吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (7): 1499-1508.doi: 10.13229/j.cnki.jdxbgxb20210049

• 车辆工程·机械工程 • 上一篇

液压伺服柔驱机构设计及其刚度连续可调分析

- 1.武汉科技大学 冶金装备及其控制教育部重点实验室,武汉 430081

2.武汉科技大学 机器人与智能系统研究院,武汉 430081

Design and stiffness continuously adjustable analysis of hydraulic servo flexible drive mechanism

Lin JIANG1,2( ),Ling ZHOU1,Hui ZHAO1,2

),Ling ZHOU1,Hui ZHAO1,2

- 1.Key Laboratory of Metallurgical Equipment and Control Technology,Ministry of Education,Wuhan University of Science and Technology,Wuhan 430081,China

2.Institute of Robotics and Intelligent Systems,Wuhan University of Science and Technology,Wuhan 430081,China

摘要:

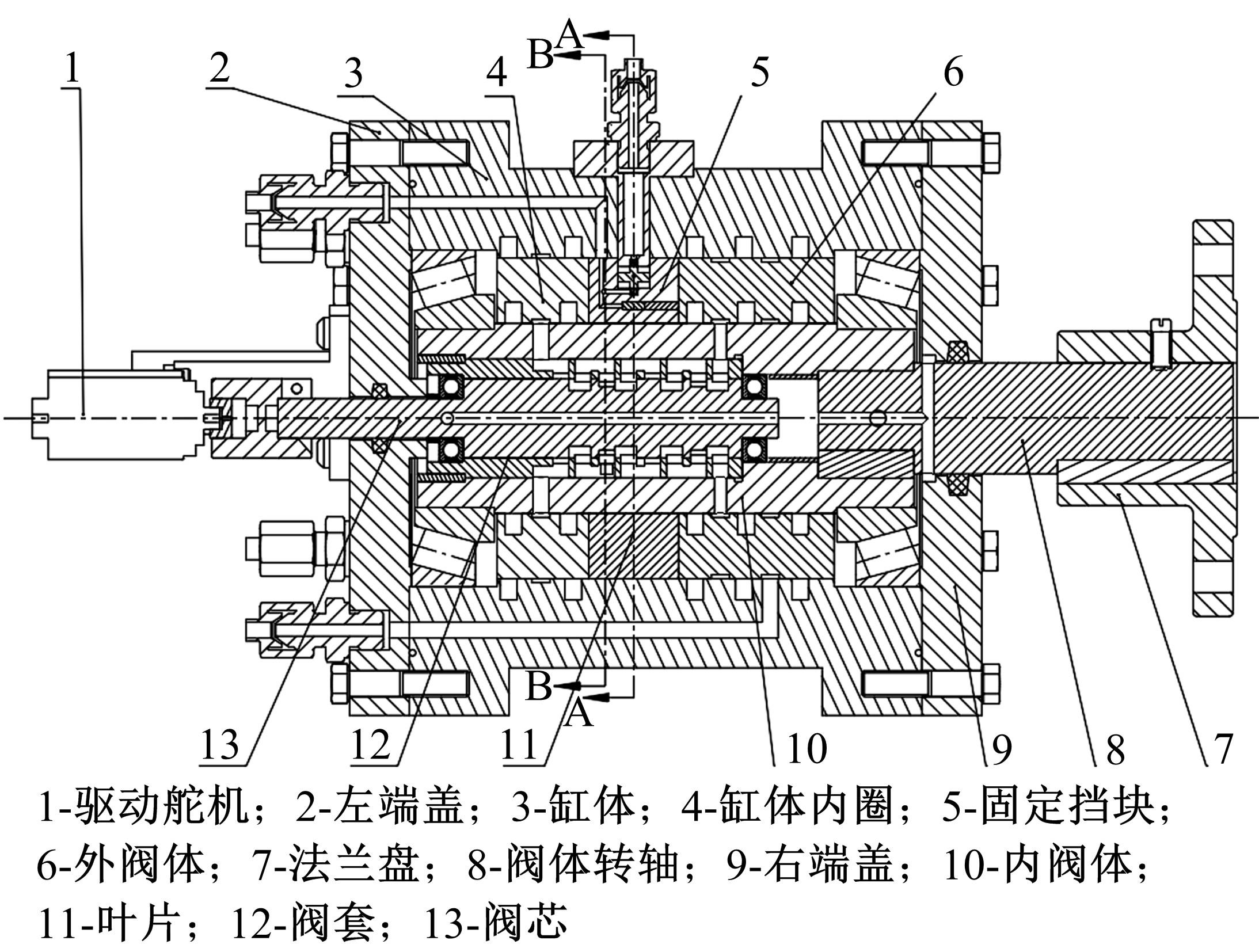

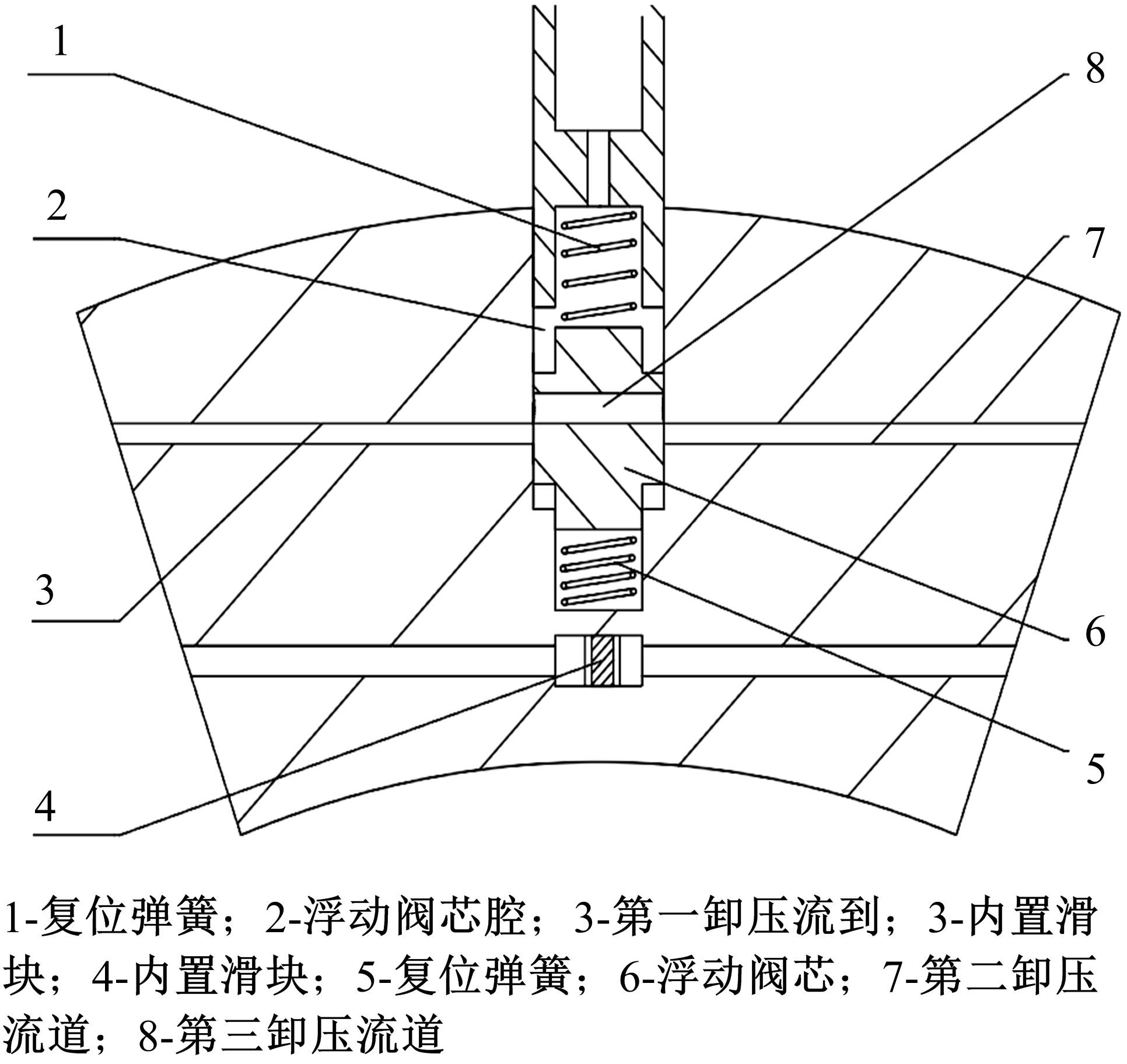

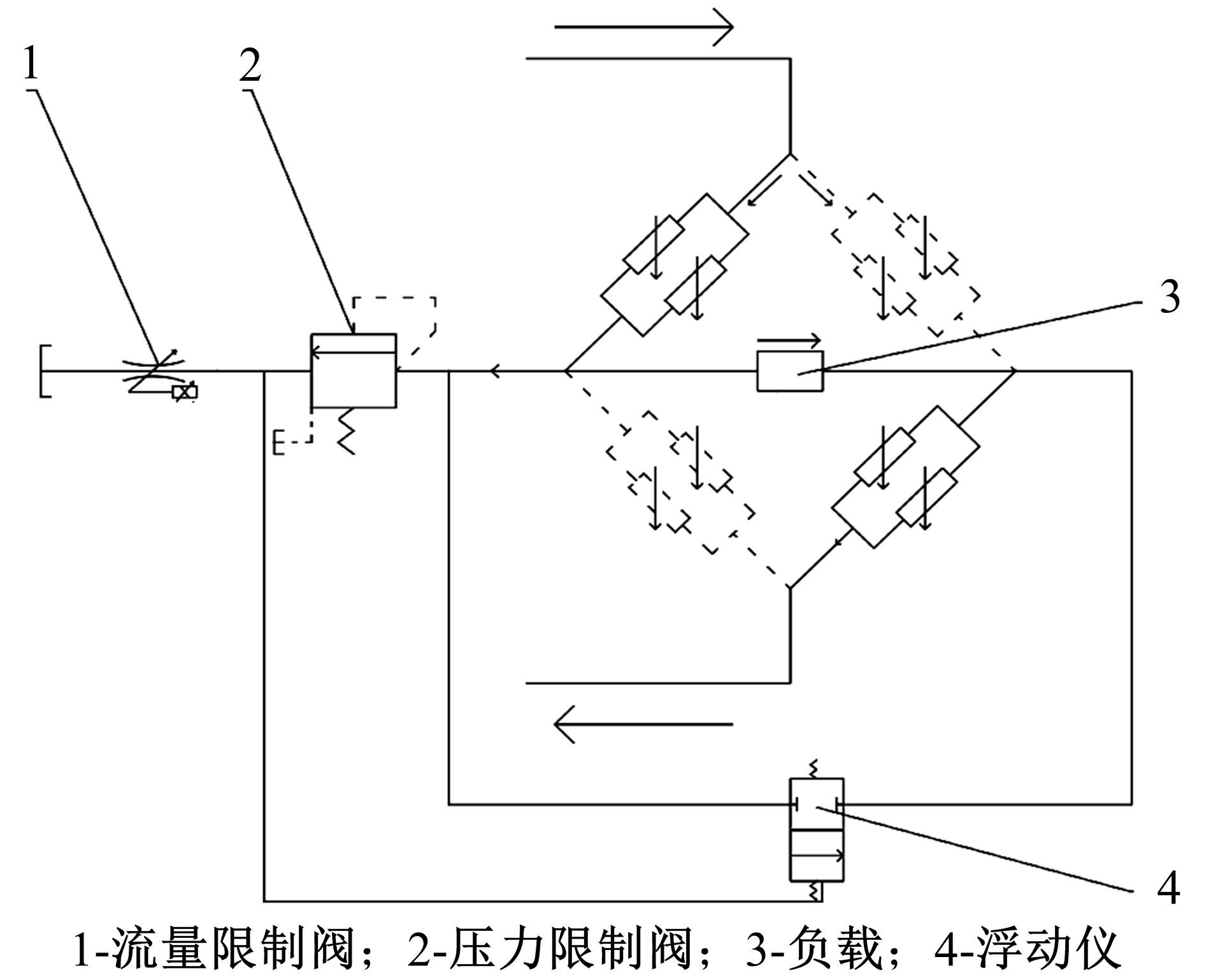

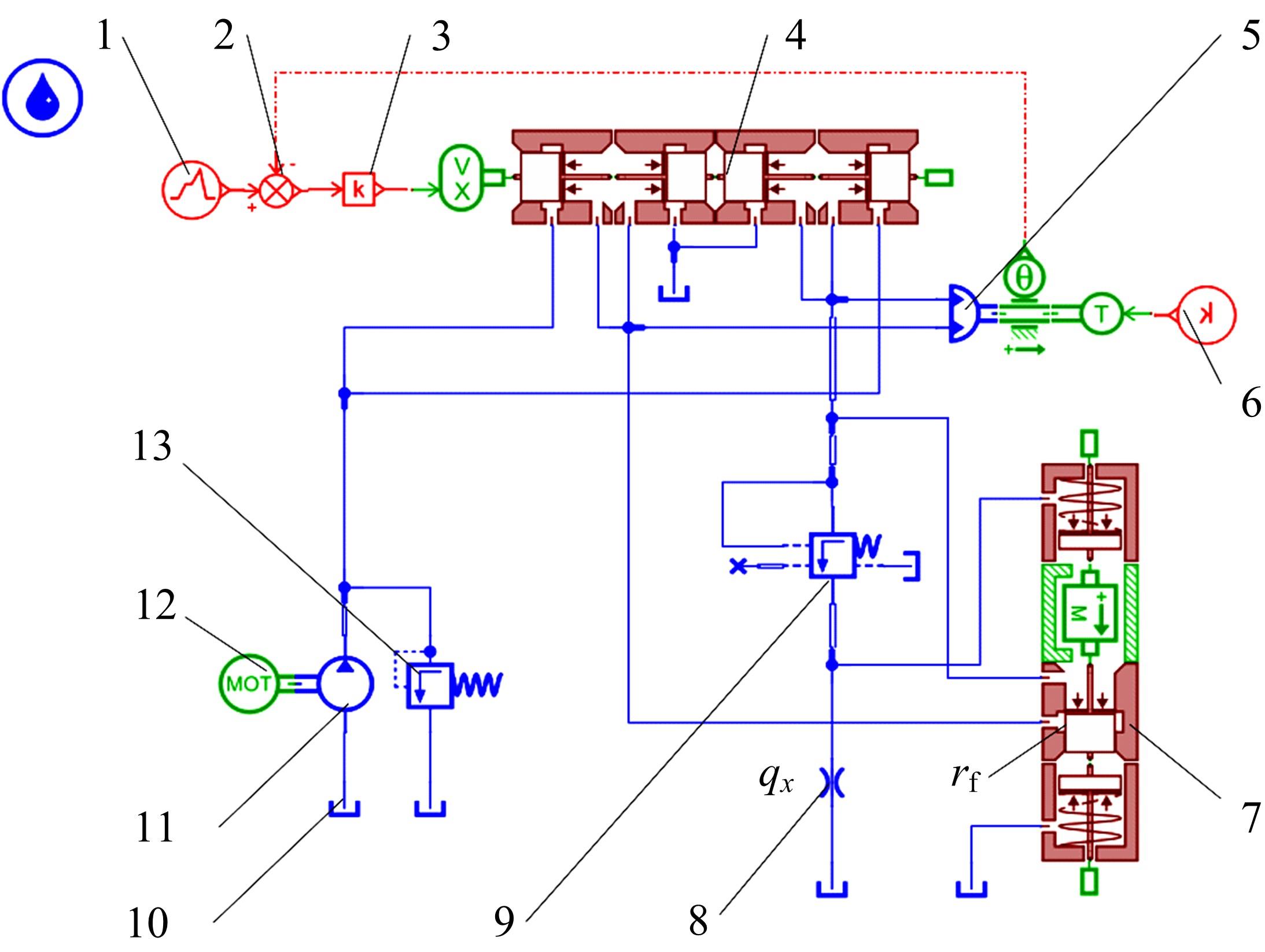

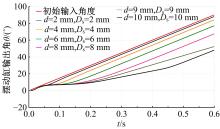

