吉林大学学报(工学版) ›› 2025, Vol. 55 ›› Issue (5): 1544-1551.doi: 10.13229/j.cnki.jdxbgxb.20231069

激光熔化沉积CrCoNi中熵合金的热腐蚀性能

王勇刚1,2( ),刘和剑1,王传洋2,王磊3,钱润东2,李东亚1,董逸君1

),刘和剑1,王传洋2,王磊3,钱润东2,李东亚1,董逸君1

- 1.苏州大学 应用技术学院,江苏 苏州 215325

2.苏州大学 机电工程学院,江苏 苏州 215137

3.苏州科技大学 机械工程学院,江苏 苏州 215009

Hot corrosion behaviors of CrCoNi medium entropy alloy by laser melting deposition

Yong-gang WANG1,2( ),He-jian LIU1,Chuan-yang WANG2,Lei WANG3,Run-dong QIAN2,Dong-ya LI1,Yi-jun DONG1

),He-jian LIU1,Chuan-yang WANG2,Lei WANG3,Run-dong QIAN2,Dong-ya LI1,Yi-jun DONG1

- 1.Applied Technology College of Soochow University,Suzhou 215325,China

2.School of Mechanical and Electrical Engineering,Soochow University,Suzhou 215137,China

3.College of Mechanical Engineering,Suzhou University of Science and Technology,Suzhou 215009,China

摘要:

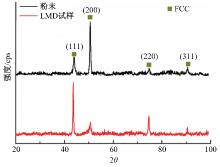

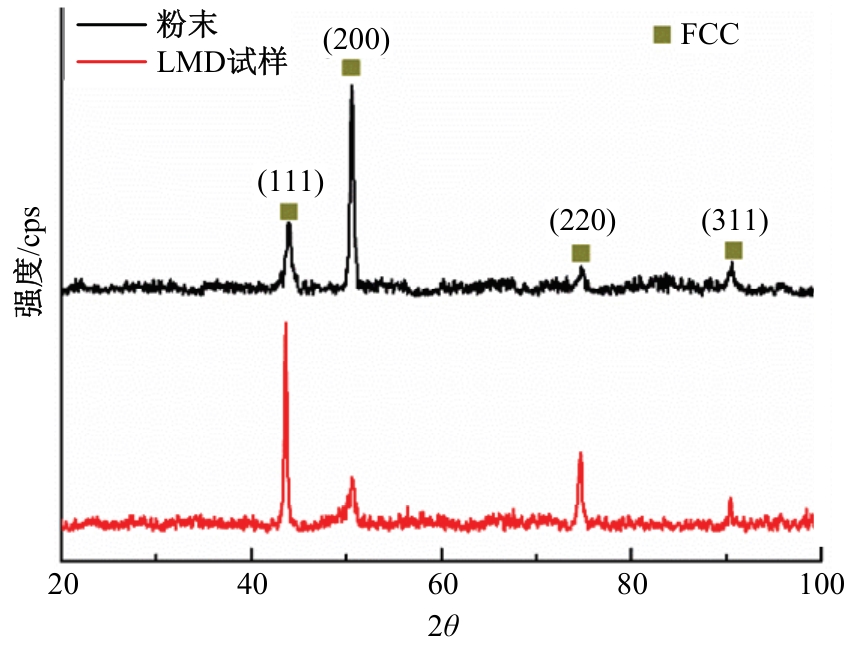

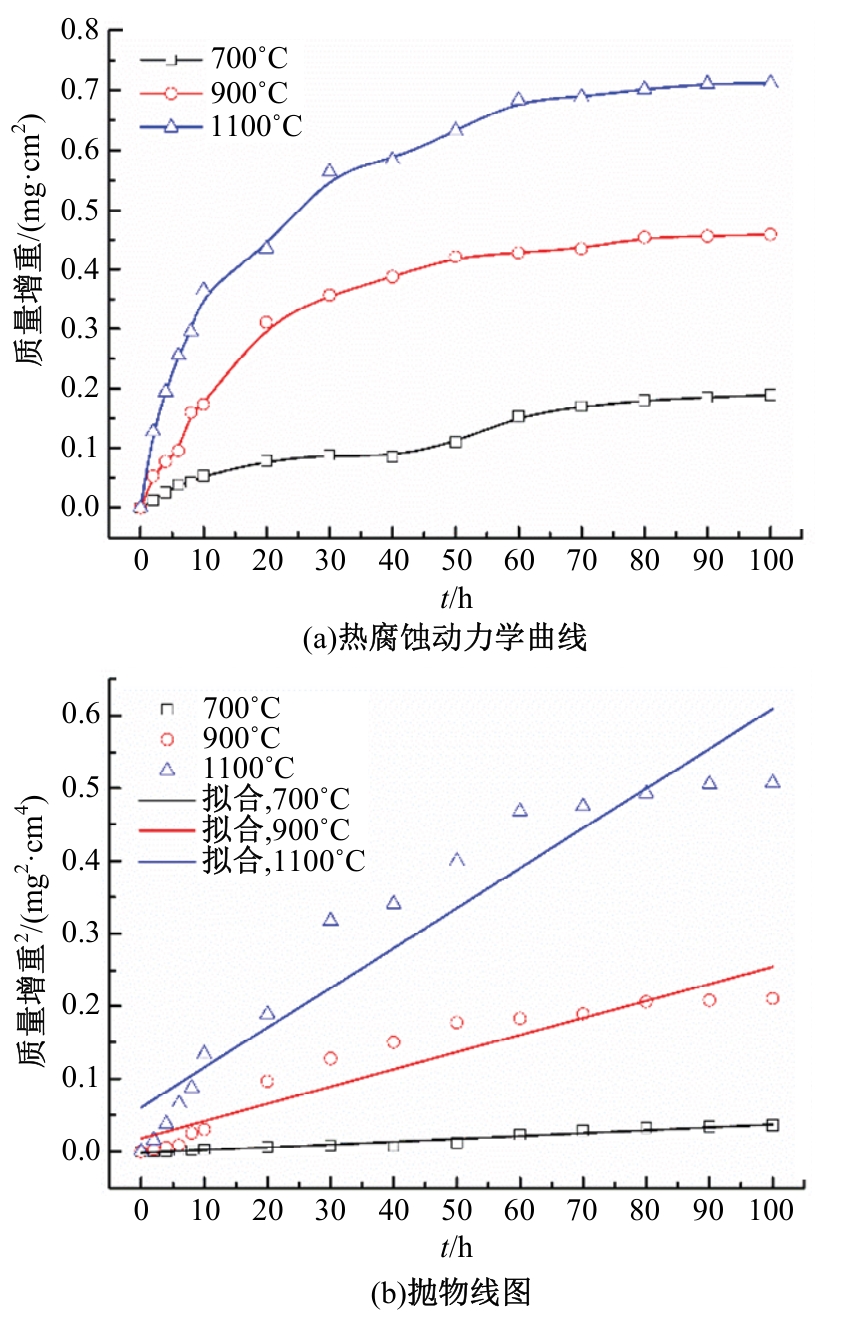

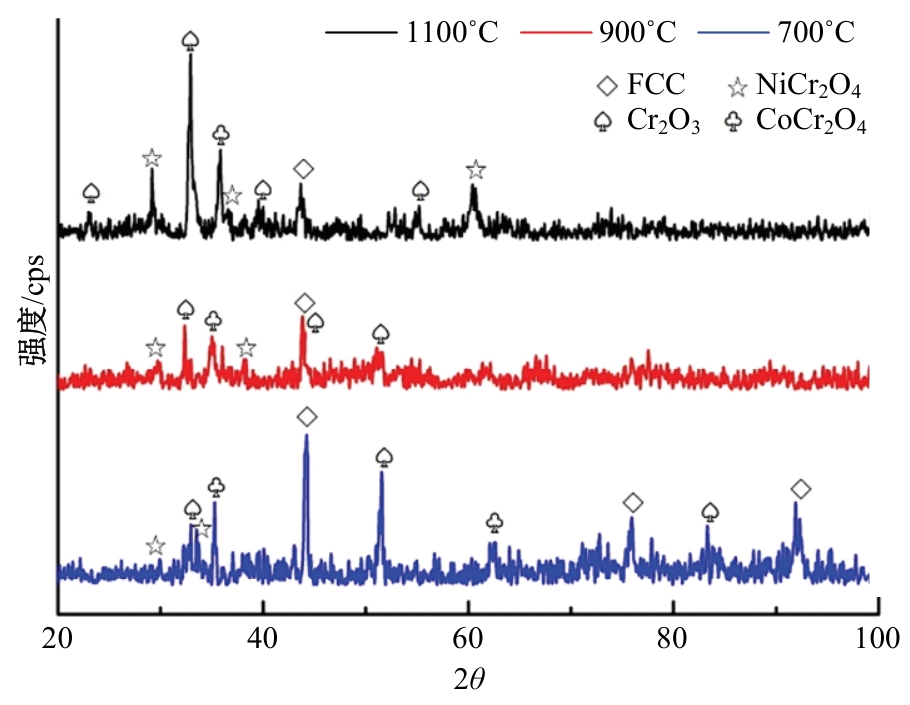

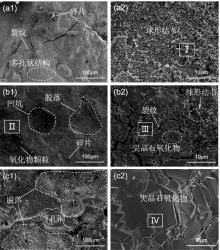

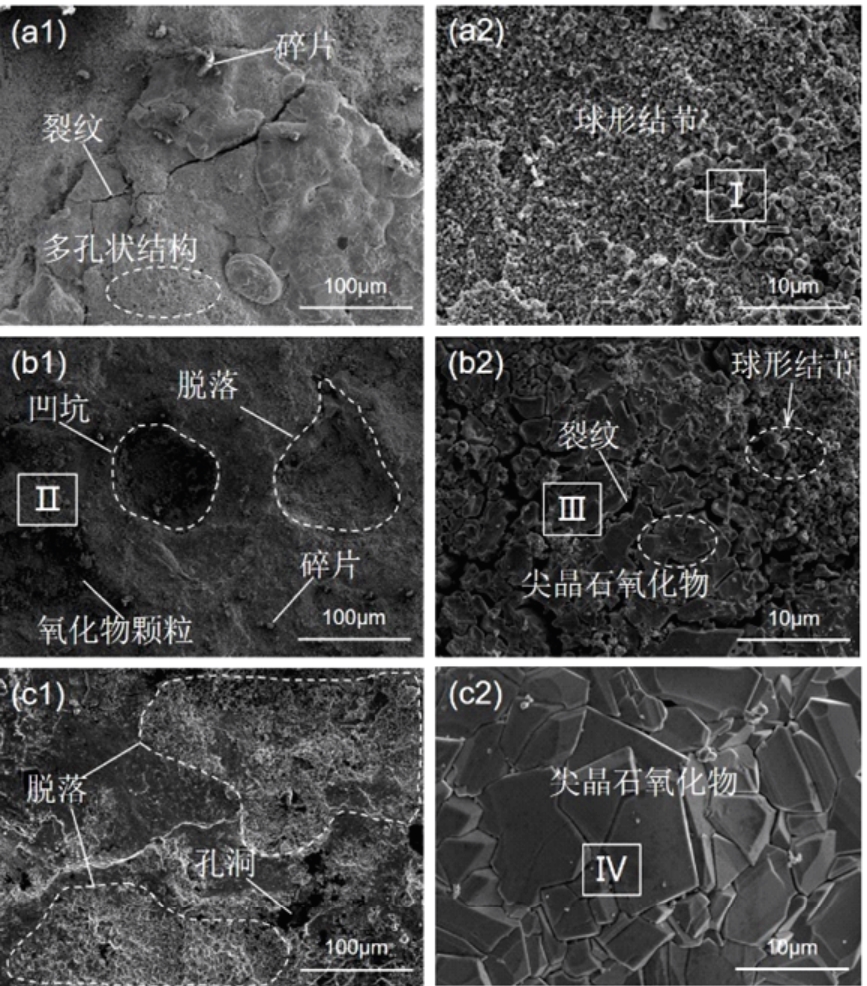

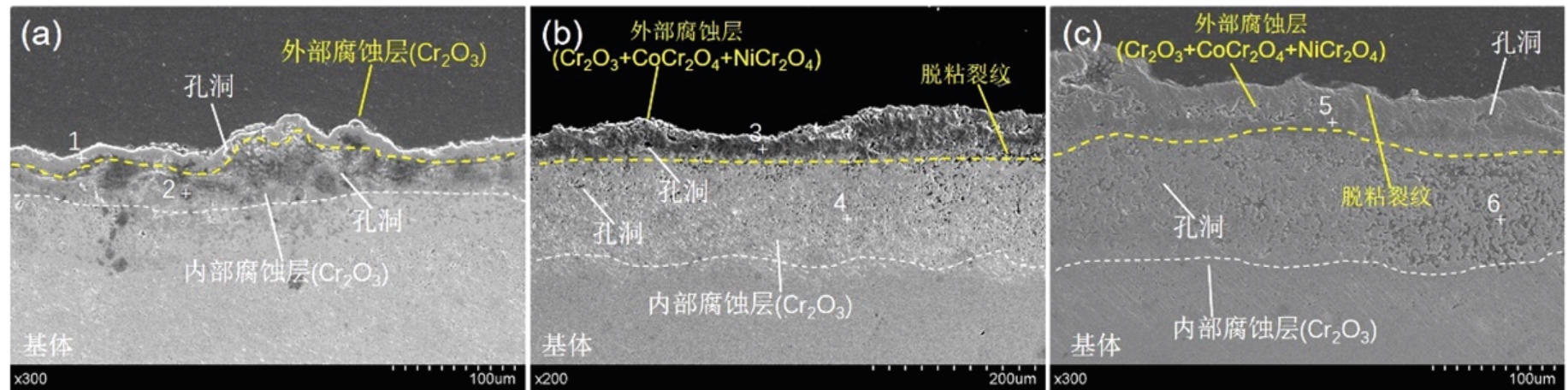

针对激光熔化沉积制备的CrCoNi中熵合金进行了热腐蚀性能研究,解决了温度对中熵合金热腐蚀动力学、腐蚀形貌及产物影响规律的问题,得到了以下结果:成形合金的物相为FCC相,试样中包含少量的气孔和裂纹,显微组织为等轴胞状和柱状的混合枝晶亚结构。在700、900、1 100 ℃ 3种温度下热腐蚀速率kp 分别为3.920 37×10-4、0.002 36、0.005 49 mg2/(cm4·h),热腐蚀动力学曲线基本遵循抛物线定律。热腐蚀层产物为Cr2O3及少量的NiCr2O4和CoCr2O4尖晶石物相。在挥发性氯气和热应力共同作用下,腐蚀层会发生破坏剥落。研究结果对促进激光熔化沉积中熵合金在高温结构件领域的应用具有理论价值。

中图分类号:

- TG139

| [1] | Jien Y E H. Recent progress in high entropy alloys[J]. European Journal of Control, 2006, 31(6): 633-648. |

