吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (8): 2236-2244.doi: 10.13229/j.cnki.jdxbgxb.20211113

• 车辆工程·机械工程 • 上一篇

液力变矩器空化数值模拟及对性能的影响

柴博森1,2,3( ),王广义1,闫东2,朱国仁1(

),王广义1,闫东2,朱国仁1( ),张进1,吕恒升1

),张进1,吕恒升1

- 1.吉林大学 机械与航空航天工程学院,长春 130022

2.吉林大学 汽车仿真与控制国家重点实验室,长春 130022

3.中机试验装备股份有限公司,长春 130103

Numerical simulation of cavitation in torque converter and analysis of its influence on performance

Bo-sen CHAI1,2,3( ),Guang-yi WANG1,Dong YAN2,Guo-ren ZHU1(

),Guang-yi WANG1,Dong YAN2,Guo-ren ZHU1( ),Jin ZHANG1,Heng-sheng LYU1

),Jin ZHANG1,Heng-sheng LYU1

- 1.School of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

2.State Key Laboratory of Automobile Simulation and Control,Jilin University,Changchun 130022,China

3.Sinotest Equipment Co. ,Ltd. ,Changchun 130103,China

摘要:

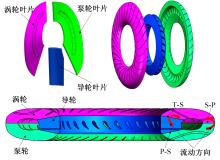

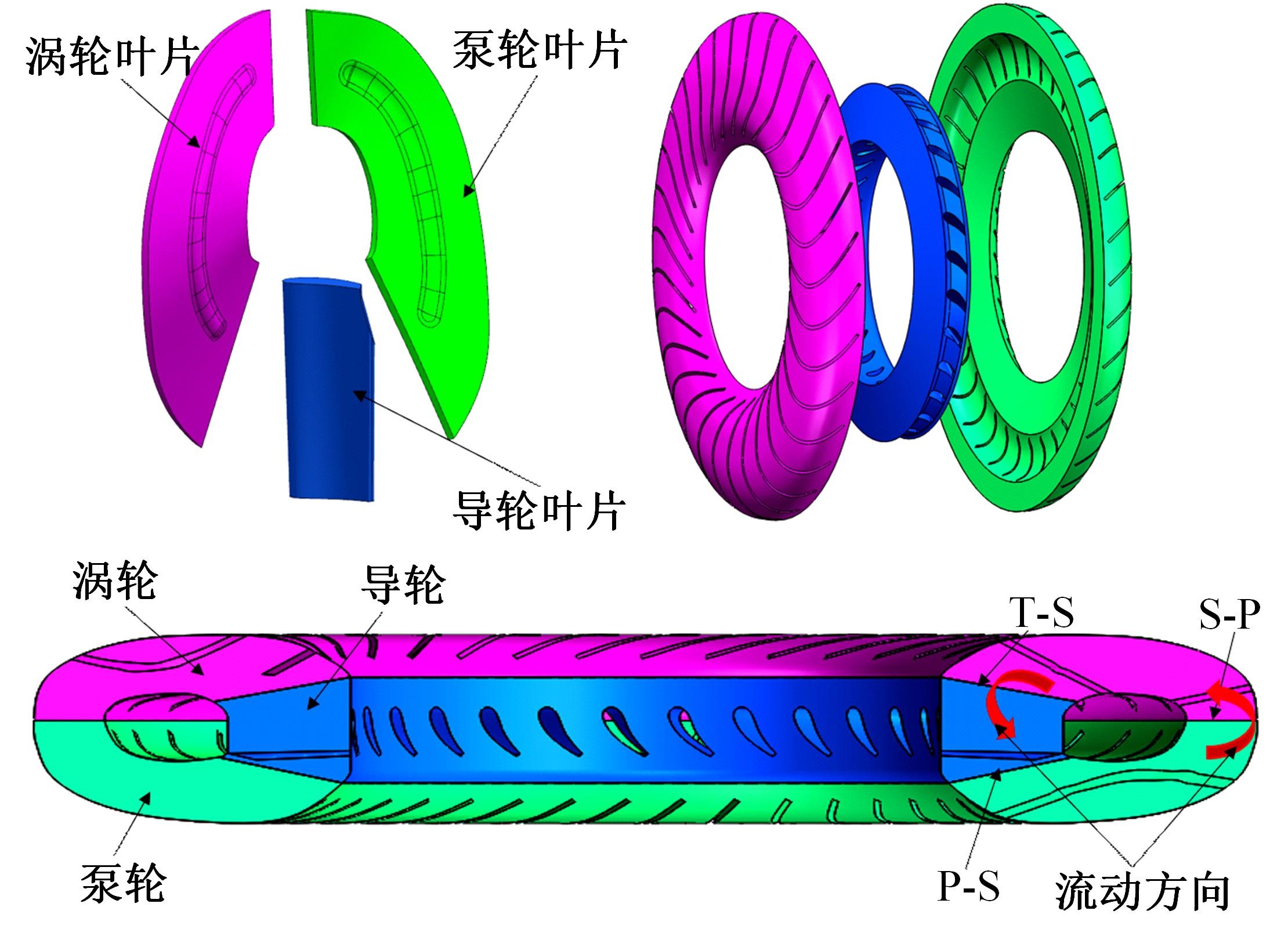

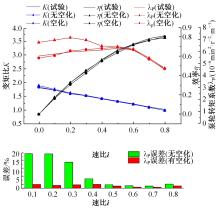

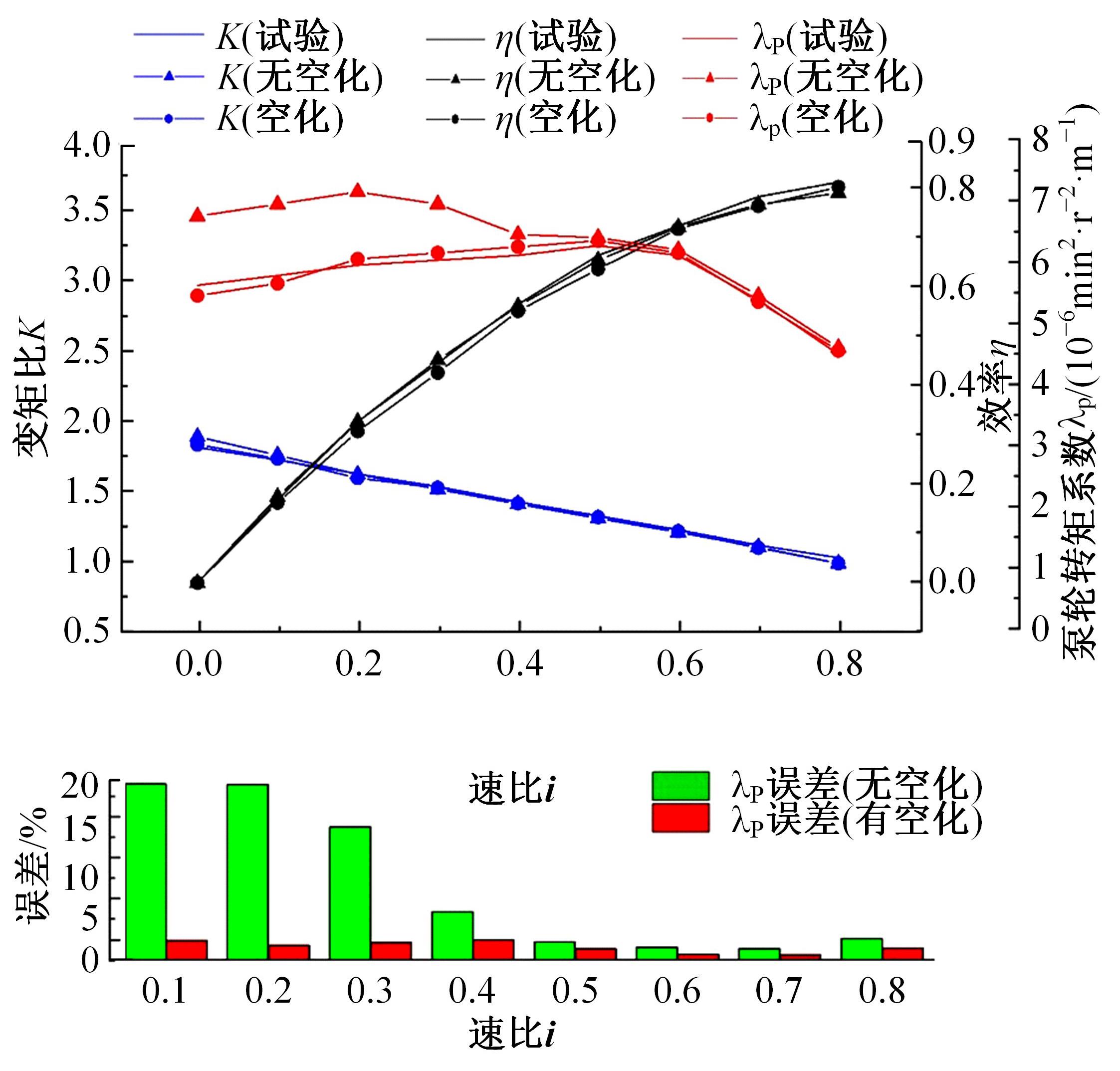

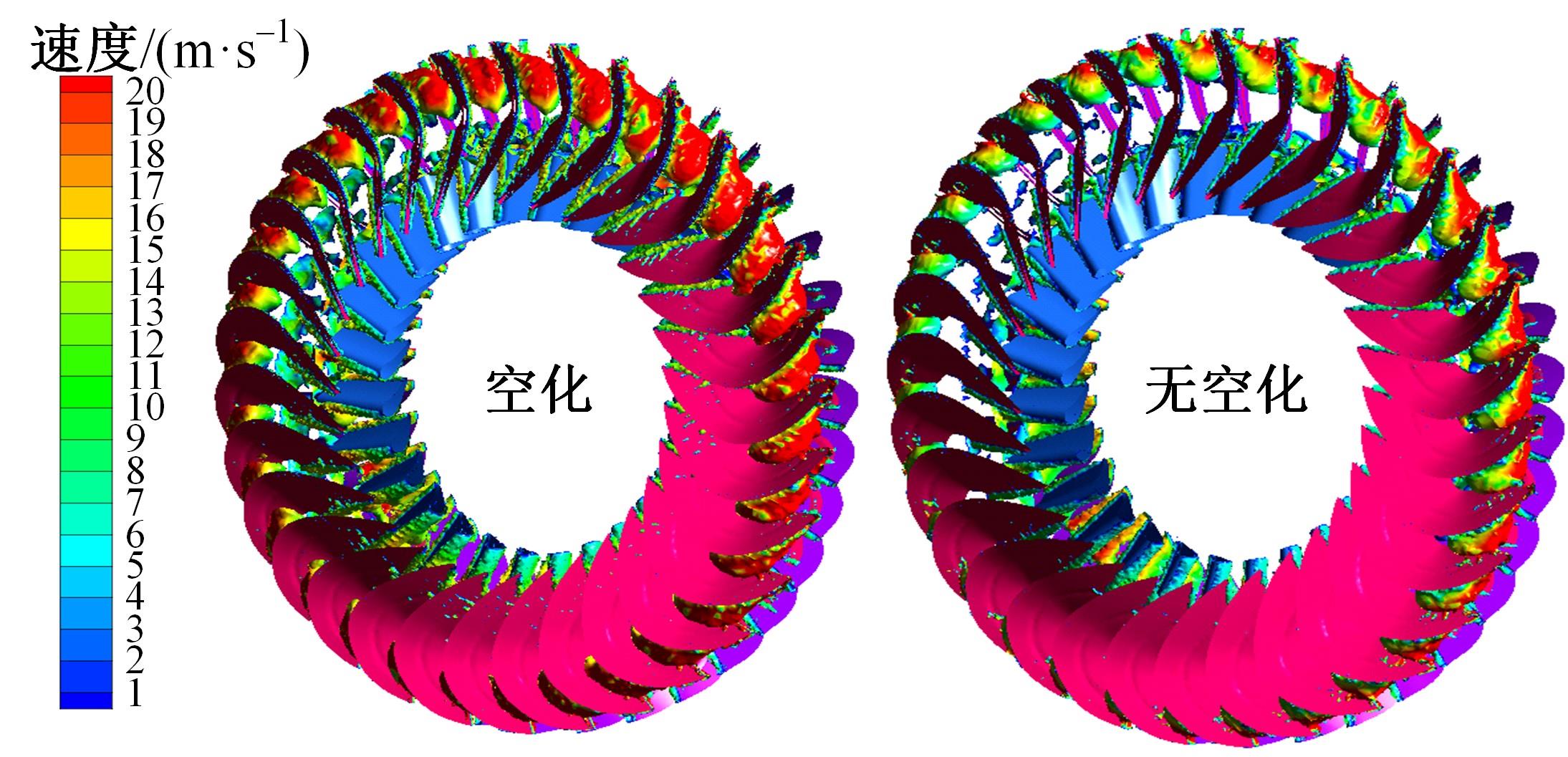

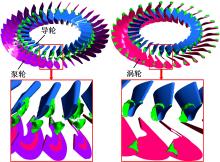

