吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (10): 2886-2896.doi: 10.13229/j.cnki.jdxbgxb.20220124

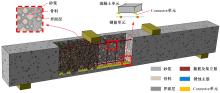

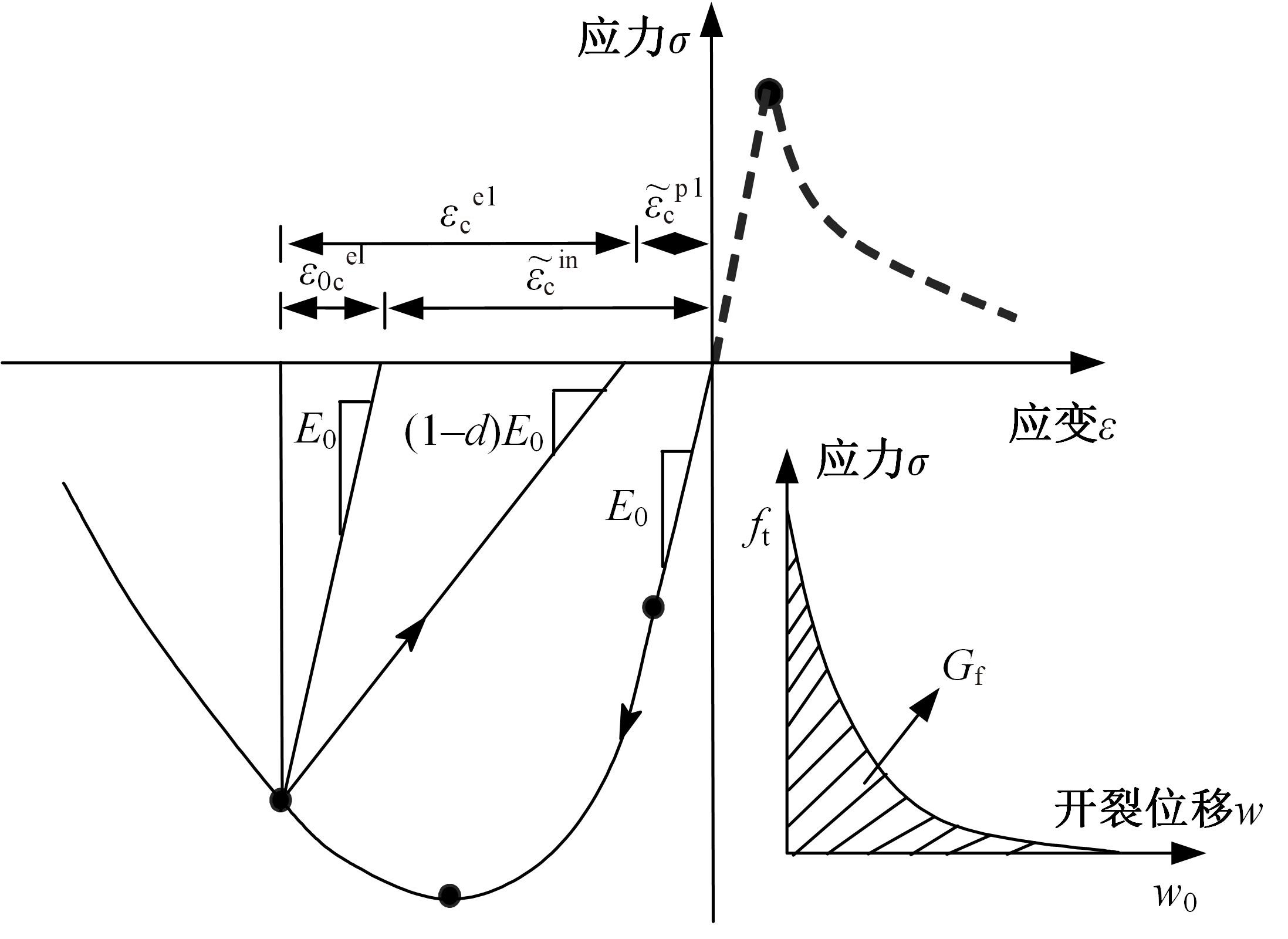

基于Connector单元的锈蚀RC梁界面粘结性能细观数值模拟

- 长沙理工大学 土木工程学院,长沙 410114

Meso-scale numerical simulation of interfacial bond behavior of corroded RC beams based on connector element