| [2] | Cantor B, Chang I T H, Knight P, et al. Microstructural development in equiatomic multicomponent alloys[J]. Materials Science and Engineering, 2004, 375: 213-218. |

| [3] | Okamoto N L, Yuge K, Tanaka K, et al. Atomic displacement in the CrMnFeCoNi high-entropy alloy—a scaling factor to predict solid solution strengthening[J]. AIP Advances, 2016, 6(12): 125008. |

| [4] | Wu Z, Bei H, Otto F, et al. Recovery, recrystallization, grain growth and phase stability of a family of FCC-structured multi-component equiatomic solid solution alloys[J]. Intermetallics, 2014, 46: 131-140. |

| [5] | Yeh J W, Chen S K, Lin S J, et al. Nanostructured high‐entropy alloys with multiple principal elements: novel alloy design concepts and outcomes[J]. Advanced Engineering Materials, 2004, 6(5): 299-303. |

| [6] | Gludovatz B, Hohenwarter A, Thurston K V S, et al. Exceptional damage-tolerance of a medium-entropy alloy CrCoNi at cryogenic temperatures[J]. Nature Communications, 2016, 7(1): 10602. |

| [7] | Zhang R, Zhao S, Ding J, et al. Short-range order and its impact on the CrCoNi medium-entropy alloy[J]. Nature, 2020, 581: 283-287. |

| [8] | 回丽, 陆家琛, 周松, 等. 热处理对TC4钛合金激光双束焊接接头疲劳性能的影响[J]. 吉林大学学报: 工学版, 2023, 53(1): 105-110. |

| Hui Li, Lu Jia-chen, Zhou Song, et al. Effect of heat treatment on fatigue properties of TC4 titanium alloy by laser double beam welded joint[J]. Journal of Jilin University (Engineering and Technology Edition), 2023, 53(1): 105-110. | |

