为2.07、1.76、1.56、1.47 N,尾筛堵塞玉米芯轴脱附力平均值分别为2、1.73、1.59、1.48 N。

中图分类号:

- S225.5

| 1 | 陈志. 玉米全价值收获关键技术与装备[M]. 北京: 科学出版社,2014. |

| 2 | 陈志, 郝付平, 王锋德, 等. 中国玉米收获技术与装备发展研究[J].农业机械学报, 2012, 43(12): 44-50. |

| Chen Zhi, Hao Fu-ping, Wang Feng-de, et al. Development of technology and equipment of corn harvester in China[J]. Transactions of the Chinese Society for Agricultural Machinery, 2012, 43(12): 44-50. | |

| 3 | 程超, 付君, 陈志, 等. 玉米籽粒收获机清选装置参数优化试验[J]. 农业机械学报, 2019, 50(7): 151-158. |

| Cheng Chao, Fu Jun, Chen Zhi, et al. Optimization experiment on cleaning device parameters of corn kernel harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(7): 151-158. | |

| 4 | 王卓, 车东, 白晓平, 等. 玉米联合收获机清选损失监测装置设计与试验[J]. 农业机械学报, 2018, 49(12): 100-108. |

| Wang Zhuo, Che Dong, Bai Xiao-ping, et al. Improvement and experiment of cleaning loss rate monitoring device for corn combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(12): 100-108. | |

| 5 | 李耀明, 王智华, 徐立章, 等. 油菜脱出物振动筛分运动分析及试验研究[J]. 农业工程学报, 2007, 23(9): 111-114. |

| Li Yao-ming, Wang Zhi-hua, Xu Li-zhang, et al. Motion analysis and experimental research of rape extractions on vibration sieve[J]. Transactions of the Chinese Society of Agricultural Engineering, 2007, 23(9): 111-114. | |

| 6 | 李立君, 胡文宇, 高自成, 等. 曲柄摇杆振动破壳油茶果粗选机运动学分析及试验[J]. 农业工程学报, 2016, 32(7): 28-35. |

| Li Li-jun, Hu Wen-yu, Gao Zi-cheng, et al. Kinematics analysis and experiment of crank rocker vibrating coarse sorting machine for unshelled oil-tea fruit[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(7): 28-35. | |

| 7 | 李洪昌, 李耀明, 唐忠, 等. 基于EDEM的振动筛分数值模拟与分析[J]. 农业工程学报, 2011, 27(5): 117-121. |

| Li Hong-chang, Li Yao-ming, Tang Zhong, et al. Numerical simulation and analysis of vibration screening based on EDEM[J]. Transactions of the Chinese Society of Agricultural Engineering, 2011, 27(5): 117-121. | |

| 8 | 李杰, 闫楚良, 杨方飞. 联合收割机振动筛的动态仿真与参数优化[J]. 吉林大学学报: 工学版, 2006, 36(5): 701-704. |

| Li Jie, Yan Chu-liang, Yang Fang-fei. Dynamic smiulation and parameter optmiization of the combine harvester vibration sieve[J]. Journal of Jilin University(Engineering and Technology Edition), 2006, 36(5): 701-704. | |

| 9 | 洪美琴. 联合收割机脱粒系统中振动筛的动力学分析[J]. 农机化研究, 2012, 34(5): 79-82. |

| Hong Mei-qin. The dynamics analysis of vibrating sieve in threshing system of combine harvester[J]. Journal of Agricultural Mechanization Research, 2012, 34(5): 79-82. | |

| 10 | 王立军, 张传根, 丁振军. 玉米收获机清选筛体结构优化[J]. 农业机械学报, 2016, 47(9): 108-114. |

| Wang Li-jun, Zhang Chuan-gen, Ding Zhen-jun. Structure optimization of cleaning screen for maize harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(9): 108-114. | |

| 11 | 王立军, 冯鑫, 武振超, 等. 玉米联合收获机贯流风阶梯式振动筛设计与试验[J]. 农业机械学报, 2018, 49(10): 115-123. |

| Wang Li-jun, Feng Xin, Wu Zhen-chao, et al. Design and test of stepped vibrating screen with cross air for maize harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(10): 115-123. | |

| 12 | 王立军, 武振超, 冯鑫, 等. 玉米收获机清选曲面筛设计与试验[J].农业机械学报, 2019, 50(2): 90-101. |

| Wang Li-jun, Wu Zhen-chao, Feng Xin, et al. Design and experiment of curved screen for maize grain harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(2): 90-101. | |