Li-zhao DAI( ),Liang ZHOU,Xiao-wen YANG,Lei WANG(

),Liang ZHOU,Xiao-wen YANG,Lei WANG( )

)

- School of Civil Engineering,Changsha University of Science and Technology,Changsha 410114,China

摘要:

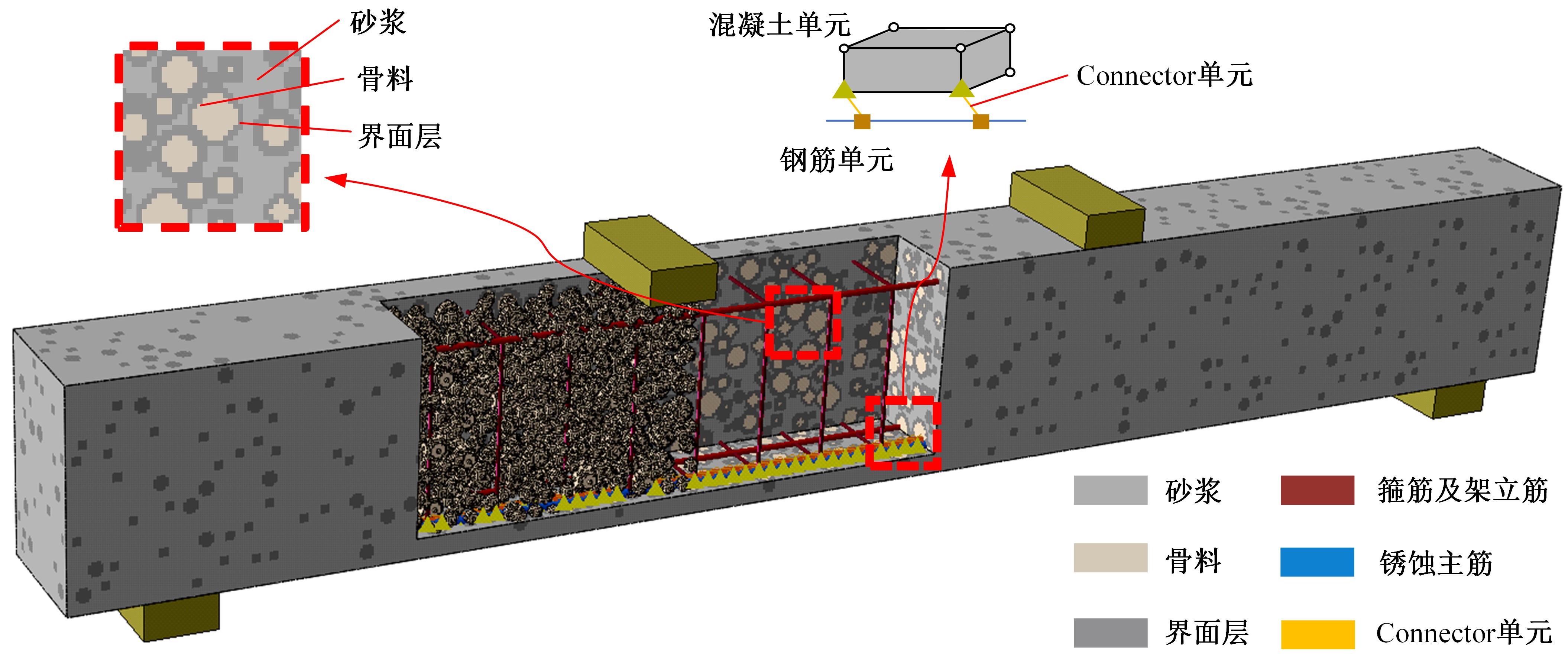

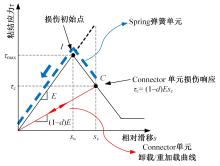

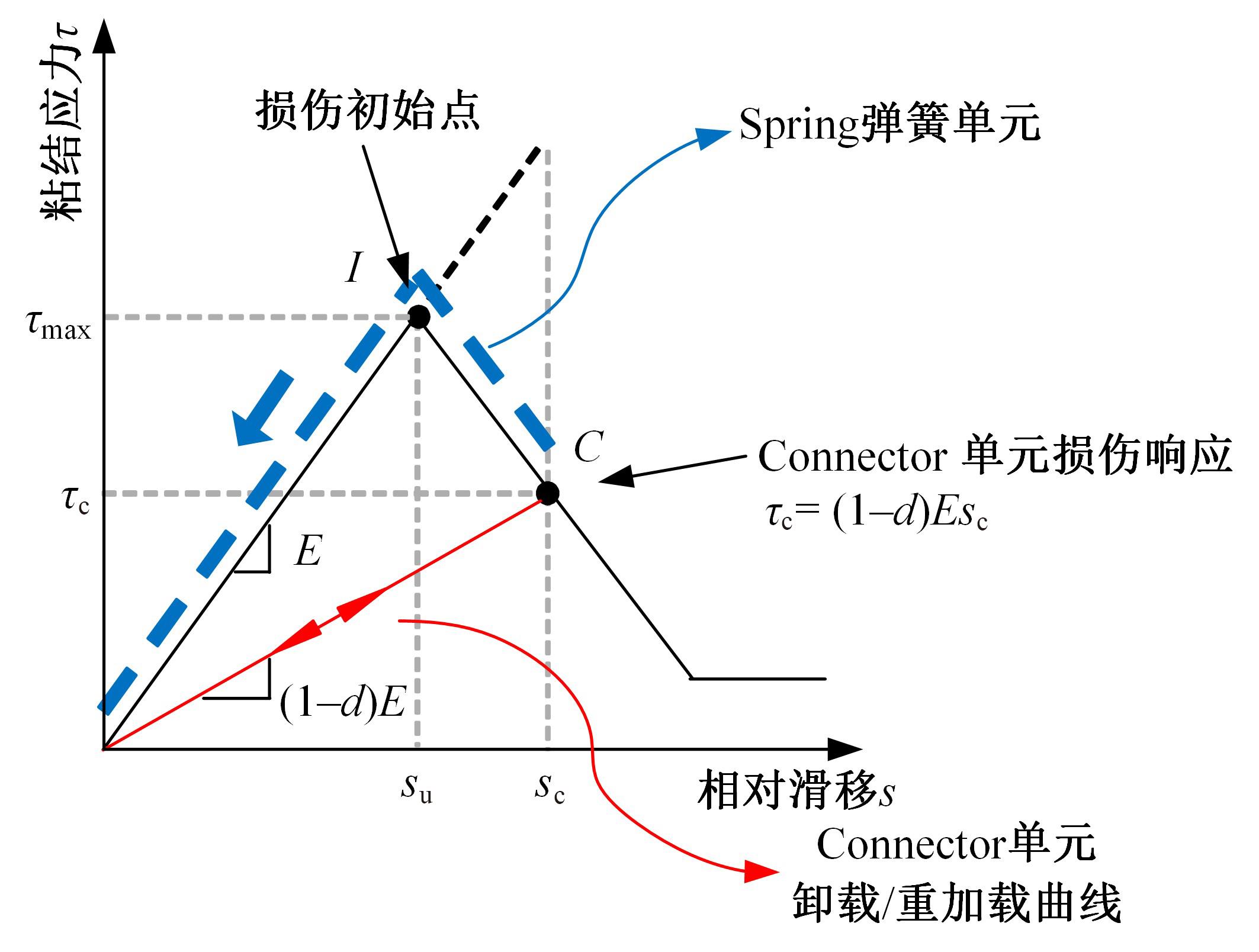

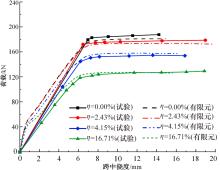

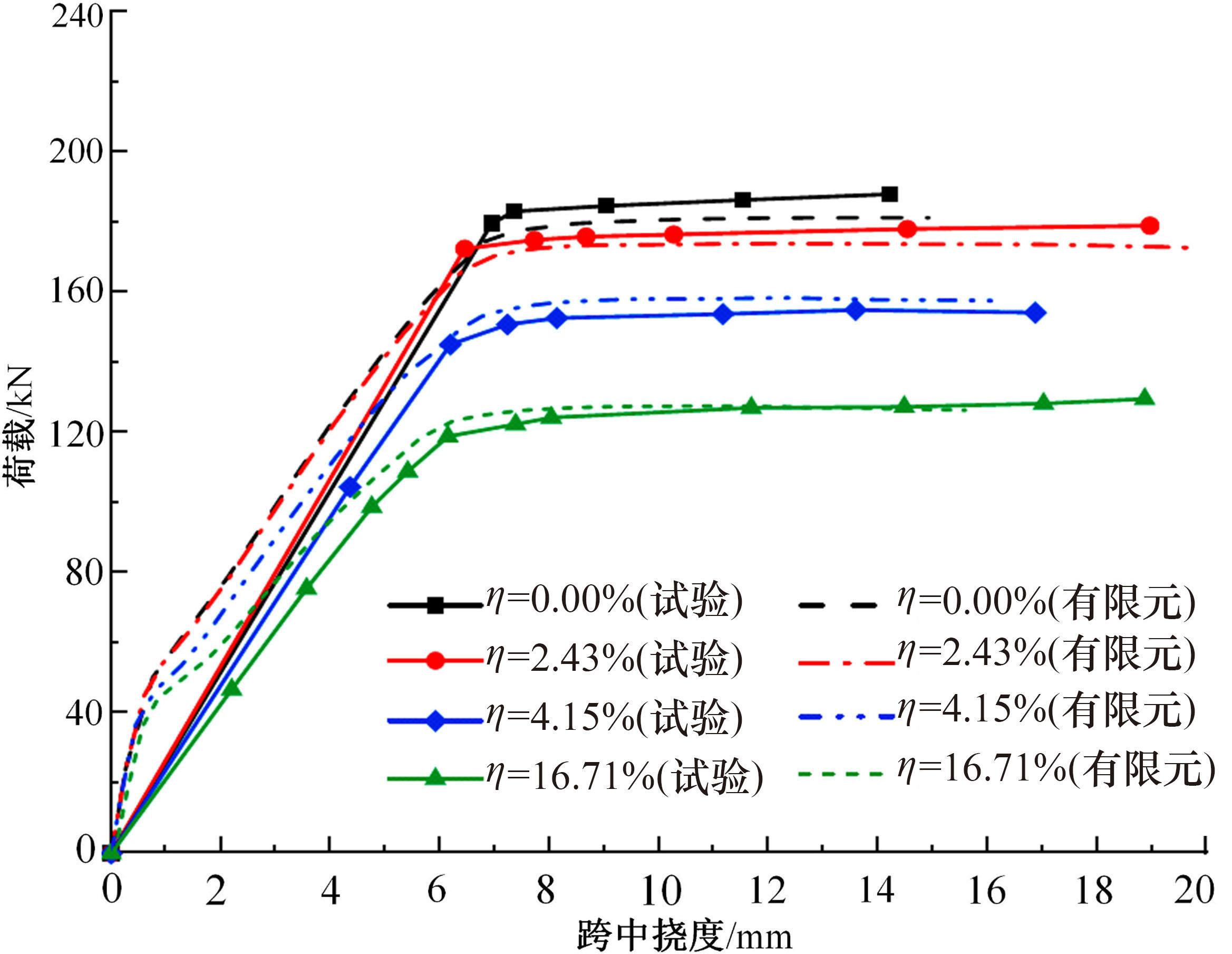

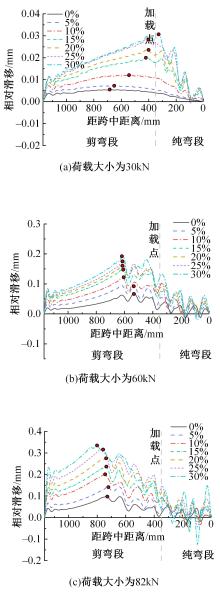

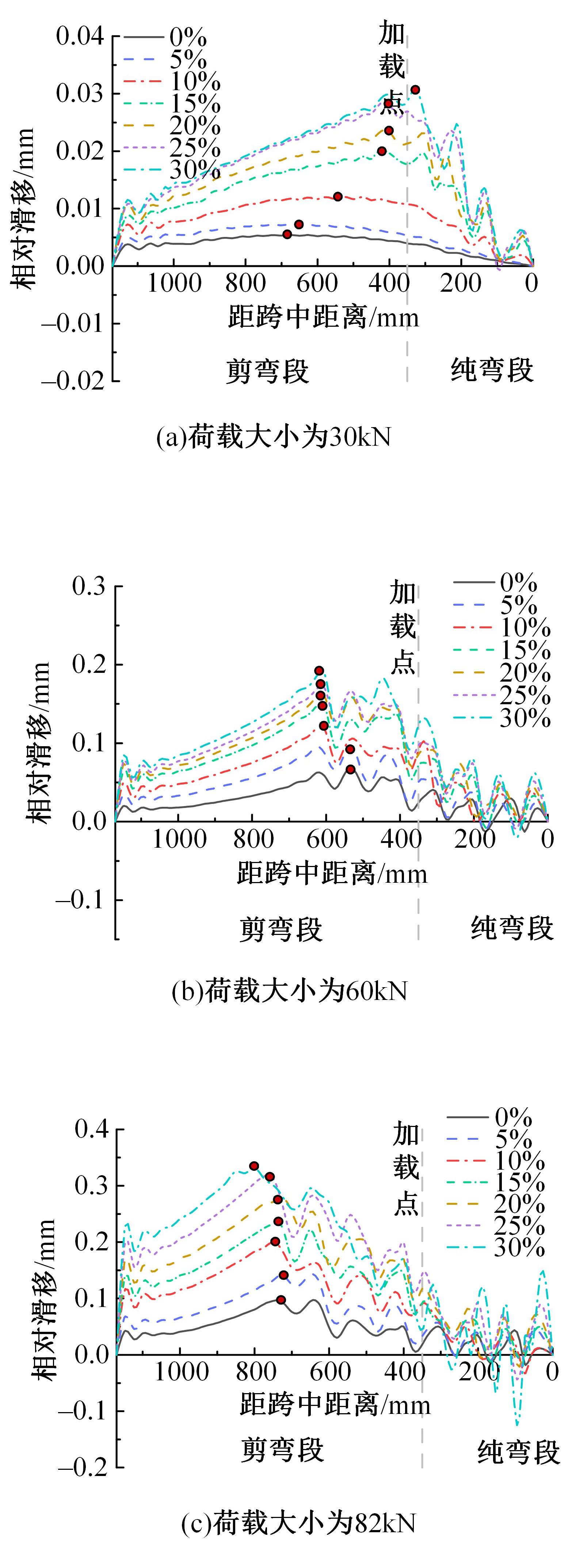

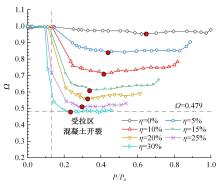

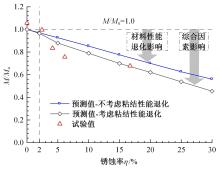

