吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (9): 2484-2494.doi: 10.13229/j.cnki.jdxbgxb.20221478

• 材料科学与工程 • 上一篇

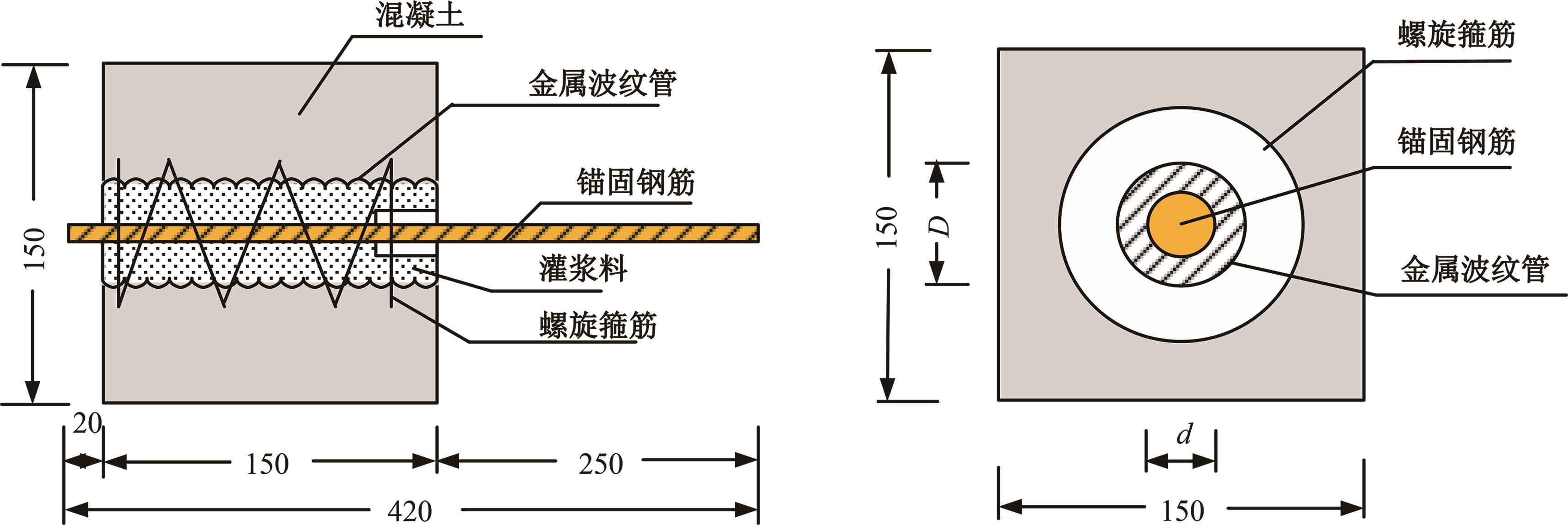

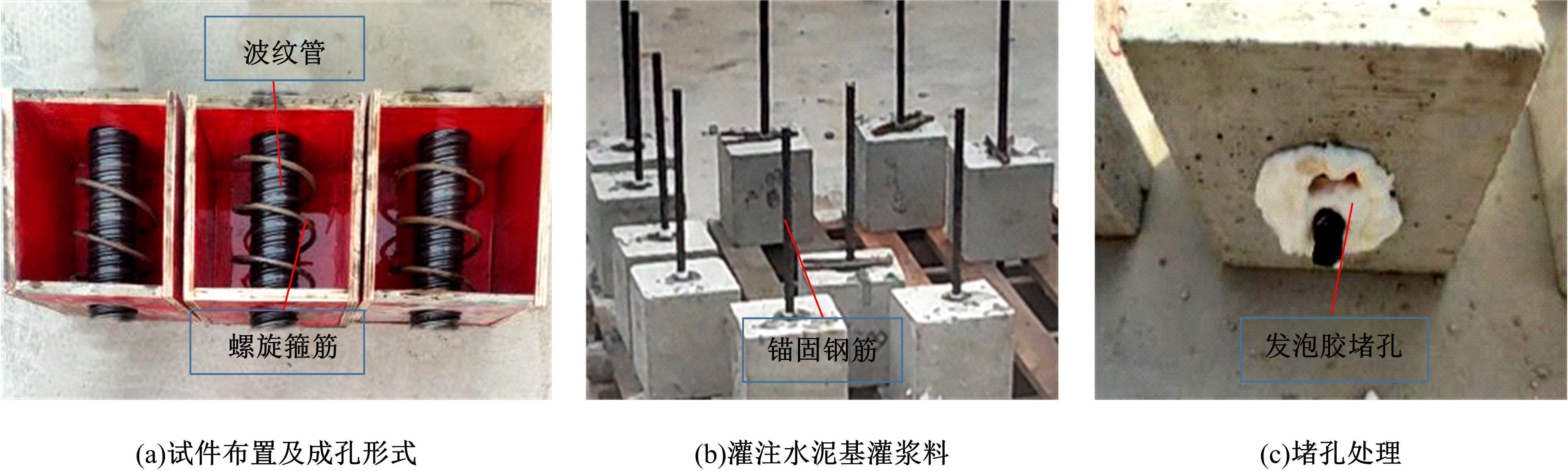

