吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (12): 2788-2795.doi: 10.13229/j.cnki.jdxbgxb20210434

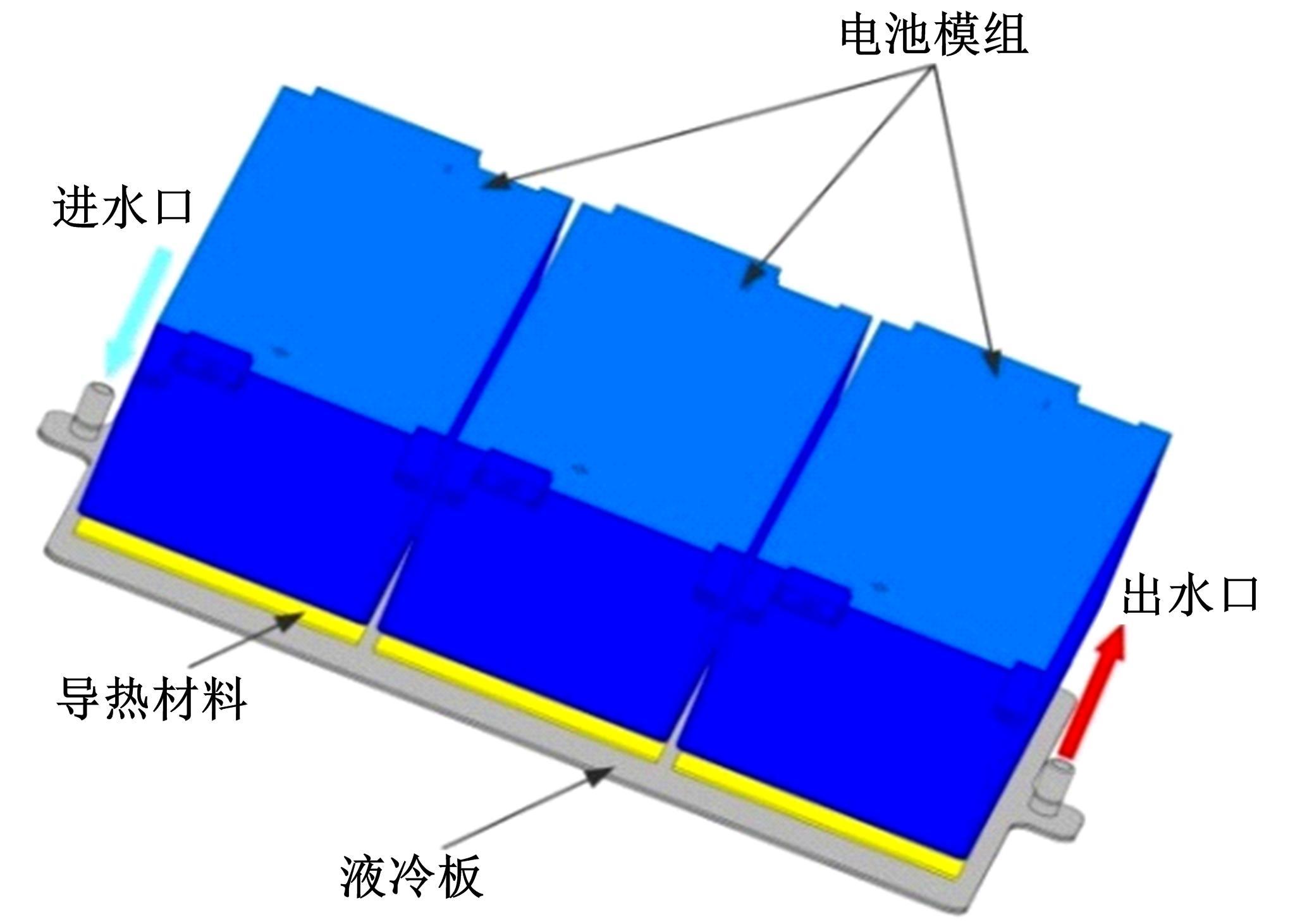

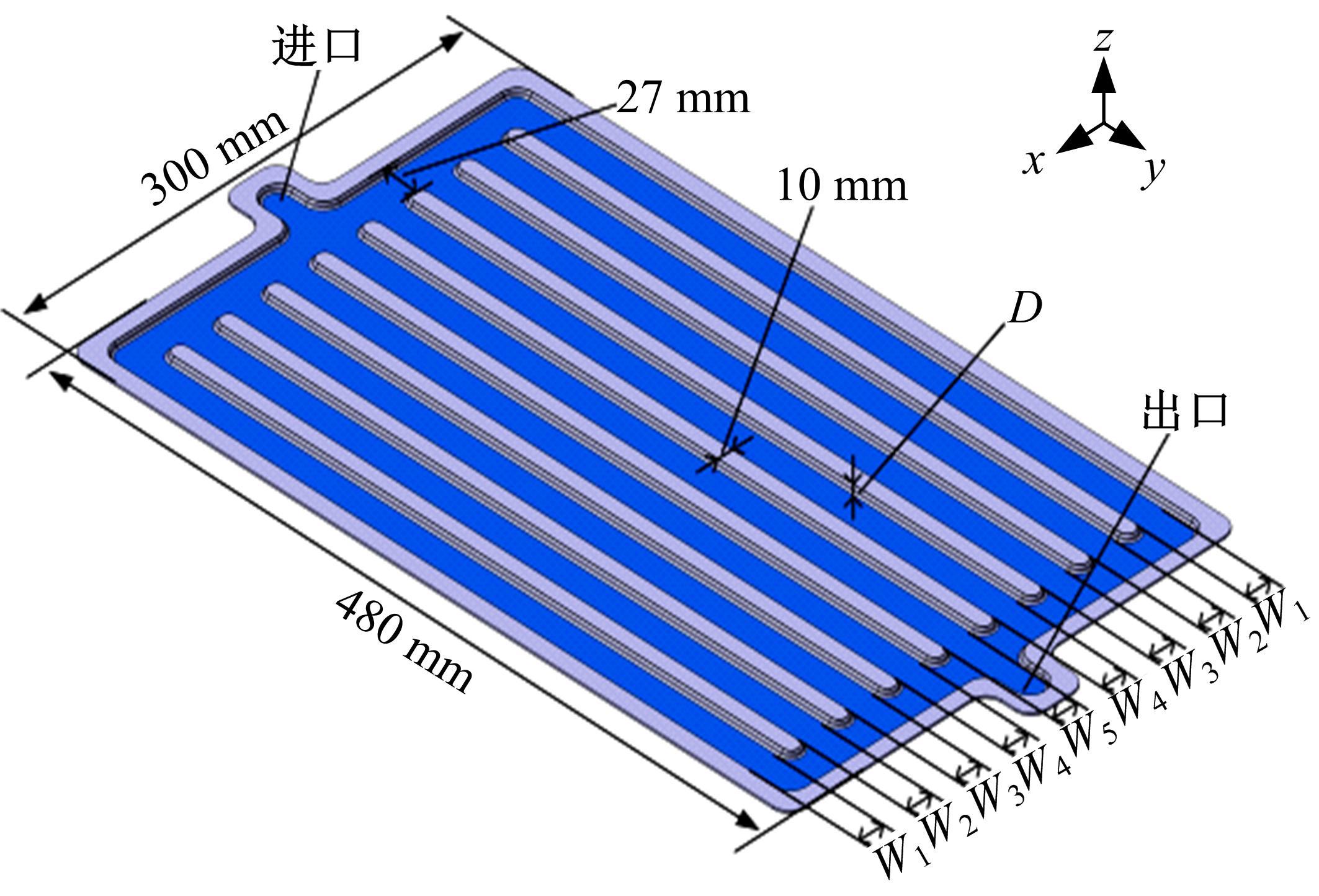

锂电池并行流道液冷板结构设计和散热性能分析

- 1.湖南大学 机械与运载工程学院,长沙 410082

2.清华大学 深圳国际研究生院,广东 深圳 518055

Structural design and thermal dissipation performance analysis of liquid cooling plates with parallel flow channels for lithium batteries

Jian-wu YU1( ),Ya-ling CHEN1,Guang-hui FAN2,Shi-gang HU1,You-yu BAO1

),Ya-ling CHEN1,Guang-hui FAN2,Shi-gang HU1,You-yu BAO1

- 1.College of Mechanical and Vehicle Engineering,Hunan University,Changsha 410082,China

2.Shenzhen International Graduate School,Tsinghua University,Shenzhen 518055,China

摘要:

