Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (5): 1322-1330.doi: 10.13229/j.cnki.jdxbgxb.20210918

Determination of elastic modulus by atomic force microscopy and microstructure analysis for polyurethane coating film

Chao XIE1( ),Qi-cai WANG1,2(

),Qi-cai WANG1,2( ),Ben-tian YU1,Sheng LI1,2,Xiao-xu LIN1,Zhi-ming LU3

),Ben-tian YU1,Sheng LI1,2,Xiao-xu LIN1,Zhi-ming LU3

- 1.College of Civil Engineering,Lanzhou Jiaotong University,Lanzhou 730070,China

2.National and Local Joint Engineering Laboratory for Disaster Prevention and Control Technology of Road and Bridge Engineering,Lanzhou Jiaotong University,Lanzhou 730070,China

3.Gansu Seventh Construction Group Co. ,Ltd. ,Gansu Lanzhou 730030,China

CLC Number:

- TB332

| 1 | 金伟良, 赵羽习.混凝土结构耐久性研究的回顾与展望[J].浙江大学学报: 工学版, 2002(4): 27-36, 59. |

| Jin Wei-liang, Zhao Yu-xi. State-of-the-art on durability of concrete structures[J]. Journal of Zhejiang University(Engineering Science), 2002(4): 27-36, 59. | |

| 2 | 张铖, 李维红, 范金朋, 等.相对法评价涂层混凝土冻融损伤[J].建筑材料学报, 2020, 23(3): 546-551. |

| Zhang Cheng, Li Wei-hong, Fan Jin-peng, et al. Relative method for evaluating freeze-thaw damage of coated concrete[J]. Journal of Building Materials, 2020, 23(3): 546-551. | |

| 3 | Almusallam A A, Khan F M, Dulaijan S U, et al. Effectiveness of surface coatings in improving concrete durability[J]. Cement & Concrete Composites, 2003, 25(4): 473-481. |

| 4 | Dubosc A, Escadeillas G, Blanc P J. Characterization of biological stains on external concrete walls and influence of concrete as underlying material[J]. Cement and Concrete Research, 2001, 31(11): 1613-1617. |

| 5 | Shikama T, Shinno H, Fukutomi M, et al. Mechanical properties of molybdenum coated with titanium carbide film[J]. Journal of Materials Science, 1983, 18(10): 3092-3098. |

| 6 | Bhattacharya A K, Nix W D. Analysis of elastic and plastic deformation associated with indentation testing of thin films on substrates[J]. International Journal of Solids & Structures, 1988, 24(12): 1287-1298. |

| 7 | Chiu C C, Case E D. Elastic modulus determination of coating layers as applied to layered ceramic composites[J]. Materials Ence and Engineering A, 1991, 132(91): 39-47. |

| 8 | Liu S, Wang Q J. Determination of young's modulus and poisson's ratio for coatings[J]. Surface & Coatings Technology, 2007, 201(14): 6470-6477. |

| 9 | 陈杨, 陈爱莲, 秦佳伟, 等.亚微米介孔二氧化硅微球的制备及其弹性模量的拟合计算[J].中国有色金属学报, 2017, 27(6): 1228-1235. |

| Chen Yang, Chen Ai-lian, Qin Jia-wei, et al. Preparation of submicrometer mesoporous silica microspheres and fitting calculation for elastic moduli[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(6): 1228-1235. | |

| 10 | 陈爱莲, 马翔宇, 王婉莹, 等.树枝状介孔氧化硅及其复合颗粒的制备和压缩弹性模量[J]. 硅酸盐学报, 2020, 48(1): 65-72. |

| Chen Ai-lian, Ma Xiang-yu, Wang Wan-ying,et al. Preparation and compressive elastic moduli of dendritic mesoporous silica particles and their composites[J]. Journal of The Chinese Ceramic Society, 2020, 48(1): 65-72. | |

| 11 | 刘畅, 许金泉, 孟祥琦, 等.基于原子力显微镜的薄膜涂层界面观测及其变形特性[J].上海交通大学学报, 2011, 45(10): 1485-1488. |

| Liu Chang, Xu Jin-quan, Meng Xiang-qi, et al. Analysis of interface macrostructure of thin coating material and its related elastic mechanical behavior based on AFM[J]. Journal of Shanghai Jiaotong University, 2011, 45(10): 1485-1488. | |

