吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (3): 820-830.doi: 10.13229/j.cnki.jdxbgxb20200130

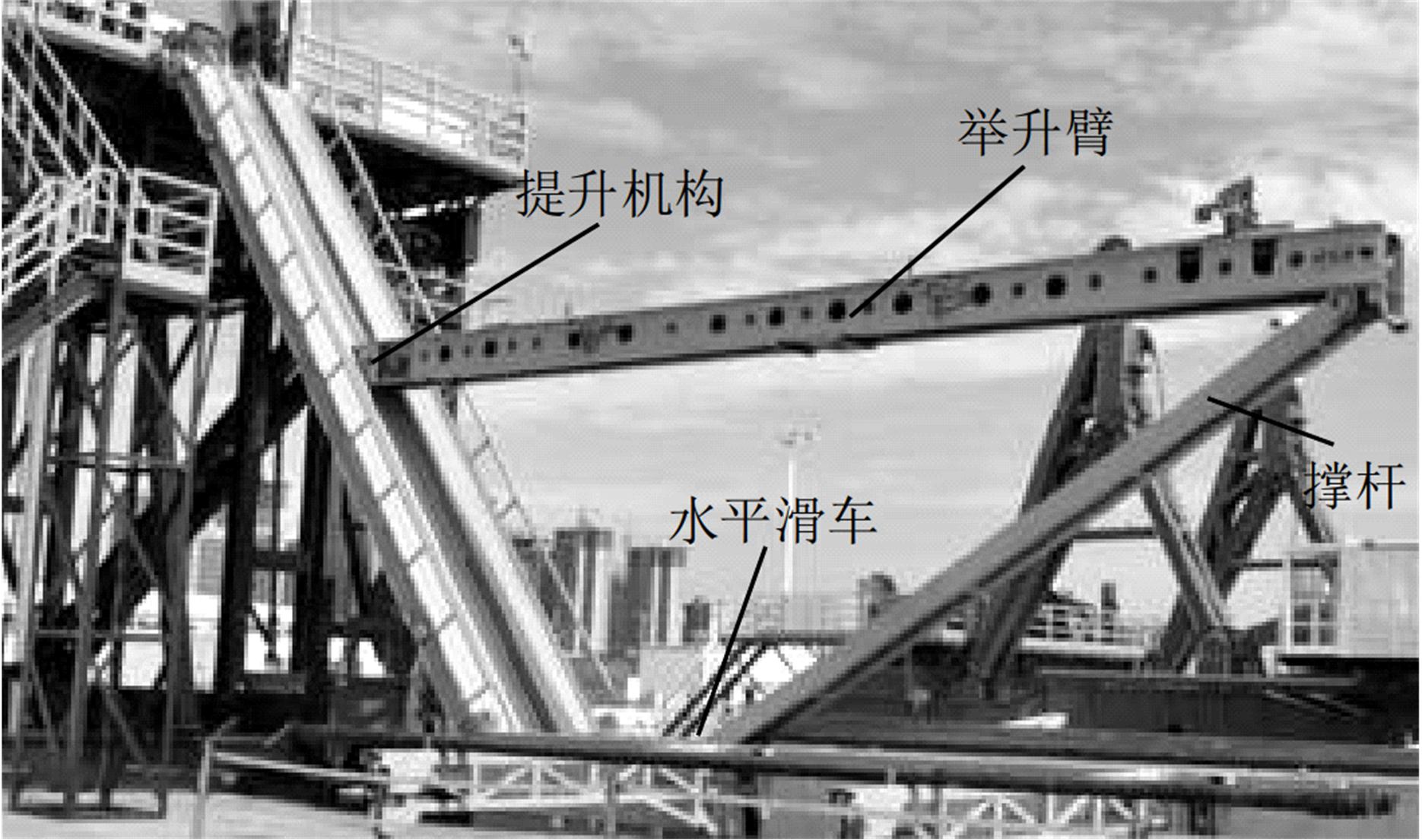

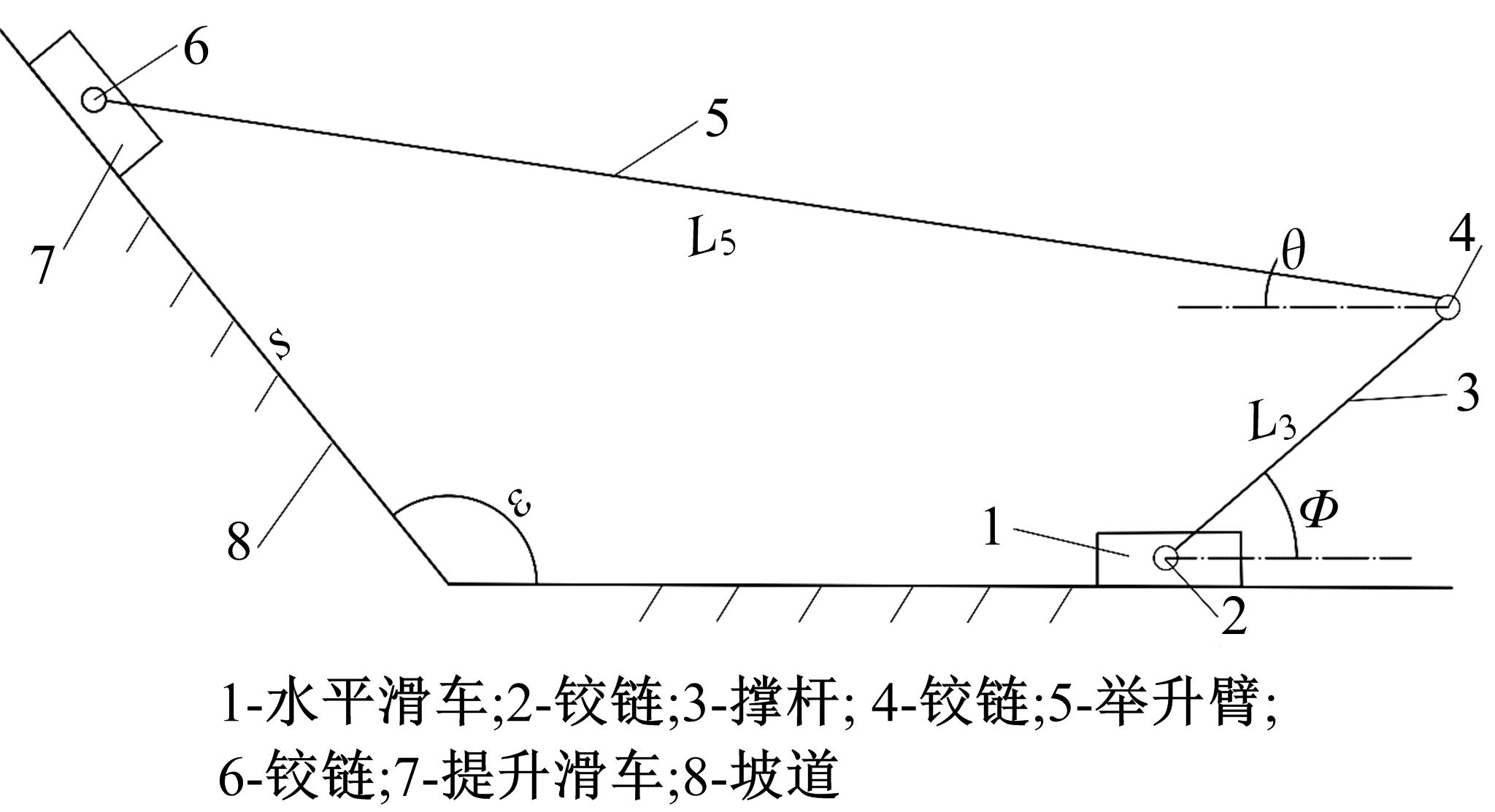

钻具输送装置非线性动力学分析及稳定性控制

- 吉林大学 机械与航空航天工程学院,长春 130022

Nonlinear dynamic analysis and stability control of drilling tool conveying mechanism

Ping YU( ),Te MU,Li-hui ZHU,Zi-ye ZHOU,Jie SONG

),Te MU,Li-hui ZHU,Zi-ye ZHOU,Jie SONG

- College of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

摘要:

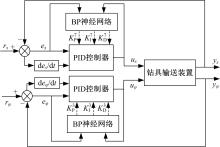

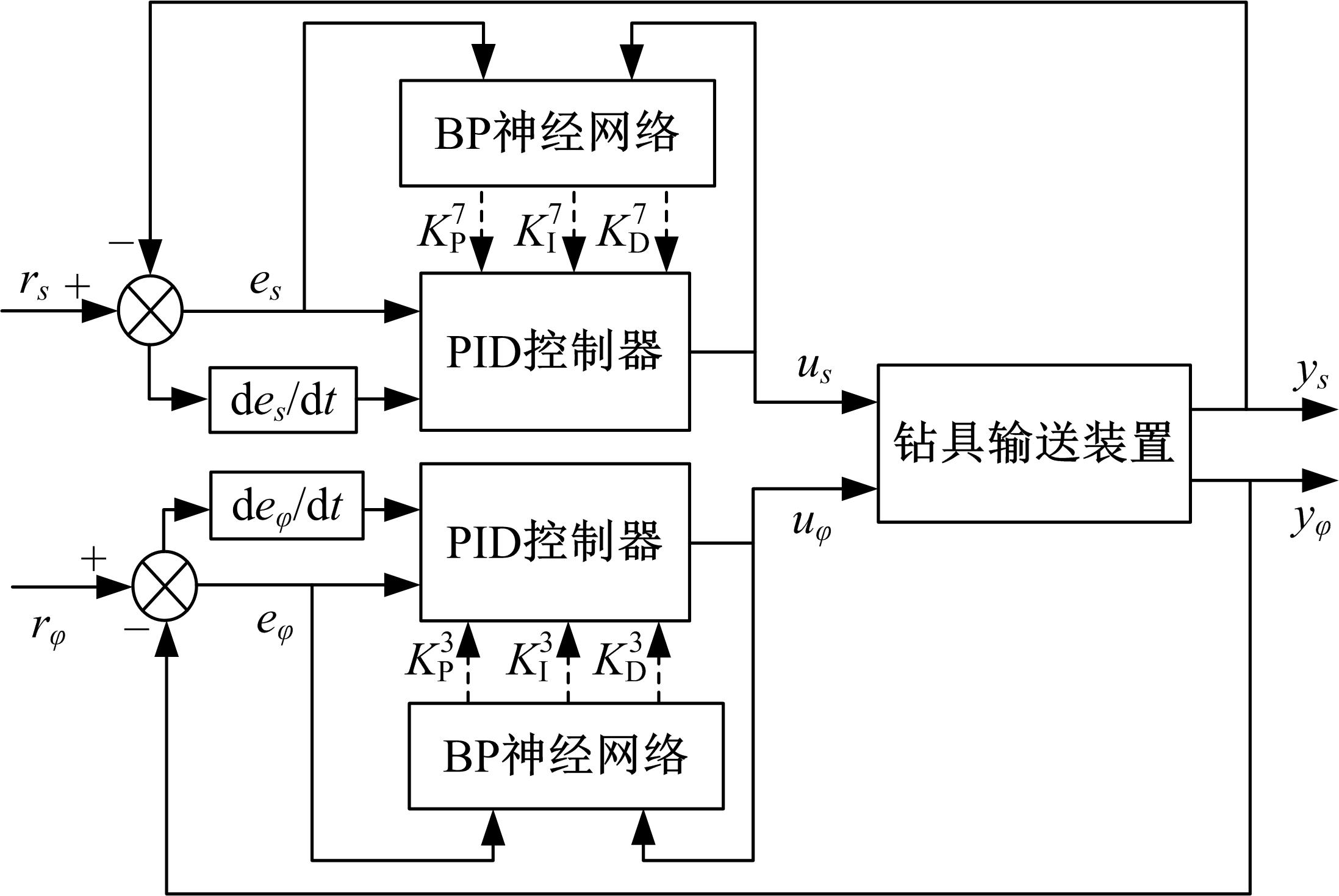

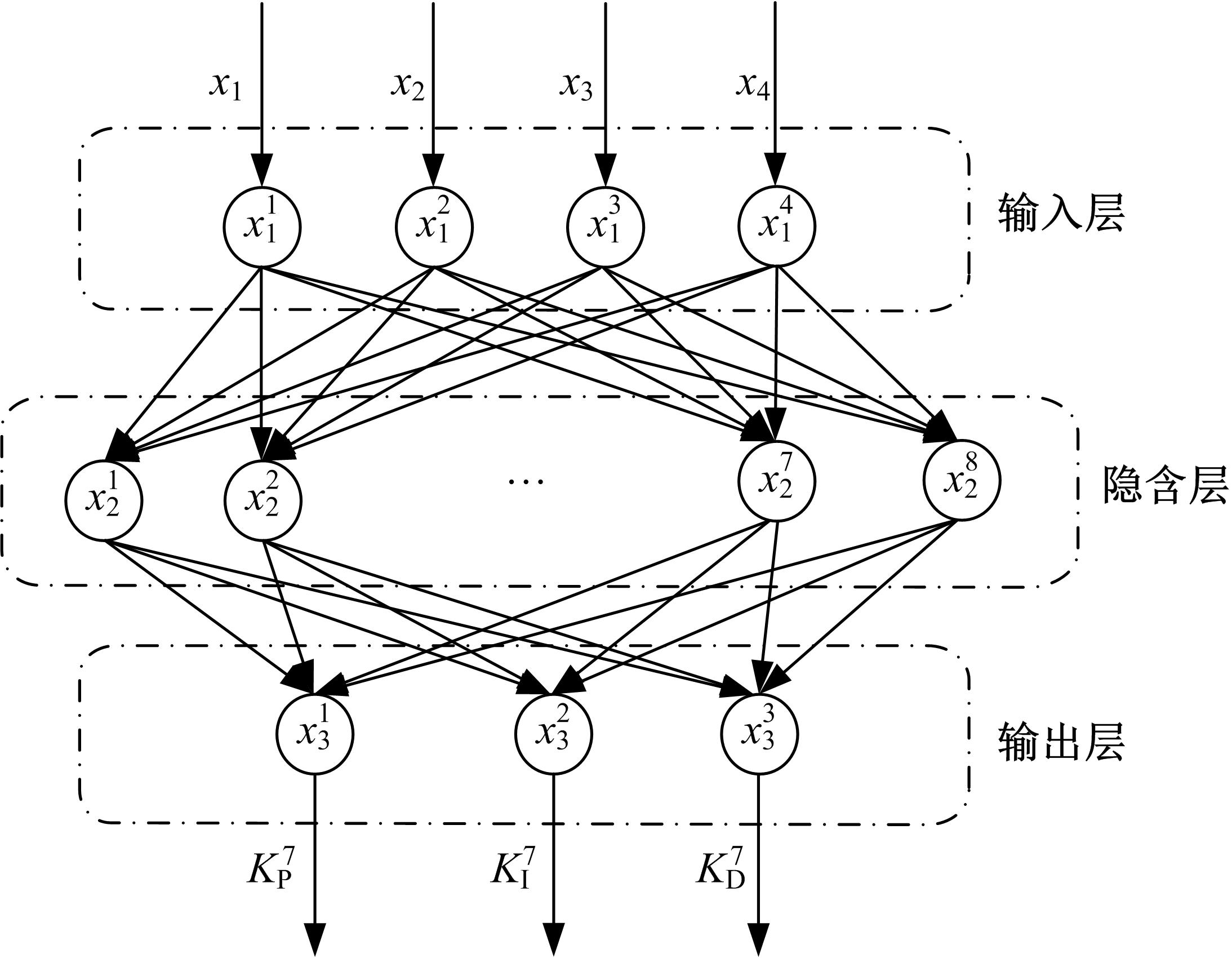

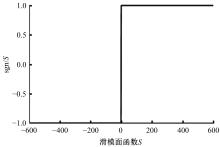

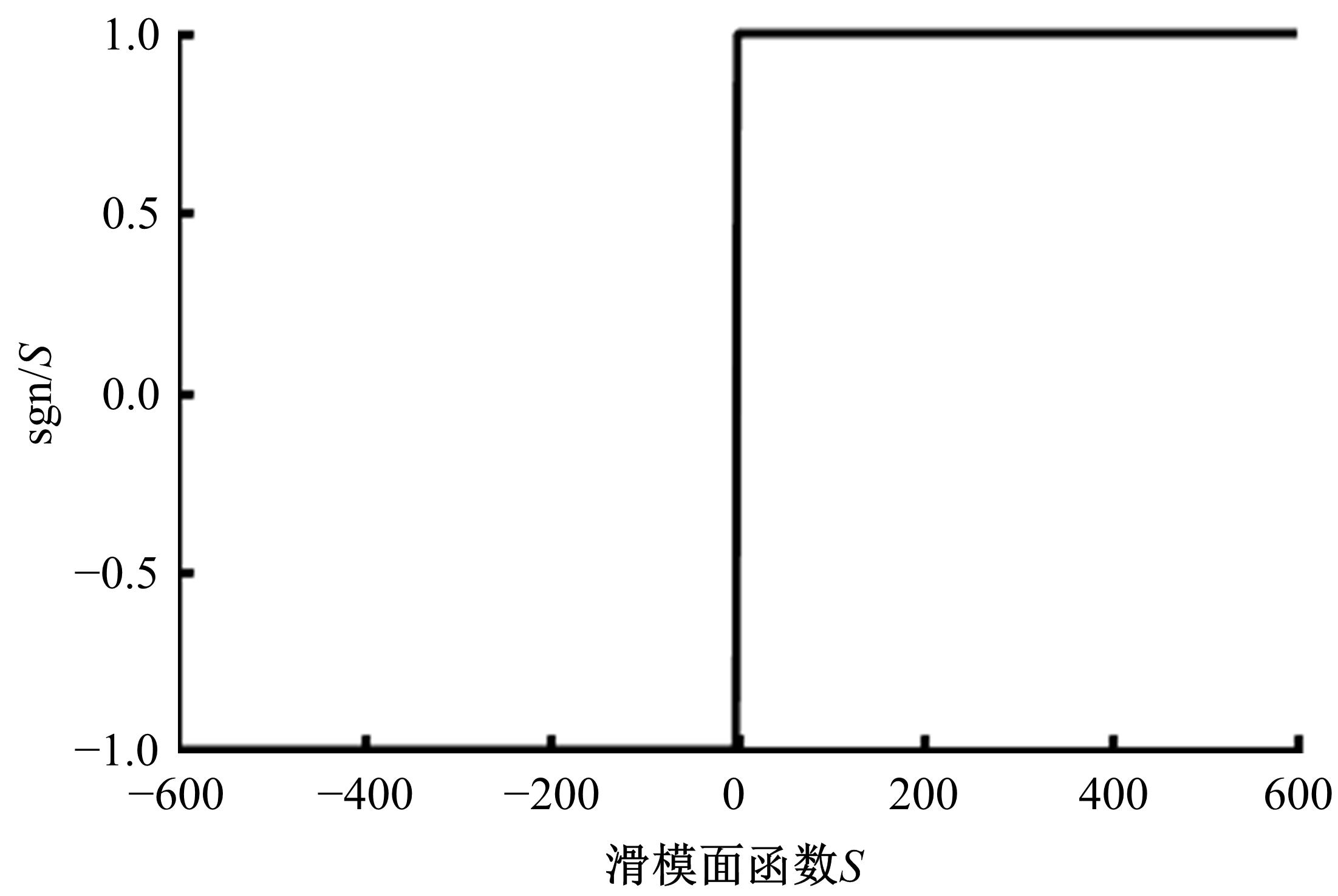

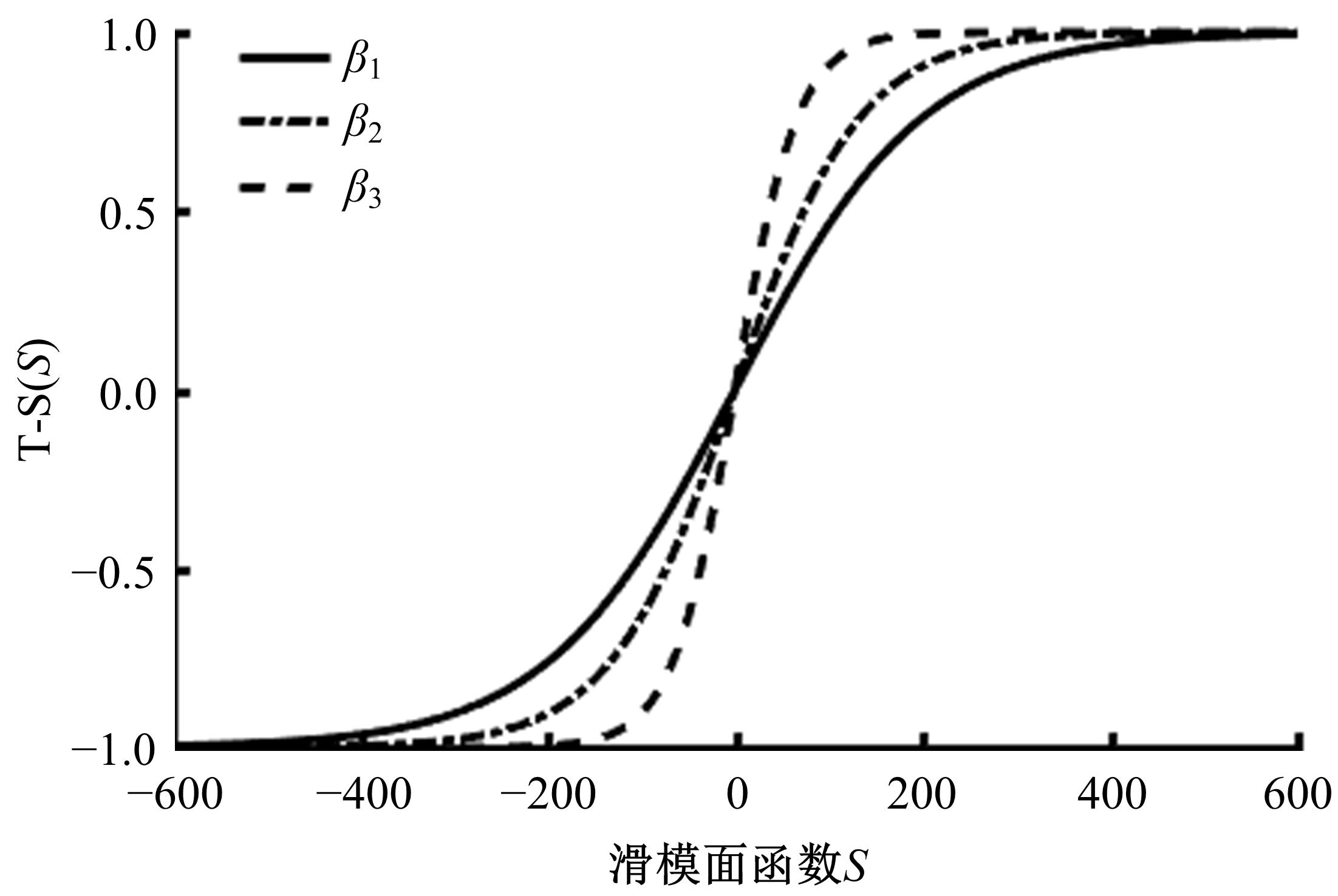

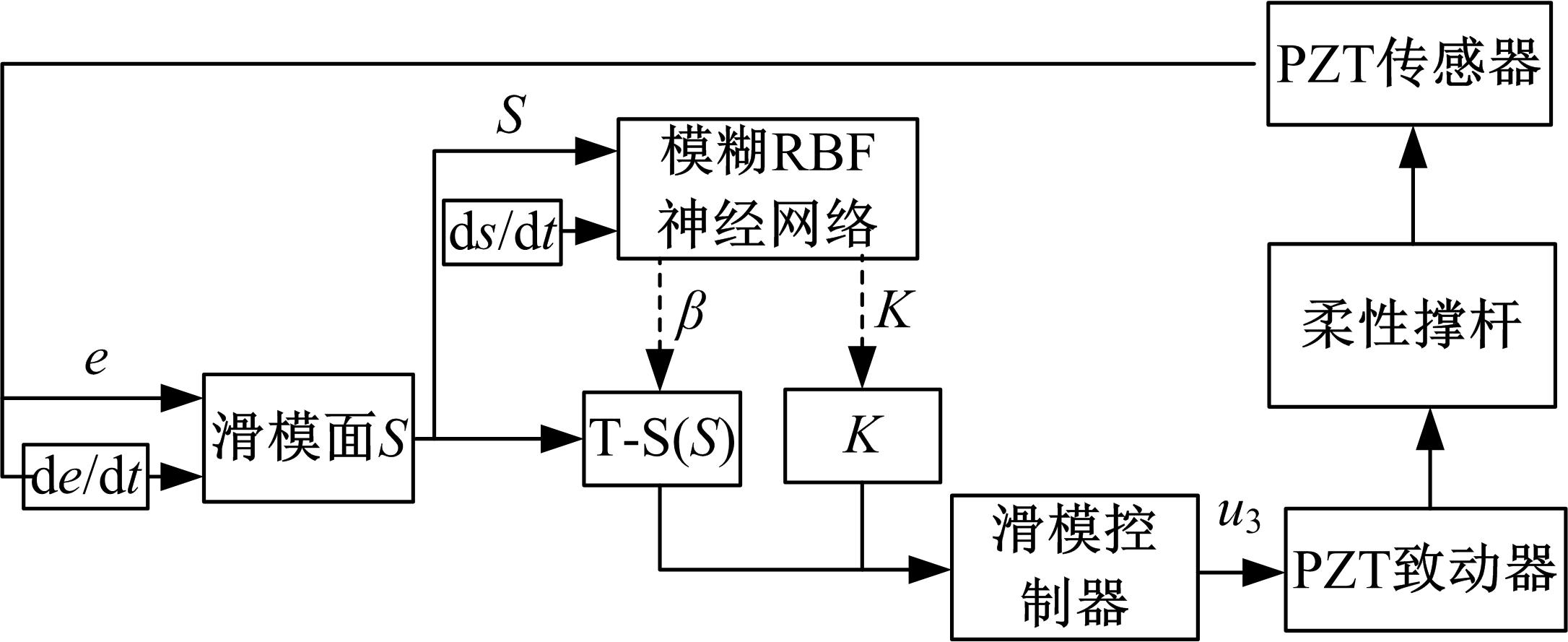

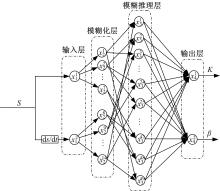

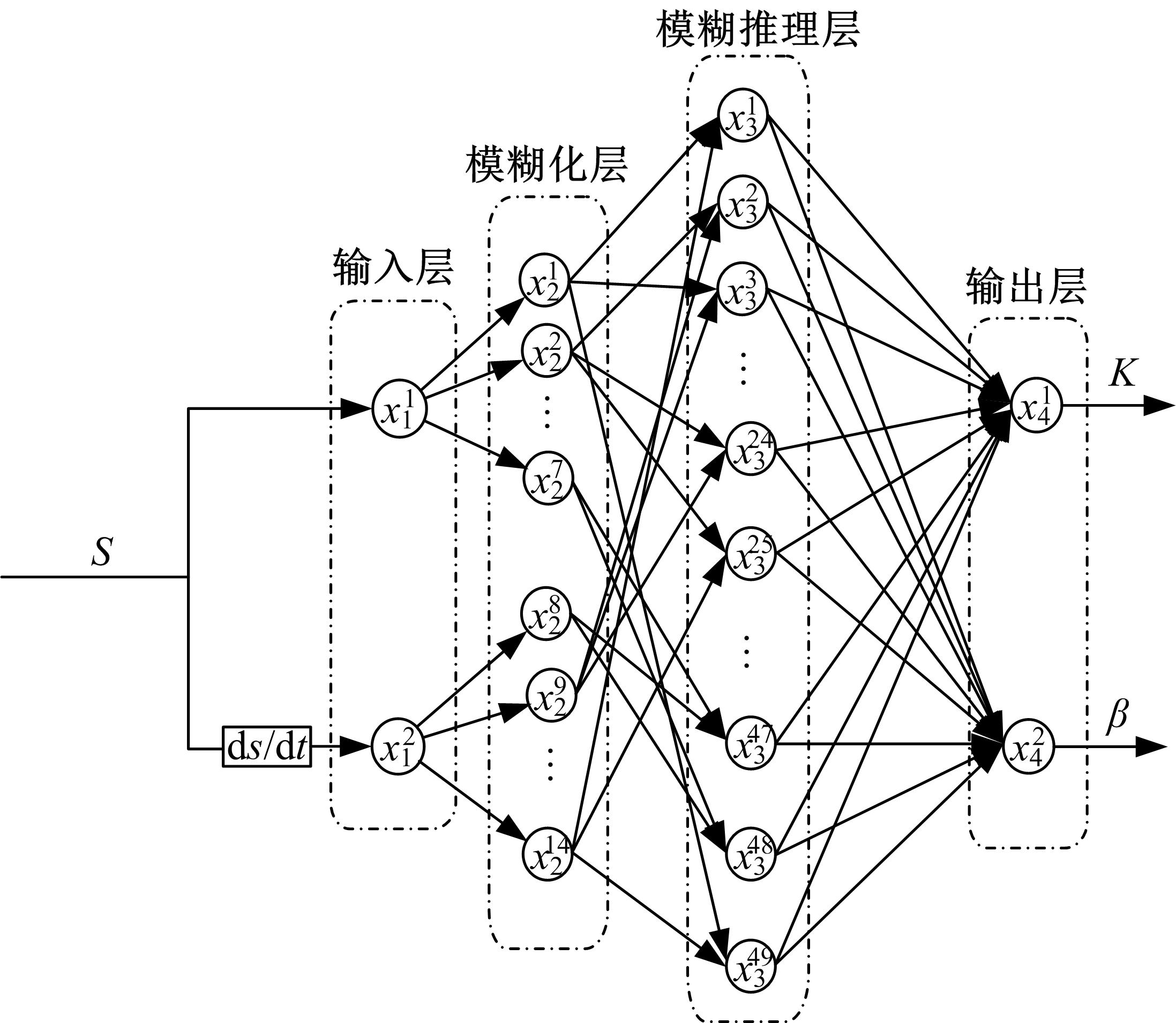

