吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (4): 926-937.doi: 10.13229/j.cnki.jdxbgxb.20220664

基于动态混合RANS/LES模型的液力变矩器内部流场的数值模拟

鄢万斌1,2( ),杨孔华3,金开雕3,陈素姣1,2,章勇华1,2,刘春宝3(

),杨孔华3,金开雕3,陈素姣1,2,章勇华1,2,刘春宝3( )

)

- 1.柳工柳州传动件有限公司 传动件研究所,广西 柳州 545007

2.广西柳工机械股份有限公司,广西 柳州 545007

3.吉林大学 机械与航空航天工程学院,长春 130022

Internal flow field in a hydrodynamic torque converter with dynamic hybrid RANS/LES model

Wan-bin YAN1,2( ),Kong-hua YANG3,Kai-diao JIN3,Su-jiao CHEN1,2,Yong-hua ZHANG1,2,Chun-bao LIU3(

),Kong-hua YANG3,Kai-diao JIN3,Su-jiao CHEN1,2,Yong-hua ZHANG1,2,Chun-bao LIU3( )

)

- 1.Research Institute of Transmission,Liugong Liuzhou Transmission Parts Co. ,Ltd. ,Liuzhou 545007,China

2.Guangxi Liugong Machinery Co. ,Ltd. ,Liuzhou 545007,China

3.School of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

摘要:

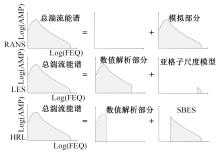

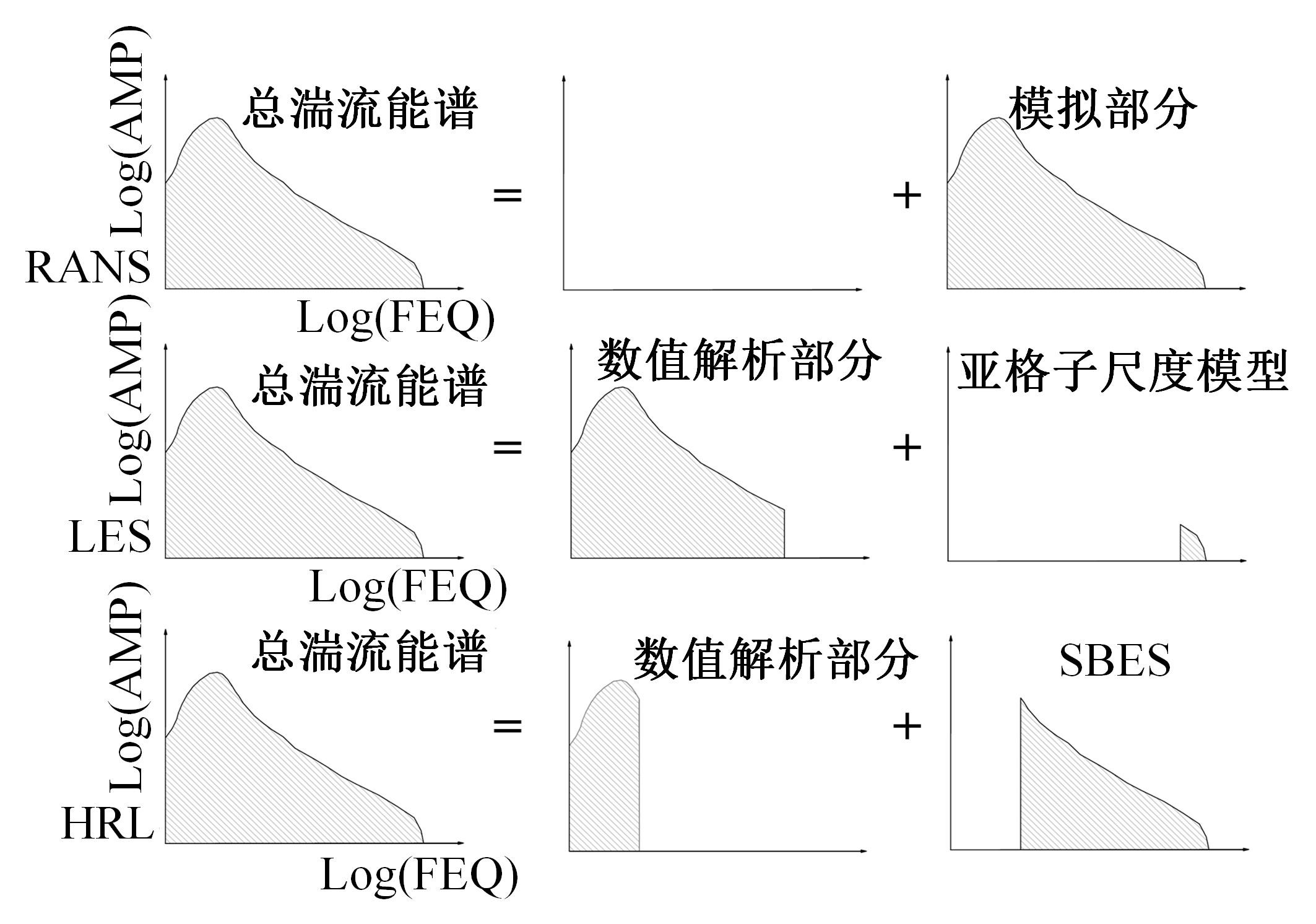

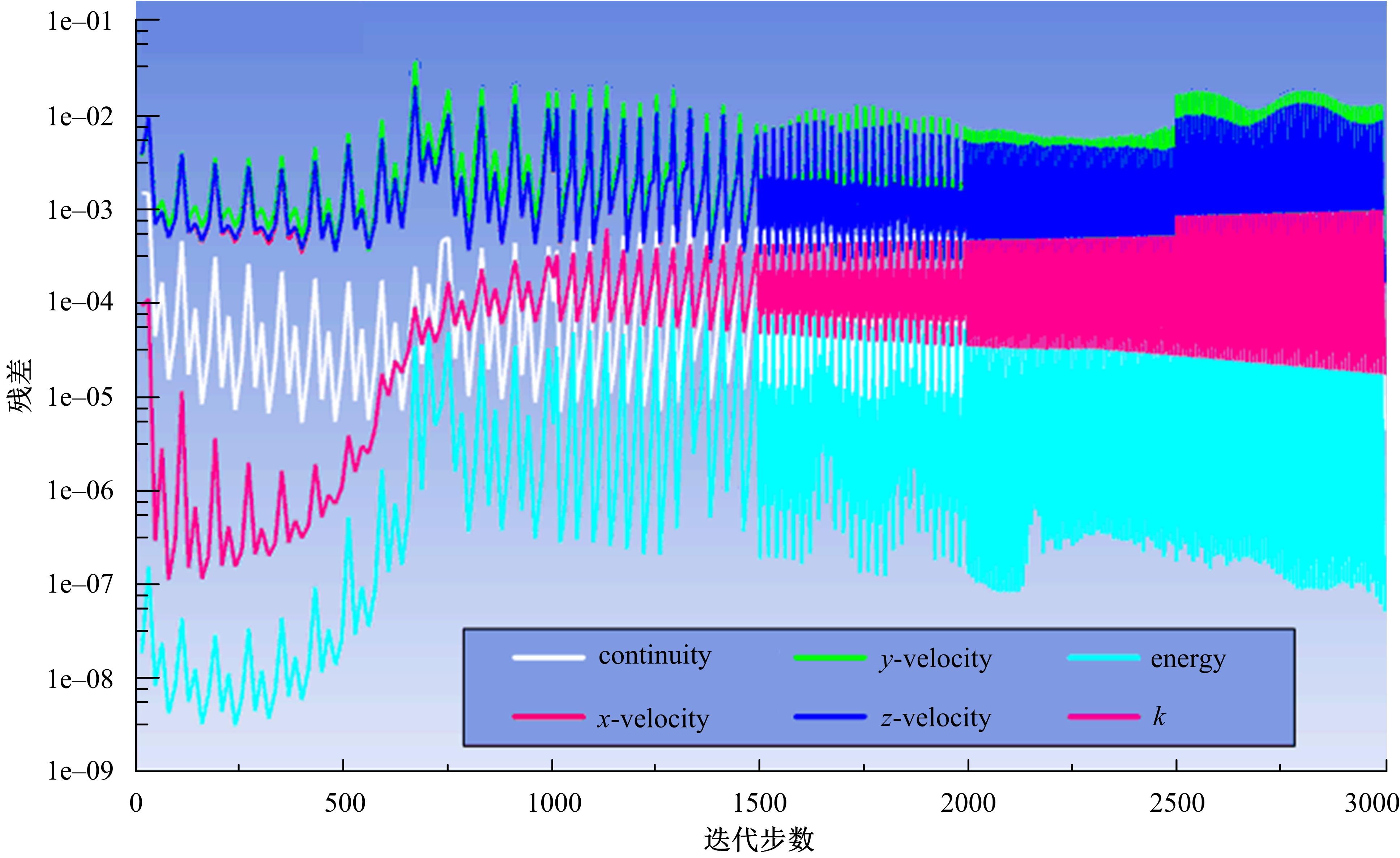

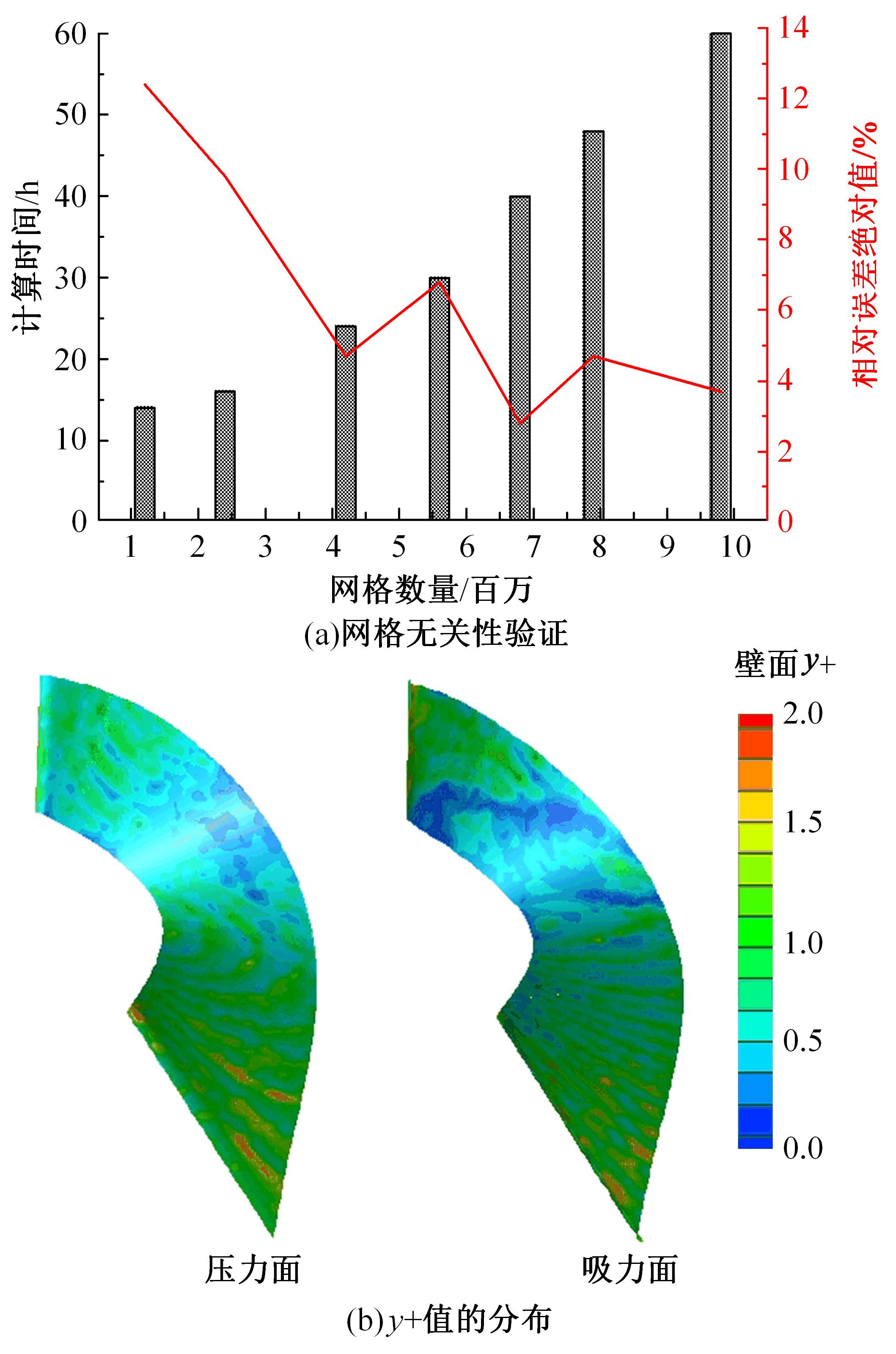