| 12 | 陈杨, 穆为彬, 陆锦霞. 核壳结构PS/CeO2复合微球弹性模量的AFM测定[J]. 摩擦学学报, 2012, 32(1): 7-13. |

| Chen Yang, Mu Wei-bin, Lu Jin-xia. Determination of elastic modulus of composite PS/CeO_2 core-shell microspheres by atomic force microscope[J]. Tribology, 2012, 32(1): 7-13. | |

| 13 | Rico F, Roca-Cusachs P, Gavara N, et al. Probing mechanical properties of living cells by atomic force microscopy with blunted pyramidal cantilever tips[J]. Physical Review E, 2005, 72(2): 021914. |

| 14 | Heuberger M. Elastic deformations of tip and sample during atomic force microscope measurements[J]. Journal of Vacuum Science & Technology B Microelectronics & Nanometer Structures, 1996, 14(2): 1250-1254. |

| 15 | Mathur A B, Collinsworth A M, Reichert W M, et al. Endothelial, cardiac muscle and skeletal muscle exhibit different viscous and elastic properties as determined by atomic force microscopy[J]. Journal of Biomechanics, 2001, 34(12): 1545-1553. |

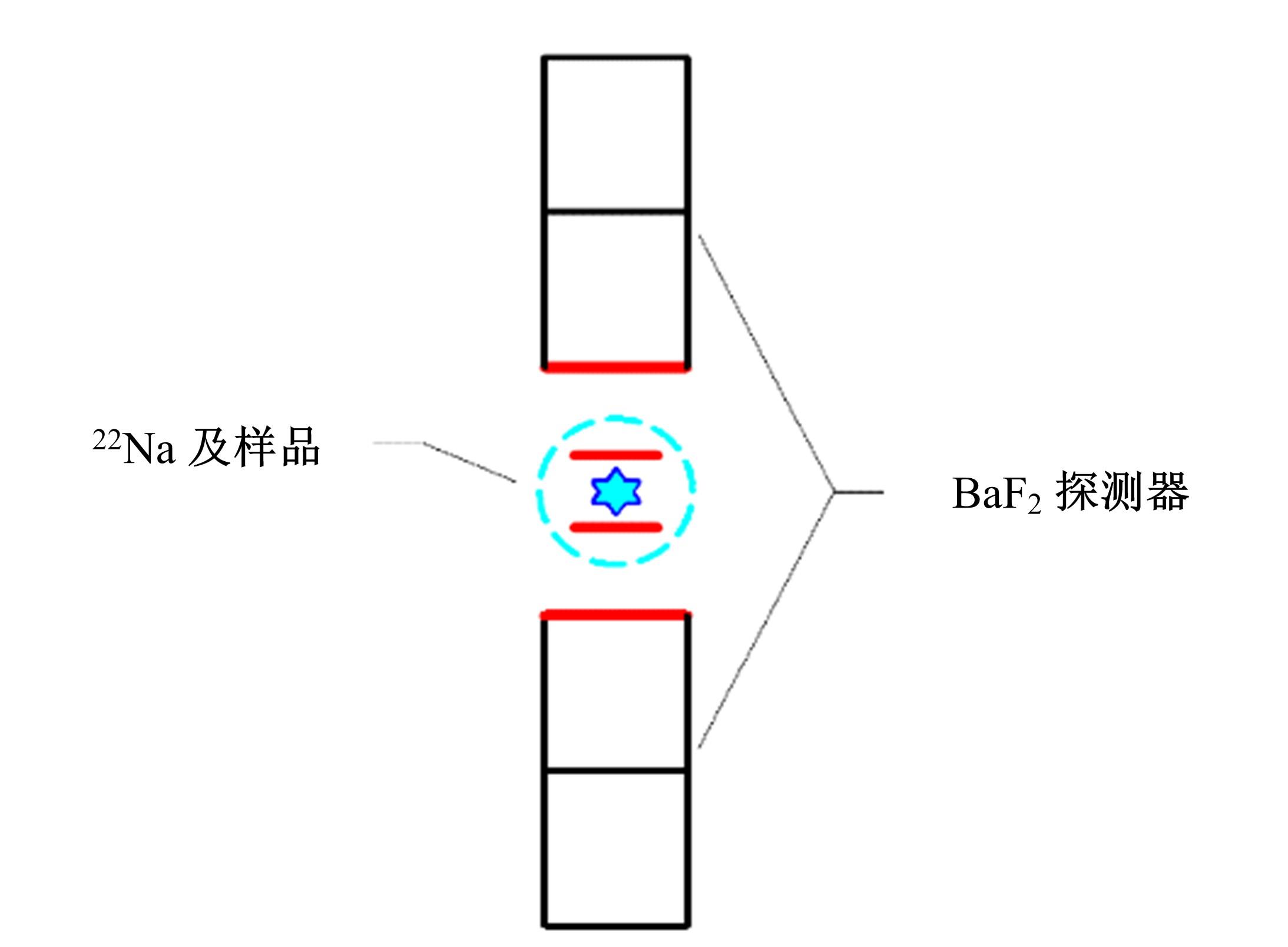

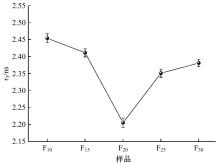

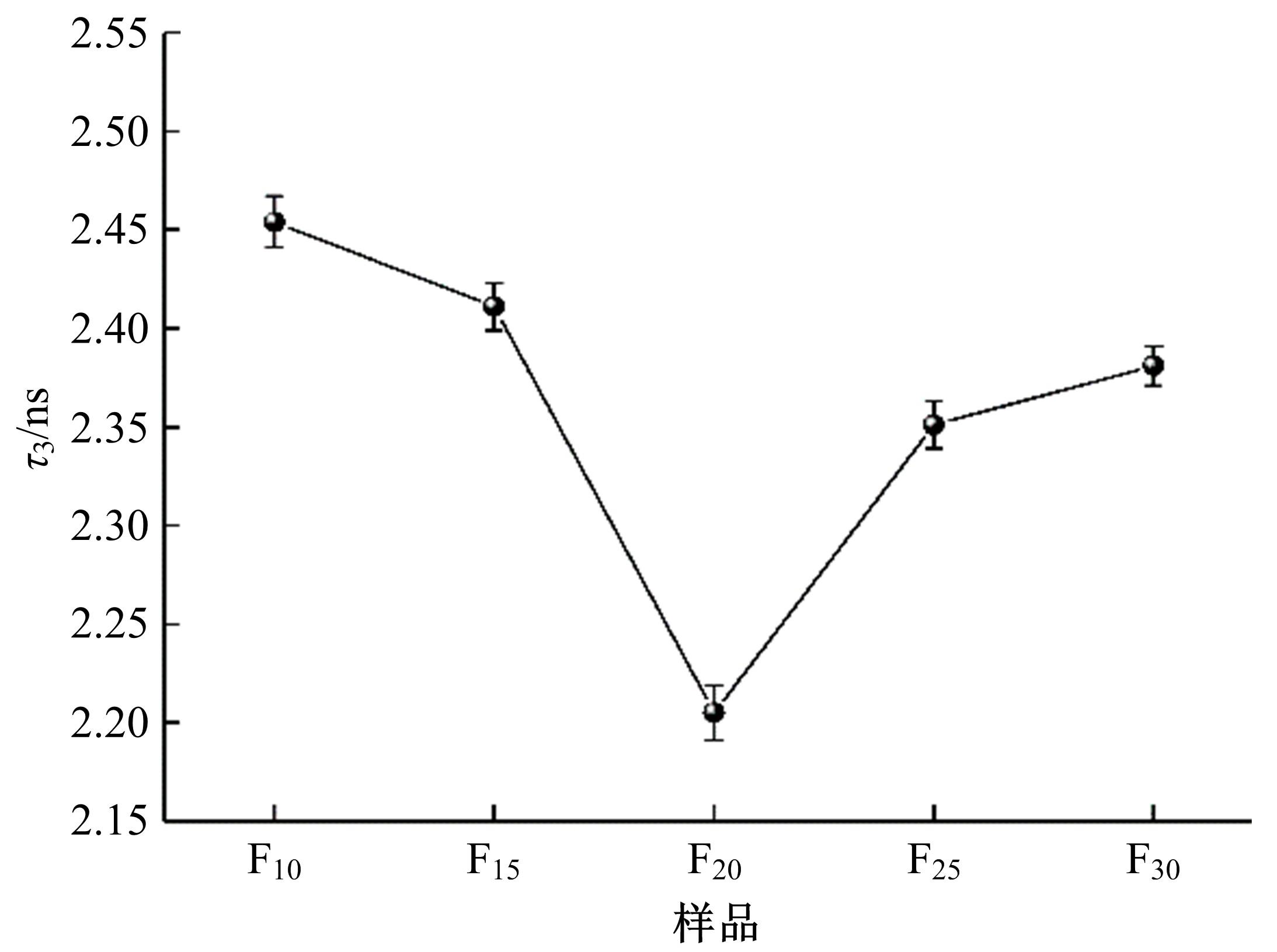

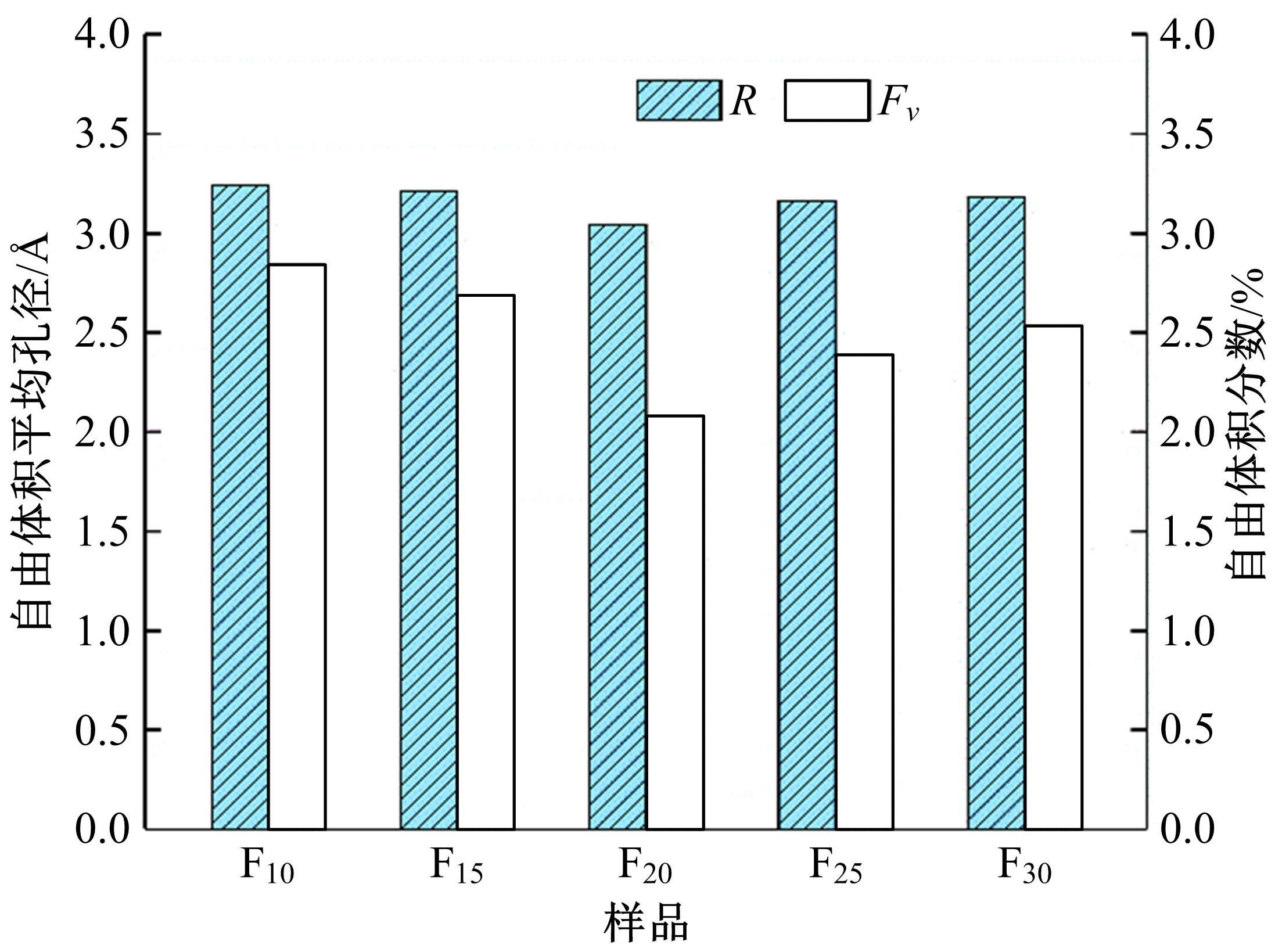

| 16 | Cheng K M, Tian C R, Du Y, et al. Effect of OPS dispersion method on the free volume of polyurethane by positron annihilation lifetime spectroscopy(PALS)[J]. Polymer Plastics Technology& Engineering, 2012, 51(4): 396-400. |