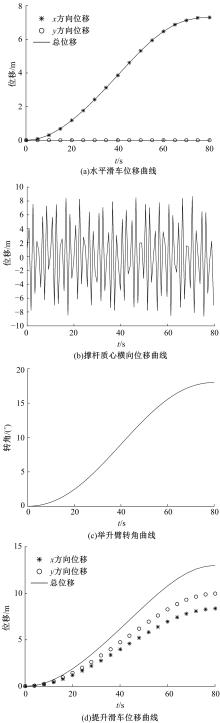

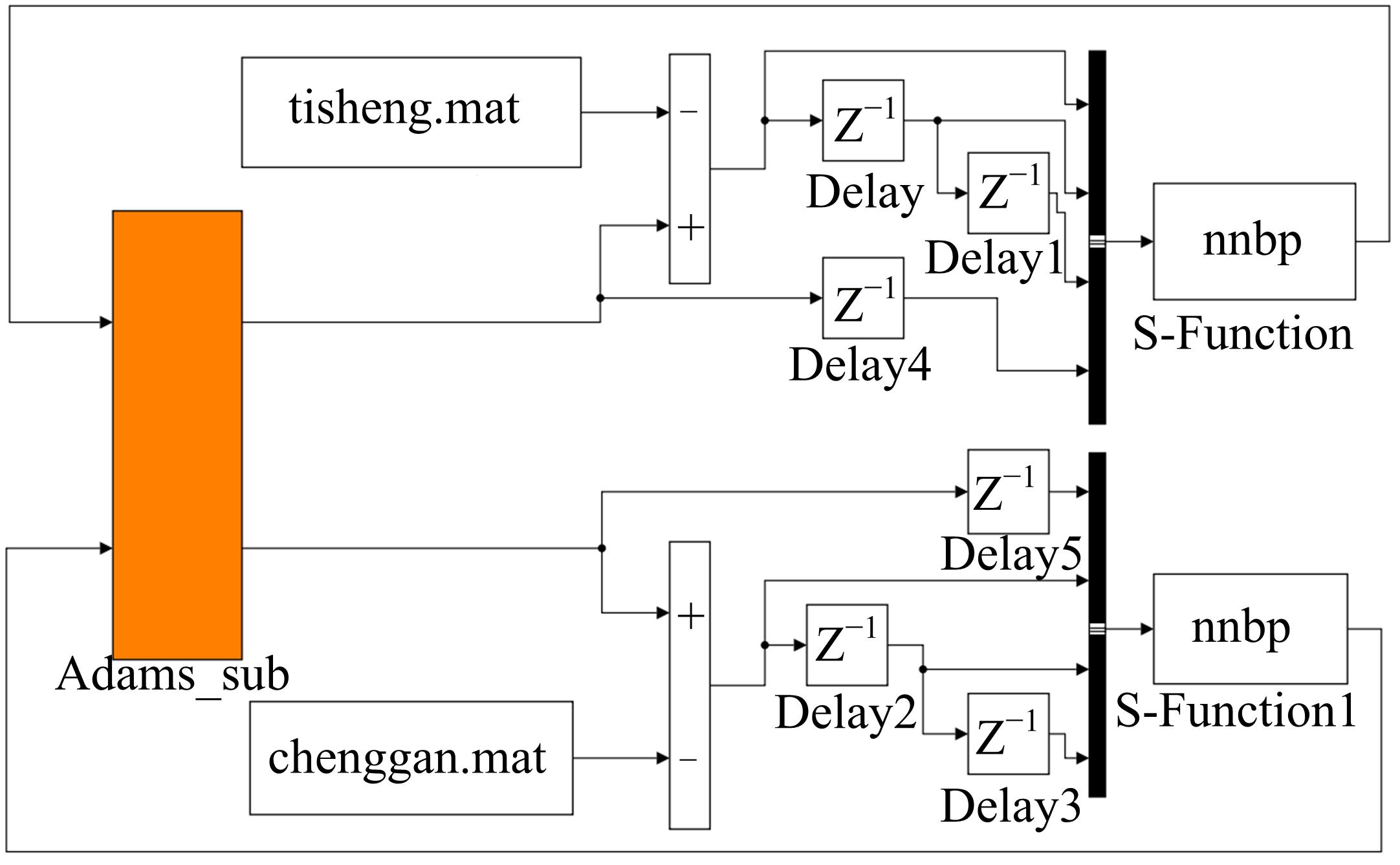

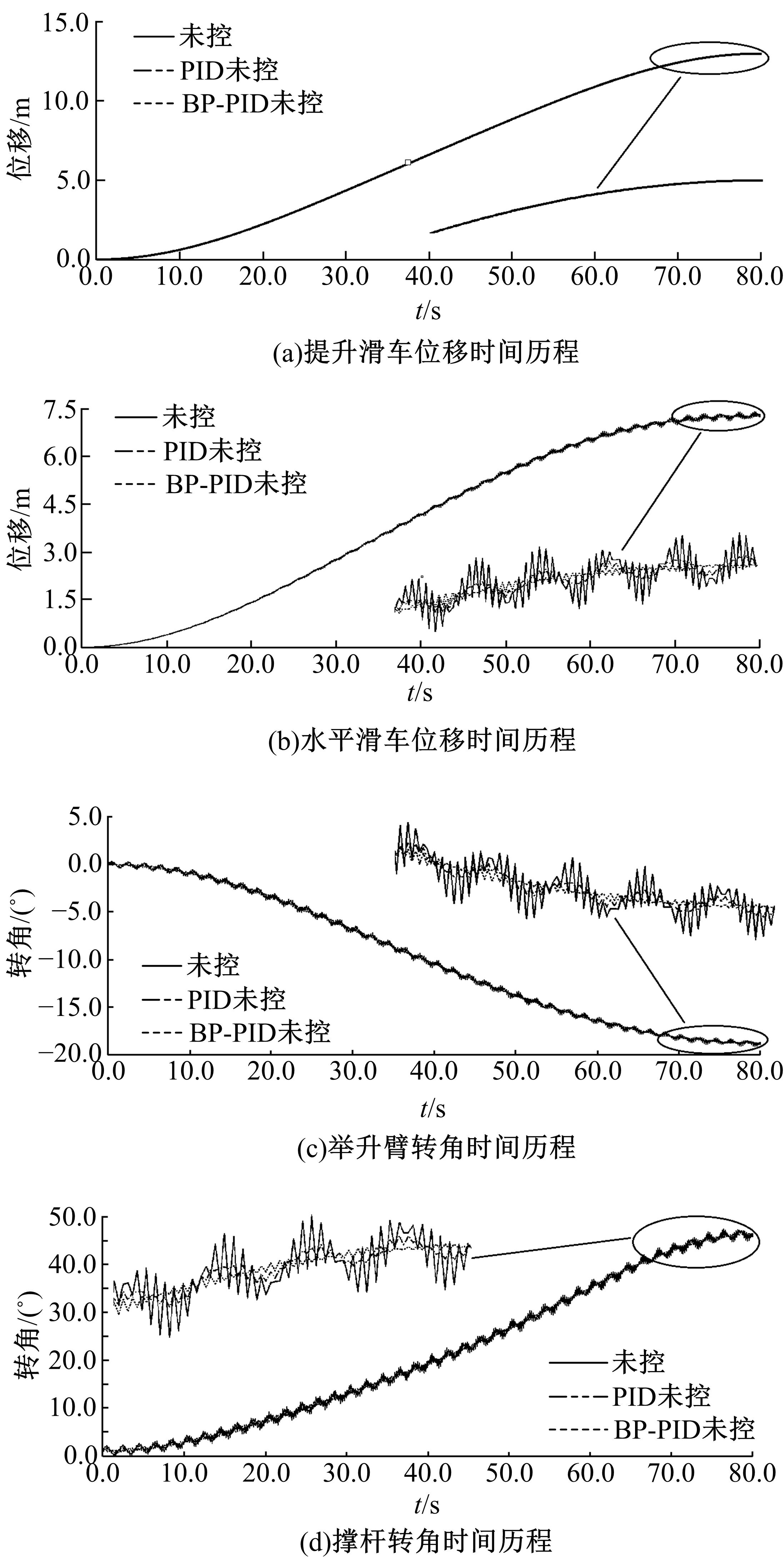

钻具输送装置为刚柔耦合多体系统,工作时由于系统参数和外部扰动的不确定,使其工作稳定性下降。针对这一问题,利用多体系统传递矩阵法建立了钻具输送装置非线性动力学模型,依据工作要求设定了轨迹函数。将钻具输送装置的工作稳定性控制分为工作位姿跟踪控制和装置内柔性体非线性振动抑制两部分。提出了基于BP神经网络的PID控制算法,对整机位姿进行动态跟踪控制;对于柔性体的振动,采用将压电材料粘贴于柔性构件表面形成智能复合材料,并利用基于模糊RBF神经网络的滑模控制算法进行抑制。仿真结果显示,整机的工作位置精度得到了显著提高,柔性体振动得到了有效抑制。

