吉林大学学报(工学版) ›› 2025, Vol. 55 ›› Issue (5): 1536-1543.doi: 10.13229/j.cnki.jdxbgxb.20240542

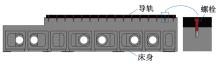

数控机床线轨装配精度建模及控制方法

刘志峰1( ),陈继民2,李迎2(

),陈继民2,李迎2( ),赵永胜2,闫兴2,孙富权2

),赵永胜2,闫兴2,孙富权2

- 1.吉林大学 机械与航空航天工程学院,长春 130022

2.北京工业大学 机械与能源工程学院,北京 100124

Modeling of CNC machine tool line rail assembly accuracy and its control method

Zhi-feng LIU1( ),Ji-min CHEN2,Ying LI2(

),Ji-min CHEN2,Ying LI2( ),Yong-sheng ZHAO2,Xing YAN2,Fu-quan SUN2

),Yong-sheng ZHAO2,Xing YAN2,Fu-quan SUN2

- 1.College of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

2.School of Mechanical and Energy Engineering,Beijing University of Technology,Beijing 100124,China

摘要:

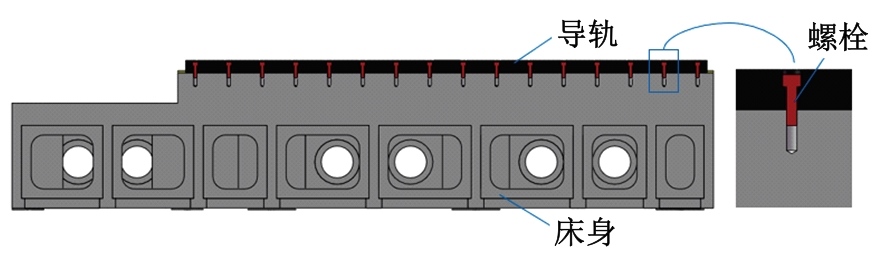

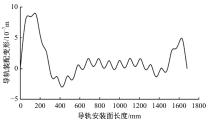

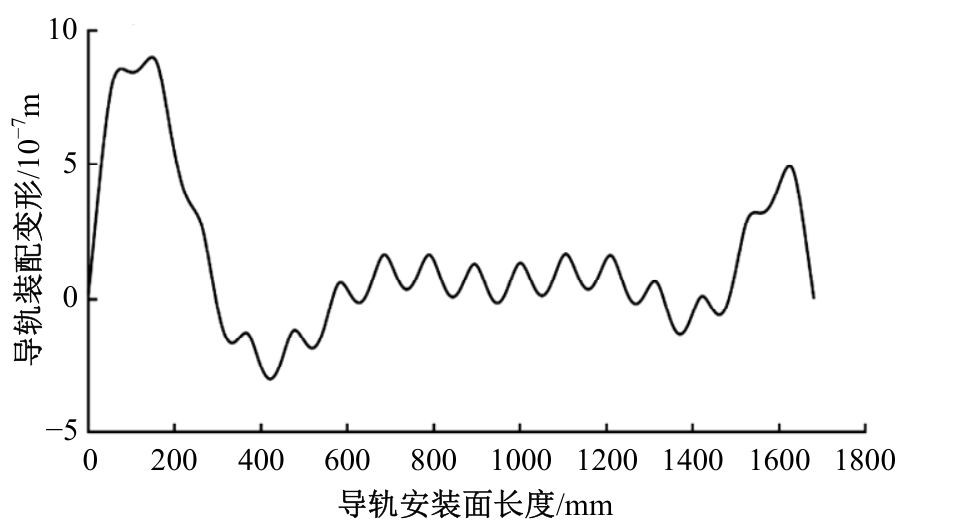