结合随机骨料模型建立了锈蚀钢筋混凝土(RC)梁三维细观数值模型,采用Connector单元捕捉加载过程中界面相互作用变化的方法。利用已有试验数据验证了该模型的合理性。分析了加载过程中锈蚀RC梁界面粘结滑移分布以及变形协调系数的变化规律,探讨了界面粘结退化对RC梁抗弯承载力的影响。研究结果表明:采用Connector单元能描述加载过程中粘结应力以及相对滑移等界面行为的变化,可作为锈蚀钢筋-混凝土界面行为模拟的有效手段;界面的最大粘结应力随锈蚀率的增加而降低,30%的锈蚀率使得极限荷载下RC梁界面最大粘结应力下降71%;锈蚀会加剧荷载作用下锈蚀RC梁界面的相对滑移,界面相对滑移峰值位置由加载点逐渐向剪弯段区域转移;锈蚀会减小界面极限变形协调系数,锈蚀率达到30%时,极限变形协调系数为0.479,抗弯承载力下降55%。

中图分类号:

- TU375.1

| 1 | 王甲春, 阎培渝. 海洋环境下钢筋混凝土中钢筋锈蚀的概率[J]. 吉林大学学报:工学版, 2014, 44(2):352-357. |

| Wang Jia-chun, Yan Pei-yu. Probabilistic analysis of rebar rust in concrete under marine environment[J]. Journal of Jilin University (Engineering and Technology Edition), 2014, 44(2):352-357. | |