中图分类号:

- TE928

| 1 | Sun Y H, Zhang F Y, Wang Q Y, et al. Application of "Crust 1" 10k ultra-deep scientific drilling rig in Songliao Basin Drilling Project (CCSD-SKII)[J]. Journal of Petroleum Science and Engineering,2016,145: 222-229. |

| 2 | 柴汇,荣学文,唐兴鹏,等. 基于能量规划的崎岖地面四足机器人平面跳跃控制[J]. 吉林大学学报:工学版,2017,47(2):557-566. |

| Chai Hui,Rong Xue-wen,Tang Xing-peng.Telescoping path optimization of a single-cylinder pin-type multi-section boom based on Hopfield neural network[J]. Journal of Jilin University(Engineering and Technology Edition),2017,47(2):557-566. | |

| 3 | Wang F, Chao Z Q, Huang L B, et al. Trajectory tracking control of robot manipulator based on RBF neural network and fuzzy sliding mode[J]. Cluster Computing, 2019,22:5799-5809. |

| 4 | Cao F F, Liu J K. Optimal trajectory control for a two-link rigid-flexible manipulator with ODE-PDE model[J]. Optimal Control Applications and Methods, 2018, 39(4): 1515-1529. |

| 5 | 朱伟,王传伟,顾开荣,等. 一种新型张拉整体并联机构刚度及动力学分析[J]. 吉林大学学报:工学版,2018,48(6):1777-1786. |

| Zhu Wei,Wang Chuan-wei,Gu Kai-rong. Stiffness and dynamics analysis of a new type of tensegrity parallel mechanism[J]. Journal of Jilin University(Engineering and Technology Edition),2018,48(6):1777-1786. | |

| 6 | Chiang C J, Chen Y C. Neural network fuzzy sliding mode control of pneumatic muscle actuators[J]. Engineering Applications of Artificial Intelligence, 2017, 65: 68-86. |