| 13 | 吴晓秋. 曲面筛筛面形状与筛分参数优化研究[D]. 泉州: 华侨大学机电及自动化学院, 2018. |

| Wu Xiao-qiu. Study on screen surface shape and screening parameters optimization of the curved screen[D]. Quanzhou: College of Mechanical Engineering and Automation, Huaqiao University, 2018. | |

| 14 | Wang L J, Ding Z J, Meng S, et al. Kinematics and dynamics of a particle on a non-simple harmonic vibrating screen[J]. Particuology, 2017, 32: 167-177. |

| 15 | Jiang H S, Zhao Y M, Duan C L, et al. Dynamic characteristics of an equal-thickness screen with a variable amplitude and screening analysis[J]. Powder Technology, 2017, 311: 239-246. |

| 16 | Ma Z, Li Y M, Xu L Z. Discrete-element method simulation of agricultural particles' motion in variable-amplitude screen box[J]. Computers and Electronics in Agriculture, 2015, 118: 92-99. |

| 17 | 王立军, 段良坤, 郑招辉, 等. 三移动两转动振动筛驱动机构优化与试验[J]. 农业机械学报, 2018, 49(6): 138-145. |

| Wang Li-jun, Duan Liang-kun, Zheng Zhao-hui, et al. Optimization and experiment on driving mechanism of vibrating screen with three translations and two rotations[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(6): 138-145. | |

| 18 | 李耀明, 刘晓飞, 马征, 等.不同支链初始相位的三维并联筛分性能研究[J]. 农业机械学报, 2017, 48(9): 88-95. |

| Li Yao-ming, Liu Xiao-fei, Ma Zheng, et al. Investigation on three-dimensional parallel screening performance based on initial phase of different branches[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(9): 88-95. | |

| 19 | 王成军, 李耀明, 马履中, 等. 3自由度混联振动筛设计[J]. 农业机械学报, 2011, 42(): 69-73. |

| Wang Cheng-jun, Li Yao-ming, Ma Lü-zhong, et al. Design of three degree of freedom hybrid vibration screen[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(Sup.l): 69-73. | |

| 20 | 李耀明, 马征, 徐立章. 油菜联合收获机筛面粘附物摩擦特性[J]. 农业机械学报, 2010, 41(12): 54-57. |

| Li Yao-ming, Ma Zheng, Xu Li-zhang. Tribological characteristics of adhesive materials on cleaning sieve of rape combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(12): 54-57. | |

| 21 | 李耀明, 马征, 徐立章. 油菜混合物与仿生筛面基体间的粘附特性[J]. 农业机械学报, 2012, 43(2): 75-78. |

| Li Yao-ming, Ma Zheng, Xu Li-zhang. Adhesion property between rape mixture and bionic screen matrix[J]. Transactions of the Chinese Society for Agricultural Machinery, 2012, 43(2): 75-78. | |

| 22 | 程超, 付君, 陈志, 等. 收获机振动筛振动参数影响不同湿度脱出物粘附特性[J]. 农业工程学报, 2019, 35(8): 29-36. |

| Cheng Chao, Fu Jun, Chen Zhi, et al. Effect of vibration parameters of vibrating screen for harvester on adhesion characteristics of threshed mixtures with different moistures[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(8): 29-36. | |

| 23 | 程超, 付君, 唐心龙, 等. 振动形式对水稻脱出物界面粘附规律的影响[J]. 吉林大学学报: 工学版, 2019, 49(4): 1128-1235. |

| Cheng Chao, Fu Jun, Tang Xin-long, et al. Effects of vibration mode on interface adhesion law of rice threshed mixtures[J]. Journal of Jilin University (Engineering and Technology Edition), 2019, 49(4): 1228-1235. | |

| 24 | 程超, 付君, 唐心龙, 等. 水稻收获机械抖动板加热脱附试验研究[J]. 农业机械学报, 2019, 50(6): 110-118. |

| Cheng Chao, Fu Jun, Tang Xin-long, et al. Heating anti-adhesion experiments of jitter plate of rice harvesting machinery[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(6): 110-118. | |

| 25 | 赵跃民, 陈惜明, 朱红. 潮湿细粒物料的透筛粘附模型[J]. 中国矿业大学学报, 2000, 29(2): 120-124. |

| Zhao Yue-min, Chen Xi-ming, Zhu Hong. Adhesive model of screening fine moist materials[J]. Journal of China University of Mining and Technology, 2000, 29(2): 120-124. | |