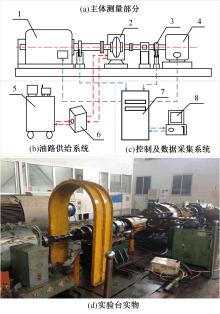

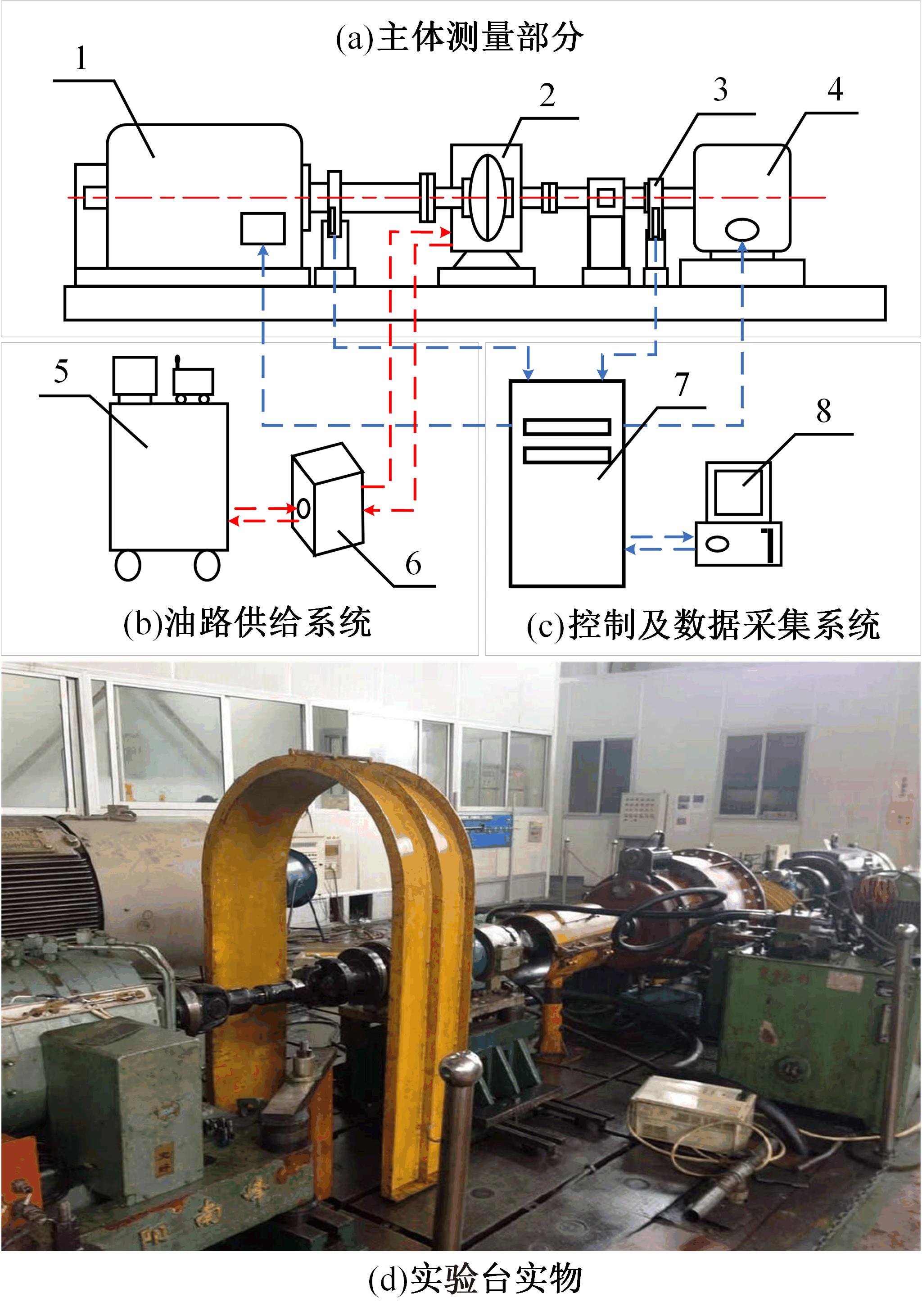

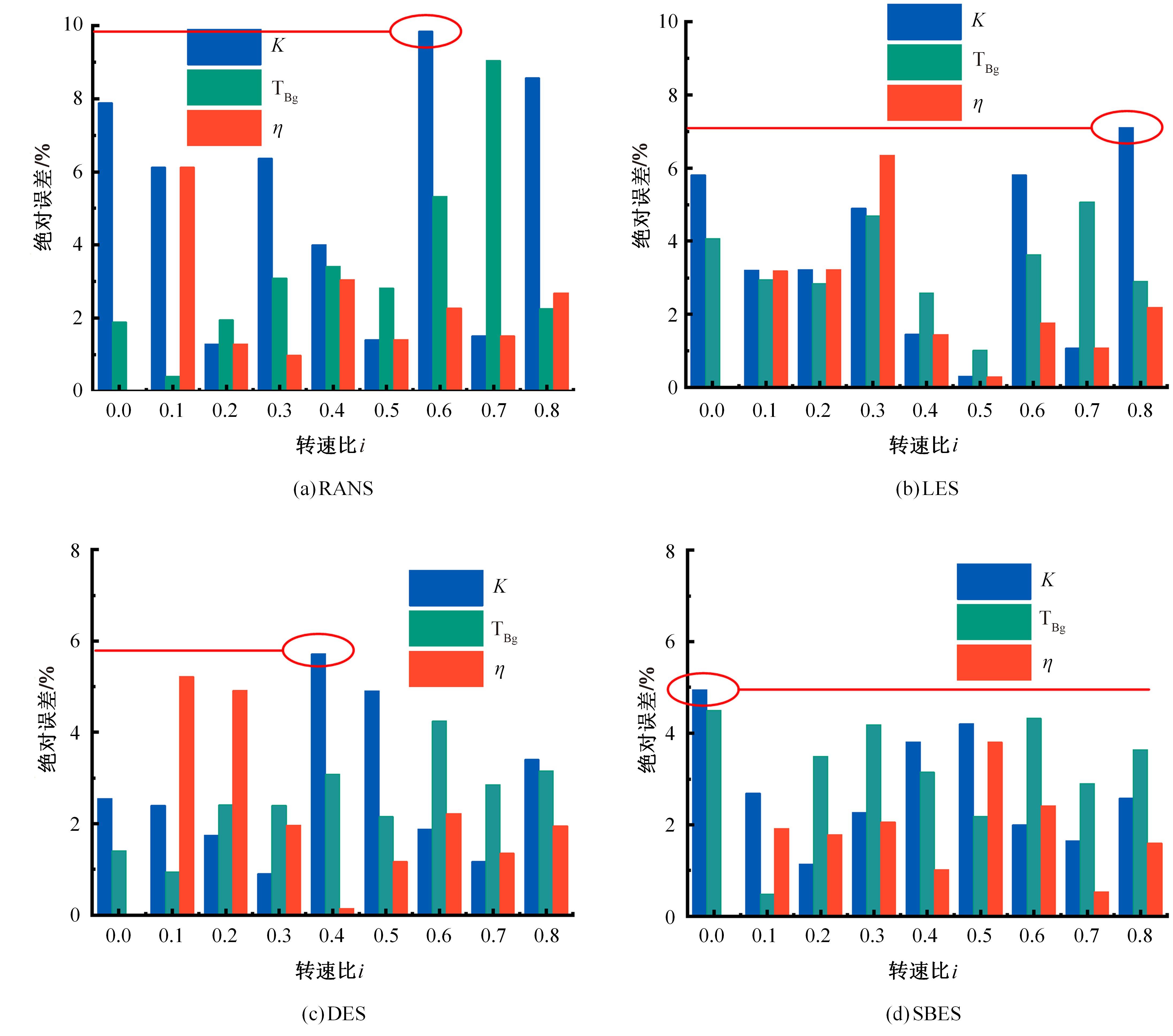

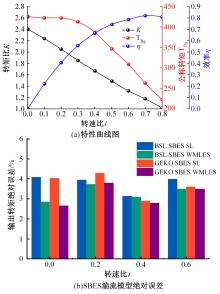

