吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (4): 1133-1138.doi: 10.13229/j.cnki.jdxbgxb.20210206

• 交通运输工程·土木工程 • 上一篇

回热对低温大质流密度实验系统能耗影响

徐振军1( ),张瑞凤1,2,陈嘉祥2,张晓慧3,密晓光3,陈杰3,陈林2,4(

),张瑞凤1,2,陈嘉祥2,张晓慧3,密晓光3,陈杰3,陈林2,4( )

)

- 1.青岛农业大学 建筑工程学院,山东 青岛 266109

2.中国科学院 工程热物理研究所,北京 100190

3.中海石油气电集团 研发中心,北京 100028

4.中国科学院大学 航空宇航学院,北京 100049

Influence for backheating on low temperature high mass experimental system

Zhen-jun XU1( ),Rui-feng ZHANG1,2,Jia-xiang CHEN2,Xiao-hui ZHANG3,Xiao-guang MI3,Jie CHEN3,Lin CHEN2,4(

),Rui-feng ZHANG1,2,Jia-xiang CHEN2,Xiao-hui ZHANG3,Xiao-guang MI3,Jie CHEN3,Lin CHEN2,4( )

)

- 1.College of Civil Engineering & Architecture,Qingdao Agricultural University,Qingdao 266109,China

2.Institute of Engineering Thermophysics,Chinese Academy of Sciences,Beijing 100190,China

3.R&D Center,CNOOC Gas & Power Group,Beijing 100028,China

4.School of Aeronautics and Astronautics,University of Chinese Academy of Sciences,Beijing 100049,China

摘要:

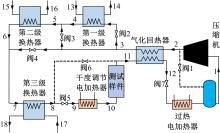

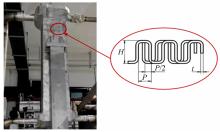

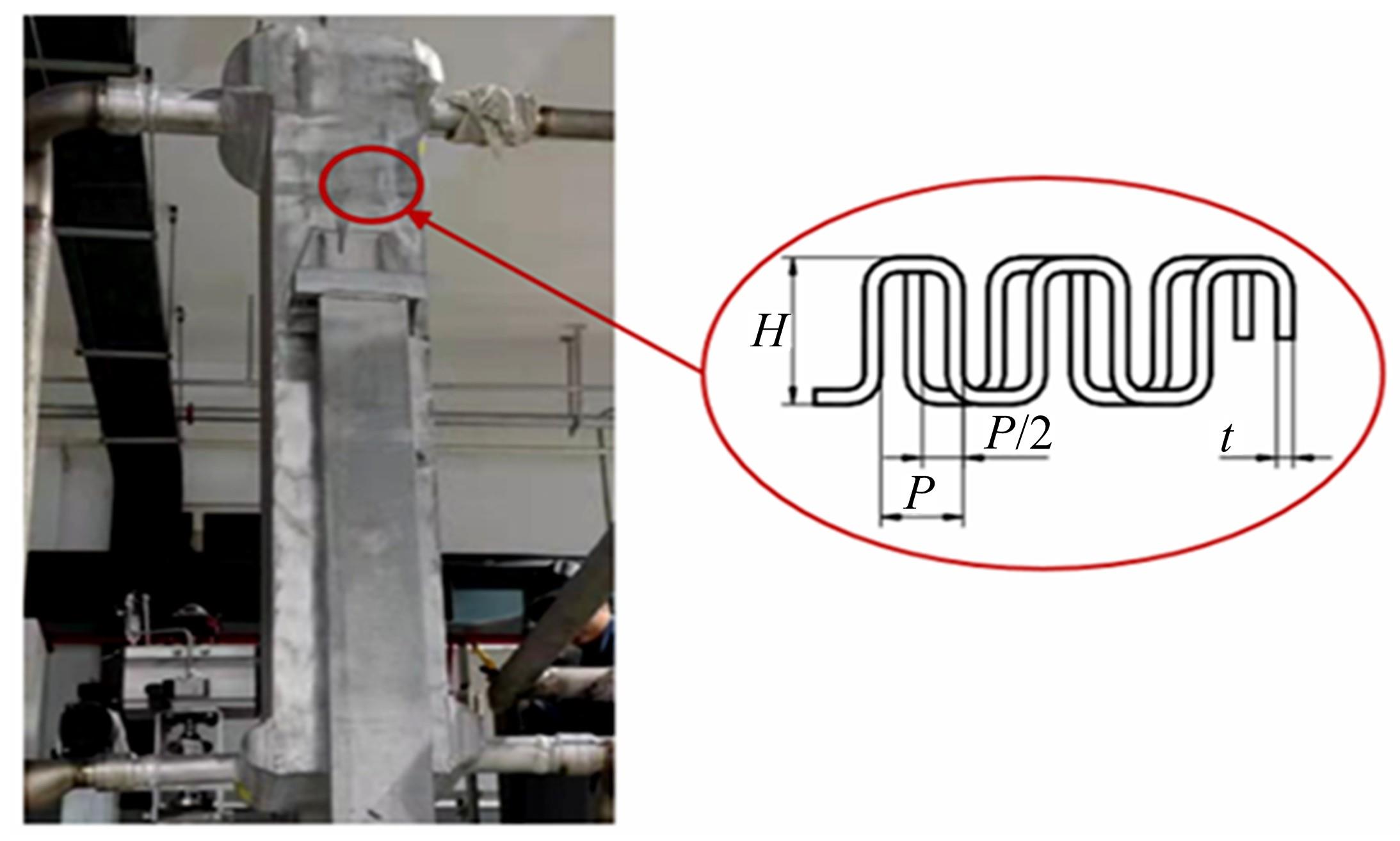

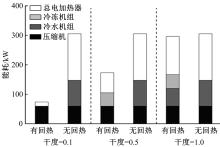

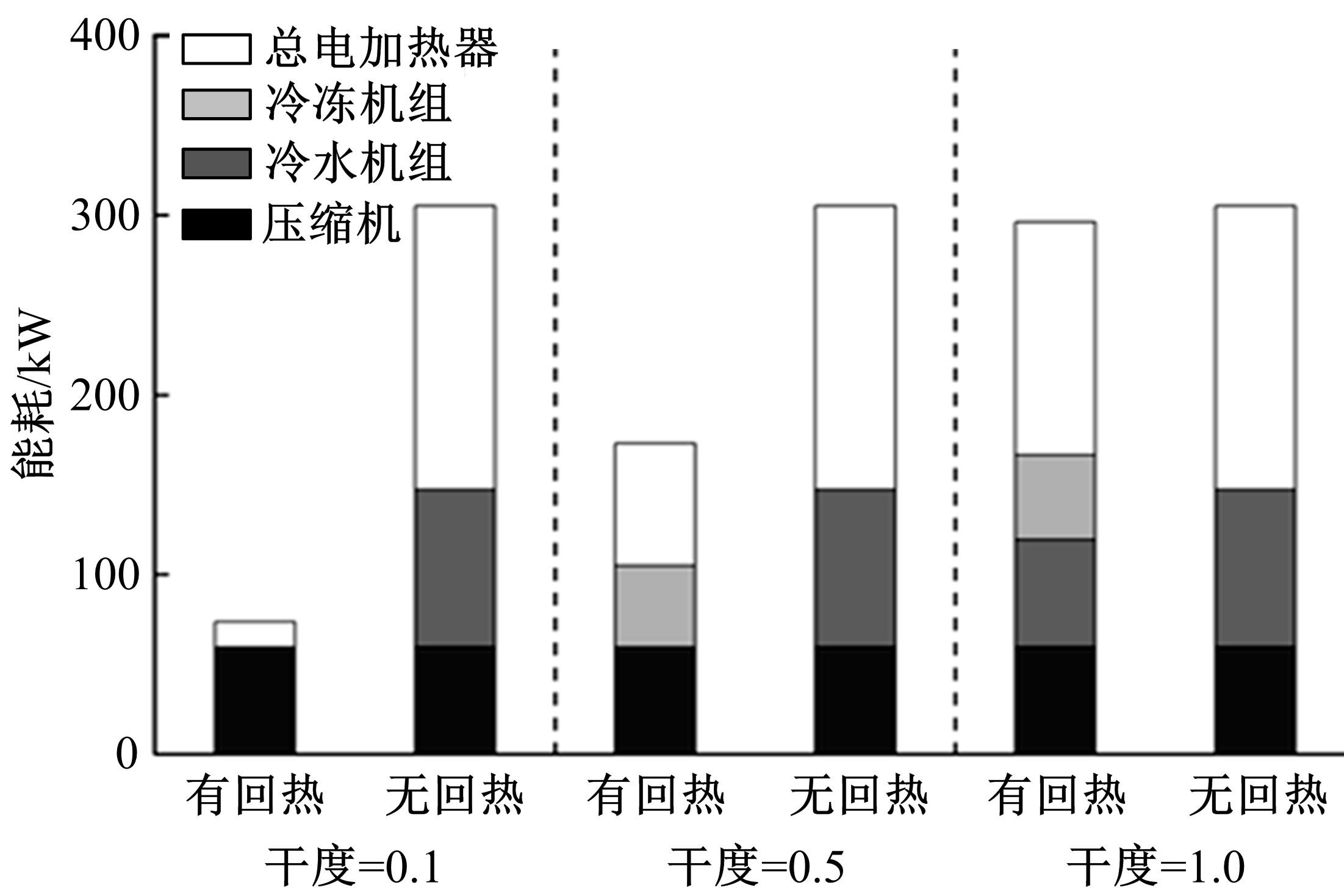

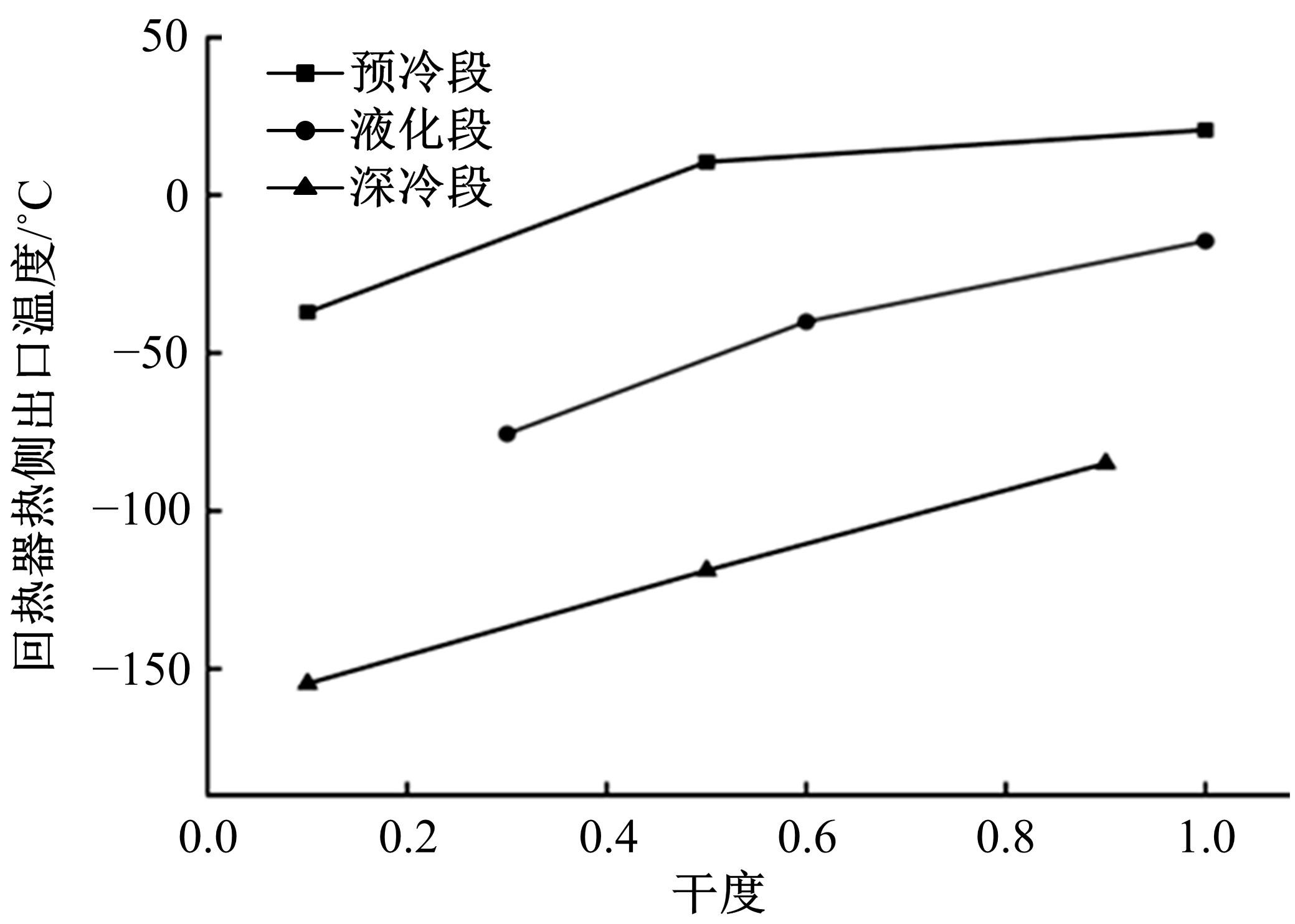

以绕管式换热器为测试件,设计搭建了带回热的大质流密度流动传热特性实验系统。该实验系统包括主测试循环回路、冷却回路、控制系统和安全通风系统。本文实验系统能够覆盖的实验工况范围如下:蒸发压力为0.15~0.85 MPa,质流密度为20~120 kg/(m2·s),干度为0~1.0,热流密度为0~10 kW/m2,温度可达-180 ℃。构建了实验系统热力学模型,获得了实验工况条件下各节点温度、压力数据和设备负荷参数。对该系统能耗进行了对比分析,研究发现,有回热系统在各个干度情况下均比无回热系统的能耗低,干度为0.1时,能耗减少75%,在干度为0.5时,能耗减少43%,在干度为1时,能耗减少3%。