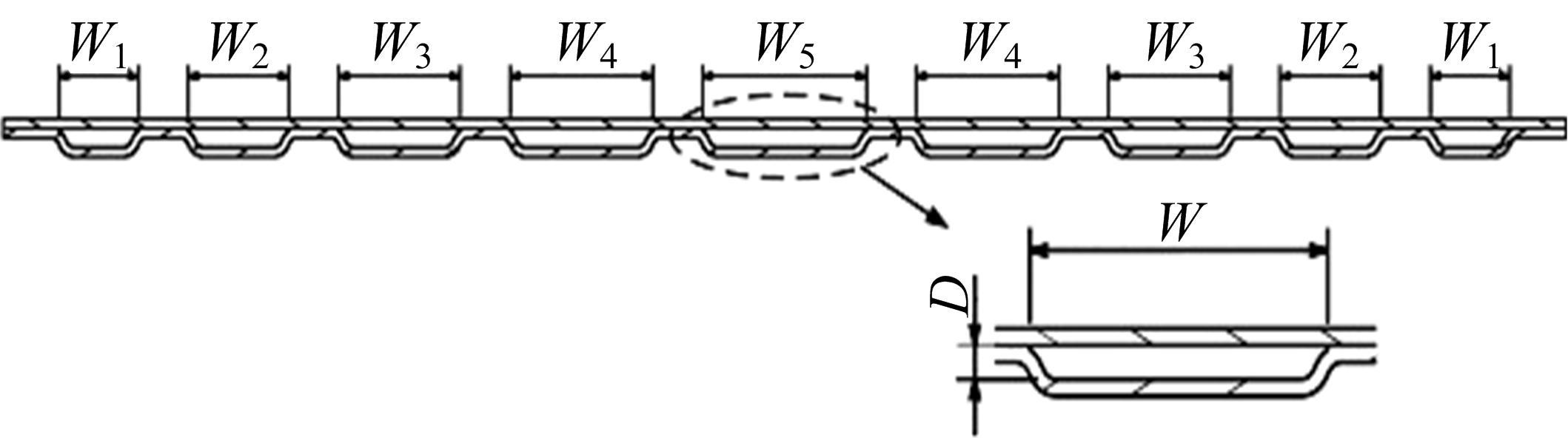

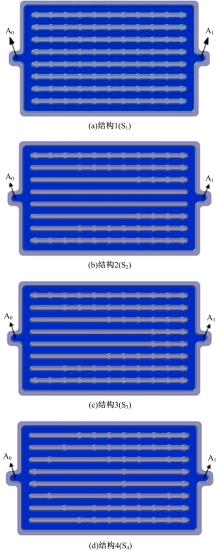

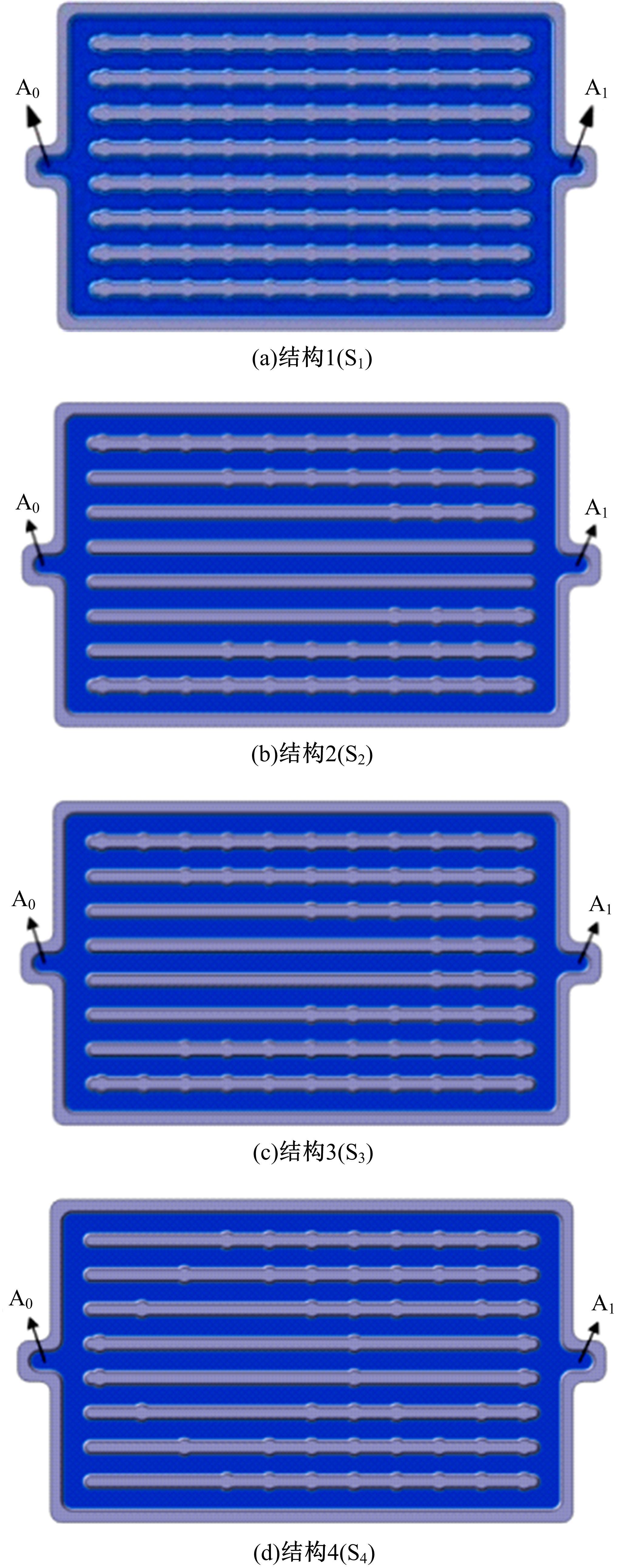

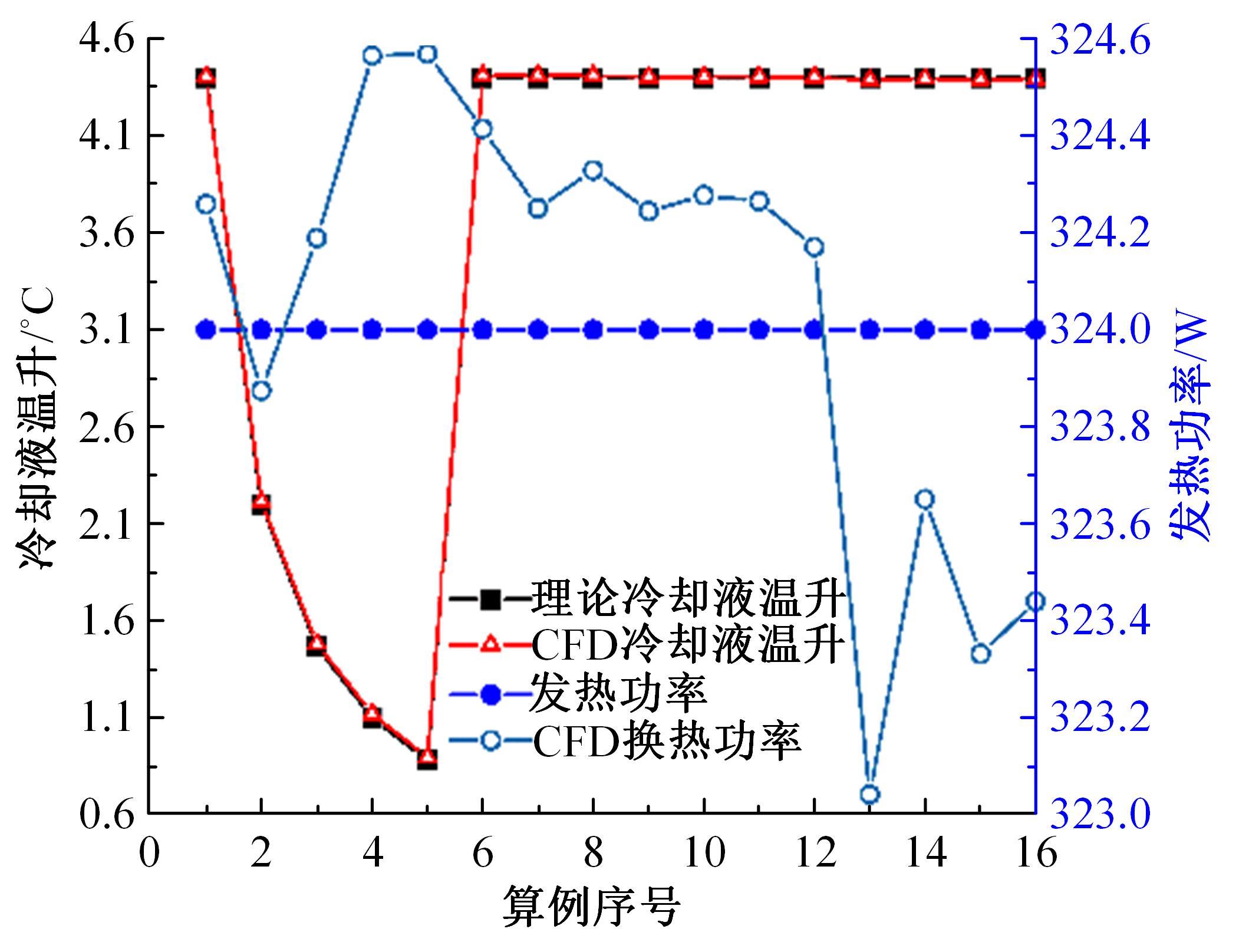

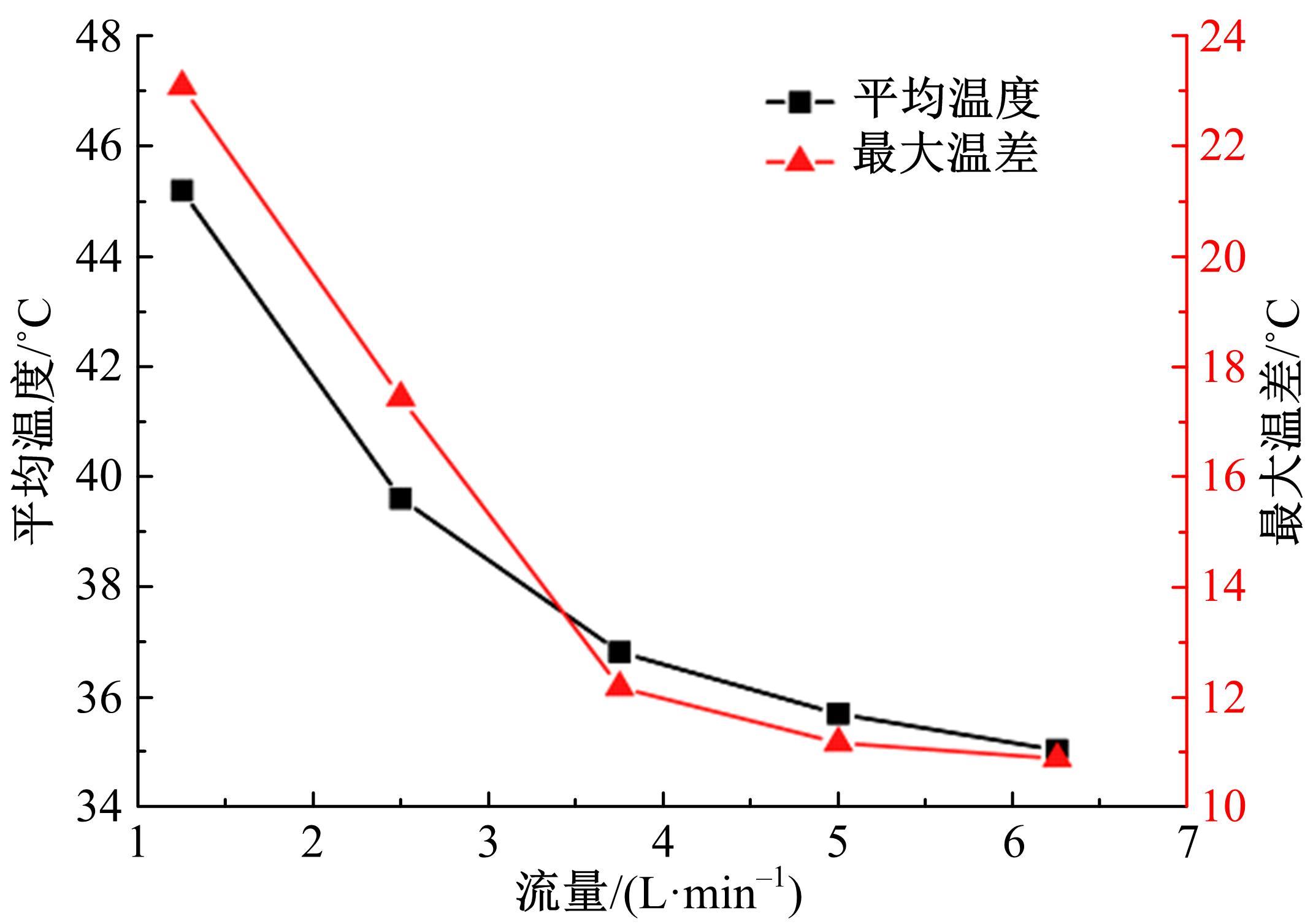

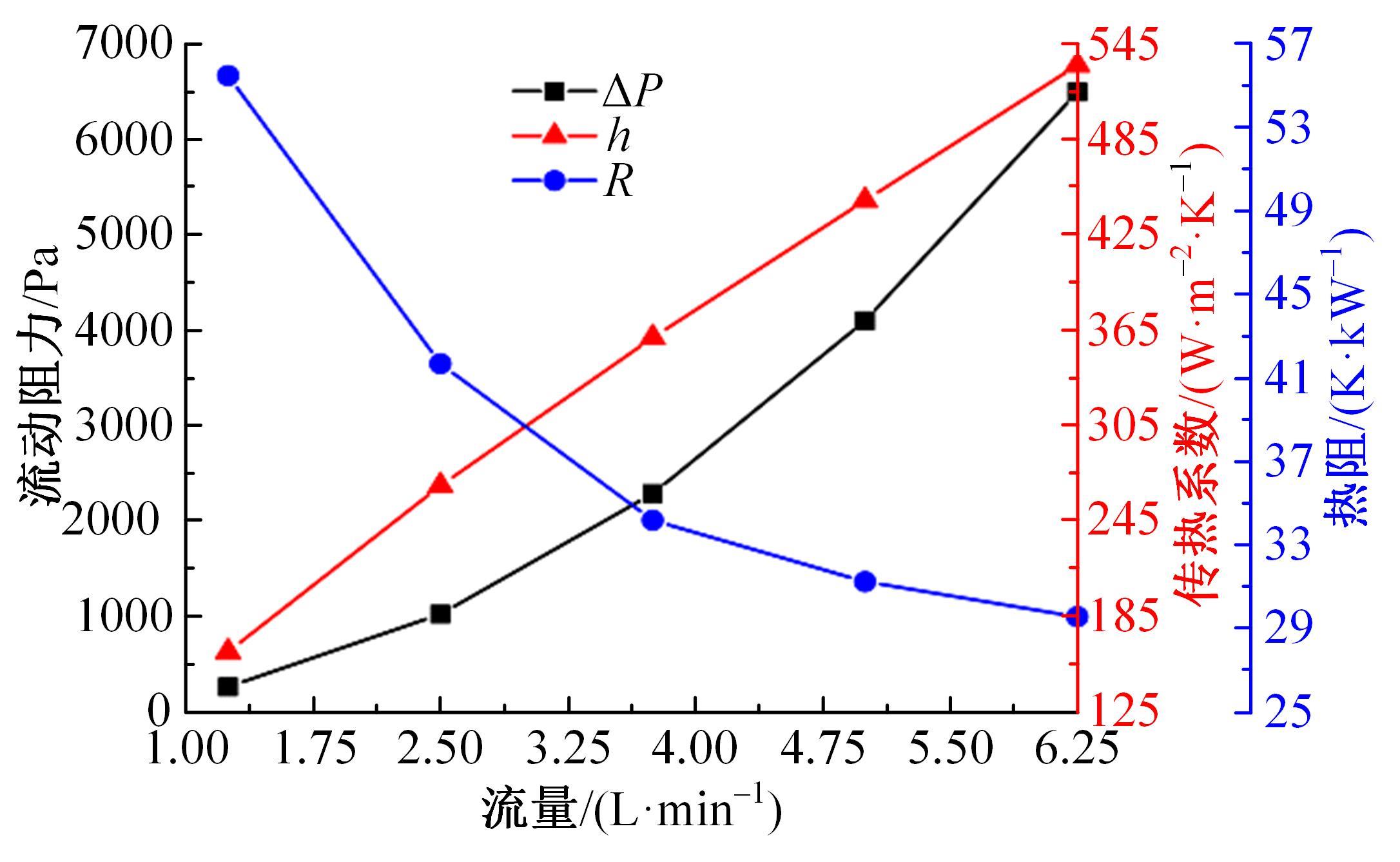

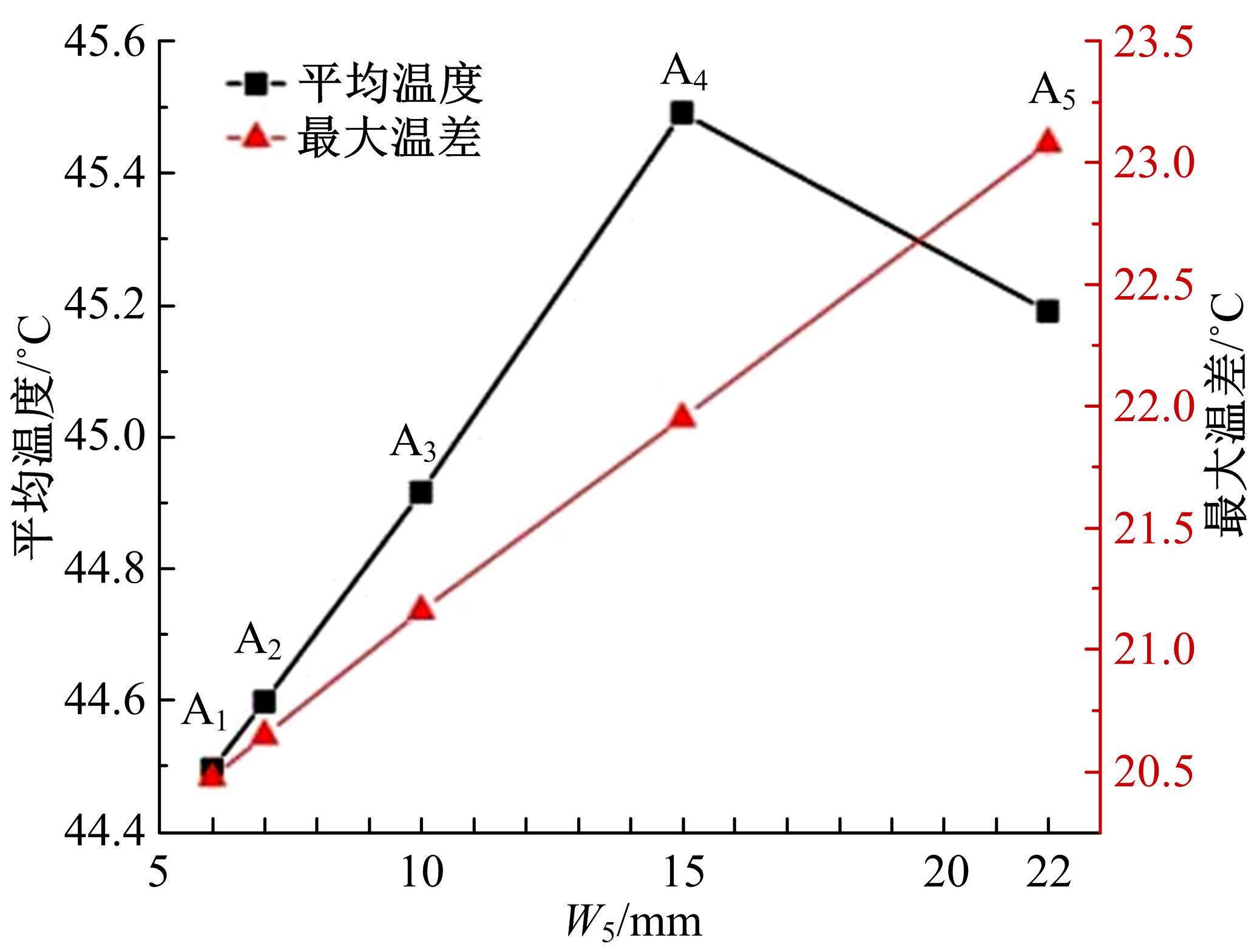