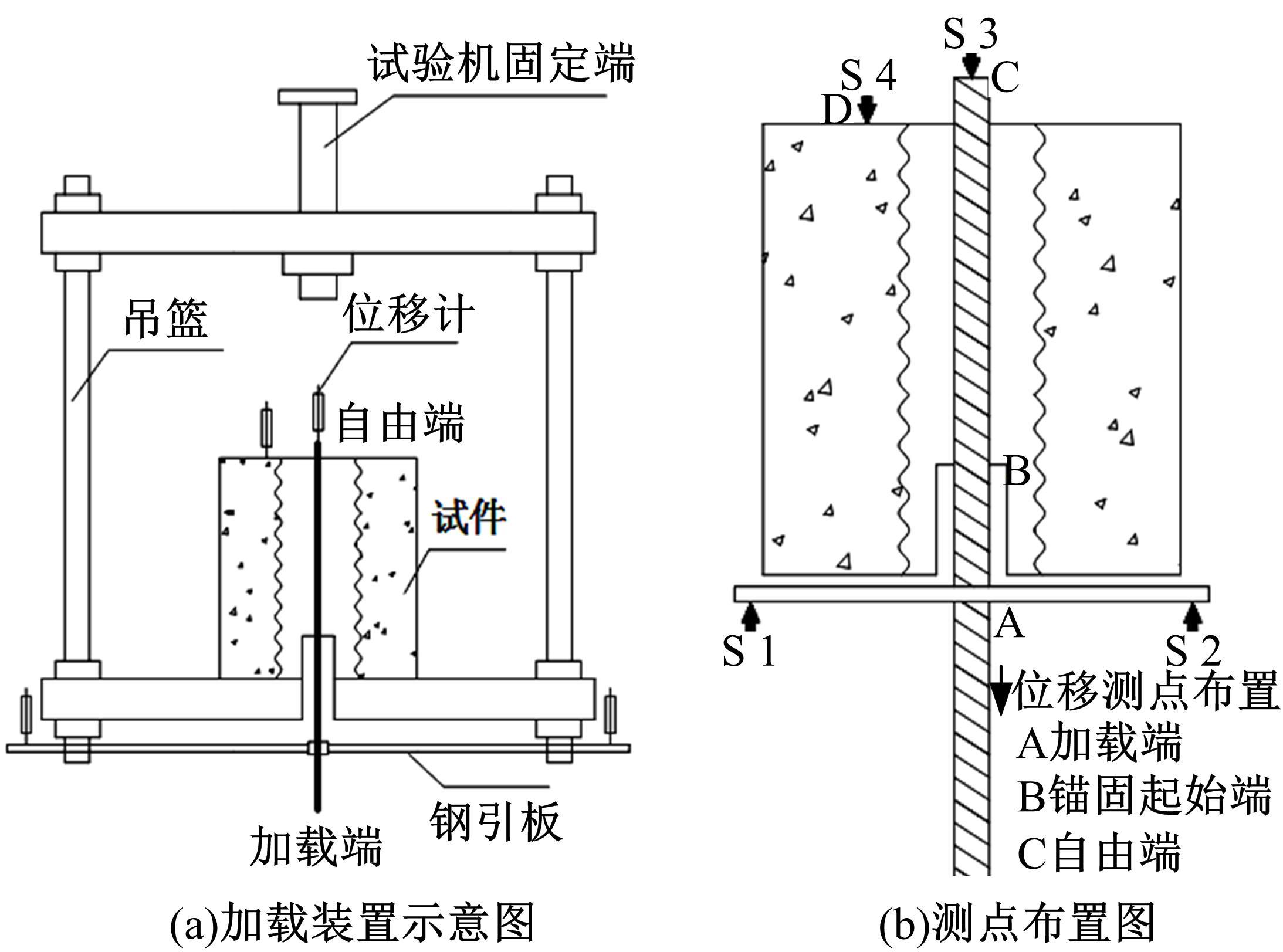

螺旋箍筋-波纹管浆锚连接锚固性能试验

- 1.河南工业大学 土木工程学院,郑州 450001

2.河南省粮油仓储建筑与安全重点实验室,郑州 450001

3.浙江东南网架股份有限公司 设计院,杭州 311209

Experiment on anchoring performance of spiral stirrup-corrugated pipe grout splicing