中图分类号:

- TB61

| 1 | 胡宗杰,肖春江,李治龙,等. 基于超声雾化的碳氢燃料多液滴流制备系统[J]. 吉林大学学报: 工学版,2012,42(4): 871-876. |

| Hu Zong-jie, Xiao Chun-jiang, Li Zhi-long, et al. Multi-droplet stream creating system of hydrocarbon fuel based on ultrasonic atomization technology[J]. Journal of Jilin University(Engineering and Technology Edition), 2012,42(4): 871-876. | |

| 2 | 牛亚楠. 多元混合制冷剂小型天然气液化装置的模拟研究[D]. 上海: 同济大学机械工程学院, 2007. |

| Niu Ya-nan. Heat balance test and energy-saving assessment of a industrial glass furnace[D]. Shanghai: School of Mechanical Engineering, Tongji University, 2007. | |

| 3 | 傅佳宏,俞小莉,药凌宇, 等,工程机械独立式冷却模块流动传热仿真对比 [J]. 吉林大学学报: 工学版,2016,46(2): 451-456. |

| Fu Jia-hong, Yu Xiao-li, Yao Ling-yu, et al. Numerical comparison of flow and heat transfer in detached cooling module for construction machinery[J]. Journal of Jilin University(Engineering and Technology Edition), 2016,46(2): 451-456. | |