| 17 | Borek J, Osoba W. Free volume changes in physically aged polyethylene by positron annihilation[J]. Polymer, 2001, 42(7): 2901-2905. |

| 18 | Jean Y C, Horn J D V, Hung W S, et al. Perspective of positron annihilation spectroscopy in polymers[J]. Macromolecules, 2013, 46(18): 7133-7145. |

| 19 | Gomaa E, Asaad J N. Effect of adding feldspar on free volume properties of crosslinked polyester studied by positron annihilation lifetime spectroscopy[J]. Journal of Applied Polymer Science, 2012, 124(4): 3142-3146. |

| 20 | 颜可珍, 王道珵.聚合物改性沥青低温性能指标研究[J].建筑材料学报, 2020, 23(2): 479-484. |

| Yan Ke-zhen, Wang Dao-cheng. Low temperature performance index of polymer modified asphalt[J]. Journal of Building Materials, 2020, 23(2): 479-484. | |

| 21 | 于本田, 王起才, 张粉芹, 等.粗骨料对混凝土性能影响的试验研究[J]. 硅酸盐通报, 2011, 30(6): 1371-1375. |

| Yu Ben-tian, Wang Qi-cai, Zhang Fen-qin, et al. Low experimental study on effect of different parameters of coarse aggregate on properties of concrete[J]. Bulletin of the Chinese Ceramic Society, 2011, 30(6): 1371-1375. | |

| 22 | Sui T, Wei L, Cao X, et al. Comparison of oxygen vacancy and interstitial oxygen in KDP and ADP crystals from density functional theory calculations[J]. Computational Materials Science,2020,182: 109783. |

| 23 | Bilodeau G G. Regular pyramid punch problem[J]. Journal of Applied Mechanics, 1992, 59(3): 519-523. |

| 24 | Wang Z, Gao Z, Wang Y, et al. A new dynamic testing method for elastic, shear modulus and Poisson's ratio of concrete[J]. Construction & Building Materials, 2015, 100(15): 129-135. |

| 25 | Tan S, Sherman R L, Ford W T. Nanoscale compression of polymer microspheres by atomic force microscopy[J]. Langmuir the Acs Journal of Surfaces & Colloids, 2004, 20(17): 7015-7034. |

| 26 | Lyne A L, Wallqvist V, Birgisson B. Adhesive surface characteristics of bitumen binders investigated by Atomic Force Microscopy[J]. Fuel, 2013, 113(1): 248-256. |

| 27 | Saalah S, Abdullah L C, Aung M M, et al. Waterborne polyurethane dispersions synthesized from jatropha oil[J]. Industrial Crops & Products, 2015, 64:194-200. |

| 28 | Lei L, Xia Z, Ou C, et al. Effects of crosslinking on adhesion behavior of waterborne polyurethane ink binder[J]. Progress in Organic Coatings, 2015, 88: 155-163. |

| 29 | Kanyanta V, Ivankovic A. Mechanical characterisation of polyurethane elastomer for biomedical applications[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2010, 3(1): 51-62. |

| 30 | Giancarlo U L, Wolfgang G K. Free volume theory and nonlinear thermo visco elasticity[J]. Polymer Engineering & Science, 2010, 32(8): 542-557. |

| 31 | Borek J, Osoba W. Free volume changes in physically aged polyethylene by positron annihilation[J]. Polymer, 2001, 42(7): 2901-2905. |

| 32 | Li Y, Liu J, Wan X, et al. Surface passivation enabled-structural engineering of I-III-VI2 nanocrystal photocatalyst[J]. Journal of Materials Chemistry A, 2020, 8(19): 9951-9962. |

| 33 | Wang B, Gong W, Liu W H, et al. Influence of physical aging and side group on the free volume of epoxy resins probed by positron[J]. Polymer, 2003, 44(14): 4047-4052. |