| [9] | Feng K, Zhang Y, Li Z, et al. Corrosion properties of laser cladded CrCoNi medium entropy alloy coating[J]. Surface and Coatings Technology, 2020, 397: 126004. |

| [10] | Adomako N K, Kim J H, Hyun Y T. High-temperature oxidation behaviour of low-entropy alloy to medium-and high-entropy alloys[J]. Journal of Thermal Analysis and Calorimetry, 2018, 133: 13-26. |

| [11] | Agustianingrum M P, Lee U, Park N. High-temperature oxidation behaviour of CoCrNi medium-entropy alloy[J]. Corrosion Science, 2020, 173: 108755. |

| [12] | Stephan S C, Schulz W, Schneider M, et al. High-temperature oxidation in dry and humid atmospheres of the equiatomic CrMnFeCoNi and CrCoNi high-and medium-entropy alloys[J]. Oxidation of Metals, 2021, 95: 105-133. |

| [13] | Piglione A, Dovgyy B, Liu C, et al. Printability and microstructure of the CoCrFeMnNi high-entropy alloy fabricated by laser powder bed fusion[J]. Materials Letters, 2018, 224: 22-25. |

| [14] | Xue P, Zhu L, Xu P, et al. Research on process optimization and microstructure of CrCoNi medium-entropy alloy formed by laser metal deposition[J]. Optics & Laser Technology, 2021, 142: 107167. |

| [15] | 贾玺泉, 徐震霖, 周生璇, 等. 退火温度对激光增材制造CoCrFeMnNi高熵合金耐点蚀性能的影响[J]. 表面技术, 2023, 52(2): 272-281. |

| Jia Xi-quan, Xu Zhen-lin, Zhou Sheng-xuan, et al. Effect of annealing temperature on pitting resistance of CoCrFeMnNi high-entropy alloy fabricated by laser additive manufacturing[J]. Surface Technology, 2023, 52(2): 272-281. | |

| [16] | Chew Y, Bi G J, Zhu Z G, et al. Microstructure and enhanced strength of laser aided additive manufactured CoCrFeNiMn high entropy alloy[J]. Materials Science and Engineering, 2019, 744: 137-144. |

| [17] | Butler T M, Weaver M L. Oxidation behavior of arc melted AlCoCrFeNi multi-component high-entropy alloys[J]. Journal of Alloys and Compounds, 2016, 674: 229-244. |

| [18] | Choi Y O, Han J W, Hong H S, et al. Study on the corrosion resistance of high strength bolt, nut and washer set (S10T) related to the surface treatment conditions[J]. Journal of Welding and Joining, 2018, 36(2): 34-39. |

| [19] | 张平, 李远田, 张金勇, 等. Si对AlCoCrFeNi高熵合金热腐蚀行为的影响[J]. 稀有金属材料与工程, 2021, 50(10): 3640-3646. |

| Zhang Ping, Li Yuan-tian, Zhang Jin-yong, et al. Effect of Si addition on hot corrosion behavior of AlCoCrFeNi high entropy alloys[J]. Rare Metal Materials and Engineering, 2021,50(10): 3640-3646. | |

| [20] | 胡凯, 刘侠, 张世宏, 等. 氧燃比对NiCrAlY涂层的微观结构及其在KCl熔盐中热腐蚀行为的影响[J].中国有色金属学报, 2021, 31(6): 1545-1558. |

| Hu Kai, Liu Xia, Zhang Shi-hong, et al. Effect of oxygen-fuel ratio on microstructure and hot corrosion behavior of NiCrAlY coatings in KCl molten salt[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(6): 1545-1558. | |

| [21] | Sugimoto K, Seto M, Tanaka S, et al. Corrosion resistance of artificial passivation films of Fe2O3‐Cr2O3‐NiO formed by metalorganic chemical vapor deposition[J]. Journal of the Electrochemical Society, 1993, 140(6): 12221606. |

| [22] | 王迪, 王栋, 谢光, 等. Pt-Al涂层对一种镍基单晶高温合金抗热腐蚀行为的影响[J].金属学报, 2021, 57(6): 780-790. |

| Wang Di, Wang Dong, Xie Guang, et al. Influence of Pt-Al coating on hot corrosion resistance behaviors of a Ni-based single-crystal superalloy[J]. Acta Metallurgica Sinica, 2021, 57(6):780-790. | |