| 4 | 孙崇正, 李玉星, 韩辉, 等. 海况倾斜条件下DMR液化工艺中绕管式换热器运行可靠性研究[J]. 油气地面工程, 2019, 38(10): 49-56. |

| Sun Chong-zheng, Li Yu-xing, Han Hui, et al. Operation reliability study on spiral wound heat exchanger of DMR liquefaction process under wave tilt conditions[J]. Oil-Gas Field Surface Engineering, 2019, 38(10): 49-56. | |

| 5 | 肖娟, 简冠平, 王家瑞. 缠绕管式换热器性能及应用研究进展[J]. 化工机械, 2016, 43(4): 423-428. |

| Xiao Juan, Jian Guan-ping, Wang Jia-rui. Progress in performance and application study for wound-tube heat Exchanger[J]. Chemical Engineering & Machinery, 2016, 43(4): 423-428. | |

| 6 | Hasan M M, Karimi I A, Alfadala H E, et al. Operational modeling of multi-stream heat exchangers with phase changes[J]. AIChE Journal, 2009, 55(1): 150-171. |

| 7 | Pacio J C, Dorao C A. A review on heat exchanger thermal hydraulic models for cryogenic applications[J]. Cryogenics, 2011, 51(7): 366-379. |

| 8 | 玄哲浩,程崟,崔淑琴. 换热器性能试验测控系统[J].吉林大学学报: 工学版, 2003, 33(1): 53-55. |

| Xuan Zhe-hao, Cheng Yin, Cui Shu-qin. Control unit for heat exchanger performance test system[J]. Journal of Jilin University(Engineering and Technology Edition), 2003, 33(1): 53-55. | |

| 9 | Neeraas B O, Fredheim A O, Aunan B. Experimental data and model for heat transfer, in liquid falling film flow on shell-side, for spiral-wound LNG heat exchanger[J]. International Journal of Heat and Mass Transfer, 2004, 47(14-16): 3565-3572. |

| 10 | 朱建鲁, 常学煜, 韩辉, 等. FLNG绕管式换热器晃动实验分析[J]. 化工学报, 2017, 68(9): 3358-3367. |

| Zhu Jian-lu, Chang Xue-yu, Han Hui, et al. Experimental study on effect of sloshing on performance of heat exchanger[J]. CIESC Journal, 2017, 68(9): 3358-3367. | |

| 11 | 李丰志, 于佳文, 鹿来运, 等. LNG绕管式换热器管侧流动与传热实验台设计及验证[J]. 哈尔滨工业大学学报, 2017, 49(2): 98-102. |

| Li Feng-zhi, Yu Jia-wen, Lu Lai-yun, et al. Design and verification for tube- side flow and heat transfer test-rig of coil-wound LNG heat exchangers[J]. Journal of Harbin Institute of Technology, 2017, 49(2): 98-102. | |

| 12 | 王刚, 巨永林. 用于天然气液化流程的组合式低温热管换热器的实验测试[J]. 化工学报, 2015, 66(): 123-131. |

| Wang Gang, Ju Yong-lin. Experimental investigation of hybrid cryogenic heat pipe heat exchanger in LNG process[J]. CIESC Journal, 2015, 66(Sup.2): 123-131. | |

| 13 | Sun C Z, Li Y X, Han H, Zhu J L. Experimental research on the adaptability of liquid natural gas spiral wound heat exchanger in dual mixed refrigeration liquefaction process[J]. Experimental Thermal and Fluid Science, 2018, 98: 124⁃136. |

| 14 | 丁超, 胡海涛, 丁国良, 等. 运行工况对LNG绕管式换热器壳侧换热特性的影响[J]. 化工学报, 2018, 69(6): 2417-2423. |

