吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (4): 811-818.doi: 10.13229/j.cnki.jdxbgxb20200953

• 车辆工程·机械工程 • 上一篇

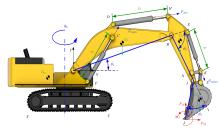

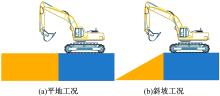

基于DEM⁃MBD联合仿真的液压挖掘机作业性能分析

王同建1( ),杨书伟1,谭晓丹1,陈晋市1(

),杨书伟1,谭晓丹1,陈晋市1( ),刘同文2,职振领1

),刘同文2,职振领1

- 1.吉林大学 机械与航空航天工程学院,长春 130022

2.三一重机有限公司 试验检验中心,江苏 昆山215300

Performance analysis of hydraulic excavator based on DEM-MBD co-simulation

Tong-jian WANG1( ),Shu-wei YANG1,Xiao-dan TAN1,Jin-shi CHEN1(

),Shu-wei YANG1,Xiao-dan TAN1,Jin-shi CHEN1( ),Tong-wen LIU2,Zhen-ling ZHI1

),Tong-wen LIU2,Zhen-ling ZHI1

- 1.College of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

2.Test and Inspection Center,Sany Heavy Machinery Co. ,Ltd. ,Kunshan 215300,China

摘要:

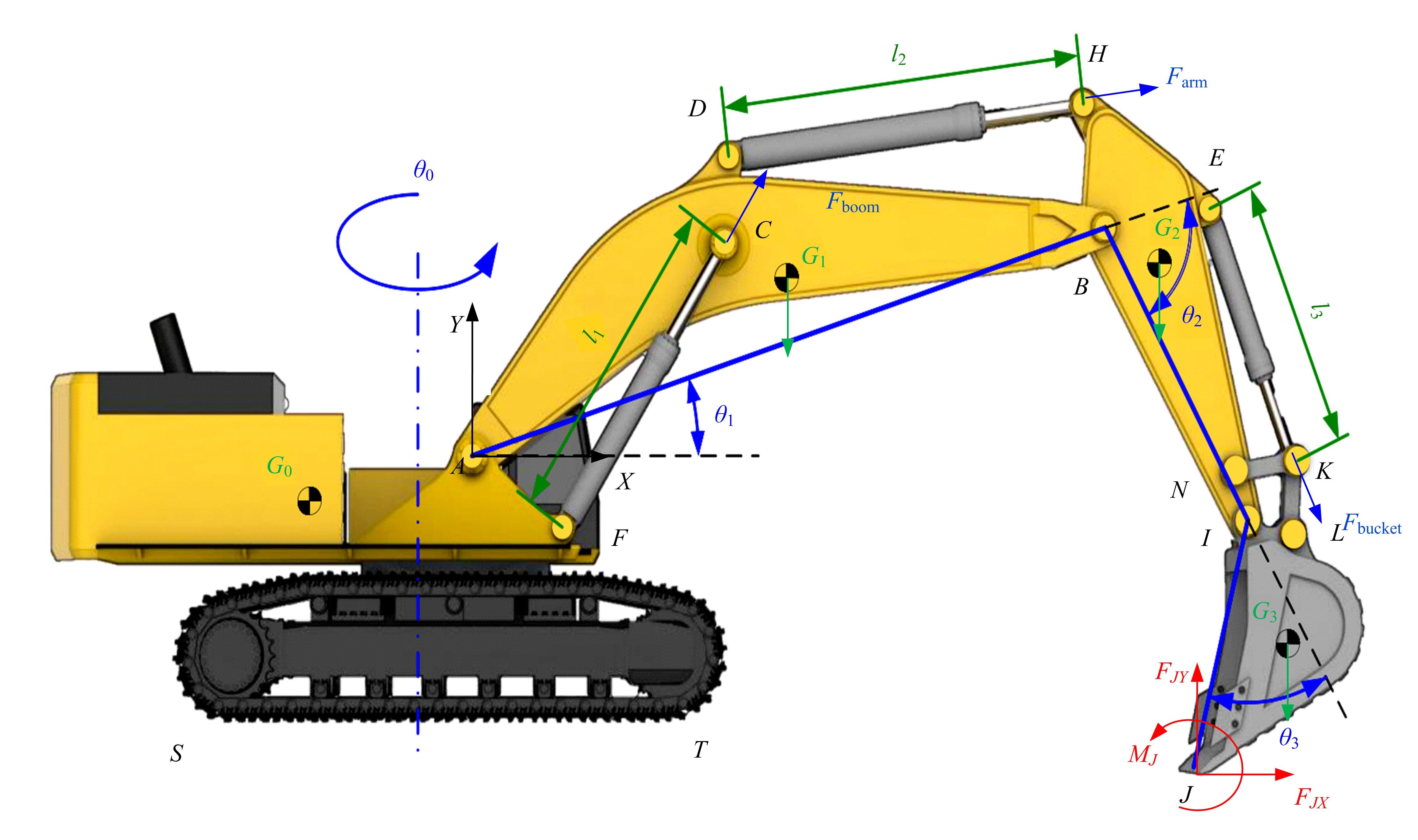

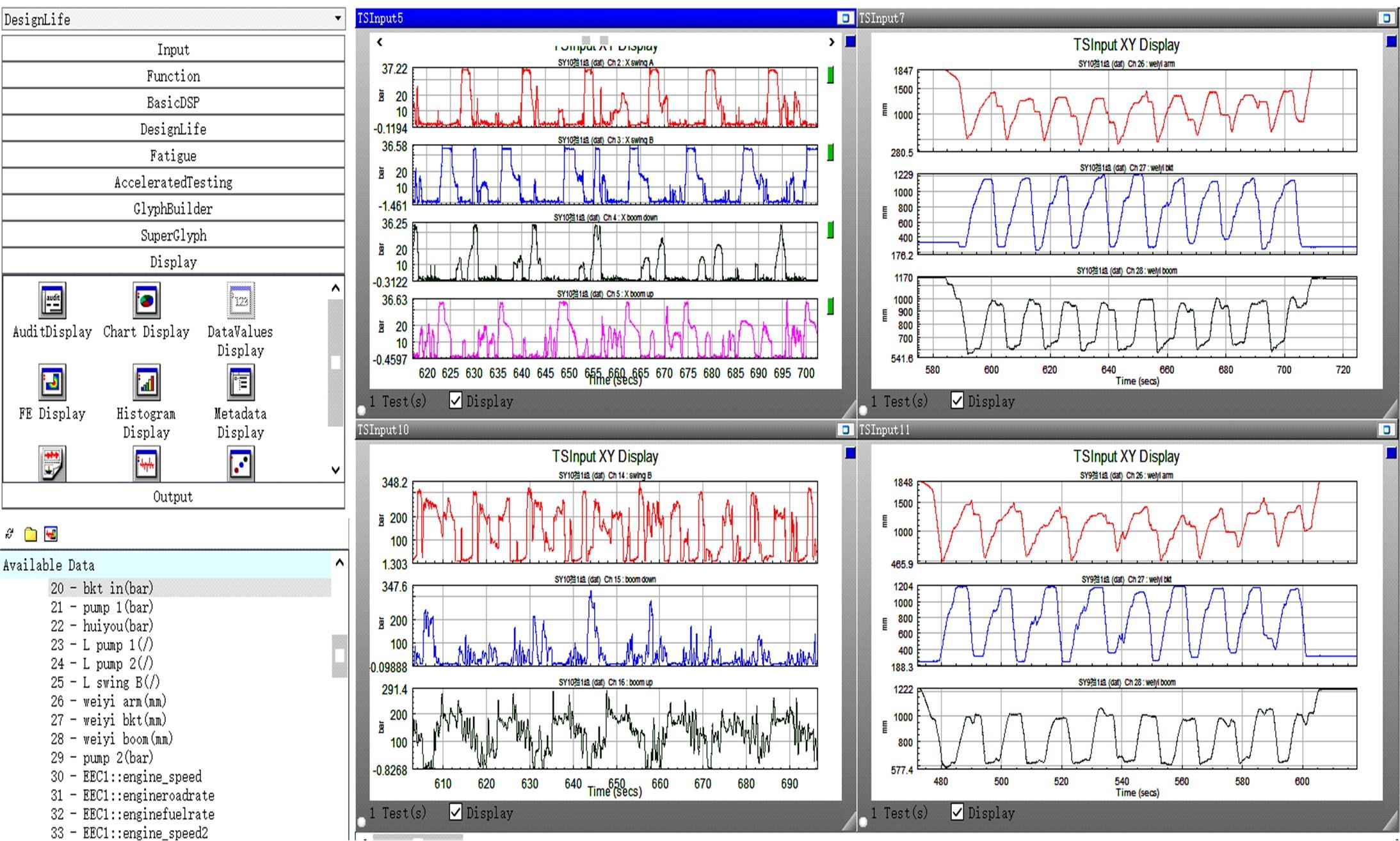

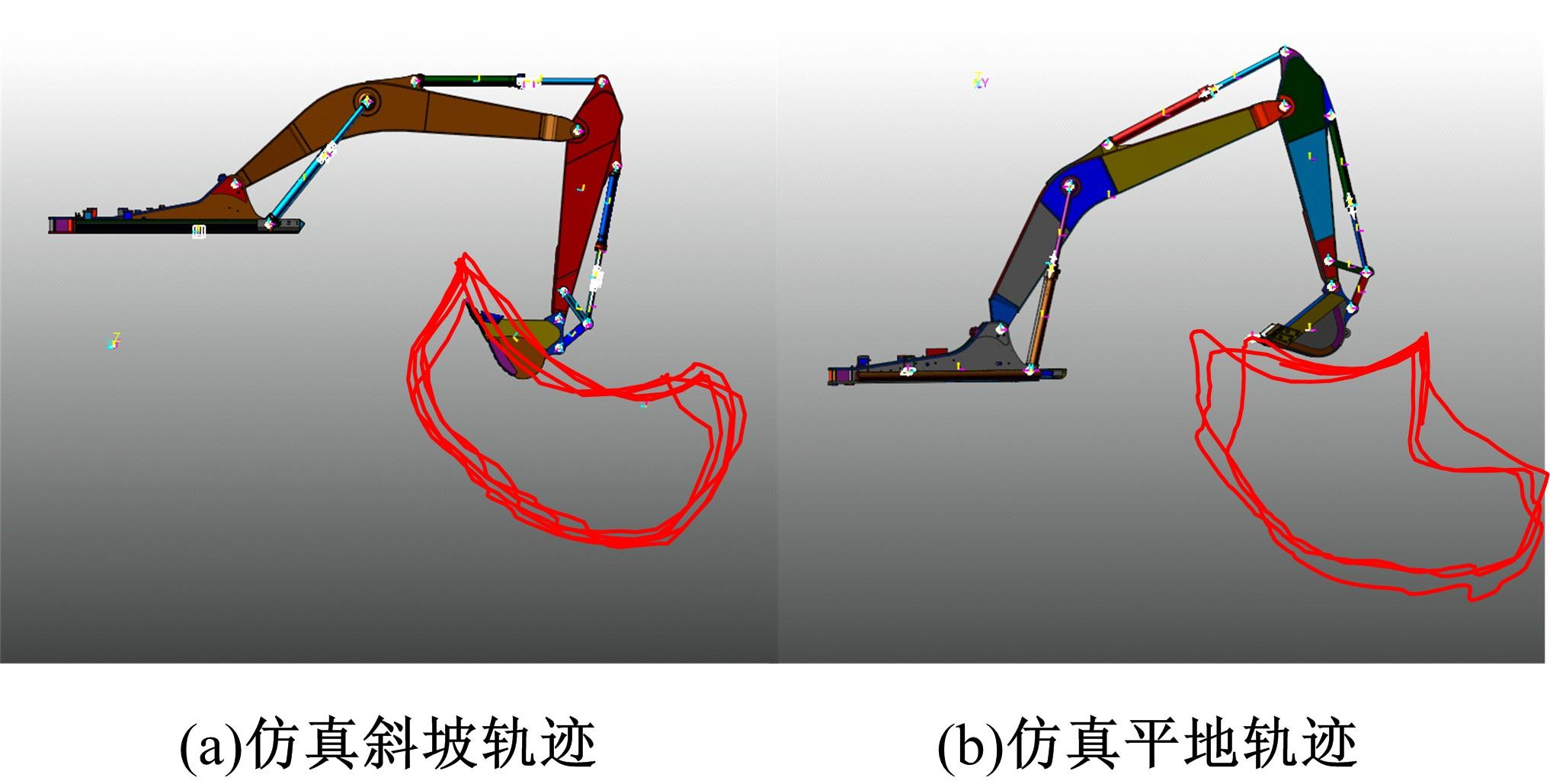

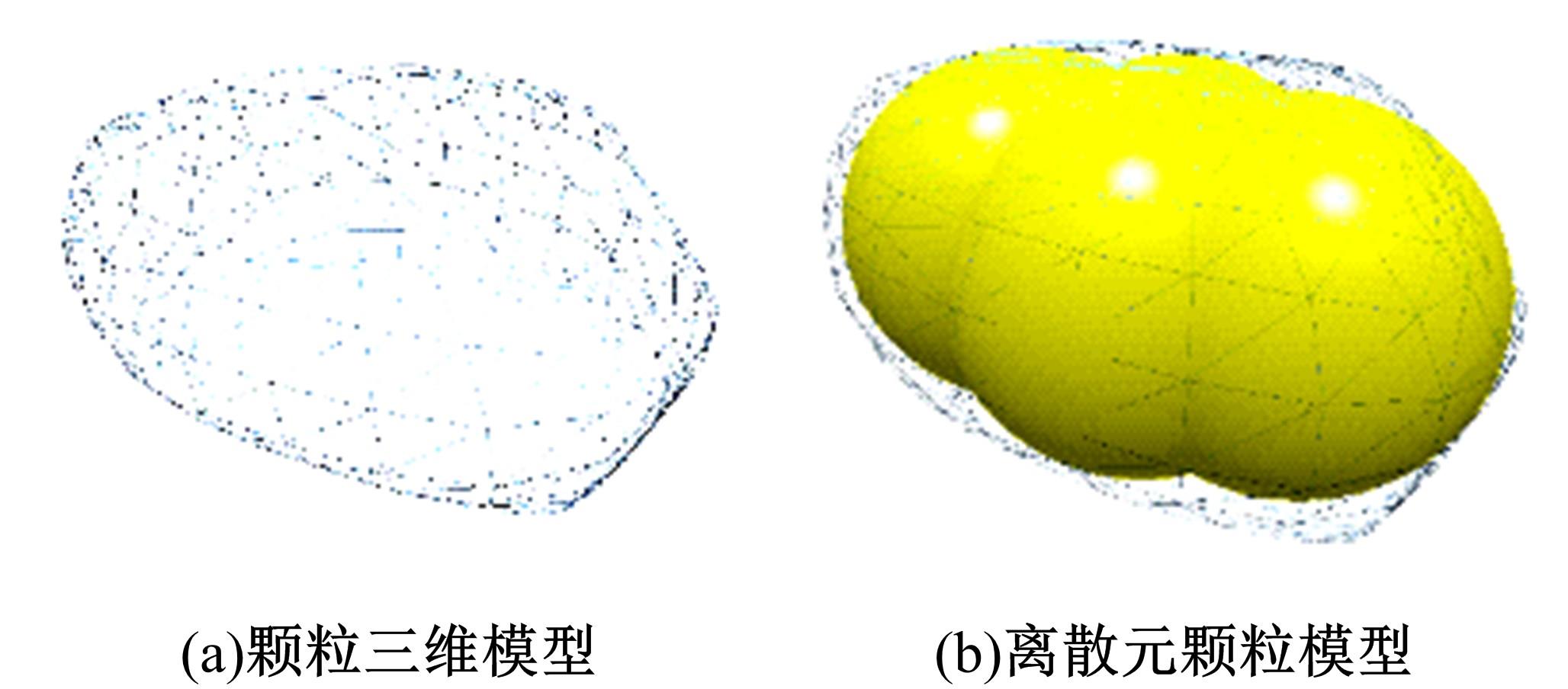

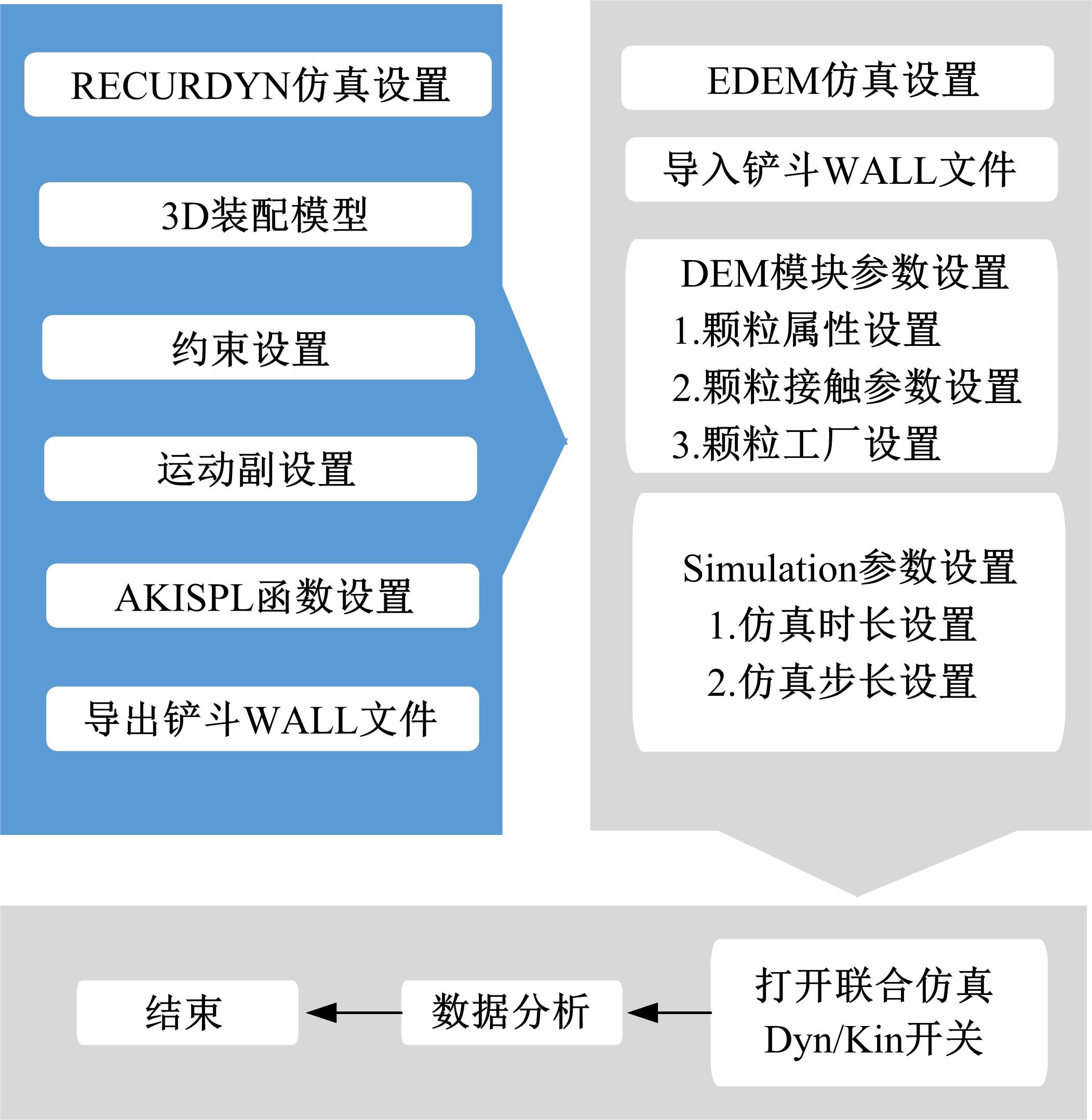

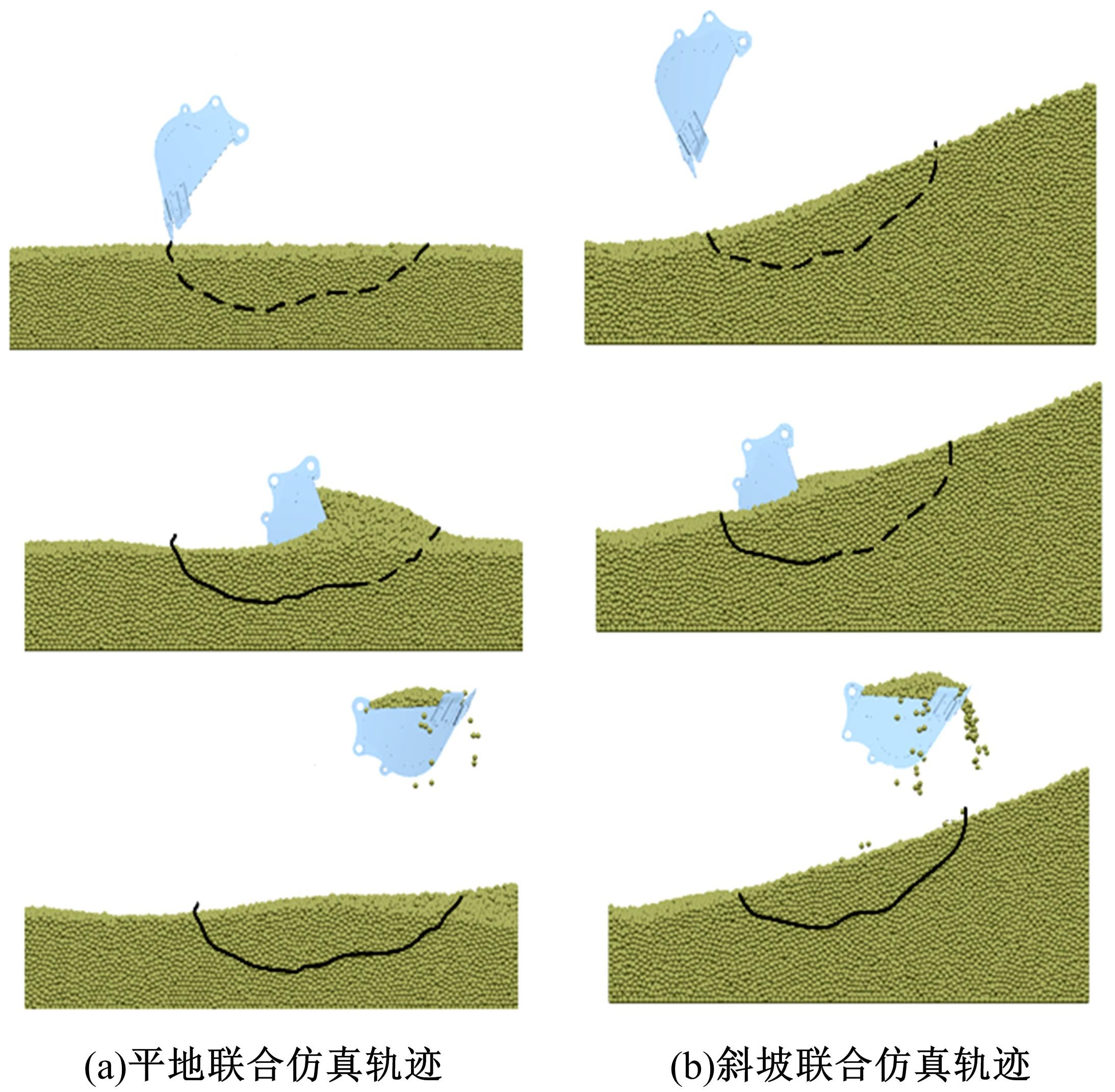

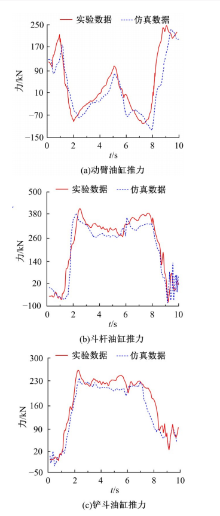

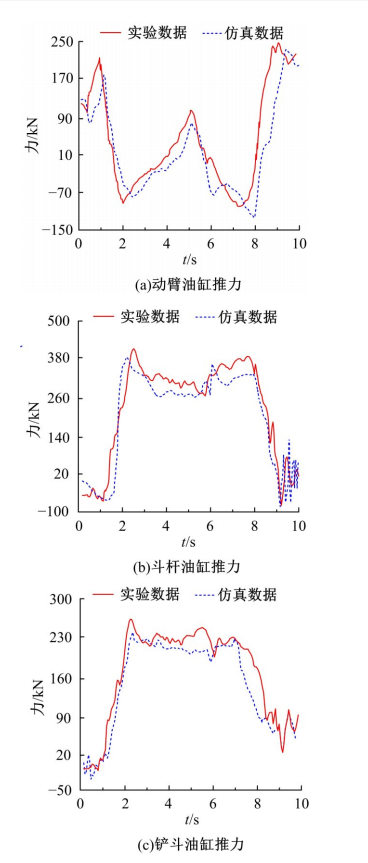

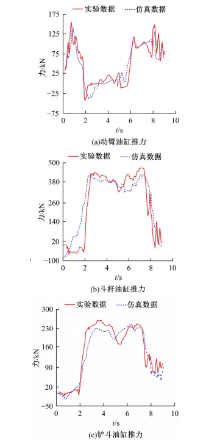

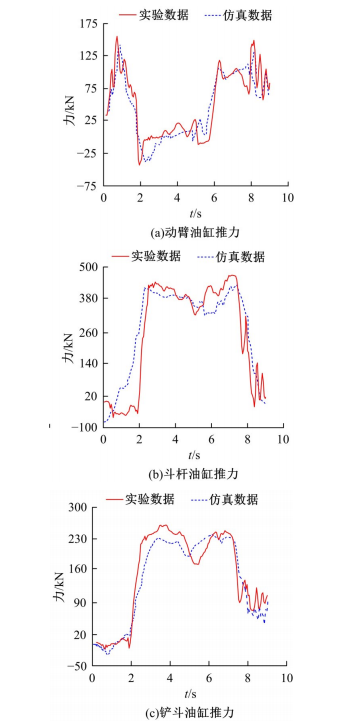

为了在挖掘机实机定型投产之前更准确地验证各构件的设计参数,提出了一种利用离散元-多体动力学(DEM-MBD)联合仿真预测挖掘作业性能的分析方法。对某国产型号液压挖掘机进行了平地、斜坡工况下的多组实验测试,得到了对应工况的载荷谱数据。