| 2 | Hussein L. Analytical modeling of bond stress at steel-concrete interface due to corrosion[D]. Toronto: Ryerson University, 2011. |

| 3 | Pei P, Zheng S S, Zhang Y X, et al. Overview on the bonding of reinforced concrete under pristine, corrosive and freeze-thaw conditions[J]. Journal of Adhesion Science and Technology, 2019, 33(7): 761-789. |

| 4 | 梁岩, 罗小勇, 肖小琼, 等. 锈蚀钢筋混凝土粘结滑移性能试验研究[J]. 工业建筑, 2012, 42(10):95-100. |

| Liang Yan, Luo Xiao-yong, Xiao Xiao-qiong, et al. Experimental study on bond-slip performance of corroded reinforced concrete[J]. Industrial Construction, 2012, 42(10):95-100. | |

| 5 | Ma Y F, Guo Z Z, Wang L, et al. Experimental investigation of corrosion effect on bond behavior between reinforcing bar and concrete[J]. Construction and Building Materials, 2017, 152: 240-249. |

| 6 | Zhang X H, Wang L, Zhang J R, et al. Bond degradation-induced incompatible strain between steel bars and concrete in corroded RC beams[J]. Journal of Performance of Constructed Facilities, 2016, 30(6): No.04016058. |

| 7 | 黄天立, 赵志彦, 宋力, 等. 纵筋锈蚀对钢筋混凝土梁抗剪性能影响的试验研究[J]. 中南大学学报:自然科学版, 2019, 50(8):1901-1911. |

| Huang Tian-li, Zhao Zhi-yan, Song Li, et al. Experimental investigation on shear performance of RC beams due to longitudinal reinforcement corrosion[J]. Journal of Central South University(Science and Technology), 2019, 50(8):1901-1911. | |

| 8 | 曹芙波, 尹润平, 王晨霞, 等. 锈蚀钢筋再生混凝土梁粘结性能及承载力研究[J]. 土木工程学报, 2016, 49():14-19. |

| Cao Fu-bo, Yin Run-ping, Wang Chen-xia, et al. Research on bond performance and bend strength of corroded reinforced recycled concrete beams[J]. China Civil Engineering Journal, 2016, 49(Sup.2):14-19. | |

| 9 | 薛昕, 杨成, 张瀚引, 等. 钢筋黏结退化的空间分布对RC梁受剪性能影响[J]. 华中科技大学学报:自然科学版, 2017, 45(1):11-16. |