Jin-quan ZHAO1,2( ),Long ZHOU1,Yong-gang DING1,2(

),Long ZHOU1,Yong-gang DING1,2( ),Rong-ji ZHU3

),Rong-ji ZHU3

- 1.College of Civil Engineering,Henan University of Technology,Zhengzhou 450001,China

2.Henan Key Laboratory of Grain Storage Facility and Safety,Zhengzhou 450001,China

3.Design Institute,Zhejiang Southeast Space Frame Co. ,Ltd. ,Hangzhou 311209,China

摘要:

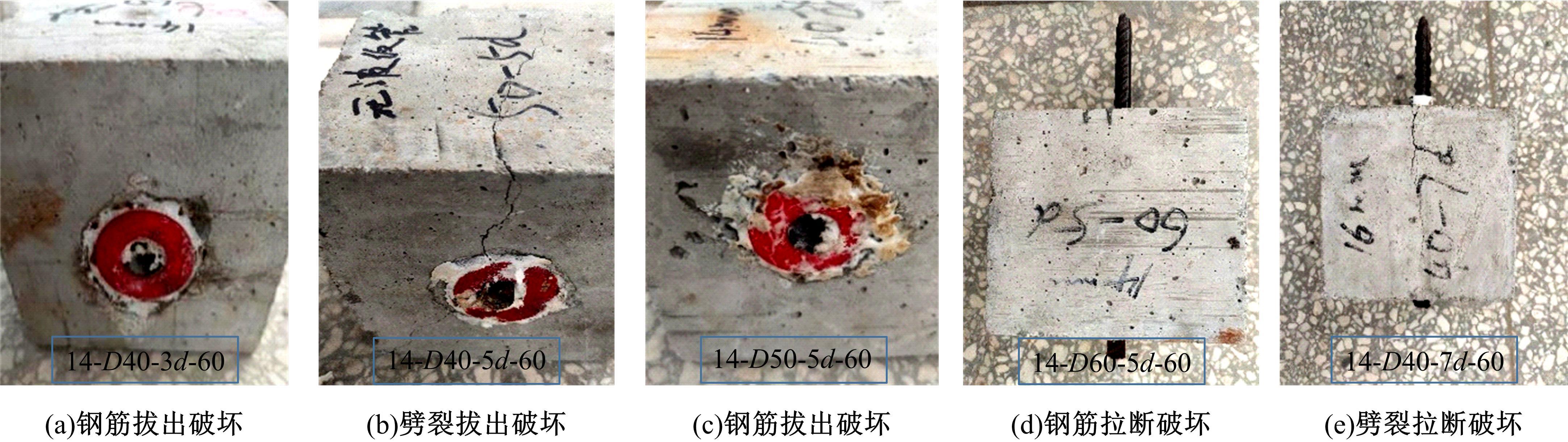

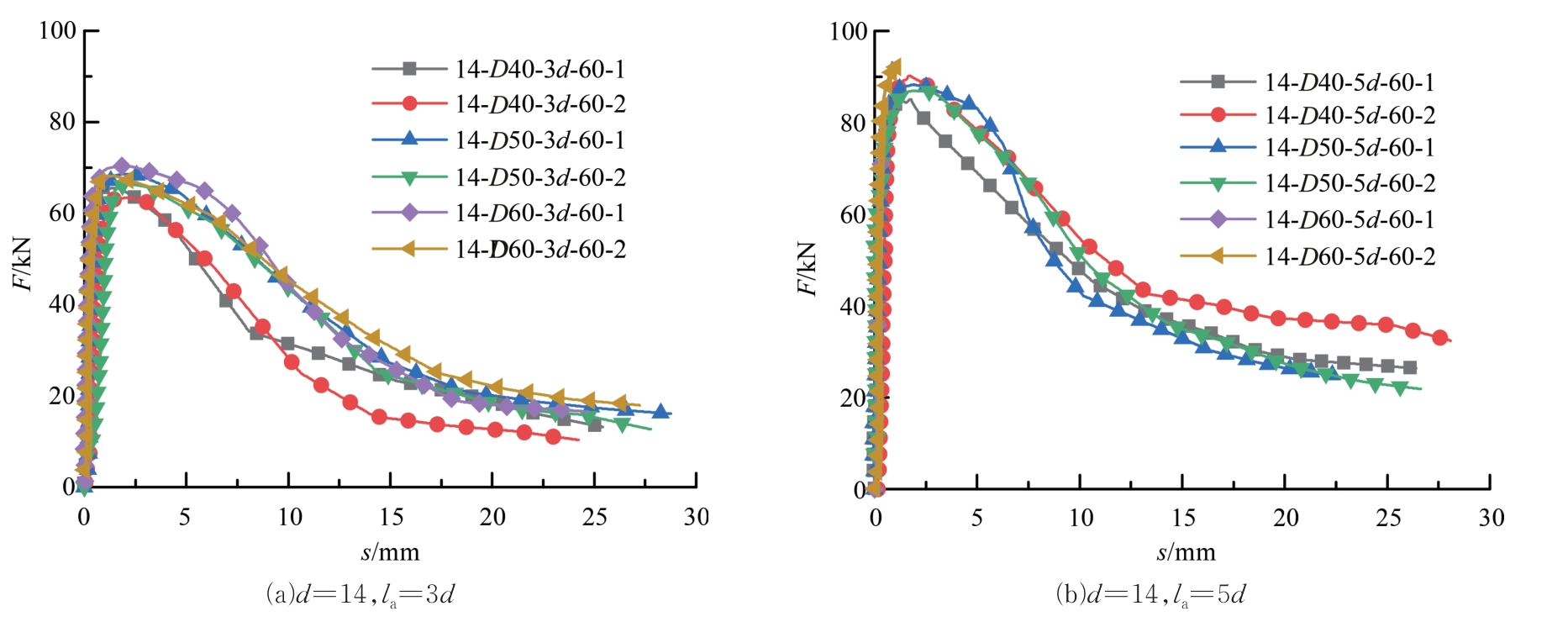

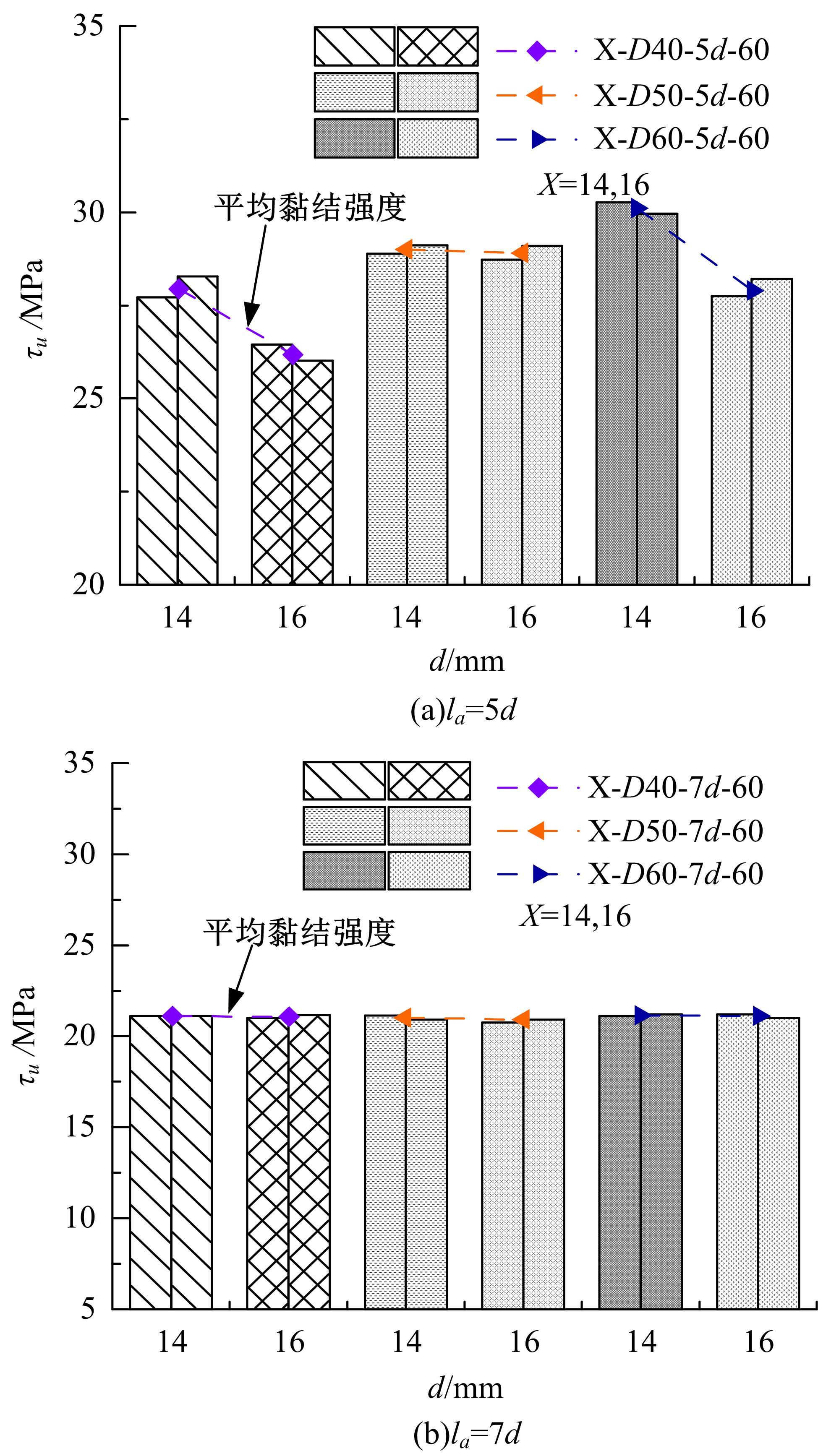

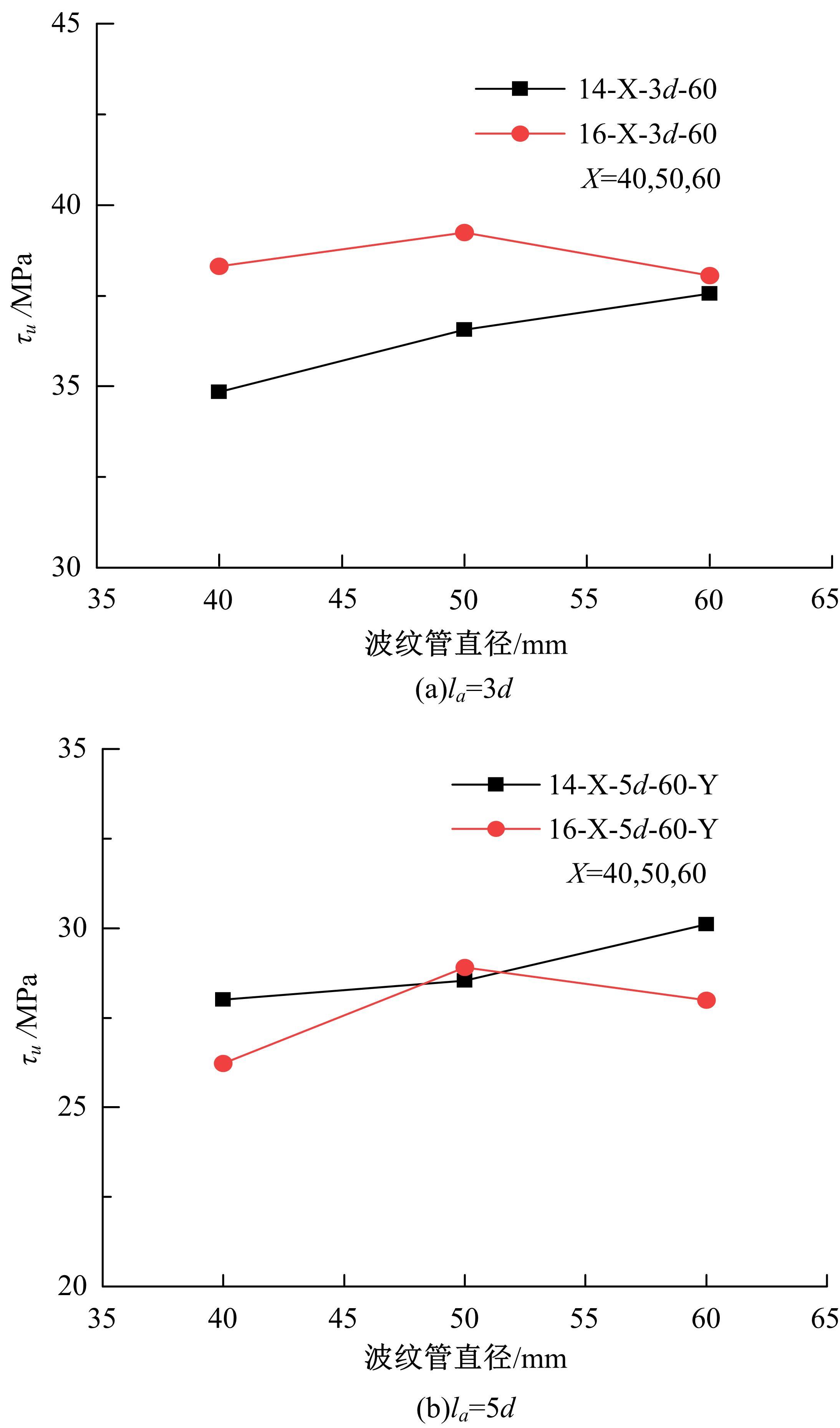

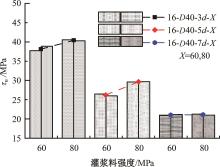