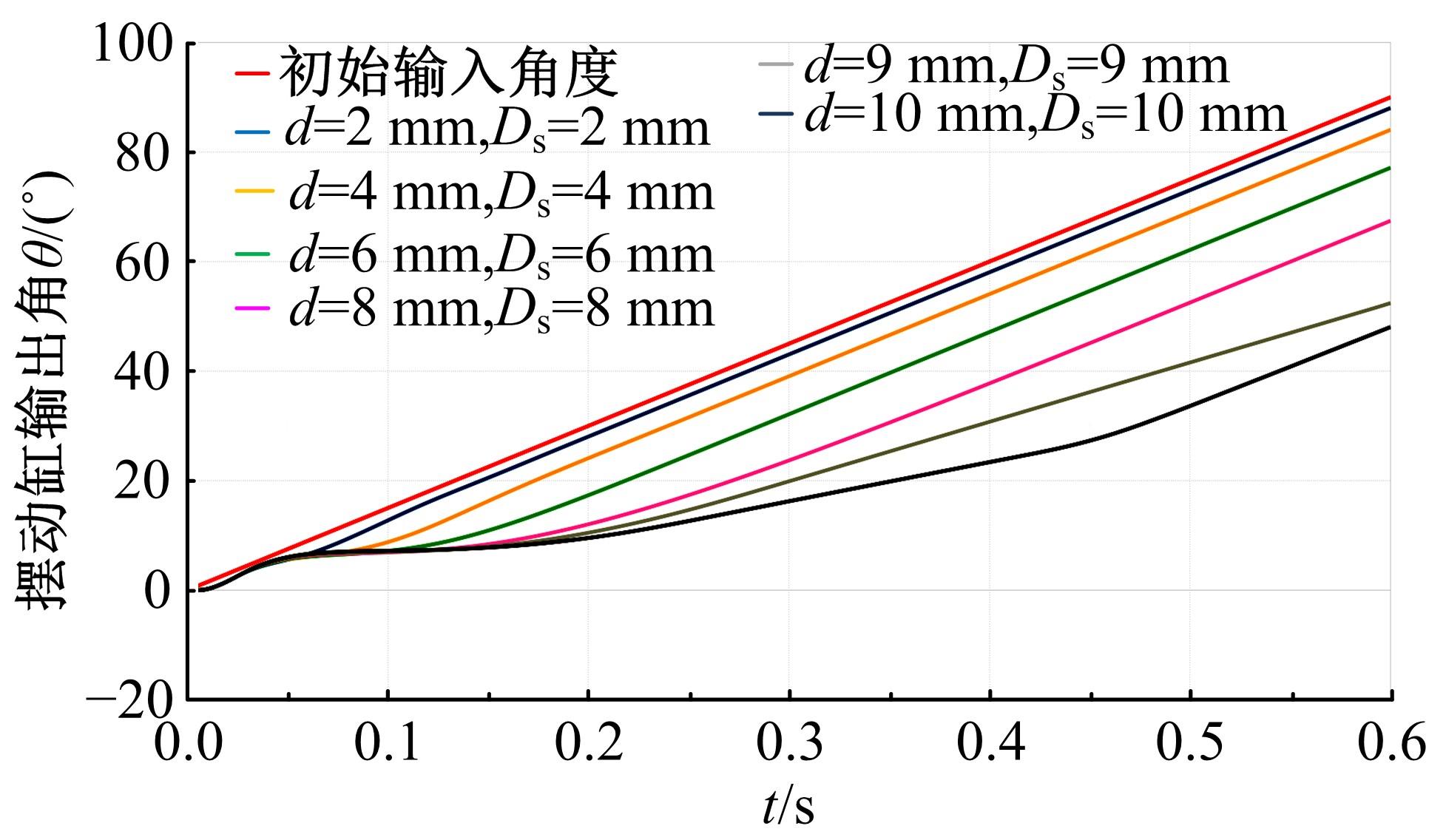

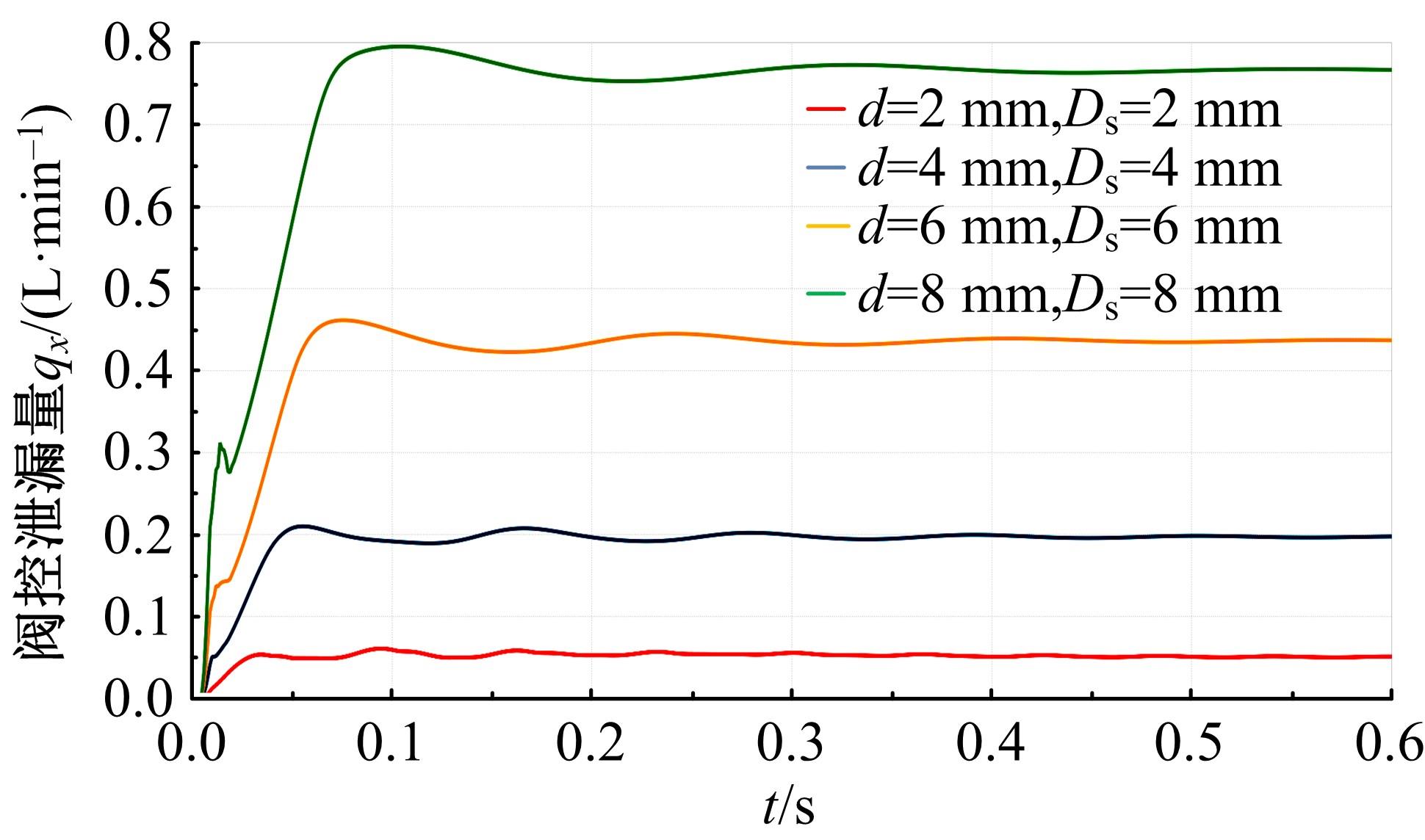

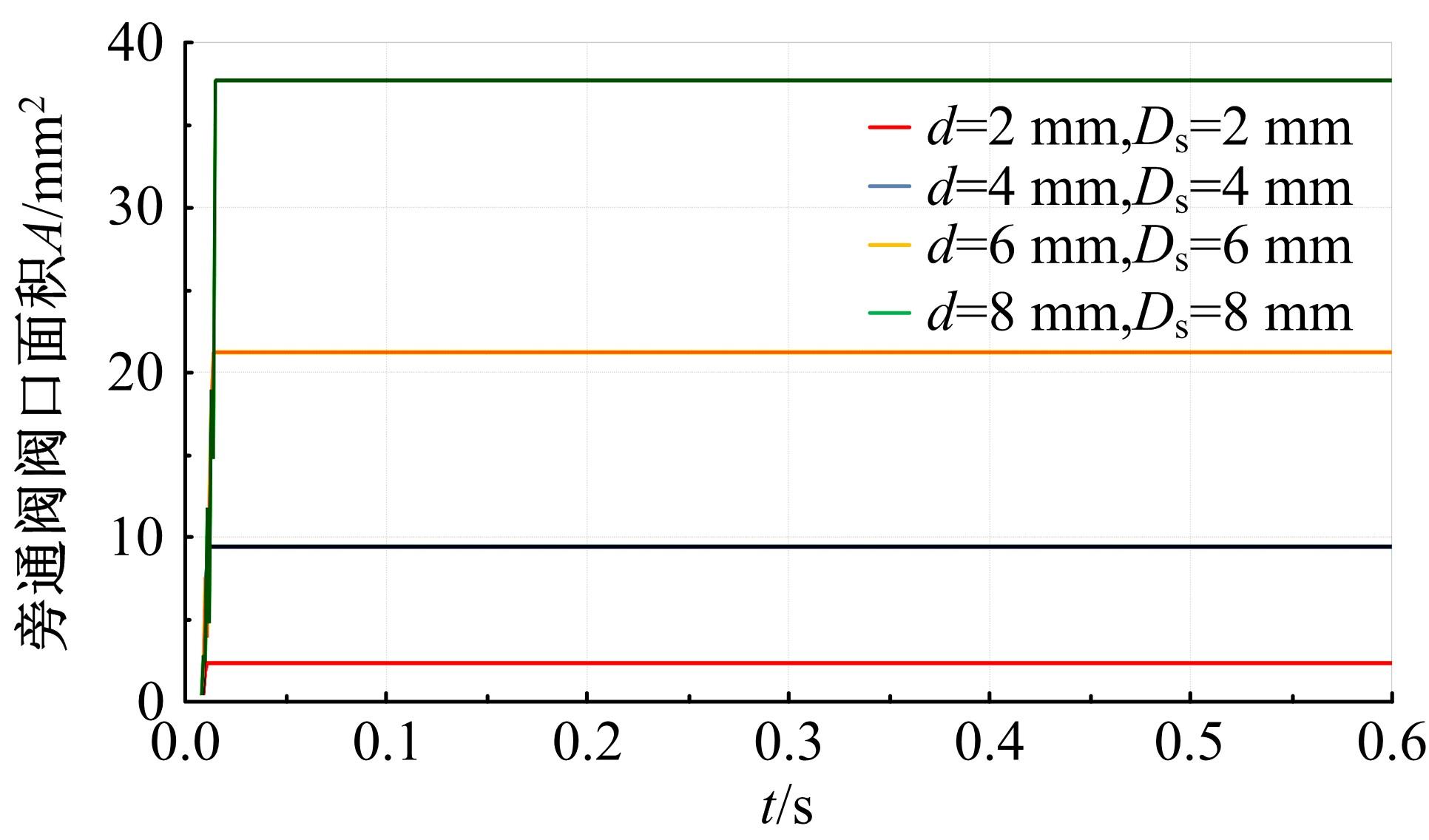

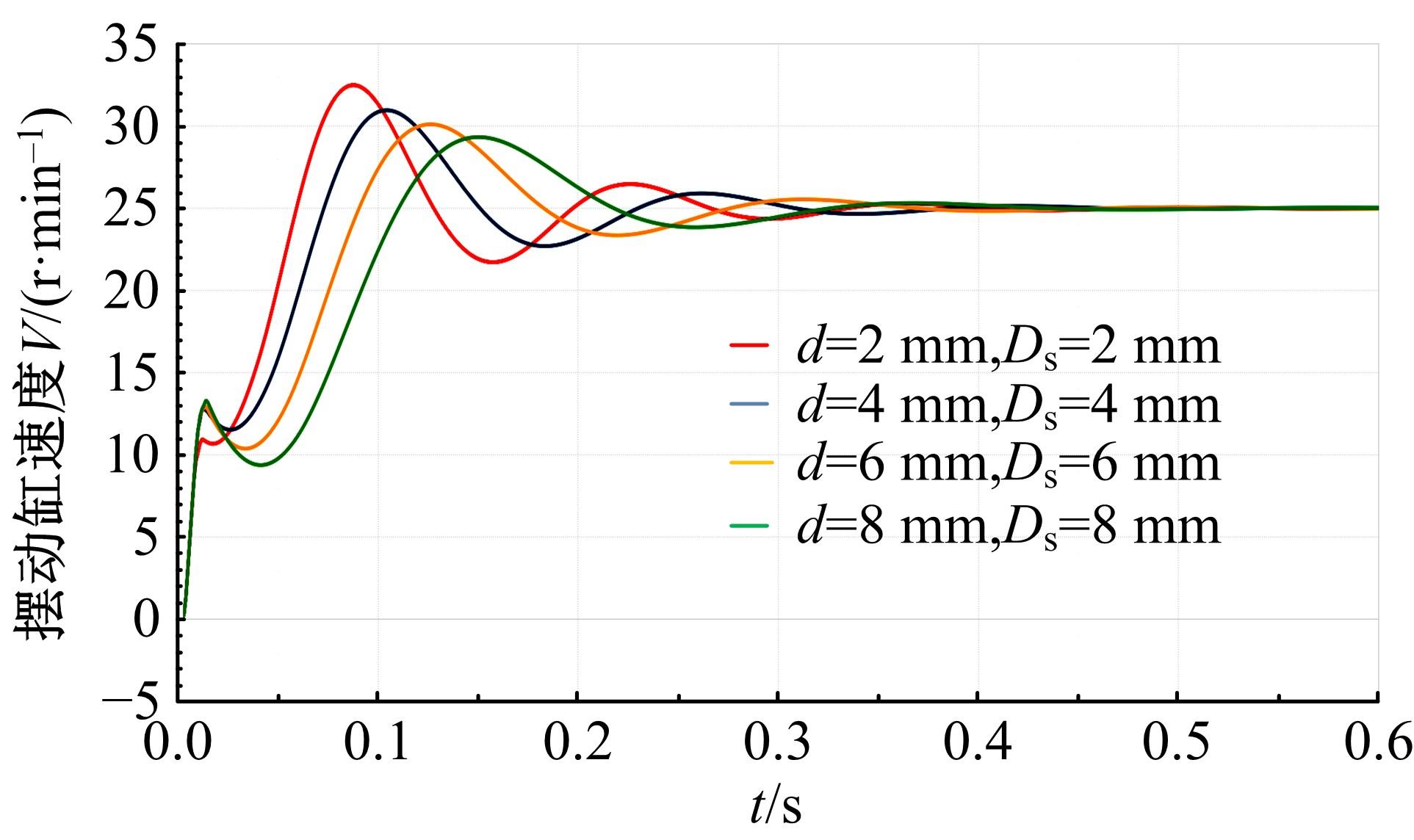

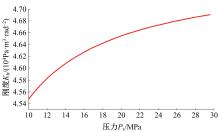

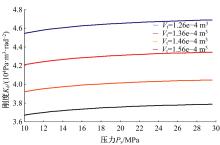

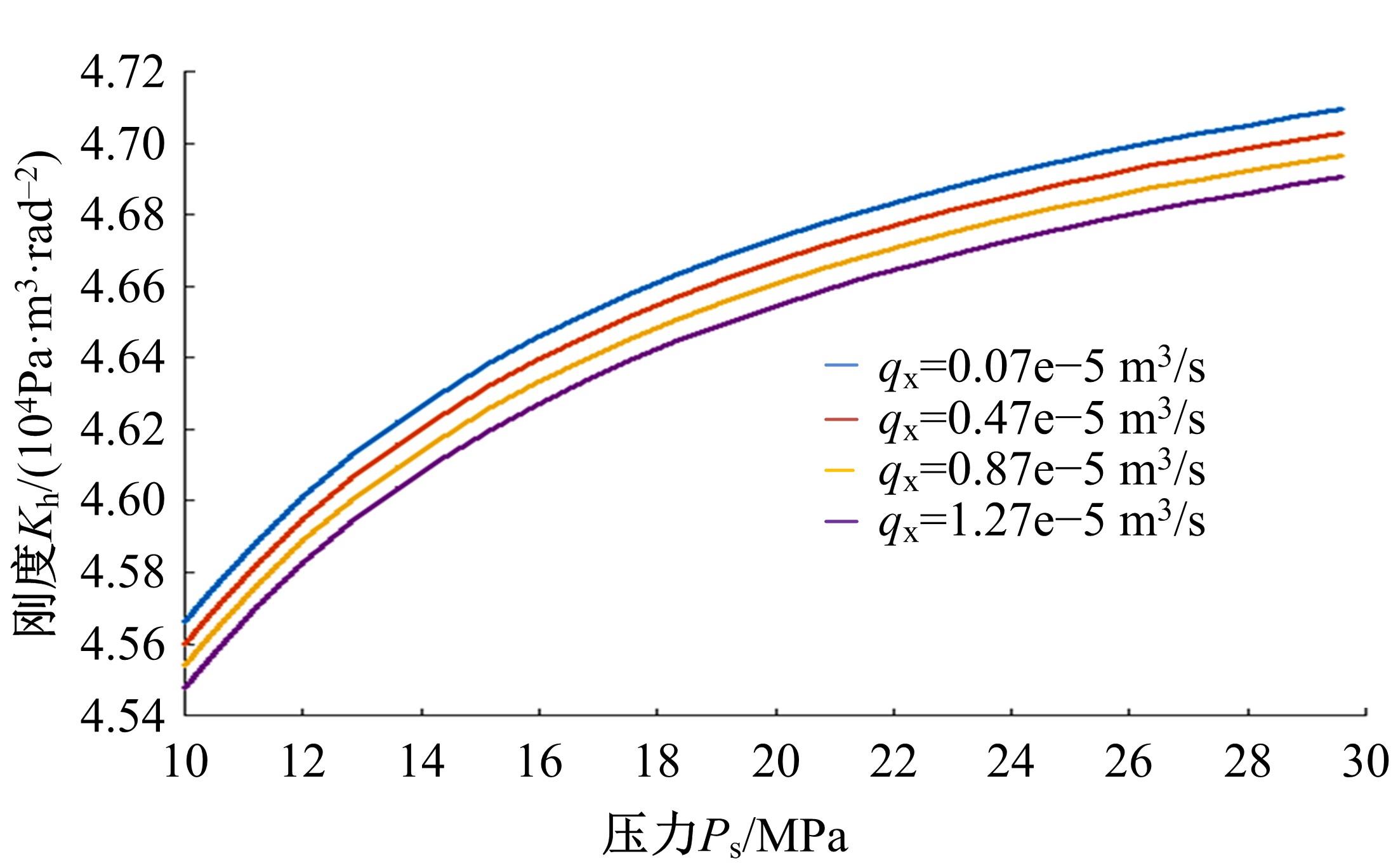

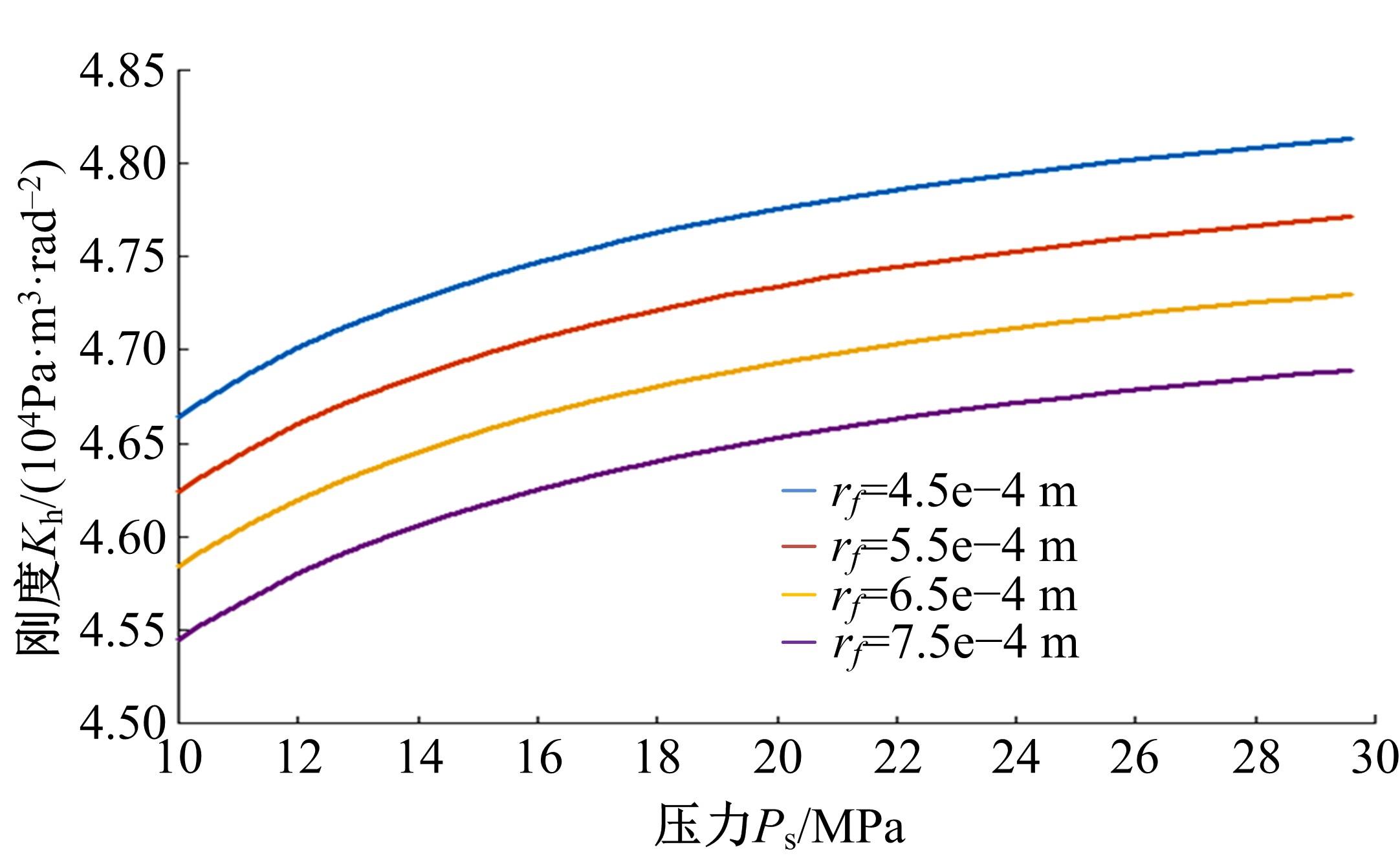

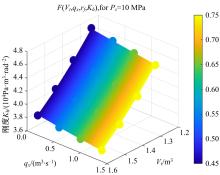

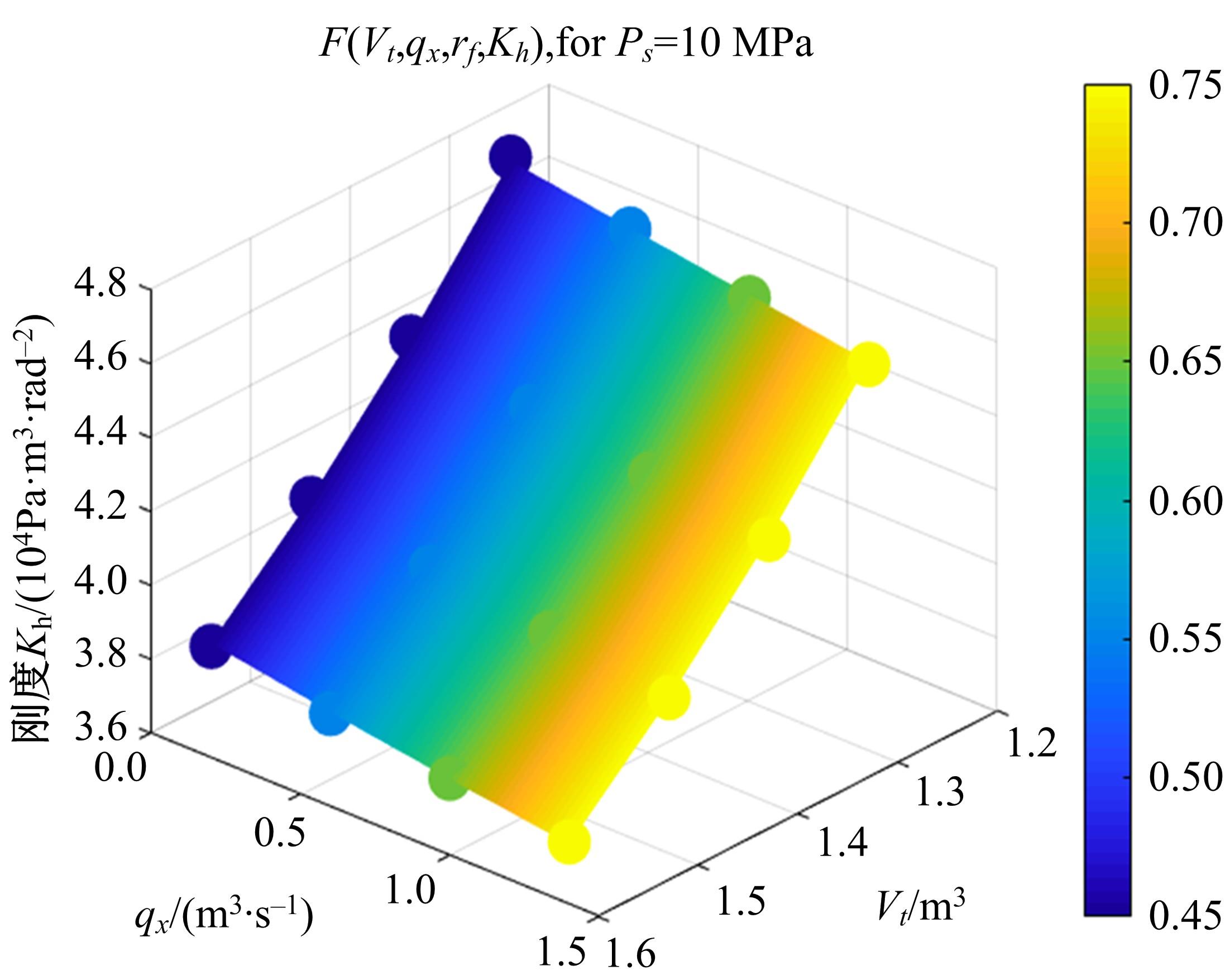