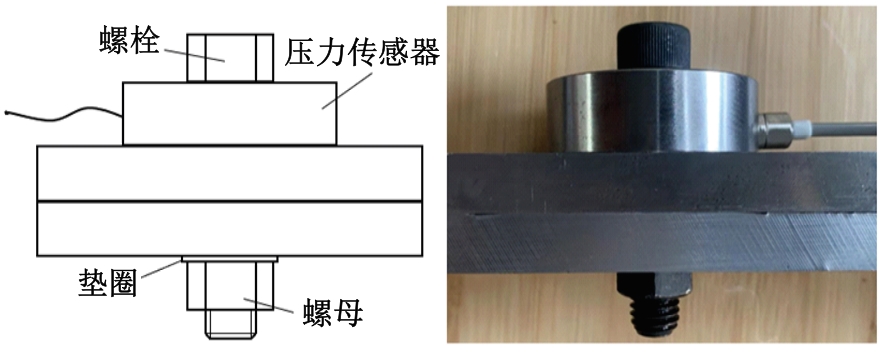

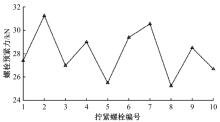

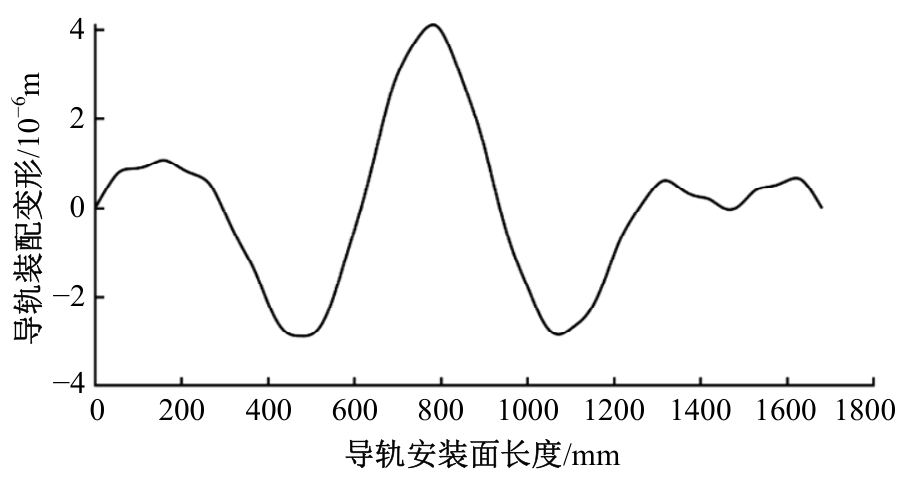

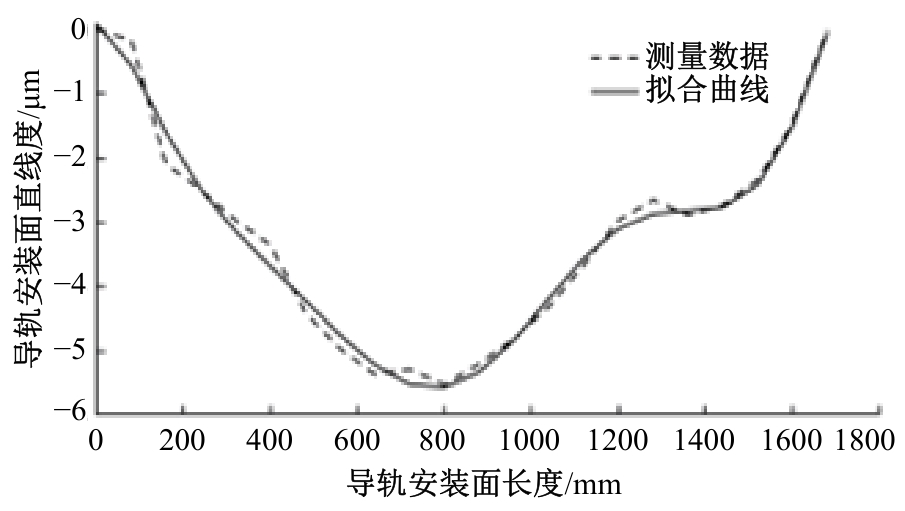

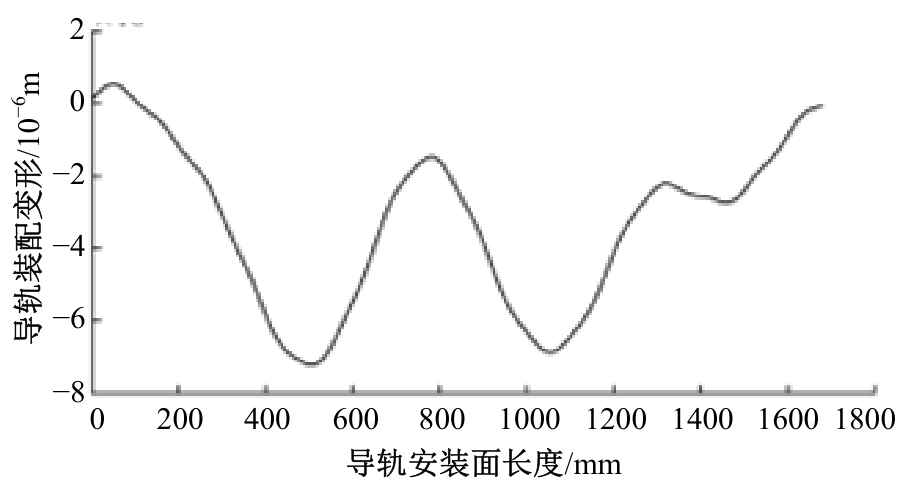

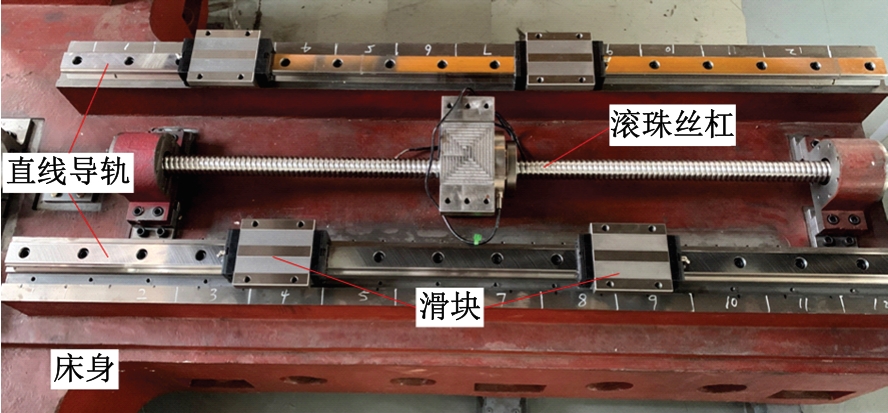

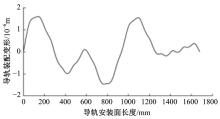

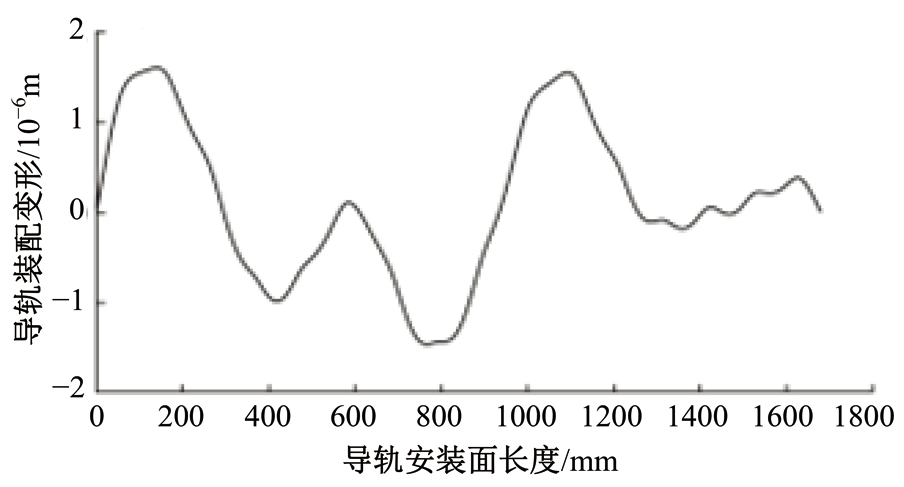

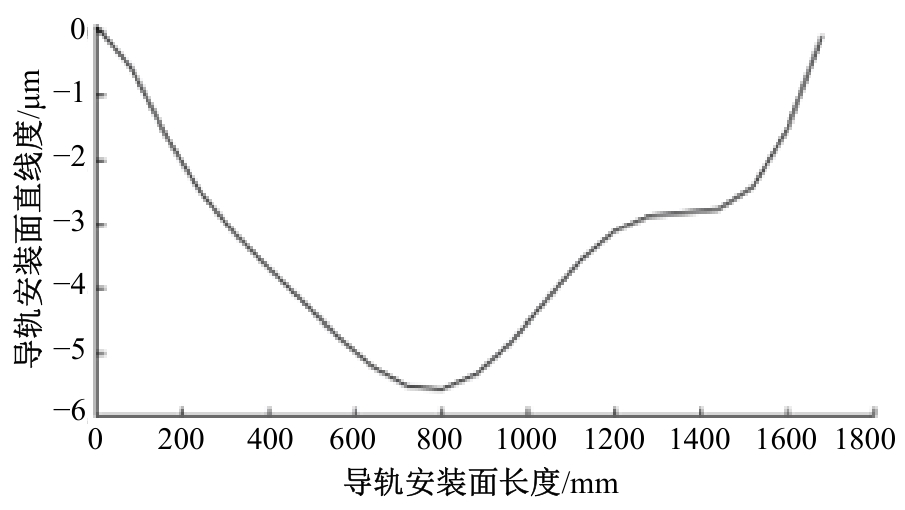

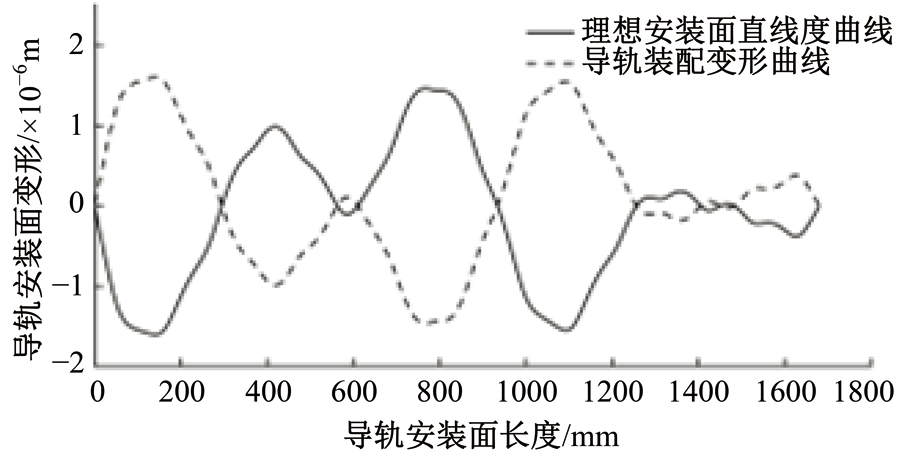

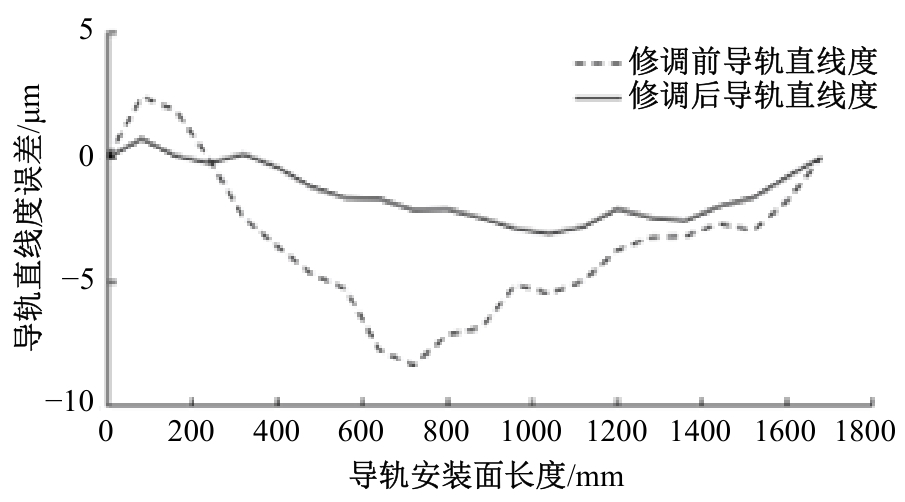

针对直线导轨装配过程中,由预紧载荷作用引起的装配变形机理不明确导致的导轨装配直线度难以预测的问题,首先在建立直线导轨装配变形模型的基础上,讨论了理想和实际情况下的导轨装配变形;其次,考虑了导轨安装面的制造误差对导轨装配精度的影响,提出了综合装配变形和制造误差的导轨装配直线度误差预测模型,并提出了基于装配变形反修制造误差的导轨装配精度控制方法;最后,搭建实验台并通过实验验证理论模型及精度控制方法的准确性,结果表明:导轨装配直线度误差减小了64.5%。

中图分类号:

- TG95

| [1] | 黄贤振, 李超, 孙超, 等. 基于失效模式和动态贝叶斯网络的数控机床可靠性分析[J].吉林大学学报:工学版,2024: 10.13229/j.cnki.jdxbgxb.2024005 |