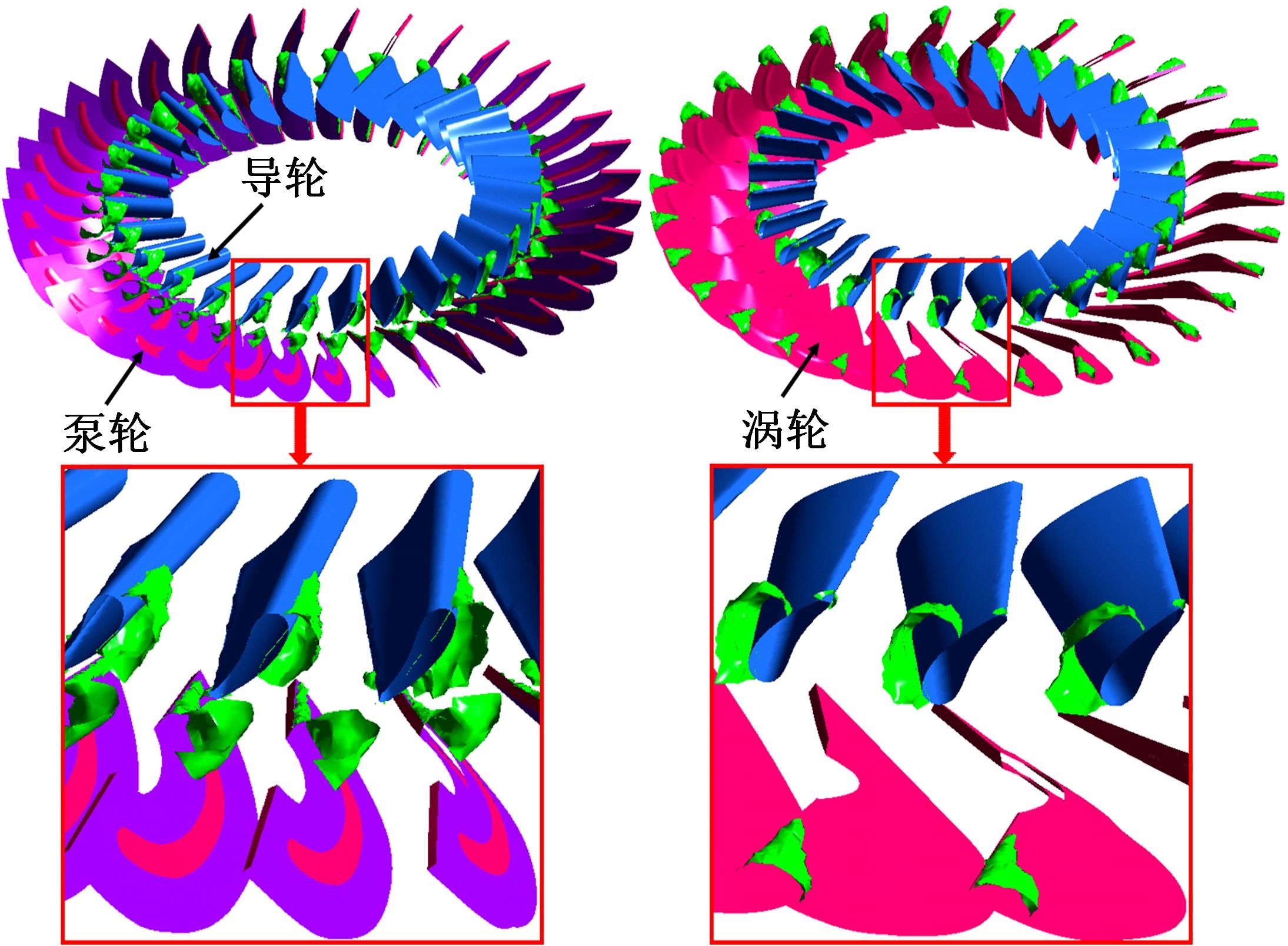

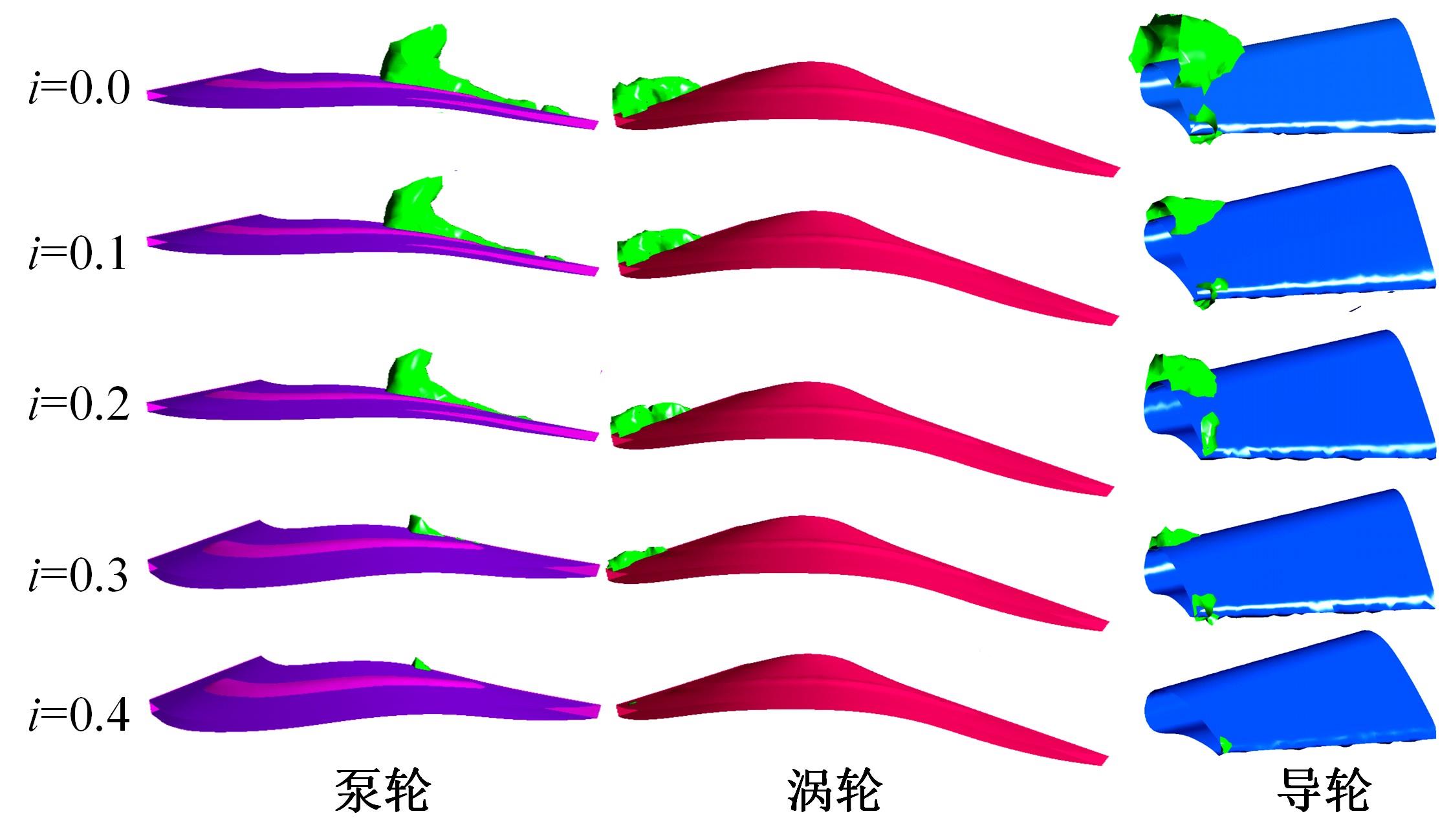

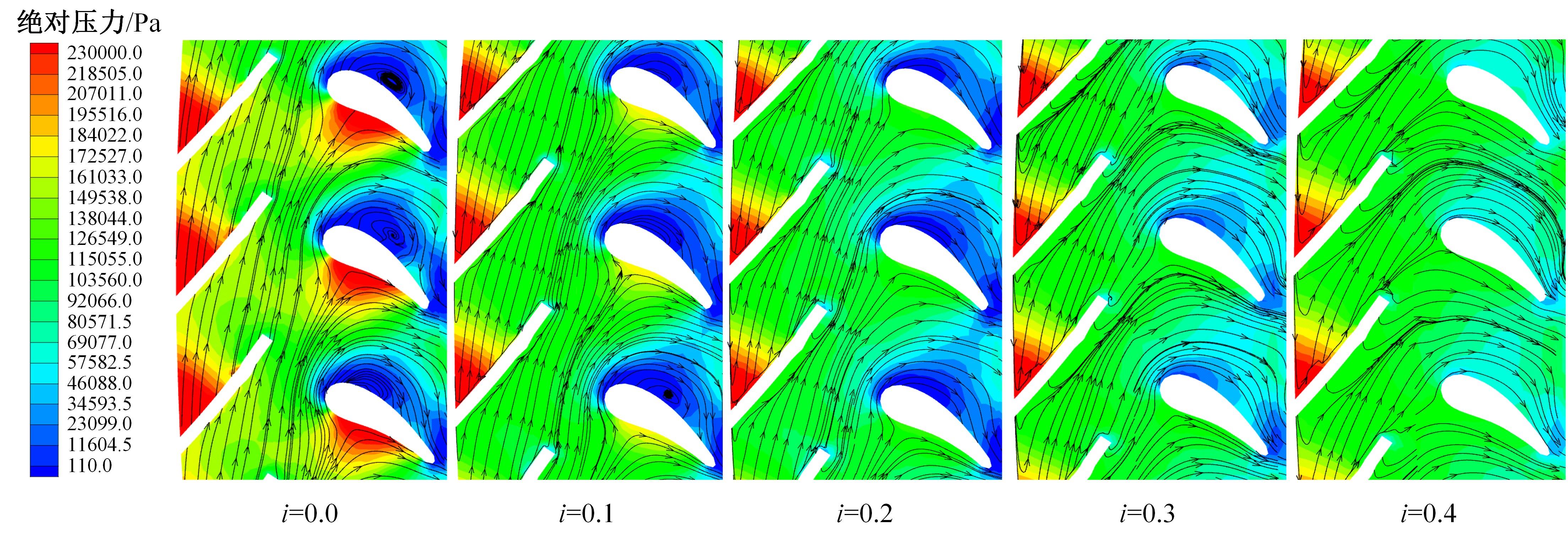

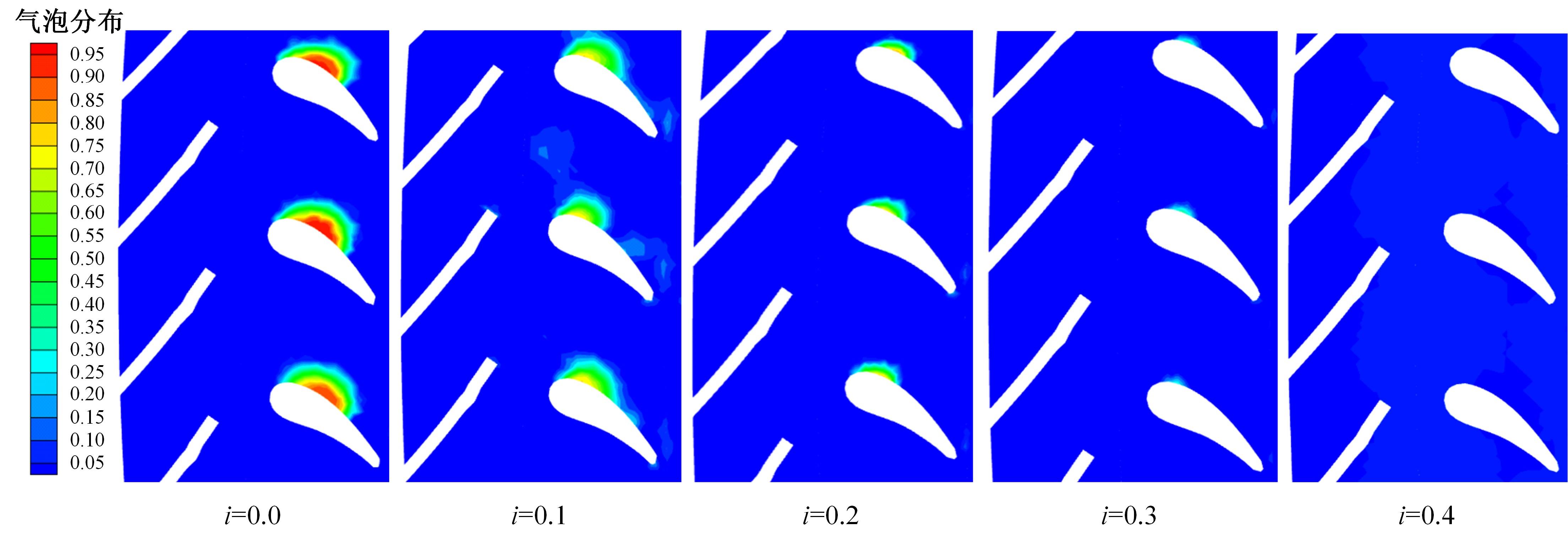

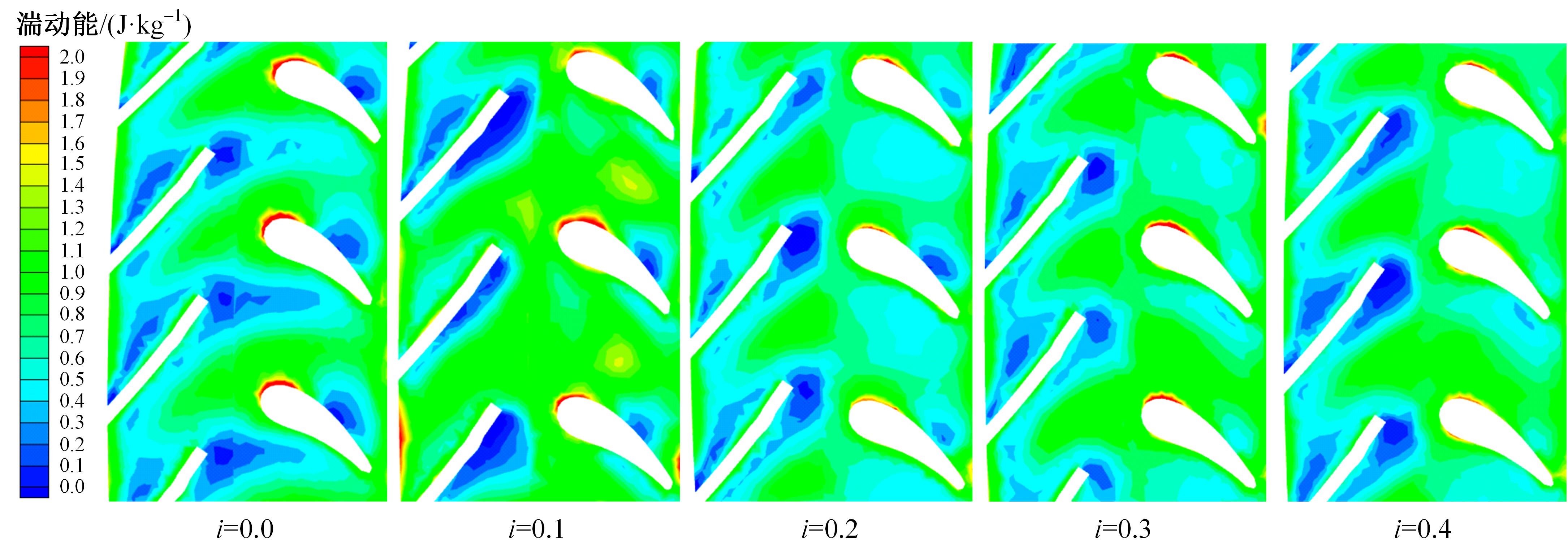

基于计算流体动力学,从是否考虑空化两个角度分别数值模拟液力变矩器流场并绘制外特性曲线,通过试验验证仿真结果准确性。为了深入剖析空化对于液力变矩器内/外特性的影响规律,基于Q准则涡识别方法提取三维涡结构特征,分析低速比工况下各叶片表面空化特征动态演化规律,重点研究导轮叶片处空化现象,阐明空化对流场时空结构分布及能量损耗的影响机理。结果表明:①考虑空化的数值模拟与试验结果吻合度高,外特性预测误差在3%以内;②不考虑空化的数值模拟结果中泵轮转矩系数与试验数据误差较大,启动工况下误差在20%以上,仿真结果严重失真;③泵轮转速为2000 r/min时,速比为0.4的工况是空化消失的临界点,随着速比降低,空化现象及其影响越发明显。研究结果可为液力变矩器高精度数值模拟提供理论指导。