为满足液压机械臂工作时输出高刚度,碰撞时变刚度实现柔顺性,让机器人在不同工作条件和场景下具有相应的柔顺性,设计了一种兼具阀控泄漏量和浮动位的液压伺服柔驱机构。首先,介绍该关节结构和变刚度原理;其次,利用Amesim建立其动态仿真模型,确定阀控泄漏量和浮动位半径范围;然后,利用MATLAB/Simulink建立其刚度仿真模型,分析单个因素与关节变刚度的关系;最后,基于MATLAB拟合关节刚度多元非线性回归方程,并通过程序实现刚度初始散点和拟合四维曲线对比图。仿真结果表明:在保证较好的动态特性时,该柔驱机构刚度能在较宽范围内连续可调。

中图分类号:

- TH12

| 1 | 王旭,陈乃建,王超,等. 助老助残轮椅用绳传动机械臂结构设计[J]. 济南大学学报:自然科学版,2020,34(3):300-305. |

| Wang Xu, Chen Nai-jian, Wang Chao, et al. Structure design of rope-driven mechanical arm for elderly and disabled wheel chair[J]. Journal of University of Jinan (Natural Science Edition),2020,34(3):300-305. | |

| 2 | Mahdi H, Chavoshian C, Mostafa J,et al. Recurrent neuro-fuzzy model of pneumatic artificial muscle position[J]. Journal of Mechanical Science and Technology,2020,34(1):499-508. |

| 3 | 朱嘉齐,章家岩,冯旭刚. 柔性臂测量机的圆光栅偏心参数标定算法[J]. 电子测量与仪器学报,2019,33(8):1-7. |

| Zhu Jia-qi, Zhang Jia-yan, Feng Xu-gang. Calibration algorithm of circular grating eccentric parameters for flexible arm measuring machine[J]. Journal of Electrical Measurement and Instrumentation,2019,33(8):1-7. | |

| 4 | Montazeri A, West C, Monk S D,et al. Dynamic modelling and parameter estimation of a hydraulic robot manipulator using a multi-objective genetic algorithm[J]. International Journal of Control,2017,90(4):661-683. |

| 5 | 蔡若凡. 一种新型的可变刚度柔性关节设计与控制研究[D]. 哈尔滨:哈尔滨工业大学机电工程学院,2017. |

| Cai Ruo-fan. Design and control research of a novel flexible joint with variable stiffness[D]. Harbin:School of Mechanic Engineering, Harbin Institute of Technology,2017. | |

| 6 | Sohn J W, Gang H G, Choi S B. An experimental study on torque characteristics of magnetorheological brake with modified magnetic core shape[J]. Advances in Mechanical Engineering, 2018, 10(1):1-8. |