| Xue Xin, Yang Cheng, Zhang Han-yin, et al. Influence of spatial distribution of bond deterioration in steel bar on shear performance of RC beams[J]. Journal of Huazhong University of Science and Technology(Natural Science Edition), 2017, 45(1):11-16. | |

| 10 | Nilson A H. Nonlinear analysis of reinforced concrete by the finite element method[J]. Journal Proceedings, 1968,65(9): 757-766. |

| 11 | 陈朝晖, 雷婷婷, 廖旻懋, 等. 基于内聚力模型的锈蚀砼梁抗弯刚度[J]. 重庆大学学报, 2017, 40(5):36-42. |

| Chen Zhao-hui, Lei Ting-ting, Liao Min-mao, et al. Numerical study on the stiffness of corroded beam based on the cohesive model[J]. Journal of Chongqing University, 2017, 40(5):36-42. | |

| 12 | Xiong X Y, Xiao Q S. Meso-scale simulation of bond behaviour between retarded-bonded tendons and concrete[J]. Engineering Structures, 2021, 228:No. 111410. |

| 13 | Verwaerde R, Guidault P, Boucard P A. A non-linear finite element connector model with friction and plasticity for the simulation of bolted assemblies[J]. Finite Elements in Analysis and Design, 2021, 195: No.103586. |

| 14 | Zhao G Q. Etude expérimentale et numérique de la résistance à l'effondrement progressif de sous-assemblages poteaux-poutres en béton armé[D]. Grenoble: Université Grenoble Alpes (ComUE), 2019. |

| 15 | Li C Q, Yang S T, Saafi M. Numerical simulation of behavior of reinforced concrete structures considering corrosion effects on bonding[J]. Journal of Structural Engineering, 2014, 140(12): No.04014092. |

| 16 | Dai L Z, Long D X, Wang L. Meso-scale modeling of concrete cracking induced by 3D corrosion expansion of helical strands[J]. Computers & Structures, 2021, 254: No.106615. |

| 17 | Jin L, Wang T, Jiang X A, et al. Size effect in shear failure of RC beams with stirrups: simulation and formulation[J]. Engineering Structures, 2019, 199: No. 109573. |

| 18 | Wriggers P, Moftah S. Mesoscale models for concrete: Homogenisation and damage behaviour[J]. Finite Elements in Analysis and Design, 2006, 42(7): 623-636. |

| 19 | Song Z H, Lu Y. Mesoscopic analysis of concrete under excessively high strain rate compression and implications on interpretation of test data[J]. International Journal of Impact Engineering, 2012, 46: 41-55. |

| 20 | Lee J, Fenves G L. Plastic-damage model for cyclic loading of concrete structures[J]. Journal of Engineering Mechanics, 1998, 124(8): 892-900. |

| 21 | 金浏, 陆凯, 宋博, 等. 考虑骨料粒径影响的BFRP筋混凝土梁剪切破坏及尺寸效应[EB/OL]. [2021-06-07]. |

| 22 | 金浏, 李炎锡, 张仁波, 等. 锈蚀钢筋混凝土柱偏心受压性能精细化模拟[EB/OL]. [2022-04-12]. |

| 23 | Coronelli D, Gambarova P. Structural assessment of corroded reinforced concrete beams: modeling guidelines[J]. Journal of Structural Engineering, 2004, 130(8): 1214-1224. |

| 24 | Zandi Hanjari K, Kettil P, Lundgren K. Analysis of mechanical behavior of corroded reinforced concrete structures[J]. ACI Structural Journal, 2011, 108(5): 532-541. |

| 25 | .混凝土结构设计规范 [S]. |

| 26 | Lee H S, Cho Y S. Evaluation of the mechanical properties of steel reinforcement embedded in concrete specimen as a function of the degree of reinforcement corrosion[J]. International Journal of Fracture, 2009, 157(1): 81-88. |