中图分类号:

- TH137.332

| 1 | 初长祥, 马文星. 工程机械液压与液力传动系统(液力卷)[M]. 北京: 化学工业出版社, 2015. |

| 2 | 刘城,闫清东, 李娟, 等. 高功率密度液力变矩器空化特性研究[J]. 机械工程学报, 2020, 56(24): 147-155. |

| Liu Cheng, Yan Qing-dong, Li Juan, et al. Investigation on the cavitation characteristics of high power-density torque converter[J]. Journal of Mechanical Engineering, 2020, 56(24):147-155. | |

| 3 | Robinette D L, Schweitzer J M, Maddock D G, et al. Predicting the onset of cavitation in automotive torque converters-part I: designs with geometric similitude[J]. International Journal of Rotating Machinery, 2008(9): 803940. |

| 4 | Robinette D L, Schweitzer J M, Maddock D G, et al. Predicting the onset of cavitation in automotive torque converters-part II: a generalized model[J]. International Journal of Rotating Machinery, 2008(9): 312753. |

| 5 | Mekkes J, Anderson C, Narain A. Static pressure measurements and cavitation signatures on the nose of a torque converters stator blades[C]∥Proceedings of 2004 International Symposium on Rotating Machinery, Honolulu, Hawaii, 2004: 49931. |

| 6 | Jaewon J, Jaedeuk J, Minsuk C, et al. Effects of cavitation on performance of automotive torque converter[J]. Advances in Mechanical Engineering, 2016, 8(6):1-9. |

| 7 | Watanabe S, Otani R, Kunimoto S, et al. Vibration characteristics due to cavitation in stator element of automotive torque converter at stall condition[C]∥American Society of Mechanical Engineers, Fluids Engineering Summer Meeting, Rio Grande, Puerto Rico, 2012: 535-541. |

| 8 | Yu D, Korivi V, Attibele P, et al. Torque converter CFD engineering-part Ⅰ: torque ratio and K factor improvement through stator modifications[C]∥SAE 2002 World Congress, Detroit, Michigan, USA, 2002: 14. |

| 9 | Yu D, Korivi V, Attibele P, et al. Torque converter CFD engineering part II: performance improvement through core leakage flow and cavitation control [C]∥SAE 2002 World Congress & Exhibition, Detroit, Michigan, USA, 2002: 1272-1285. |

| 10 | 赵丽丽. 基于CFD的液力变矩器内流场气蚀研究[D]. 太原: 太原科技大学机械工程学院, 2016. |

| Zhao Li-li. The cavitation research of the flow field in the hydraulic torque converter based on CFD[D]. Taiyuan: College of Mechanical Engineering, Taiyuan University of Science and Technology, 2016. | |

| 11 | Liu C, Wei W, Yan Q D, et al. Influence of stator blade geometry on torque converter cavitation[J]. Journal of Fluids Engineering Transactions of the Asme, 2018, 140(4): 041102. |

| 12 | Liu C, Wei W, Yan Q D, et al. Torque converter capacity improvement through cavitation control by design[J]. Journal of Fluids Engineering: Transactions of the ASME, 2017, 139(4): 041103. |

| 13 | Liu C, Wei W, Yan Q D, et al. On the application of passive flow control for cavitation suppression in torque converter stator[J]. International Journal of Numerical Methods for Heat and Fluid Flow, 2019, 29(1): 204-222. |

| 14 | 刘春宝, 李静, 卜卫羊,等. 尺度解析湍流模拟方法在液力传动流动数值模拟中的应用[J]. 液压与汽动,2019, 6: 58-62. |

| Liu Chun-bao, Li Jing, Bu Wei-yang, et al. Application of scale-resolving simulation in hydrodynamic transmission[J]. Chinese Hydraulics & Pneumatics, 2019, 6: 58-62. | |

| 15 | 卢秀泉, 马霖, 马文星, 等. 导轮关键参数对液力变矩偶合器性能的影响[J]. 吉林大学学报: 工学版, 2019, 49(2): 444-450. |

| Lu Xiu-quan, Ma Lin, Ma Wen-xing, et al. Effects of key parameters of stator on the performance of hydrodynamic coupling torque converter[J]. Journal of Jilin University (Engineering and Technology Edition), 2019, 49(2): 444-450. | |