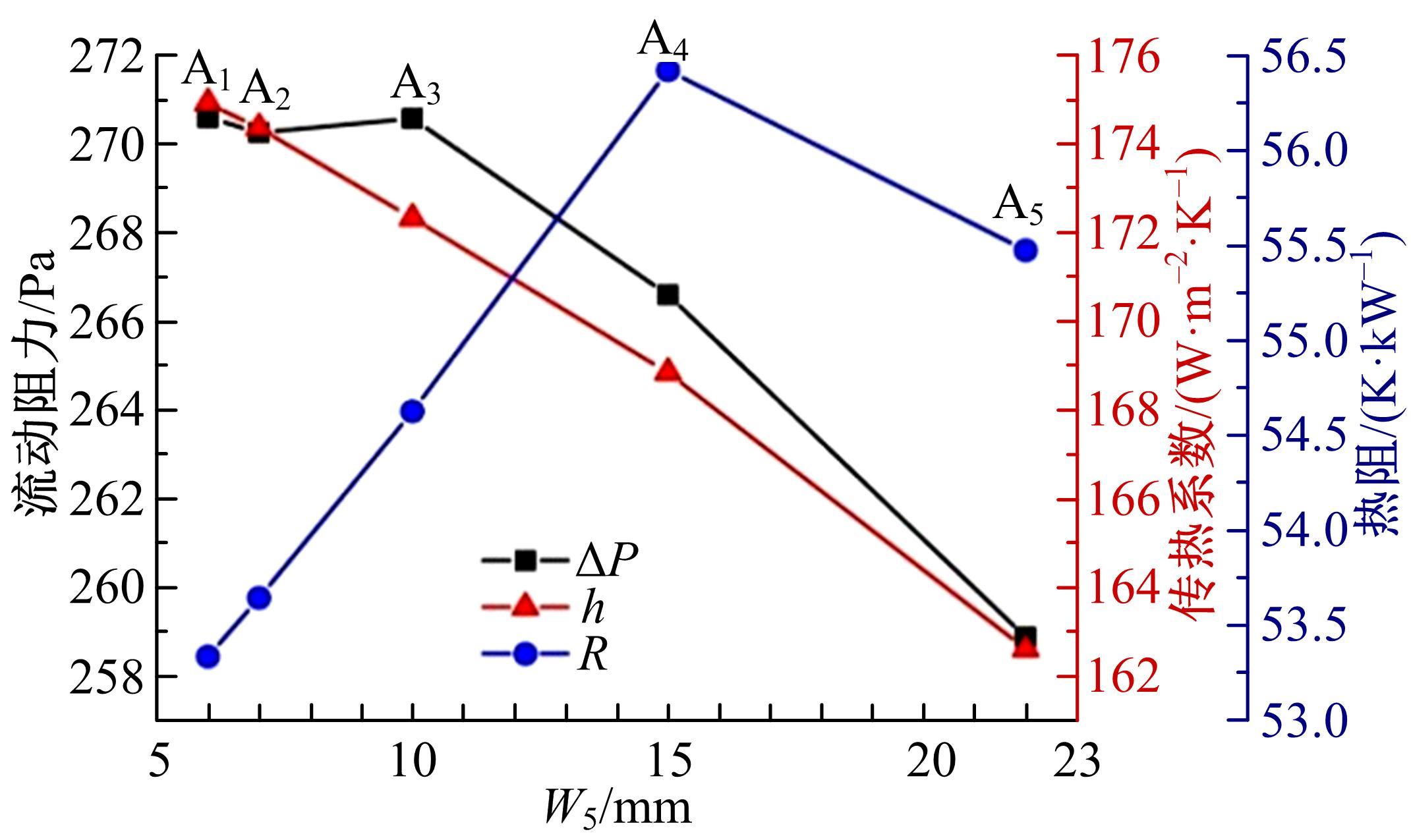

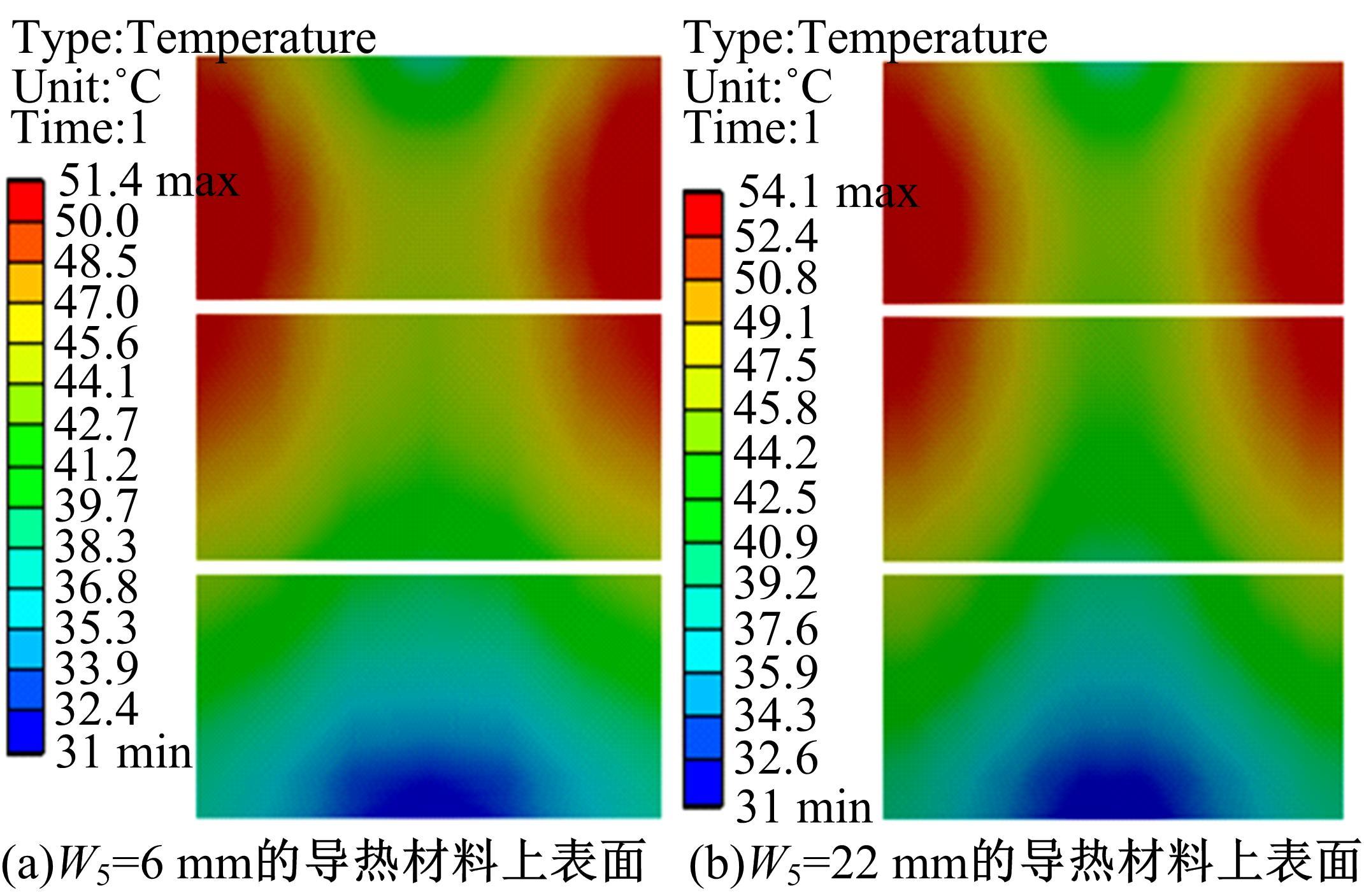

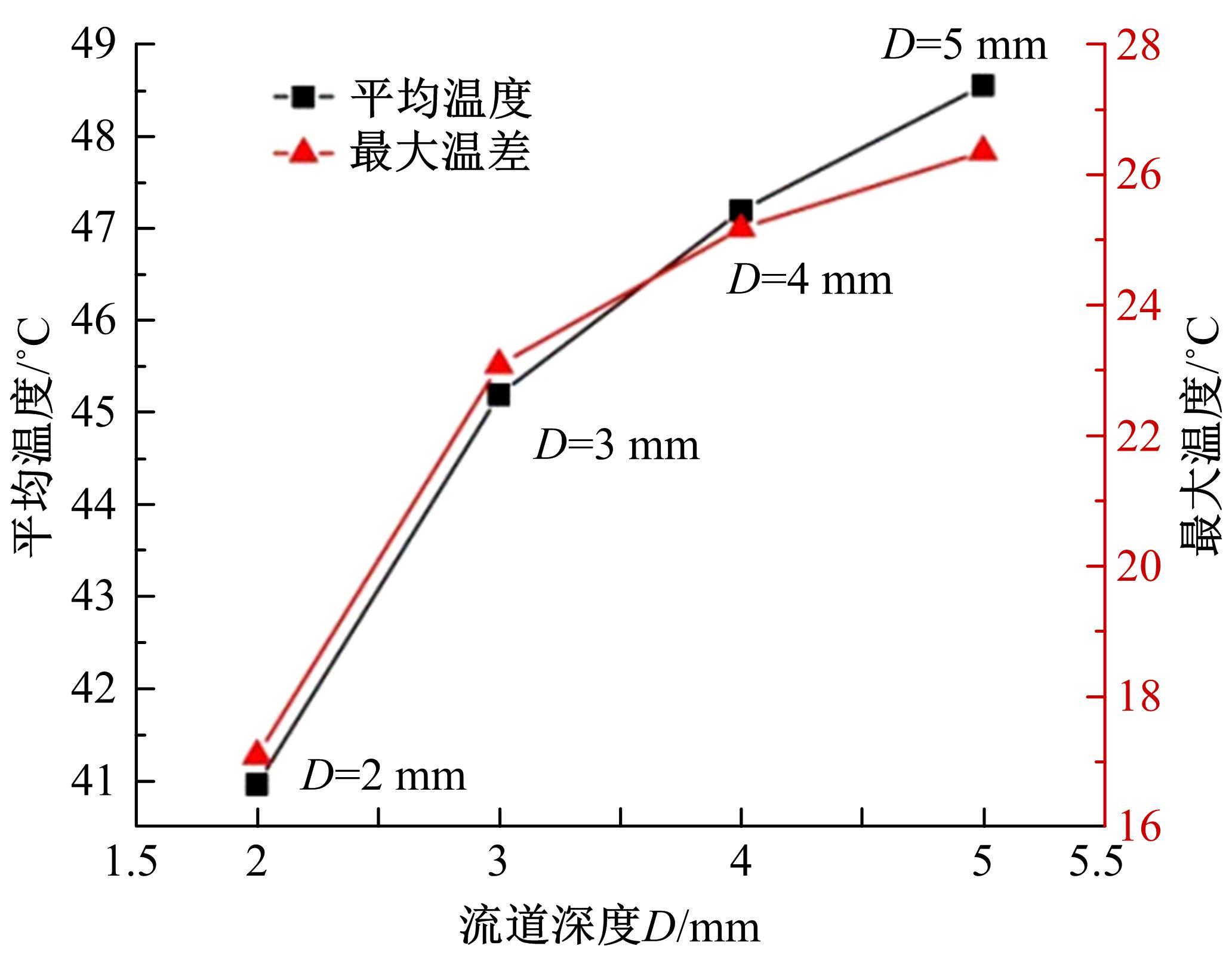

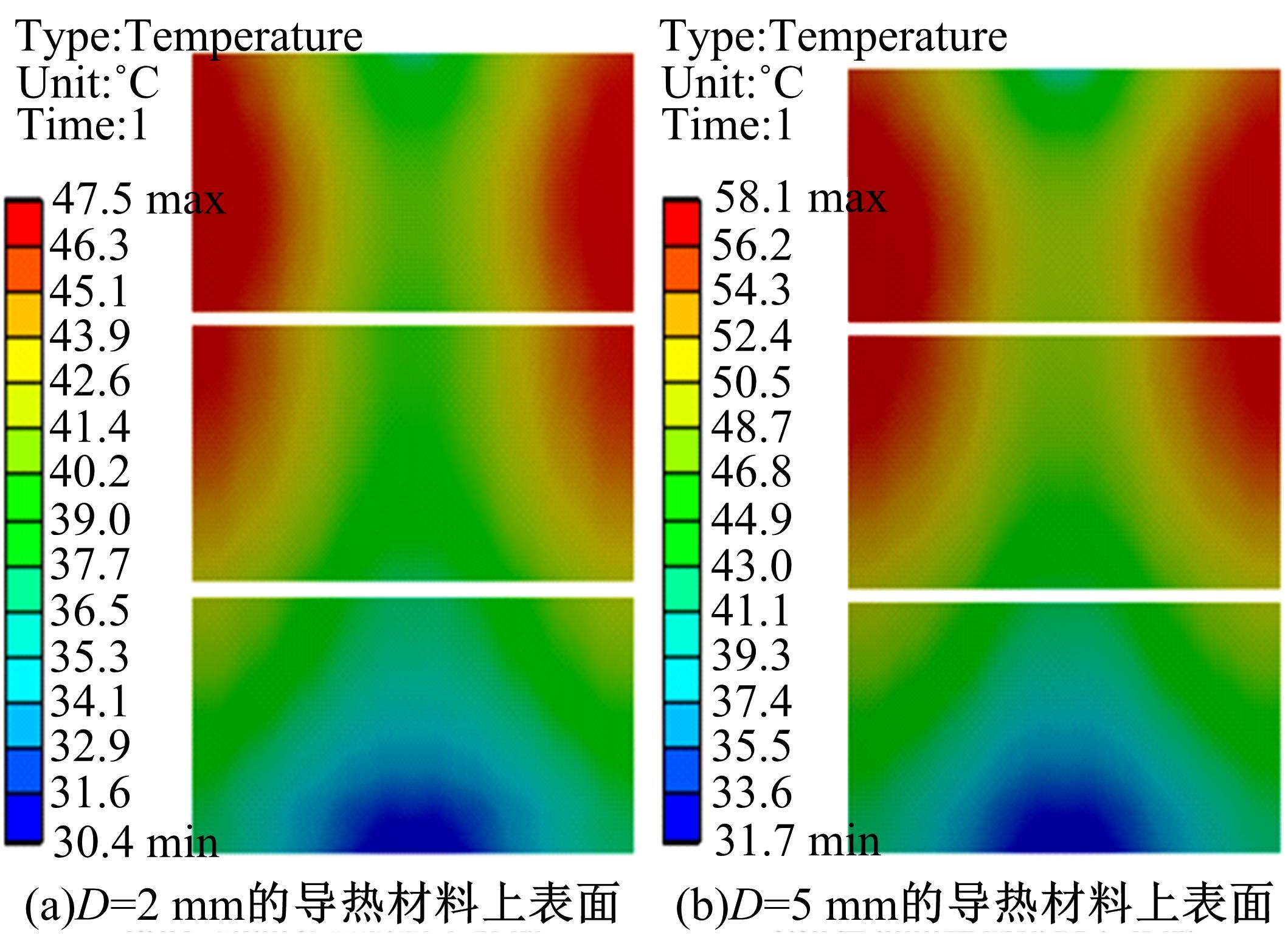

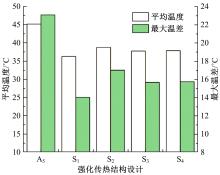

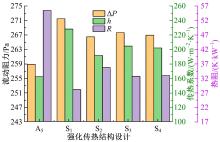