| 26 | 陶秀祥, 赵跃民, 杨国华, 等. 潮湿细粒煤炭筛分过程堵孔机理的研究[J]. 煤炭学报, 2000, 25(2): 196-199. |

| Tao Xiu-xiang, Zhao Yue-min, Yang Guo-hua,et al. Study on the mechanism of aperture blinding in the screening of moist fine coal[J]. Journal of China Coal Society, 2000, 25(2): 196-199. | |

| 27 | . 玉米机械试验方法[S]. |

| 28 | 李耀明. 谷物联合收割机的设计与分析[M]. 北京: 机械工业出版社, 2014. |

| 29 | 刘克毅, 王维新. 统收式采棉机风送系统设计及研究[J]. 农机化研究, 2011, 33(5): 115-118. |

| Liu Ke-yi, Wang Wei-xin. Design and research of closed-type cotton pickers air flow system[J]. Journal of Agricultural Mechanization Research, 2011, 33(5):115-118. |

| [1] | 丛茜,徐金,马博帅,张晓超,陈廷坤. 基于虚拟仿真的拖拉机后悬挂检测装置设计与实验[J]. 吉林大学学报(工学版), 2021, 51(2): 754-760. |

| [2] | 陈学深,黄柱健,马旭,齐龙,方贵进. 水稻机械除草避苗控制系统设计与试验[J]. 吉林大学学报(工学版), 2021, 51(1): 386-396. |

| [3] | 耿端阳,谭德蕾,于兴瑞,苏国粱,王骞,鹿秀凤,金诚谦. 玉米柔性脱粒滚筒脱粒元件设计与试验[J]. 吉林大学学报(工学版), 2020, 50(5): 1923-1933. |

| [4] | 高锐涛,单建,杨洲,文晟,兰玉彬,张泉勇,汪洋. 植保无人机变量喷雾处方图实时解译系统的设计与试验[J]. 吉林大学学报(工学版), 2020, 50(1): 361-374. |

| [5] | 程超,付君,郝付平,陈志,周德义,任露泉. 清选筛运动参数对玉米芯轴堵筛规律的影响[J]. 吉林大学学报(工学版), 2020, 50(1): 351-360. |

| [6] | 刘恩泽,吴文福. 基于综合指标品质评价算法的单色水果生长状态检测互联网架构[J]. 吉林大学学报(工学版), 2019, 49(6): 2019-2026. |

| [7] | 程超,付君,唐心龙,陈志,任露泉. 振动形式对水稻脱出物界面粘附规律的影响[J]. 吉林大学学报(工学版), 2019, 49(4): 1228-1235. |

| [8] | 秦嘉浩,李臻,光岡宗司,井上英二,宋正河,朱忠祥. 基于模型实验的拖拉机配置对稳定性的影响差异[J]. 吉林大学学报(工学版), 2019, 49(4): 1236-1245. |

| [9] | 梁方,尤泳,王德成,王光辉,贺长彬,李帅. 运动参数对草地切根刀具与土壤作用关系的影响[J]. 吉林大学学报(工学版), 2019, 49(3): 903-911. |

| [10] | 王扬, 王晓梅, 陈泽仁, 于建群. 基于离散元法的玉米籽粒建模[J]. 吉林大学学报(工学版), 2018, 48(5): 1537-1547. |

| [11] | 陈东辉, 吕建华, 龙刚, 张宇晨, 常志勇. 基于ADAMS的半悬挂式农业机组静侧翻稳定性[J]. 吉林大学学报(工学版), 2018, 48(4): 1176-1183. |

| [12] | 贾洪雷, 王万鹏, 陈志, 庄健, 王文君, 刘慧力. 基于土壤坚实度的仿形弹性镇压辊镇压力实时测量方法[J]. 吉林大学学报(工学版), 2018, 48(4): 1169-1175. |

| [13] | 王扬, 吕凤妍, 徐天月, 于建群. 大豆籽粒形状和尺寸分析及其建模[J]. 吉林大学学报(工学版), 2018, 48(2): 507-517. |

| [14] | 贾洪雷, 郑嘉鑫, 袁洪方, 郭明卓, 王文君, 于路路. 大豆播种机双V型筑沟器设计与试验[J]. 吉林大学学报(工学版), 2017, 47(1): 323-331. |

| [15] | 肖志锋, 乐建波, 吴南星, 刘相东. 操作压力对过热蒸汽流化床干燥的影响[J]. 吉林大学学报(工学版), 2015, 45(4): 1375-1380. |

|

||