| 34 | El-Meniawi M A H, Mahmoud K R, Megahed M. Positron annihilation spectroscopy and mechanical properties studies for epoxy matrices reinforced with different nanoparticles[J]. Journal of Polymer Research, 2016, 23(9): 181. |

| [1] | Ping JIANG,Lin ZHOU,Tian-hao MAO,Jun-ping YUAN,Wei WANG,Na LI. Damage model and time effect of cement⁃modified waste slurry [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(12): 2874-2882. |

| [2] | Shuan-cheng GU,Hong-bin NIE. Analysis of damage model of mortars strengthened with CFRP under ultimate freeze⁃thaw and load [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 2108-2120. |

| [3] | Zhi-jun LI,Hao LIU,Li-peng ZHANG,Zhen-guo LI,Yuan-kai SHAO,Zhi-yang LI. Simulation on influence of microstructure of the wall on deep bed filtration of particulate filter [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 422-434. |

| [4] | Wen-biao GONG,Rui ZHU,Xin-zhe QIE,Heng CUI,Ming-yue GONG. Microstructure and properties of 6082 aluminum alloyultra⁃thick plate preparated by friction stir weld [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 512-519. |

| [5] | Peng-hui WANG,Hong-xia QIAO,Qiong FENG,Hui CAO,Shao-yong WEN. Durability model of magnesium oxychloride-coated reinforced concrete under the two coupling factors [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 191-201. |

| [6] | Xin TONG,Ya-jiao ZHANG,Yu-shan HUANG,Zheng-zheng HU,Qing WANG,Zhi-hui ZHANG. Microstructure and mechanical properties of 304L stainless steel processed by selective laser melting [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1615-1621. |

| [7] | Jin⁃zhong LU,Wan⁃ting ZHOU,Sheng⁃yang ZHANG,Yi⁃kai SHAO,Chang⁃yu WANG,Kai⁃yu LUO. Effect of coverage layer on corrosion resistance of 6061⁃T6 aluminum alloy subjected to laser shock peening [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 842-849. |

| [8] | JIANG Qiu-yue,YANG Hai-feng,TAN Cai-wang. Strengthening properties of welded joints of 22MnB5 super high strength steel [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1806-1810. |

| [9] | ZHENG Xiao-yi, SUN Da-qian, LI Xin, DU Gui-gang, XIN Wei-da, REN Zhen-an. Microstructure and properties of cladded Al-Nb layers reinforced by NbAl3 [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1531-1536. |

| [10] | ZHAO Yu-guang, YANG Xue-hui, XU Xiao-feng, ZHANG Yang-yang, NING Yu-heng. Effects of Al-10Sr modifiers with different states, modification temperature and holding time on microstructure of ZL114A alloy [J]. 吉林大学学报(工学版), 2018, 48(1): 212-220. |

| [11] | ZHANG Zhi-qiang, LIU Cong-hao, HE Dong-ye, LI Xiang-ji, LI Ji-xuan. Effect of hot stamping process of boron steel on shape precision based on performance gradient distribution [J]. 吉林大学学报(工学版), 2017, 47(6): 1829-1833. |

| [12] | CUI Ya-nan, HAN Ji-wei, FENG Lei, LI Jia-di, WANG Le. Microstructure of asphalt under salt freezing cycles [J]. 吉林大学学报(工学版), 2017, 47(2): 452-458. |

| [13] | XU Hong, LIU Ya-nan, YU Ting, GU Zheng-wei, LI Xiang-ji, ZHANG Zhi-qiang. Inelastic recovery behavior and microscopic mechanism of high strength DP780 steel during cyclic loading-unloading [J]. 吉林大学学报(工学版), 2017, 47(1): 191-198. |

| [14] | ZHAO Hong-wei, DONG Xiao-long, ZHANG Lin, HU Xiao-li. Determination of the elastic moduli of bulk materials by four-point bending automatic test [J]. 吉林大学学报(工学版), 2016, 46(1): 140-145. |

| [15] | ZHAO Yu, LI Yan-he, ZHANG Pei, ZHAO Ke, LIU Wei-chao. Experimental study of the dynamic characteristics of clay [J]. 吉林大学学报(工学版), 2015, 45(6): 1791-1797. |

|

||