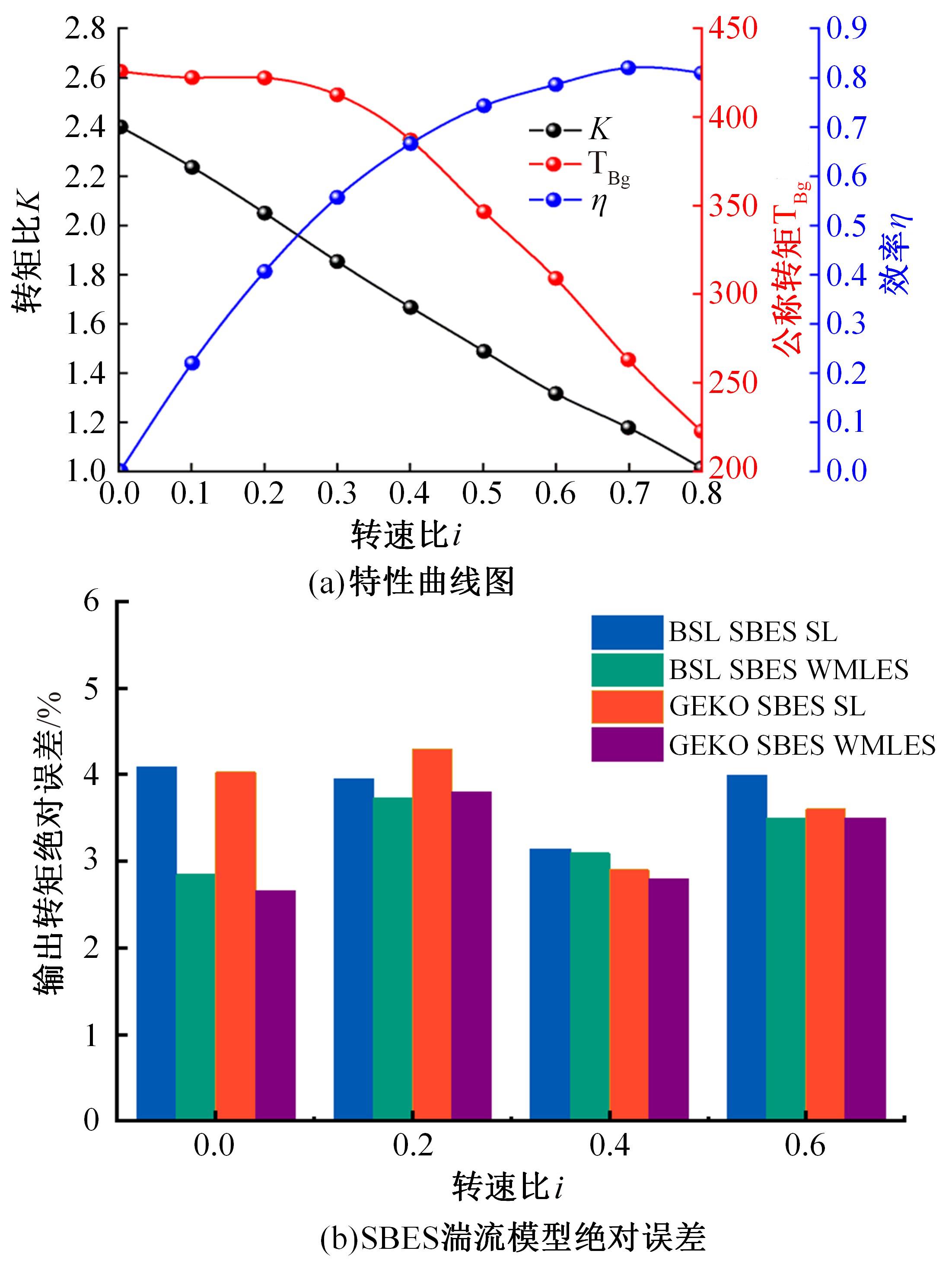

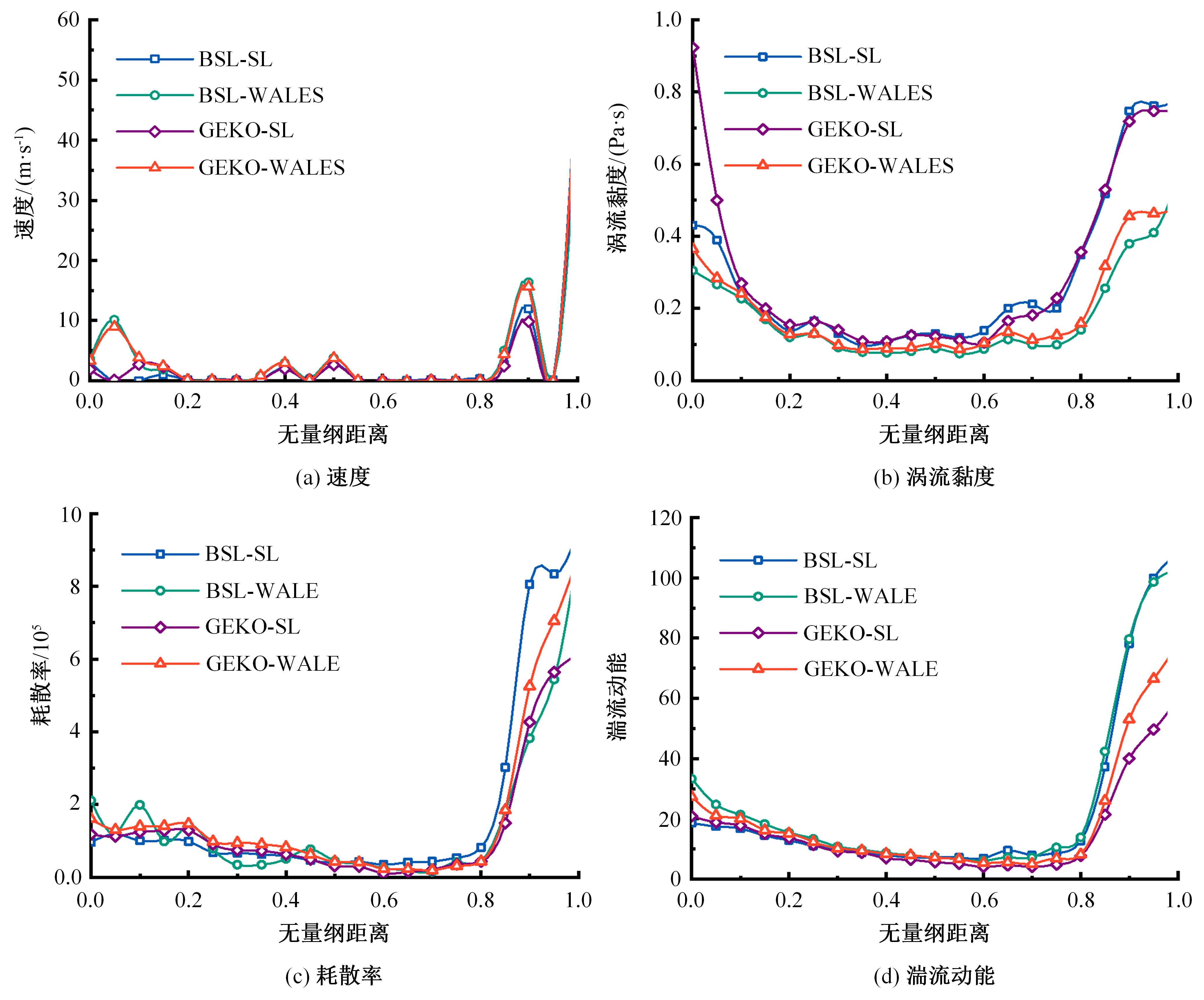

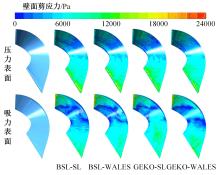

针对传统的一维束流研究方法无法对高功率密度液力变矩器工作腔内部复杂的时变瞬态湍流流动状态进行描述的问题,通过对计算流体力学(CFD)计算中的湍流模型进行设置,将RANS、LES、DES和SBES模型与精细六面体网格和介质动态物理化学特性进行高效的耦合集成,为液力变矩器(TC)瞬态仿真提供指导,以预测其外特性性能和复杂内流场分布。通过定性、定量分析液力变矩器内部的流动结构和导轮叶片边界层涡系拟序结构的时序演化,发现动态混合模型(DHRL)中的应力混合涡模拟(SBES)方法能够充分辨视工作腔内边界层的流动,实现了多流域耦合复杂流动现象的精准捕捉,并通过台架实验得到原始特性预测结果的最大误差不足4%。另外,本文还阐明了工作腔内流动损失产生机制,揭示了涡结构产生、发展、输运、破碎及合成等一系列主导湍流转捩过程的流动机制,为高效地开发新产品以及改进原有产品提供了计算方法。