为了对螺旋箍筋-波纹管约束浆锚连接在装配式结构中的应用提供理论依据,设计并制作了21个锚固拉拔试件,通过单向拉拔试验,分析了试件的受力过程及不同影响因素对试件黏结锚固强度的影响规律。结果表明:试件的破坏形态主要为拔出、劈裂拔出、拉断和劈裂拉断等4种;黏结强度随着锚固长度和钢筋直径的增加而减小;随着波纹管直径的增大,黏结强度与钢筋直径呈非线性变化;平均极限黏结强度随着灌浆料强度的增加而提高且锚固长度可进一步缩短至5d。工程应用中,当钢筋直径不大于16 mm时,建议锚固长度取5~7d,孔径比取2.5~4.28,当灌浆料强度fcu≥80 MPa时,锚固长度不低于5d。

中图分类号:

- TU375

| 1 | 郭家旭, 胡少伟, 齐浩, 等. 考虑灌浆料龄期的钢筋-金属波纹管浆锚连接锚固性能试验研究[J]. 土木与环境工程学报, 2024, 46(2):108-116. |

| Guo Jia-xu, Hu Shao-wei, Qi Hao, et al. Experimental study on anchorage property of rebar-metallic bellows slurry anchor connection considering grout age[J]. Journal of Civil and Environmental Engineering, 2024, 46(2):108-116. | |

| 2 | 毛小勇, 高奕昕. 约束浆锚搭接连接高温性能试验研究[J]. 建筑结构学报, 2020, 41(7): 117-123. |