| [23] | Jiang D, Li Z, Xu J, et al. High-temperature oxidation behaviors of an equiatomic CrMnFeCoNi high entropy alloy[J]. Materials Today Communications, 2022, 32: 104185. |

| [24] | Wang Y, Zhang M, Jin J, et al. Oxidation behavior of CoCrFeMnNi high entropy alloy after plastic deformation[J]. Corrosion Science, 2020, 163: 108285. |

| [25] | Chen L, Lan H, Huang C, et al. Hot corrosion behavior of porous nickel-based alloys containing molybdenum in the presence of NaCl at 750° C[J]. Engineering Failure Analysis, 2017, 79: 245-252. |

| [26] | Cao J, Zhang J, Hua Y, et al. Microstructure and hot corrosion behavior of the Ni-based superalloy GH202 treated by laser shock processing[J]. Materials Characterization, 2017, 125: 67-75. |

| [1] | 王建,马文虎,谢太林,郭华,尹必峰. 重型拖拉机新型双离合全动力换挡变速箱液压系统设计与试验[J]. 吉林大学学报(工学版), 2025, 55(5): 1806-1816. |

| [2] | 商蕾,杨萍,杨祥国,潘建欣,杨军,张梦如. 基于APSO-BP-PID控制的质子交换膜燃料电池热管理系统温度控制[J]. 吉林大学学报(工学版), 2024, 54(9): 2401-2413. |

| [3] | 蒋林,李国龙,王时龙,徐凯,李喆裕. 基于主成分回归的进给轴热膨胀误差建模[J]. 吉林大学学报(工学版), 2024, 54(8): 2149-2155. |

| [4] | 张则强,王灿,刘俊琦,计丹,刘思璐. 基于改进麻雀搜索算法的平行行排序问题[J]. 吉林大学学报(工学版), 2024, 54(7): 1851-1861. |

| [5] | 回丽,金磊,宋万万,周松,安金岚. 转向架用SMA490BW钢不同焊接区域裂纹扩展速率[J]. 吉林大学学报(工学版), 2024, 54(3): 650-656. |

| [6] | 杨志军,张驰,黄观新. 基于浮动坐标法的刚柔耦合定位平台力学模型[J]. 吉林大学学报(工学版), 2024, 54(2): 385-393. |

| [7] | 邬伟骏,吴江波,张家乐,周强,杨乔洪,秦训鹏. 新型多功能高空作业平台稳定性分析和尺度综合[J]. 吉林大学学报(工学版), 2024, 54(12): 3450-3459. |

| [8] | 王磊,刘小鹏,周松,安金岚,张宏杰,丛家慧. 超声滚压对2024铝合金疲劳裂纹扩展行为的影响[J]. 吉林大学学报(工学版), 2024, 54(12): 3486-3495. |

| [9] | 张帆,韩宁,杜青,部竞琦,彭志军. MMH凝胶液滴蒸发与燃烧过程的数值仿真[J]. 吉林大学学报(工学版), 2024, 54(11): 3114-3124. |

| [10] | 周焕林,郭鑫,王选,方立雪,龙凯. 考虑几何非线性的多相多孔结构拓扑优化设计[J]. 吉林大学学报(工学版), 2024, 54(10): 2754-2763. |

| [11] | 石林榕,赵武云. 西北寒旱农区胡麻滚勺式精量穴播器的设计及试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2706-2717. |

| [12] | 柴博森,王广义,闫东,朱国仁,张进,吕恒升. 液力变矩器空化数值模拟及对性能的影响[J]. 吉林大学学报(工学版), 2023, 53(8): 2236-2244. |

| [13] | 陈国辉,徐业银,焦映厚. 考虑偏转的斜齿轮啮合刚度及其振动分析[J]. 吉林大学学报(工学版), 2023, 53(7): 1902-1910. |

| [14] | 陈贵升,罗国焱,李靓雪,黄震,李一. 柴油机颗粒捕集器孔道流场及其高原环境下噪声特性分析[J]. 吉林大学学报(工学版), 2023, 53(7): 1892-1901. |

| [15] | 于立娟,安阳,何佳龙,李国发,王升旭. 机电装备载荷谱外推技术研究进展及发展趋势[J]. 吉林大学学报(工学版), 2023, 53(4): 941-953. |

|