为探究并行流道液冷板的散热性能,采用计算流体力学(CFD)数值计算方法对液冷板进行三维稳态分析,对比研究了液冷板在不同冷却液流量、流道宽度、流道深度和强化传热结构下的散热性能、均温性能以及能耗性能。结果表明:增加流量在一定程度上可以提升液冷板的散热性能,但持续增大流量不仅会增加系统能耗,而且改善效果十分受限。流道宽度从中心向两侧递减变化、流道深度减小、布置强化传热结构的设计都有利于提高液冷系统的散热和均温性能;相对于等宽(A5)流道设计,整体布置强化传热结构(S1)的流道设计可使液冷板的平均温度和最大温差分别降低8.9 ℃和9.06 ℃。本文研究成果可为电池热管理系统的结构设计提供理论指导。

中图分类号:

- U469.72

| 1 | Fathabadi H. A novel design including cooling media for lithium-ion batteries pack used in hybrid and electric vehicles[J]. Journal of Power Sources, 2014, 245: 495-500. |

| 2 | Hua Y, Zhou S D, Cui H G, et al. A comprehensive review on inconsistency and equalization technology of lithium-ion battery for electric vehicles[J]. International Journal of Energy Research, 2020, 44: 11059-11087. |

| 3 | Börner M, Friesen A, Grützke M, et al. Correlation of aging and thermal stability of commercial 18650-type lithium ion batteries[J]. Journal of Power Sources, 2017, 342: 382-392. |

| 4 | An Z J, Jia L, Ding Y, et al. A review on lithium-ion power battery thermal management technologies and thermal safety[J]. Journal of Thermal Science, 2017, 26: 391-412. |

| 5 | Scrosati B, Garche J. Lithium batteries: status, prospects and future[J]. Journal of Power Sources, 2010, 195(9): 2419-2430. |