根据实验过程中挖掘机的挖掘过程以及料堆形状,利用动力学软件RECURDYN与离散元软件EDEM进行了联合仿真,还原了挖掘过程中挖掘机的作业状态。对比实验采集的载荷谱推导所得的数据和联合仿真数据,结果表明:联合仿真得到的各组油缸推力以及挖掘阻力数据与实验数据的相关系数均大于0.9,证实离散元-多体动力学联合仿真分析方法适用于挖掘机的挖掘作业性能分析。

中图分类号:

- TU621

| 1 | 戴文跃, 梁昊. 装载机工作装置的动力学仿真与综合优化设计[J]. 吉林大学学报: 工学版, 2004, 34(4): 602-605. |

| Dai Wen-yue, Liang Hao. Dynamic simulation and comprehensive optimum design of working device of loader[J]. Journal of University(Engineering and Technology Edition), 2004, 34(4):602-605. | |

| 2 | 聂阳文, 胡星, 闫磊. 基于ADAMS的液压挖掘机工作装置优化分析[J]. 计算机仿真, 2019, 36(11): 300-304. |

| Nie Yang-wen, Hu Xing, Yan Lei. Optimization analysis for working device of hydraulic-excavators based on ADAMS[J]. Computer Simulation,2019, 36(11): 300-304. | |

| 3 | Chen H H, Zi J P. The application of virtual prototyping technology in the kinematic analysis of hydraulic excavator working device[J]. Advanced Materials Research, 2012, 538-541: 3235-3239. |

| 4 | Li X, Wang G, Miao S, et al. Optimal design of a hydraulic excavator working device based on parallel particle swarm optimization[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2017, 39: 3793-3805. |