| Mao Xiao-yong, Gao Yi-xin. Experimental research on connection performance of restraint grouting-anchoring over lap-joint of steel bar subjected to high temperature[J]. Journal of Building Structures, 2020, 41(7): 117-123. | |

| 3 | 李宪军, 邓美林, 何廷树. 装配式建筑套筒灌浆连接系统膨胀约束关键技术研究[J]. 建筑结构, 2021, 51(9): 43-48. |

| Li Xian-jun, Deng Mei-lin, He Ting-shu. Research on the key technology of restrained expansion of the sleeve grouting connection system in prefabricated building[J]. Building Structure, 2021, 51(9): 43-48. | |

| 4 | Chen J, Chen X L, Ding F X, et al. Mechanical performance of overlap connections with grout-filled anchor reinforcements in embedded metal corrugated pipe[J]. Archives of Civil and Mechanical Engineering, 2020, 20(4): No.128. |

| 5 | Hosseini S J A, Rahman A B A. Efects of spiral confnement to the bond behavior of deformed reinforcement bars subjected to axial tension[J]. Engineering Structures, 2016(112): 1-13. |

| 6 | 陈云钢, 刘家彬, 郭正兴, 等. 预制混凝土结构波纹管浆锚钢筋锚固性能试验研究[J]. 建筑技术, 2014, 45(1): 65-67. |

| Chen Yun-gang, Liu Jia-bin, Guo Zheng-xing, et al. Experimental study on grouting connection in bellows for steel bar anchorage of precast concrete strucure[J]. Architecture Technology, 2014, 45(1): 65-67. | |