| Huang Xian-zhen, Li Chao, Sun Chao, et al. Reliability analysis of CNC machine tools based on failure modes and dynamic Bayesian networks[J]. Journal of Jilin University(Engineering and Technology Edition), 2024: 10.13229/j.cnki.jdxbgxb.2024005 | |

| [2] | Ajani I, Lu C. Assembly variation analysis of the non-rigid assembly with a deformation gradient model[J]. Assembly Automation, 2022, 42(1): 40-53. |

| [3] | Mu X K, Wang Y L, Yuan B, et al. A new assembly precision prediction method of aeroengine high-pressure rotor system considering manufacturing error and deformation of parts[J]. Journal of Manufacturing Systems,2021, 61: 112-124. |

| [4] | Yang X, Ran Y, Wang Z C, et al. Early prediction method for assembly precision of mechanical system and assessment of precision reliability[J]. The International Journal of Advanced Manufacturing Technology, 2021, 112: 203-220. |

| [5] | 蔡尚文, 汪惠芬, 刘庭煜. 基于误差传递模型的机床进给系统装配精度预测与调整方法[J]. 机械制造与自动化, 2016, 45(6): 6-10. |

| Cai Shang-wen, Wang Hui-fen, Liu Ting-yu. Assembly precision prediction and adjustment method based on error propagation model[J]. Mach Build Autom, 2016, 45(6): 6-10. | |

| [6] | Liu T, Cao Y L, Wang J, et al. Assembly error calculation with consideration of part deformation[J]. Procedia Cirp, 2016, 43: 58-63. |

| [7] | Lu C, Wang S L. An approach to evaluating product assembly precision considering the effect of joint surface deformation[J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2014, 228(14): 2604-2617. |

| [8] | Song L Q, Zhang Q, Zhao X S, et al. The influence of the mounting surface error on the deformation of the guideway[J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2024, 238(9): 4071-4084. |

| [9] | Liu C, Zhao C Y, Wen B C. Dynamics analysis on the MDOF model of ball screw feed system considering the assembly error of guide rails[J]. Mechanical Systems and Signal Processing, 2022, 178: 109290. |

| [10] | Sun G M, He G Y, Weng L T, et al. Research on assembly deformation of machine tool guideway[C]∥ IEEE International Conference on Advanced Manufacturing, Chongqing, China, 2018: 231-234. |

| [11] | Zheng B, Yu H D, Lai X M. Assembly deformation prediction of riveted panels by using equivalent mechanical model of riveting process[J]. The International Journal of Advanced Manufacturing Technology, 2017, 92: 1955-1966. |

| [12] | Sun Y P, Wang D L, Dong H M, et al. Pre-deformation for assembly performance of machine centers[J]. Chinese Journal of Mechanical Engineering, 2014, 27(3): 528-536. |