| Ding Chao, Hu Hai-tao, Ding Guo-liang, et al. Influences of working conditions on heat transfer characteristics in shell side of LNG spiral wound heat exchangers[J]. CIESC Journal, 2018, 69(6): 2417-2423. | |

| 15 | Peng D Y, Robinson D B. A new two-constant equation of state[J]. Industrial & Engineering Chemistry Research, 1976, 15(1): 59-64. |

| [1] | 杨子荣,李岩,冀雪峰,刘芳,郝冬. 质子交换膜燃料电池运行工况参数敏感性分析[J]. 吉林大学学报(工学版), 2022, 52(9): 1971-1981. |

| [2] | 徐振军,王浩,赵开元,郝博轶,李清清,王常浩. 复合太阳能的燃气机热泵热力学性能[J]. 吉林大学学报(工学版), 2022, 52(8): 1759-1763. |

| [3] | 赵同宾,吴宜胜,段耀宗,黄震,韩东. RP-3航空煤油的润滑特性和改善措施[J]. 吉林大学学报(工学版), 2022, 52(3): 533-540. |

| [4] | 余剑武,陈亚玲,范光辉,胡仕港,包有玉. 锂电池并行流道液冷板结构设计和散热性能分析[J]. 吉林大学学报(工学版), 2022, 52(12): 2788-2795. |

| [5] | 朱思峰,赵明阳,柴争义. 边缘计算场景中基于粒子群优化算法的计算卸载[J]. 吉林大学学报(工学版), 2022, 52(11): 2698-2705. |

| [6] | 徐振军,王浩,王银成,张诺,陈孟,李清清. 微通道低温换热器流动传热性能[J]. 吉林大学学报(工学版), 2022, 52(10): 2294-2299. |

| [7] | 滕文龙,丛炳虎,商云坤,张予宸,白天. 基于MEA⁃BP神经网络的建筑能耗预测模型[J]. 吉林大学学报(工学版), 2021, 51(5): 1857-1865. |

| [8] | 潘凤文,弓栋梁,高莹,徐明伟,麻斌. 基于锂离子电池线性化模型的电流传感器故障诊断[J]. 吉林大学学报(工学版), 2021, 51(2): 435-441. |

| [9] | 刘富,安毅,董博,李元春. 基于ADP的可重构机械臂能耗保代价分散最优控制[J]. 吉林大学学报(工学版), 2020, 50(1): 342-350. |

| [10] | 孟育博, 李丕茂, 张幽彤, 王志明. 共轨系统压力波动和多次喷射油量偏差的抑制[J]. 吉林大学学报(工学版), 2018, 48(3): 760-766. |

| [11] | 孙正, 黄钰期, 俞小莉. 径向滑动轴承润滑油膜流动-传热过程仿真[J]. 吉林大学学报(工学版), 2018, 48(3): 744-751. |

| [12] | 孟育博, 张幽彤, 王志明, 张晓晨, 樊利康, 李涛. 压电喷油器压电执行器热-电-机械耦合迟滞特性[J]. 吉林大学学报(工学版), 2018, 48(2): 480-485. |

| [13] | 杨智勇, 吴功平, 王伟, 郭磊, 杨守东, 曹琪, 张义杰, 胡鹏. 高压巡检机器人下坡节能控速方法[J]. 吉林大学学报(工学版), 2017, 47(2): 567-576. |

| [14] | 吴志军, 赵文伯, 张青. 基于热氛围燃烧器的湍流射流起升火焰基础研究进展[J]. 吉林大学学报(工学版), 2016, 46(6): 1881-1891. |

| [15] | 崔金生, 侯绪研, 邓宗全, 潘万竞, 姜生元. 真空颗粒系统有效导热系数测量试验台研制及试验[J]. 吉林大学学报(工学版), 2016, 46(2): 457-464. |

|

||