| 5 | Yu Y, Xu J, Pang X P,et al. Lightweight and high-strength design of an excavator bucket under uncertain loading [J]. Mathematical Problems in Engineering Mathematical Problems in Engineering, 2019(1): 1-12. |

| 6 | 李因武, 吴庆文, 常志勇, 等. 基于仿生斗齿的反铲液压挖掘机动臂仿真优化设计[J]. 吉林大学学报: 工学版, 2018, 48(3): 821-827. |

| Li Yin-wu, Wu Qing-wen, Chang Zhi-yong,et al. Simulation and optimal design of backhoe hudraulic excavator based on bionic teeth[J]. Journal of University (Engineering and Technology Edition), 2018, 48(3): 821-827. | |

| 7 | Gao W, Tan Y Q, Zang M Y. A cubic arranged spherical discrete element model[J]. International Journal of Computational Methods, 2014, 11(5): No. 1350102. |

| 8 | Shi C, Li D J, Xu W Y, et al. Discrete element cluster modeling of complex mesoscopic particles for use with the particle flow code method[J]. Granular Matter, 2015, 17(3): 377-387. |

| 9 | Yong P, Bao J X. Comparative study of 2D and 3D micromechanical discrete element modeling of indirect tensile tests for asphalt mixtures[J]. International Journal of Geomechanics, 2018, 18(6): No. 4018046. |

| 10 | Fang Z Q, Hu G M, Li W W,et al. Comparisons of digging trajectories of excavator bucket in digging process by DEM simulations[C]∥International Conference On Mechanical Science and Mechanical Design,Changsha, China,2015:478-484. |

| 11 | Tekeste M Z, Balvanz L R, Hatfield J L, et al. Discrete element modeling of cultivator sweep-to-soil interaction: Worn and hardened edges effects on soil-tool forces and soil flow[J]. Journal of Terramechanics, 2019, 82:1-11. |

| 12 | 毕秋实, 王国强, 陈立军, 等. 基于离散元-多体动力学联合仿真的机械式挖掘机挖掘阻力仿真与试验[J]. 吉林大学学报:工学版, 2019, 49(1): 106-116. |