| [13] | Motosh N. Development of design charts for bolts preloaded up to the plastic range[J]. Journal of Manufacturing Science and Engineering, 1976, 98(3): 849-851. |

| [14] | Ekinci T O, Mayer J R R. Relationships between straightness and angular kinematic errors in machines[J]. International Journal of Machine Tools and Manufacture, 2007, 47(12):1997-2004. |

| [15] | Tang H, Duan J A, Zhao Q C. A systematic approach on analyzing the relationship between straightness & angular errors and guideway surface in precise linear stage[J]. International Journal of Machine Tools and Manufacture, 2017, 120: 2-9. |

| [1] | 赵昌龙,马晨,杨俊宝,赵钦祥,贾晓宇,马洪楠. 预置表面织构对激光熔覆316L涂层的影响[J]. 吉林大学学报(工学版), 2025, 55(3): 899-911. |

| [2] | 蔡安江,王沛彭,王晨曦,李玲. 多主轴头数控机床虚拟仿真加工平台的构建方法[J]. 吉林大学学报(工学版), 2024, 54(6): 1528-1536. |

| [3] | 董长斌,李龙坤,刘永平,裴王鹏. 非圆齿轮传动误差及齿侧间隙的数值模拟与试验[J]. 吉林大学学报(工学版), 2024, 54(4): 865-873. |

| [4] | 蔡安江,刘晨阳,王沛彭. 旋转角度优化下的五轴数控机床后置处理算法[J]. 吉林大学学报(工学版), 2023, 53(9): 2493-2498. |

| [5] | 吴飞,农皓业,马晨浩. 基于粒子群优化算法⁃长短时记忆模型的刀具磨损预测方法[J]. 吉林大学学报(工学版), 2023, 53(4): 989-997. |

| [6] | 赵泓荀,杨兆军,陈传海,田海龙,王立平. 考虑参数权重的数控机床电主轴加速试验优化设计[J]. 吉林大学学报(工学版), 2022, 52(2): 409-416. |

| [7] | 于立娟,刘昂,杨兆军,田海龙,陈传海,高景文. 基于网络层次和数据包络的数控机床可靠性分析[J]. 吉林大学学报(工学版), 2022, 52(2): 400-408. |

| [8] | 宋林,王立平,吴军,关立文,刘知贵. 基于信息物理融合和数字孪生的可靠性分析[J]. 吉林大学学报(工学版), 2022, 52(2): 439-449. |

| [9] | 陈传海,王成功,杨兆军,刘志峰,田海龙. 数控机床可靠性建模研究现状及发展动态分析[J]. 吉林大学学报(工学版), 2022, 52(2): 253-266. |

| [10] | 章子玲,胡雄,亓寅,王微,陶志强,刘志峰. 基于向量投影响应面的数控机床几何误差分配方法[J]. 吉林大学学报(工学版), 2022, 52(2): 384-391. |

| [11] | 李国龙,陶小会,徐凯,李喆裕. 数控机床转台位置相关几何误差的快速测量与辨识[J]. 吉林大学学报(工学版), 2021, 51(2): 458-467. |

| [12] | 段春争,张方圆,寇文能,魏斌. 高速硬切削表面白层马氏体相变[J]. 吉林大学学报(工学版), 2019, 49(5): 1575-1583. |

| [13] | 李洪洲, 杨兆军, 许彬彬, 王彦鹍, 贾玉辉, 侯超. 数控机床可靠性评估试验周期设计[J]. 吉林大学学报(工学版), 2016, 46(5): 1520-1527. |

| [14] | 杨兆军, 杨川贵, 陈菲, 郝庆波, 郑志同, 王松. 基于PSO算法和SVR模型的加工中心可靠性模型参数估计[J]. 吉林大学学报(工学版), 2015, 45(3): 829-836. |

| [15] | 陈传海, 杨兆军, 陈菲, 郝庆波, 许彬彬, 阚英男. 基于Bootstrap-Bayes的加工中心主轴可靠性建模[J]. 吉林大学学报(工学版), 2014, 44(01): 95-100. |

|