| 27 | Ma Y F, Zhang J R, Wang L, et al. Probabilistic prediction with Bayesian updating for strength degradation of RC bridge beams[J]. Structural Safety, 2013, 44: 102-109. |

| 28 | CEB-FIP. Model code [S]. |

| 29 | 狄生林. 钢筋混凝土梁的非线性有限元分析[J]. 东南大学学报:自然科学版, 1984, 24(2):87-96. |

| Di Sheng-lin. Nonlinear finite element analysis of reinforced concrete beam[J]. Journal of Southeast University(Natural Science Edition), 1984, 24(2):87-96. |

| [1] | 范亮,徐英铭,谭阳. 集束群钉式装配组合梁界面滑移计算[J]. 吉林大学学报(工学版), 2023, 53(9): 2533-2541. |

| [2] | 樊学平,周衡,刘月飞. 桥梁时变可靠性的多过程贝叶斯动态混合预测[J]. 吉林大学学报(工学版), 2023, 53(8): 2332-2338. |

| [3] | 毛亚娜,刘世忠,杏剑,杨华,焦峪波. 超高性能玻璃砂混凝土-高强钢筋粘结滑移特性及其声发射参数表征[J]. 吉林大学学报(工学版), 2023, 53(6): 1686-1694. |

| [4] | 宫亚峰,吴树正,毕海鹏,周冬明,谭国金,黄晓明. 玄武岩纤维活性粉末混凝土与钢绞线粘结滑移过程声学特性表征[J]. 吉林大学学报(工学版), 2023, 53(6): 1819-1832. |

| [5] | 熊二刚,巩忠文,罗佳明,范团结. 基于数字图像相关技术的钢筋混凝土梁裂缝试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1094-1104. |

| [6] | 匡亚川,陈立斌,李超举,贺宇豪. 栓钉剪力连接件力学性能分析[J]. 吉林大学学报(工学版), 2023, 53(2): 538-546. |

| [7] | 王晓东,李宁静,李强. 高压脉冲放电破碎混凝土梁试验[J]. 吉林大学学报(工学版), 2023, 53(2): 496-504. |

| [8] | 褚云朋,孙鑫晖,李明,姚勇,黄汉杰. 下击暴流作用下圆形马鞍面屋盖风压特性[J]. 吉林大学学报(工学版), 2022, 52(8): 1826-1833. |

| [9] | 姚勇,苏留锋,李明,褚云朋,黄汉杰. 下击暴流作用下双面球壳型屋面风载特性[J]. 吉林大学学报(工学版), 2022, 52(3): 615-625. |

| [10] | 匡亚川,宋哲轩,刘胤虎,莫小飞,伏亮明,罗时权. 新型装配式双舱综合管廊力学性能试验[J]. 吉林大学学报(工学版), 2022, 52(3): 596-603. |

| [11] | 王毅红,田桥罗,兰官奇,姚圣法,张建雄,刘喜. 630 MPa高强钢筋混凝土大偏压柱受力性能试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2626-2635. |

| [12] | 龚永智,况锦华,柯福隆,周泉,罗小勇. UHPC连接的装配式剪力墙节点抗震性能试验[J]. 吉林大学学报(工学版), 2022, 52(10): 2367-2375. |

| [13] | 樊学平,杨光红,尚志鹏,赵小雄,肖青凯,刘月飞. 考虑适用性的大跨桥梁主梁动态可靠性融合预测[J]. 吉林大学学报(工学版), 2022, 52(1): 144-153. |

| [14] | 刘福寿,魏琦,徐文婷,谭国金. 基于弹性波传播和谱单元法的桁架结构损伤检测[J]. 吉林大学学报(工学版), 2021, 51(6): 2087-2095. |

| [15] | 樊学平,杨光红,肖青凯,刘月飞. 大跨桥梁主梁失效概率分析的最优R-Vine Copula[J]. 吉林大学学报(工学版), 2021, 51(4): 1296-1305. |

|

||