| 16 | 刘树成, 潘鑫, 魏巍, 等. 基于复杂性测度的变矩器流场仿真湍流模型稳健性分析[J]. 吉林大学学报: 工学版, 2013, 43(3): 613-618. |

| Liu Shu-cheng, Pan Xin, Wei Wei, et al. Complexity-based robustness analysis of turbulence model in torque converter flow field simulation[J]. Journal of Jilin University(Engineering and Technology Edition), 2013, 43(3): 613-618. | |

| 17 | Hesse F, Morgans A S. Simulation of wake bimodality behind squareback bluff-bodies using LES[J]. Computers & Fluids, 2021, 223: 104901. |

| 18 | Shur M L, Spalart P R, Strelets M K, et al. A hybrid RANS-LES approach with delayed-DES and wall-modelled LES capabilities[J]. International Journal of Heat & Fluid Flow, 2008, 29(6): 1638-1649. |

| 19 | 张春泽, 刁伟, 尤建锋, 等. 长短叶片水轮机尾水涡带动态特性数值分析[J]. 华中科技大学学报: 自然科学版, 2017, 45(7): 66-73. |

| Zhang Chun-ze, Diao Wei, You Jian-feng, et al. Numerical analysis of dynamic characteristics of the vortex rope in a francis turbine with splitter blades[J]. Journal of Huazhong University of Science and Technology (Natural Science Edition), 2017, 45(7): 66-73. | |

| 20 | Robinette D, Anderson C, Blough J, et al. Characterizing the effect of automotive torque converter design parameters on the onset of cavitation at stall[J]. SAE International Journal of Passenger Cars-Mechanical Systems, 2007, 116(6): 1735-1746. |

| [1] | 陈国辉,徐业银,焦映厚. 考虑偏转的斜齿轮啮合刚度及其振动分析[J]. 吉林大学学报(工学版), 2023, 53(7): 1902-1910. |

| [2] | 陈贵升,罗国焱,李靓雪,黄震,李一. 柴油机颗粒捕集器孔道流场及其高原环境下噪声特性分析[J]. 吉林大学学报(工学版), 2023, 53(7): 1892-1901. |

| [3] | 王峰,刘双瑞,王佳盈,宋佳玲,王俊,张久鹏,黄晓明. 尺寸和形状效应对多孔结构风阻系数的影响[J]. 吉林大学学报(工学版), 2023, 53(6): 1677-1685. |

| [4] | 李胜,朱佳,黄德惠,陈存福,费洪庆,丰伟,胡兴军. 空冷中冷器百叶窗翅片结构参数优化[J]. 吉林大学学报(工学版), 2023, 53(4): 998-1006. |

| [5] | 王建,于威,王斌. 高原状态下甲醇替代率对柴油机燃烧与排放的影响[J]. 吉林大学学报(工学版), 2023, 53(4): 954-963. |

| [6] | 于立娟,安阳,何佳龙,李国发,王升旭. 机电装备载荷谱外推技术研究进展及发展趋势[J]. 吉林大学学报(工学版), 2023, 53(4): 941-953. |

| [7] | 朱凌,王秋成. 空间几何约束下新能源汽车驱动系统协调控制方法[J]. 吉林大学学报(工学版), 2022, 52(7): 1509-1514. |

| [8] | 金兆辉,谷乐祺,洪伟,解方喜,尤田. 液压可变气门系统压力波动的影响分析[J]. 吉林大学学报(工学版), 2022, 52(4): 773-780. |

| [9] | 张岩,刘玮,张树勇,裴毅强,董蒙蒙,秦静. 二/四冲程可变柴油机燃烧室热负荷的改善[J]. 吉林大学学报(工学版), 2022, 52(3): 504-514. |

| [10] | 李国发,王彦博,何佳龙,王继利. 机电装备健康状态评估研究进展及发展趋势[J]. 吉林大学学报(工学版), 2022, 52(2): 267-279. |

| [11] | 孙健,彭斌,朱兵国. 新型无油涡旋压缩机内部热力学特性和性能测试[J]. 吉林大学学报(工学版), 2022, 52(12): 2778-2787. |

| [12] | 王磊,黄秉汉,丛家慧,回丽,周松,徐永臻. 超声冲击对搅拌摩擦焊缝疲劳性能的影响[J]. 吉林大学学报(工学版), 2022, 52(11): 2542-2548. |

| [13] | 赵文伯,李玉洁,邓俊,李理光,吴志军. 针阀运动规律及其对喷嘴内流和喷雾特性影响[J]. 吉林大学学报(工学版), 2022, 52(10): 2234-2243. |

| [14] | 胡兴军,张靖龙,辛俐,罗雨霏,王靖宇,余天明. 冷却管结构及风速对空冷中冷器性能的影响[J]. 吉林大学学报(工学版), 2021, 51(5): 1557-1564. |

| [15] | 赵庆武,程勇,杨雪,王宁. 高重频纳秒脉冲放电点火系统设计[J]. 吉林大学学报(工学版), 2021, 51(2): 414-421. |

|

||