| 7 | 毛艳,成凯. 基于Hopfield神经网络的单缸插销式伸缩臂伸缩路径优化[J].吉林大学学报:工学版,2020,50(1):53-65. |

| Mao Yan,Cheng Kai. Telescoping path optimization of a single-cylinder pin-type multi-section boom based on Hopfield neural network[J]. Journal of Jilin University(Engineering and Technology Edition), 2020,50(1):53-65. | |

| 8 | Qiu Zhi-cheng, Wang Xian-feng, Zhang Xian-min, et al. A novel vibration measurement and active control method for a hinged flexible two-connected piezoelectric plate[J]. Mechanical Systems and Signal Processing, 2018,107:357-395. |

| 9 | 王杰,钱利勤,陈新龙,等. 自动猫道起升系统动力学模型与分析[J]. 工程设计学报, 2016,23(5):437-443, 460. |

| Wang Jie,Qian Li-qin,Chen Xin-long, et al. Dynamics model and analysis of the lifting system of automatic catwalk[J]. Journal of Engineering Design,2016,23(5):437-443, 460. | |

| 10 | 于萍,宋杰,赵楠. 自动猫道翻转机构失效研究[J]. 机械设计与制造,2019(10):257-261. |

| Yu Ping,Song Jie,Zhao Nan. Failure analysis of turnover mechanism in automatic catwalk[J]. Machinery Design & Manufacture,2019(10):257-261. | |

| 11 | Pawlus W, Choux M, Hansen M R, et al. Load torque estimation method to design electric drivetrains for offshore pipe handling equipment[J]. Journal of Offshore Mechanics and Arctic Engineering, 2016, 138(4):041304. |

| 12 | 黄悦华,赵亮亮,李峰,等. 基于ADAMS的动力猫道扶持臂变幅机构优化设计[J]. 石油矿场机械,2016,44(7):36-38. |

| Huang Yue-hua,Zhao Liang-liang,Li Feng. Optimization design of the amplitude variation mechanism of supportive arm of power catwalk based on ADAMS[J]. Oil Field Equipment, 2016,44(7):36-38. | |

| 13 | 康思杰. 基于刚柔耦合模型的钻具自动输送装置动态特性研究[D]. 长春: 吉林大学机械与航空航天工程学院,2017. |

| Kang Si-jie. Study on the dynamic characteristics of drilling tool automatic conveying mechanism based on rigid-flexible coupling model[D]. Changchun:College of Mechanical and Aerospace Engineering, Jilin University, 2017. | |

| 14 | Rong Bao, Rui Xiao-ting, Wang Guo-ping, et al. Erratum: new efficient method for dynamic modeling and simulation of flexible multibody systems moving in plane[J]. Multibody System Dynamics, 2010, 24(2):201-202. |

| 15 | Rong Bao, Rui Xiao-ting, Tao Ling. Dynamics and genetic fuzzy neural network vibration control design of a smart flexible four-bar linkage mechanism[J]. Multibody System Dynamics, 2012, 38(4):291-311. |

| [1] | 宋强,孙丹婷,章伟. 纯电动车机械式自动变速器换挡非线性建模及控制[J]. 吉林大学学报(工学版), 2021, 51(3): 810-819. |

| [2] | 陈国迎,姚军,王鹏,夏其坤. 适用于后轮轮毂驱动车辆的稳定性控制策略[J]. 吉林大学学报(工学版), 2021, 51(2): 397-405. |

| [3] | 姜继海,赵存然,张冠隆,车明阳. 航空煤油柱塞泵摩擦副涂层材料摩擦性能[J]. 吉林大学学报(工学版), 2021, 51(1): 147-153. |

| [4] | 胡明伟,王洪光,潘新安. 基于正交设计的协作机器人全域结构优化设计[J]. 吉林大学学报(工学版), 2021, 51(1): 370-378. |

| [5] | 刘兆惠, 王超, 吕文红, 管欣. 基于非线性动力学分析的车辆运行状态参数数据特征辨识[J]. 吉林大学学报(工学版), 2018, 48(5): 1405-1410. |

| [6] | 李玲, 施树明, 王宪彬, 于壮. 发动机制动下高速转弯车辆稳定性[J]. 吉林大学学报(工学版), 2017, 47(1): 64-70. |

| [7] | 高琳琳, 金立生, 郑义, 李科勇. 四轮转向车辆的径向基函数神经网络复合控制器设计[J]. 吉林大学学报(工学版), 2016, 46(2): 366-372. |

| [8] | 何磊, 马伯祥, 郑宏宇, 王祥. 基于无源理论的线控转向汽车稳定性控制[J]. 吉林大学学报(工学版), 2015, 45(6): 1737-1742. |

| [9] | 武冬梅, 丁海涛, 郭孔辉. 基于线性估计模型的电动汽车质心侧偏角估计[J]. 吉林大学学报(工学版), 2014, 44(4): 901-906. |

| [10] | 刘昌盛, 何清华, 张大庆, 李铁辉, 龚俊, 赵喻明. 混合动力挖掘机势能回收系统参数优化与试验[J]. 吉林大学学报(工学版), 2014, 44(2): 379-386. |

| [11] | 龚俊, 何清华, 张大庆, 张云龙, 刘昌盛, 唐中勇. 混合动力叉车节能效果评价及能量回收系统试验[J]. 吉林大学学报(工学版), 2014, 44(01): 29-34. |

| [12] | 李静, 余春贤, 陆辉, 高月磊. 基于模型预测的车辆稳定控制[J]. 吉林大学学报(工学版), 2013, 43(增刊1): 504-508. |

| [13] | 刘志峰, 张志民, 张敬莹, 罗兵. 基于多项式的等高齿锥齿轮时变啮合刚度建模[J]. 吉林大学学报(工学版), 2013, 43(04): 939-944. |

| [14] | 许洪国, 彭涛, 刘宏飞, 许言. 半挂汽车转向稳定性反馈线性化控制[J]. 吉林大学学报(工学版), 2012, 42(02): 272-278. |

| [15] | 蔡仲昌, 刘辉, 项昌乐, 张喜清, 王明正. 车辆多级行星传动系统强迫扭转振动与动载特性[J]. 吉林大学学报(工学版), 2012, 42(01): 19-26. |

|

||