中图分类号:

- TH137.332

| 1 | Li Ming-xue, Yang Guo-lai, Li Xiao-qing, et al. Variable universe fuzzy control of adjustable hydraulic torque converter based on multi-population genetic algorithm[J]. IEEE Access, 2019, 7: 29236-29244. |

| 2 | You Yong, Sun Dong-ye, Qin Da-tong. Shift strategy of a new continuously variable transmission based wheel loader[J]. Mechanism and Machine Theory, 2018, 130: 313-329. |

| 3 | Liu Cheng, Wei Wei, Yan Qing-dong, et al. On the application of passive flow control for cavitation suppression in torque converter stator[J]. International Journal of Numerical Methods for Heat & Fluid Flow, 2019, 29(1): 204-222. |

| 4 | Liu Cheng, Xiang Chang-le, Yan Qing-dong, et al. Development and validation of a CFD based optimization procedure for the design of torque converter cascade[J]. Engineering Applications of Computational Fluid Mechanics, 2019, 13(1): 128-141. |

| 5 | Lei Y L, Wang C, Liu Z J, et al. Analysis of the full flow field of Torque Converter[J]. dvanced Materials Research, 2012, 468: 674-677. |

| 6 | Song K, Kim K, Park J, et al. Development of the integrated process for torque converter design and analysis[C]//SAE Paper, 2008-01-0785. |

| 7 | Odier N, Thacker A, Harnieh M, et al. A mesh adaptation strategy for complex wall-modeled turbomachinery LES[J]. Computers & Fluids, 2021, 214: No.104766. |

| 8 | Yang X I A, Sadique J, Mittal R, et al. Integral wall model for large eddy simulations of wall-bounded turbulent flows[J]. Physics of Fluids, 2015, 27(2): 25112. |

| 9 | Jung J H, Kang S, Hur N. A numerical study of a torque converter with various methods for the accuracy improvement of performance prediction[J]. Progress in Computational Fluid Dynamics, 2011, 11(3,4): 261-268. |

| 10 | de la Fuente P, Stoff H, Volgmann W, et al. Numerical analysis into the effects of the unsteady flow in an automotive hydrodynamic torque converter[C]∥The International Conference of Mechanical Engineering, London,UK, 2011:6-8. |

| 11 | Shin S, Chang H, Athavale M. Numerical investigation of the pump flow in an automotive torque converter[J]. SAE Transactions, 1999(1): 1969-1977. |

| 12 | Fernando D, Gao S, Garrett S J. The effect of surface roughness on rotor-stator cavity flows[J]. Physics of Fluids, 2018, 30(6): No.64103. |

| 13 | Lee C, Jang W, Lee J M, et al. Three dimensional flow field simulation to estimate performance of a torque converter[C]∥SAE 2000 World Congress, Detroit,USA,2001. |

| 14 | Wu Guang-qiang, Yan Peng. System for torque converter design and analysis based on CAD/CFD integrated platform[J]. Chinese Journal of Mechanical Engineering, 2008, 21(4): 35-39. |

| 15 | Umavathi J C. Free convective flow in a vertical rectangular duct filled with porous matrix for viscosity and conductivity variable properties[J]. International Journal of Heat and Mass Transfer, 2015, 81: 383-403. |

| 16 | Umavathi J C, Ojjela O. Effect of variable viscosity on free convection in a vertical rectangular duct[J]. International Journal of Heat and Mass Transfer, 2015, 84: 1-15. |

| 17 | Syawitri T P, Yao Y, Yao J, et al. Assessment of stress-blended eddy simulation model for accurate performance prediction of vertical axis wind turbine[J]. International Journal of Numerical Methods for Heat & Fluid Flow, 2021, 31(2): 655-673. |

| 18 | Rezaeiha A, Montazeri H, Blocken B. CFD analysis of dynamic stall on vertical axis wind turbines using Scale-Adaptive Simulation (SAS): comparison against URANS and hybrid RANS/LES[J]. Energy Conversion and Management, 2019, 196: 1282-1298. |

| 19 | Dorogi D, Baranyi L. Identification of upper branch for vortex-induced vibration of a circular cylinder at Re=300[J]. Journal of Fluids and Structures, 2020, 98:No.103135. |

| 20 | Liu Chun-bao, Ma Wen-xin, Zhu Xi-lin. 3D transient calculation of internal flow field for hydrodynamic torque converter[J]. Journal of Mechanical Engineering, 2010, 46(14): 161-166. |

| 21 | Tabor G R, Baba-Ahmadi M H. Inlet conditions for large eddy simulation: a review[J]. Computers & Fluids, 2010, 39(4): 553-567. |

| 22 | Liu Chun-bao, Li Jing, Bu Wei-yang, et al. Application of scale-resolving simulation to a hydraulic coupling, a hydraulic retarder, and a hydraulic torque converter[J]. Journal of Zhejiang University(Science A), 2018, 19(12): 904-925. |

| 23 | Gritskevich M S, Garbaruk A V, Schuetze J, et al. Development of DDES and IDDES formulations for the k-omega shear stress transport model[J]. Flow Turbulence and Combustion, 2012, 88(3): 431-449. |