| 6 | 范光辉,余剑武,罗红,等. 混合动力汽车电池性能影响因素分析与试验[J]. 吉林大学学报:工学版, 2019, 49(5): 1451-1458. |

| Fan Guang-hui, Yu Jian-wu, Luo Hong, et al. Influencing factors analysis and experimental study of battery performances in hybrid electric vehicle[J]. Journal of Jilin University (Engineering and Technology Edition), 2019, 49(5):1451-1458. | |

| 7 | Situ W F, Yang X Q, Li X X, et al. Effect of high temperature environment on the performance of LiNi0.5Co0.2Mn0.3O2 battery[J]. International Journal of Heat & Mass Transfer, 2017, 104:743-748. |

| 8 | Feng X N, Zheng S Q, Ren D S, et al. Key characteristics for thermal runaway of li-ion batteries[J]. Energy Procedia, 2019, 158:4684-4689. |

| 9 | Petzl M, Kasper M, Danzer M A. Lithium plating in a commercial lithium-ion battery—a low-temperature aging study[J]. Journal of Power Sources, 2015, 275:799-807. |

| 10 | 高青,王浩东,刘玉彬,等. 动力电池应急冷却喷管结构设计分析[J].吉林大学学报:工学版, 2021, 52(5): 981-988. |

| Gao Qing, Wang Hao-dong, Liu Yu-bin, et al. Analysis on nozzle design of power battery emergency cooling[J]. Journal of Jilin University (Engineering and Technology Edition), 2021, 52(5): 981-988. | |

| 11 | Wang Y, Zhang G, Yang X. Optimization of liquid cooling technology for cylindrical power battery module[J]. Applied Thermal Engineering, 2019, 162: No.114200. |

| 12 | Tang Z G, Wang S C, Liu Z Q, et al. Numerical analysis of temperature uniformity of a liquid cooling battery module composed of heat-conducting blocks with gradient contact surface angles[J]. Applied Thermal Engineering, 2020, 178: No.115509. |

| 13 | Zhao C R, Sousa A C M, Jiang F M. Minimization of thermal non-uniformity in lithium-ion battery pack cooled by channeled liquid flow[J]. International Journal of Heat and Mass Transfer, 2018, 129:660-670. |

| 14 | Sheng L, Su L, Zhang H, et al. Numerical investigation on a lithium ion battery thermal management utilizing a serpentine-channel liquid cooling plate exchanger[J]. International Journal of Heat & Mass Transfer, 2019, 141:658-668. |

| 15 | Patil M S, Seo J H, Panchal S, et al. Investigation on thermal performance of water-cooled li-ion pouch cell and pack at high discharge rate with U-turn type microchannel cold plate[J]. International Journal of Heat and Mass Transfer, 2020, 155: No.119728. |

| 16 | Xu X M, Tong G Y, Li R Z, et al. Numerical study and optimizing on cold plate splitter for lithium battery thermal management system[J]. Applied Thermal Engineering, 2020, 167: No.114787. |

| 17 | Siruvuri D V, Budarapu P R. Studies on thermal management of lithium-ion battery pack using water as the cooling fluid[J]. Journal of Energy Storage, 2020, 29: No.101377. |

| 18 | Deng T, Ran Y, Yin Y L, et al. Multi-objective optimization design of thermal management system for lithium-ion battery pack based on non-dominated sorting genetic algorithm II[J]. Applied Thermal Engineering, 2020, 164: No.114394. |

| [1] | 王登峰,陈宏利,那景新,陈鑫. 单双搭接接头经高温老化后的失效对比[J]. 吉林大学学报(工学版), 2023, 53(2): 346-354. |

| [2] | 张佩,王志伟,杜常清,颜伏伍,卢炽华. 车用质子交换膜燃料电池空气系统过氧比控制方法[J]. 吉林大学学报(工学版), 2022, 52(9): 1996-2003. |

| [3] | 王克勇,鲍大同,周苏. 基于数据驱动的车用燃料电池故障在线自适应诊断算法[J]. 吉林大学学报(工学版), 2022, 52(9): 2107-2118. |

| [4] | 曹起铭,闵海涛,孙维毅,于远彬,蒋俊宇. 质子交换膜燃料电池低温启动水热平衡特性[J]. 吉林大学学报(工学版), 2022, 52(9): 2139-2146. |

| [5] | 隗海林,王泽钊,张家祯,刘洋. 基于Avl-Cruise的燃料电池汽车传动比及能量管理策略[J]. 吉林大学学报(工学版), 2022, 52(9): 2119-2129. |

| [6] | 刘岩,丁天威,王宇鹏,都京,赵洪辉. 基于自适应控制的燃料电池发动机热管理策略[J]. 吉林大学学报(工学版), 2022, 52(9): 2168-2174. |

| [7] | 李丞,景浩,胡广地,刘晓东,冯彪. 适用于质子交换膜燃料电池系统的高阶滑模观测器[J]. 吉林大学学报(工学版), 2022, 52(9): 2203-2212. |

| [8] | 池训逞,侯中军,魏伟,夏增刚,庄琳琳,郭荣. 基于模型的质子交换膜燃料电池系统阳极气体浓度估计技术综述[J]. 吉林大学学报(工学版), 2022, 52(9): 1957-1970. |

| [9] | 裴尧旺,陈凤祥,胡哲,翟双,裴冯来,张卫东,焦杰然. 基于自适应LQR控制的质子交换膜燃料电池热管理系统温度控制[J]. 吉林大学学报(工学版), 2022, 52(9): 2014-2024. |

| [10] | 胡广地,景浩,李丞,冯彪,刘晓东. 基于高阶燃料电池模型的多目标滑模控制[J]. 吉林大学学报(工学版), 2022, 52(9): 2182-2191. |

| [11] | 陈凤祥,伍琪,李元松,莫天德,李煜,黄李平,苏建红,张卫东. 2.5吨燃料电池混合动力叉车匹配、仿真及优化[J]. 吉林大学学报(工学版), 2022, 52(9): 2044-2054. |

| [12] | 武小花,余忠伟,朱张玲,高新梅. 燃料电池公交车模糊能量管理策略[J]. 吉林大学学报(工学版), 2022, 52(9): 2077-2084. |

| [13] | 高青,王浩东,刘玉彬,金石,陈宇. 动力电池应急冷却喷射模式实验分析[J]. 吉林大学学报(工学版), 2022, 52(8): 1733-1740. |

| [14] | 王奎洋,何仁. 基于支持向量机的制动意图识别方法[J]. 吉林大学学报(工学版), 2022, 52(8): 1770-1776. |

| [15] | 刘汉武,雷雨龙,阴晓峰,付尧,李兴忠. 增程式电动汽车增程器多点控制策略优化[J]. 吉林大学学报(工学版), 2022, 52(8): 1741-1750. |

|