| 7 | Groothuis S, Rusticelli G, Zucchelli A,et al. The variable stiffness actuator vsaUT-II:mechanical design,modeling,and identification[J]. IEEE/ASME Transactions on Mechatronics,2014,19(2):589-597. |

| 8 | 张明, 房立金, 孙凤,等. 永磁变刚度柔性关节的力学分析与控制器设计[J]. 机械工程学报, 2019, 55(5):89-96. |

| Zhang Ming, Fang Li-jin, Sun Feng,et al. Mechanical analysis and controller design of flexible joint with permanent magnet variable stiffness[J]. Journal of Mechanical Engineering,2019,55(5):89-96. | |

| 9 | 李满宏,马艳悦,张明路,等. 基于凸轮机构的变刚度仿生柔性关节设计与分析[J]. 仪器仪表学报,2019,40(2):216-225. |

| Li Man-hong, Ma Yan-yue, Zhang Ming-lu,et al. Design and analysis of bionic flexible joint with variable stiffness based on cam mechanism[J]. Chinese Journal of Scientific Instrument,2019,40(2): 216-225. | |

| 10 | 蒋林,陈新元,赵慧,等. 基于液压转角伺服的液压关节研究[J]. 机电工程,2011,28(3):265-268. |

| Jiang Lin, Chen Xin-yuan, Zhao Hui, et al. Research on hydraulic joint based on hydraulic angle servo[J]. Mechanical and Electrical Engineering,2011,28(3):265-268. | |

| 11 | 潘孝越,蒋林, 任利胜,等. 液压伺服柔顺关节的变刚度设计与研究[J]. 武汉科技大学学报,2020,43(4):290-296. |

| Pan Xiao-yue, Jiang Lin, Ren Li-sheng, et al. Design and research on variable stiffness of hydraulic servo compliant joint[J]. Journal of Wuhan University of Science and Technology,2020,43(4):290-296. | |

| 12 | 恭飞,王雪婷,杜奕. 基于AMEsim的液压系统建模与仿真[J]. 软件,2020,41(1):42-45. |

| Gong Fei, Wang Xue-ting, Du Yi. Modeling and simulation of hydraulic system based on AMESim [J]. Software, 2020,41(1) :42-45. | |

| 13 | 彭贺,马文星,王忠山,等. 丘陵山地拖拉机车身调平控制仿真分析与试验[J].吉林大学学报:工学版,2019,49(1):157-165. |

| Peng He, Ma Wen-xing, Wang Zhong-shan,et al. Simulation analysis and experiment on leveling control of tractor body in hilly mountains[J]. Journal of Jilin University (Engineering and Technology Edition), 2019,49(1):157-165. | |

| 14 | 陈德刚,孙仁云,陈勇,等. 基于AMESim的天然气发动机电控调压器仿真研究[J]. 机床与液压,2012,40(11):109-112. |

| Chen De-gang, Sun Ren-yun, Chen Yong,et al. Simulation research on electrically controlled voltage regulator of natural gas engine based on AMESim[J]. Machine Tool & Hydraulics,2012, 40(11):109-112. | |

| 15 | Jiang Lin, Zhu Zhi-chao, Liu Hong-hai,et al. Analysis of dynamic characteristics of water hydraulic rotating angle self-servo robot joint actuator[J]. Journal of Intelligent & Robotic Systems,2018,92(2):279-291. |

| 16 | 马铭泽,田拥胜,王涛,等. 基于AMESim的比例伺服流量阀建模与仿真[J]. 液压气动与密封,2017, 37(1):16-19. |

| Ma Ming-ze, Tian Yong-sheng, Wang Tao,et al. Modeling and simulation of proportional servo flow valve based on AMESim[J]. Hydraulics Pneumatics & Seals,2017,37(1):16-19. | |

| 17 | 徐巨华. 油液体积弹性模量对电液伺服系统动态特性影响研究[D]. 杭州:浙江大学机械工程学院,2013. |

| Xu Ju-hua. Study on the influence of oil volume elastic modulus on dynamic characteristics of electro-hydraulic servo system[D]. Hangzhou:School of Mechanic Engineering, Zhejiang University,2013. | |

| 18 | 周志鸿,闫建辉,刘连华. 间隙泄漏量的分析计算[J]. 凿岩机械气动工具,2002(4):14-17. |

| Zhou Zhi-hong, Yan Jian-hui, Liu Lian-hua. Analysis and calculation of clearance leakage[J]. Rock Drilling Machinery and Pneumatic Tools,2002(4):14-17. | |

| 19 | 伍家驹,于阳,李园庭,等. 非对称T型滤波器设计的一种五维可视化算法[J]. 中国电机工程学报,2010,30(33):30-36. |

| Wu Jia-ju, Yu Yang, Li Yuan-ting,et al. A five-dimensional visualization algorithm for design of asymmetric T-filter[J]. Proceedings of the CSEE,2010,30(33):30-36. | |

| 20 | 伍家驹,马若飞,王长坤,等. 实现五维数据可视化的一种方法[J]. 电力电子技术, 2011,45(12):90-92. |

| Wu Jia-ju, Ma Ruo-fei, Wang Chang-kun, et al. A method to realize five-dimensional data visualization[J]. Power Electronics,2011,45(12):90-92. |

| [1] | 李学勇,赵仲秋,张春松,路长厚. 基于有限元的人体⁃机械手交互力计算方法[J]. 吉林大学学报(工学版), 2021, 51(5): 1612-1619. |

| [2] | 施昕昕,黄家才,高芳征. 基于分数阶BICO滤波器的运动控制测量噪声抑制[J]. 吉林大学学报(工学版), 2021, 51(5): 1873-1878. |

| [3] | 于萍,穆特,朱黎辉,周子业,宋杰. 钻具输送装置非线性动力学分析及稳定性控制[J]. 吉林大学学报(工学版), 2021, 51(3): 820-830. |

| [4] | 姜继海,赵存然,张冠隆,车明阳. 航空煤油柱塞泵摩擦副涂层材料摩擦性能[J]. 吉林大学学报(工学版), 2021, 51(1): 147-153. |

| [5] | 胡明伟,王洪光,潘新安. 基于正交设计的协作机器人全域结构优化设计[J]. 吉林大学学报(工学版), 2021, 51(1): 370-378. |

| [6] | 刘昌盛, 何清华, 张大庆, 李铁辉, 龚俊, 赵喻明. 混合动力挖掘机势能回收系统参数优化与试验[J]. 吉林大学学报(工学版), 2014, 44(2): 379-386. |

| [7] | 龚俊, 何清华, 张大庆, 张云龙, 刘昌盛, 唐中勇. 混合动力叉车节能效果评价及能量回收系统试验[J]. 吉林大学学报(工学版), 2014, 44(01): 29-34. |

|

||