| 24 | Chen Jie, Wu Guang-qiang. Kriging-assisted design optimization of the impeller geometry for an automotive torque converter[J]. Structural and Multidisciplinary Optimization, 2018, 57(6): 2503-2514. |

| 25 | Smagorinsky J. General circulation experiments with the primitive equations: I. the basic experiment[J]. Monthly Weather Review, 1963, 91(3): 99-164. |

| 26 | Nicoud F, Ducros F. Subgrid-scale stress modelling based on the square of the velocity gradient tensor[J]. Flow, Turbulence and Combustion, 1999, 62(3): 183-200. |

| 27 | Liu Chun-bao, Li Jing, Bu Wei-yang, et al. Large eddy simulation for improvement of performance estimation and turbulent flow analysis in a hydrodynamic torque converter[J]. Engineering Applications of Computational Fluid Mechanics, 2018, 12(1): 635-651. |

| 28 | Liu Chun-bao, Yang Kong-hua, Li Jing, et al. Performance improvement and flow field investigation in hydraulic torque converter based on a new design of segmented blades[J]. Journal of Automobile Engineering, 2020, 234(8): 2162-2675. |

| 29 | Su Wen-tao, Li Feng-chen, Li Xiao-bin, et al. Assessment of LES performance in simulating complex 3D flows in turbo-machines[J]. Engineering Applications of Computational Fluid Mechanics, 2012, 6(3): 356-365. |

| 30 | Hunt J C, Wray A A, Eddies Moin P., streams, and convergence zones in turbulent flows[C]∥Proceedings of the 1988 Summer Program on Studying Turbulence Using Numerical Simulation Databases, 1988:193-208. |

| [1] | 柴博森,王广义,闫东,朱国仁,张进,吕恒升. 液力变矩器空化数值模拟及对性能的影响[J]. 吉林大学学报(工学版), 2023, 53(8): 2236-2244. |

| [2] | 胡兴军,张靖龙,罗雨霏,辛俐,李胜,胡金蕊,兰巍. 冷却管结构及进气方向对空冷中冷器性能的影响[J]. 吉林大学学报(工学版), 2021, 51(6): 1933-1942. |

| [3] | 张斌,程国赞,洪昊岑,赵春晓,杨华勇. 基于计算流体仿真的双作用叶片泵气蚀机理分析[J]. 吉林大学学报(工学版), 2021, 51(3): 831-839. |

| [4] | 陈鑫,阮新建,李铭,王宁,王佳宁,潘凯旋. 基于大涡模拟的离散格式改进方法及应用[J]. 吉林大学学报(工学版), 2019, 49(6): 1756-1763. |

| [5] | 胡兴军,惠政,郭鹏,张扬辉,张靖龙,王靖宇,刘飞. 基于流固耦合的汽车气动特性[J]. 吉林大学学报(工学版), 2019, 49(5): 1414-1419. |

| [6] | 孙正, 黄钰期, 俞小莉. 径向滑动轴承润滑油膜流动-传热过程仿真[J]. 吉林大学学报(工学版), 2018, 48(3): 744-751. |

| [7] | 王靖宇, 薛超坦, 胡兴军, 曹杰汛, 岳磊, 施蓉. 基于空调送风参数的车室内流模拟[J]. 吉林大学学报(工学版), 2017, 47(1): 50-57. |

| [8] | 谭越, 马文星, 刘春宝. 冲焊型液力变矩器叶片成形的精密控制[J]. 吉林大学学报(工学版), 2013, 43(增刊1): 530-534. |

| [9] | 闫清东, 刘树成, 魏巍, 杨汇斌. 基于改进雷达图法的变矩器匹配评价[J]. 吉林大学学报(工学版), 2013, 43(06): 1510-1516. |

| [10] | 雷雨龙, 刘振杰, 李兴忠, 付尧, 郑宏鹏. 起步工况下液力变矩器滑差控制转速优化[J]. 吉林大学学报(工学版), 2013, 43(06): 1447-1452. |

| [11] | 谭越, 马文星, 卢秀泉. 基于流固耦合的冲焊型液力变矩器焊接强度分析[J]. 吉林大学学报(工学版), 2013, 43(04): 928-932. |

| [12] | 王松林, 马文星, 胡晶, 褚亚旭, 宋建军. 双涡轮液力变矩器超越离合器的改进及分析[J]. 吉林大学学报(工学版), 2013, 43(04): 922-927. |

| [13] | 刘树成, 魏巍, 闫清东, 周洽. 液力变矩器导轮空转特性无叶片数值仿真[J]. 吉林大学学报(工学版), 2013, 43(01): 22-27. |

| [14] | 张英朝, 韦甘, 张喆. 不同尾翼两厢轿车的气动特性数值模拟[J]. 吉林大学学报(工学版), 2011, 41(01): 1-0005. |

| [15] | 张英朝, 张喆, 李杰. 基于计算流体力学的虚拟风洞试验[J]. 吉林大学学报(工学版), 2010, 40(增刊): 90-0094. |

|

||