| Bi Qiu-shi, Wang Guo-qiang, Chen Li-jun,et al. Numerical simulation and experiment on excavation resistance of mechanical excavator based on DEM-MBD co-simulation[J]. Journal of University(Engineering and Technology Edition), 2019, 49(1): 106-116. | |

| 13 | Cleary P W, Morrison R D, Sinnott M D. Prediction of slurry grinding due to media and coarse rock interactions in a 3D pilot SAG mill using a coupled DEM+SPH model[J]. Minerals Engineering, 2020, 159: No. 106614. |

| 14 | Cleary P W. DEM simulation of industrial particle flows: case studies of dragline excavators, mixing in tumblers and centrifugal mills[J]. Powder Technology, 2000, 1-3: 83-104. |

| 15 | Cleary P W. Effect of rock shape representation in DEM on flow and energy utilization in a pilot SAG mill[J]. Computational Particle Mechanics, 2019, 6(6): 461-477. |

| 16 | Grima A P, Wypych P W. Development and validation of calibration methods for discrete element modelling[J]. Granular Matter, 2011, 13(2): 127-132. |

| [1] | 于向军,槐元辉,李学飞,王德武,俞安. 基于克里金和粒子群算法的装载机铲掘轨迹规划[J]. 吉林大学学报(工学版), 2020, 50(2): 437-444. |

| [2] | 马芳武,倪利伟,吴量,聂家弘,徐广健. 轮腿式全地形移动机器人位姿闭环控制[J]. 吉林大学学报(工学版), 2019, 49(6): 1745-1755. |

| [3] | 闫光,卢建中,张开宇,孟凡勇,祝连庆. 温度解耦大量程光纤光栅应变传感器[J]. 吉林大学学报(工学版), 2019, 49(5): 1682-1688. |

| [4] | 胡满江, 罗禹贡, 陈龙, 李克强. 基于纵向频响特性的整车质量估计[J]. 吉林大学学报(工学版), 2018, 48(4): 977-983. |

| [5] | 李因武, 吴庆文, 常志勇, 杨成. 基于仿生斗齿的反铲液压挖掘机动臂仿真优化设计[J]. 吉林大学学报(工学版), 2018, 48(3): 821-827. |

| [6] | 刘汉光, 王国强, 孟东阁, 赵寰宇. 液压挖掘机履带行走装置的合理预张紧力[J]. 吉林大学学报(工学版), 2018, 48(2): 486-491. |

| [7] | 靳立强, 孙志祥, 郑迎. 电动轮汽车复合再生制动系统防抱协调控制[J]. 吉林大学学报(工学版), 2017, 47(5): 1344-1351. |

| [8] | 刘海鸥, 张国鑫, 席军强, 张洪彦, 徐宜. 履带车辆传动系统动态载荷谱信号去噪[J]. 吉林大学学报(工学版), 2017, 47(1): 42-49. |

| [9] | 彭贝, 高宇, 冯培恩, 邱清盈. 液压挖掘机回转启动过程节能技术[J]. 吉林大学学报(工学版), 2016, 46(6): 1912-1921. |

| [10] | 张钦国, 秦四成, 马润达, 杨立光, 郗元, 刘晋侨. 装载机工作装置液压系统热特性[J]. 吉林大学学报(工学版), 2016, 46(3): 811-817. |

| [11] | 邱清盈, 魏振凯, 高宇, 冯培恩, 殷鹏龙. 挖掘机工作装置疲劳分析方法[J]. 吉林大学学报(工学版), 2016, 46(1): 159-165. |

| [12] | 李飞龙, 林勇刚, 李伟, 刘宏伟, 崔宝玲. 风能静液压传动控制技术[J]. 吉林大学学报(工学版), 2014, 44(6): 1664-1668. |

| [13] | 宫海彬, 苏建, 王兴宇, 徐观, 张益瑞. 基于极值外推的高速列车齿轮传动装置载荷谱编制[J]. 吉林大学学报(工学版), 2014, 44(5): 1264-1269. |

| [14] | 王同建, 陈晋市, 赵锋, 赵庆波, 刘昕晖, 袁华山. 全液压转向系统机液联合仿真及试验[J]. 吉林大学学报(工学版), 2013, 43(03): 607-612. |

| [15] | 王登峰, 季枫, 陈书明, 苏丽俐, 郝赫. 多轴重型汽车气动制动防抱死系统性能仿真与试验[J]. 吉林大学学报(工学版), 2012, 42(增刊1): 7-12. |

|

||