| 7 | 余琼, 许雪静, 尤高帅. 带肋钢筋与灌浆料黏结性能试验[J]. 哈尔滨工业大学学报, 2017, 49(12): 91-101. |

| Yu Qiong, Xu Xue-jing, You Gao-shuai. Experimental study on bond behavior for ribbed steel bars and grout[J]. Journal of Harbin Institute of Technology, 2017, 49(12): 91-101. | |

| 8 | 王浩, 柳家为, 石棚, 等. 钢筋-金属波纹管灌浆连接的锚固性能试验研究[J]. 东南大学学报, 2020, 50(2): 215-221. |

| Wang Hao, Liu Jia-wei, Shi Peng, et al. Experimental study on anchorage performance ofrebar-corrugated metal duct for grout splicing[J]. Journal of Southeeast University, 2020, 50(2): 215-221. | |

| 9 | 陈俊, 肖岩, 尹齐. 预埋波纹套管的钢筋-高强浇筑料黏结锚固性能试验研究[J]. 建筑结构学报, 2015, 36(7): 140-147. |

| Chen Jun, Xiao Yan, Yin Qi. Bonding strength of rebar anchorage in embedded corrugated sleeve with high strength grout[J]. Journal of Building Structures, 2015, 36(7): 140-147. | |

| 10 | Chen J, Zhao C H, Ding F X, et al. Mechanical performance of the grouted lapped double reinforcements anchored in embedded corrugated sleeves[J]. Structures, 2020, 28: 1354-1365. |

| 11 | 姜洪斌, 张海顺, 刘文清, 等. 预制混凝土结构插入式预留孔灌浆钢筋锚固性能[J]. 哈尔滨工业大学学报, 2011, 43(4): 28-31, 36. |

| Jiang Hong-bin, Zhang Hai-shun, Liu Wen-qing, et al. Experimental study on plug-in filling hole for steel bar anchorage of the PC structure[J]. Journal of Harbin Institute of Technology, 2011, 43(4): 28-31, 36. | |

| 12 | Zheng Y F, Zhu Z F, Guo Z X, et al. Behavior and splice length of deformed bars lapping in spirally confined grout-filled corrugated duct[J]. Advances in Materials Science and Engineering, 2019, 2019: 1-11. |

| 13 | Ma C F, Jiang H B, Wang Z Y. Experimental investigation of precast RC interior beam-column-slab joints with grouted spiral-confined lap connection[J]. Engineering Structures, 2019, 196: No. 109317. |

| 14 | Hosseini S J A, Rahman A B A, Osman M H,et al. Bond behavior of spirally confined splice of deformed bars in grout[J]. Construction and Building Materials, 2015, 80: 180-194. |

| 15 | 葛继平, 夏樟华, 江恒. 灌浆波纹管装配式桥墩双向拟静力试验[J].中国公路学报, 2018, 31(12): 221-230, 266. |

| Ge Ji-ping, Xia Zhang-hua, Jiang Heng. Biaxial quasi-static eperiment of precast segmengtal bridge piers with grouting corrugated pipe connection[J]. China Journal of Highway and Transport, 2018, 31(12): 221-230, 266. | |

| 16 | 陈昕, 刘明, 姚大鹏, 等. 考虑波纹管组合钢筋浆锚搭接长度的装配式剪力墙拟静力试验[J]. 大连理工大学学报, 2016, 56(6): 616-623. |

| Chen Xin, Liu Ming, Yao Da-peng, et al. Quasi-static experiments on lap length of precast shear walls assembled with reinforcement grouting anchor connection and corrugated pipes[J]. Journal of Dalian University of Technology, 2016, 56(6): 616-623. | |

| 17 | 陈昕, 李家旭, 杨永生, 等. 预埋波纹管单排钢筋浆锚连接的预制剪力墙抗震性能研究[J]. 沈阳建筑大学学报, 2021, 37(5): 814-822. |

| Chen Xin, Li Jia-xu, Yang Yong-sheng, et al. Research on seismic performance of precast shear wall connected by embedded corrugated pipe and single row of steel bars[J]. Journal of Shenyang Jianzhu University, 2021, 37(5): 814-822. | |

| 18 | .普通混凝土力学性能试验方法标准 [S]. |

| 19 | .水泥基灌浆材料应用技术规范 [S]. |

| 20 | 余琼, 孙佳秋, 袁炜航. 带肋钢筋与套筒约束灌浆料黏结性能试验[J]. 哈尔滨工业大学学报, 2018, 50(12): 98-106. |

| Yu Qiong, Sun Jia-qiu, Yuan Wei-hang. Experimental study on bond behavior between ribbed steel bars and sleeve constrained grouting matrrial[J]. Journal of Harbin Institute of Technology, 2018, 50(12): 98-106. | |

| 21 | 徐有邻, 沈文都, 汪洪. 钢筋砼粘结锚固性能的试验研究[J]. 建筑结构学报, 1994(3): 26-37. |

| Xu You-lin, Shen Wen-du, Wang Hong. An experimental study of bond-anchorage properties of bars in concrete[J]. Journal of Building Structures, 1994(3): 26-37. | |

| 22 | . 混凝土结构设计规范 [S]. |

| 23 | ACI318—14. Building code requirements for structural concrete [S]. |

| 24 | 山显彬. 变形钢筋与自密实混凝土之间粘结锚固性能试验研究[D]. 哈尔滨: 哈尔滨工业大学土木工程学院, 2008. |

| Shan Xian-bin. Experimental research on bonding prop-erties between deformed bars and self-compacting concrete[D]. Harbin: School of Civil Engineering, Harbin Institute of Technology, 2008. |

| [1] | 杨伟松,张安,许卫晓,李海生,杜轲. 刚度增强型金属连梁阻尼器的抗震性能[J]. 吉林大学学报(工学版), 2024, 54(9): 2469-2483. |

| [2] | 阎奇武,邹忠亮. 减震结构阻尼器优化布置混合算法[J]. 吉林大学学报(工学版), 2024, 54(8): 2267-2274. |

| [3] | 姜封国,周玉明,白丽丽,梁爽. 改进磷虾群算法及其在结构优化中的应用[J]. 吉林大学学报(工学版), 2024, 54(8): 2256-2266. |

| [4] | 张广泰,周乘孝,刘诗拓. 盐渍土环境下纤维锂渣混凝土柱恢复力模型[J]. 吉林大学学报(工学版), 2024, 54(7): 1944-1957. |

| [5] | 刁延松,任义建,杨元强,赵凌云,刘秀丽,刘芸. 带有摩擦耗能组件的可更换钢梁柱拼接节点抗震性能试验[J]. 吉林大学学报(工学版), 2024, 54(6): 1643-1656. |

| [6] | 樊学平,刘月飞. 基于改进高斯混合粒子滤波新算法的桥梁极值应力动态预测[J]. 吉林大学学报(工学版), 2024, 54(4): 1038-1044. |

| [7] | 刘一凡,缪志伟,申晨,耿祥东. 基于蒙特卡罗法的不均匀锈蚀钢筋力学性能评估[J]. 吉林大学学报(工学版), 2024, 54(4): 1007-1015. |

| [8] | 樊学平,周衡,刘月飞. 基于Gaussian Copula-贝叶斯动态模型的桥梁构件时变可靠性分析[J]. 吉林大学学报(工学版), 2024, 54(2): 485-493. |

| [9] | 范亮,徐英铭,谭阳. 集束群钉式装配组合梁界面滑移计算[J]. 吉林大学学报(工学版), 2023, 53(9): 2533-2541. |

| [10] | 樊学平,周衡,刘月飞. 桥梁时变可靠性的多过程贝叶斯动态混合预测[J]. 吉林大学学报(工学版), 2023, 53(8): 2332-2338. |

| [11] | 熊二刚,巩忠文,罗佳明,范团结. 基于数字图像相关技术的钢筋混凝土梁裂缝试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1094-1104. |

| [12] | 王晓东,李宁静,李强. 高压脉冲放电破碎混凝土梁试验[J]. 吉林大学学报(工学版), 2023, 53(2): 496-504. |

| [13] | 匡亚川,陈立斌,李超举,贺宇豪. 栓钉剪力连接件力学性能分析[J]. 吉林大学学报(工学版), 2023, 53(2): 538-546. |

| [14] | 戴理朝,周亮,杨晓文,王磊. 基于Connector单元的锈蚀RC梁界面粘结性能细观数值模拟[J]. 吉林大学学报(工学版), 2023, 53(10): 2886-2896. |

| [15] | 褚云朋,孙鑫晖,李明,姚勇,黄汉杰. 下击暴流作用下圆形马鞍面屋盖风压特性[J]. 吉林大学学报(工学版), 2022, 52(8): 1826-1833. |

|

||