Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (6): 1555-1562.doi: 10.13229/j.cnki.jdxbgxb.20221103

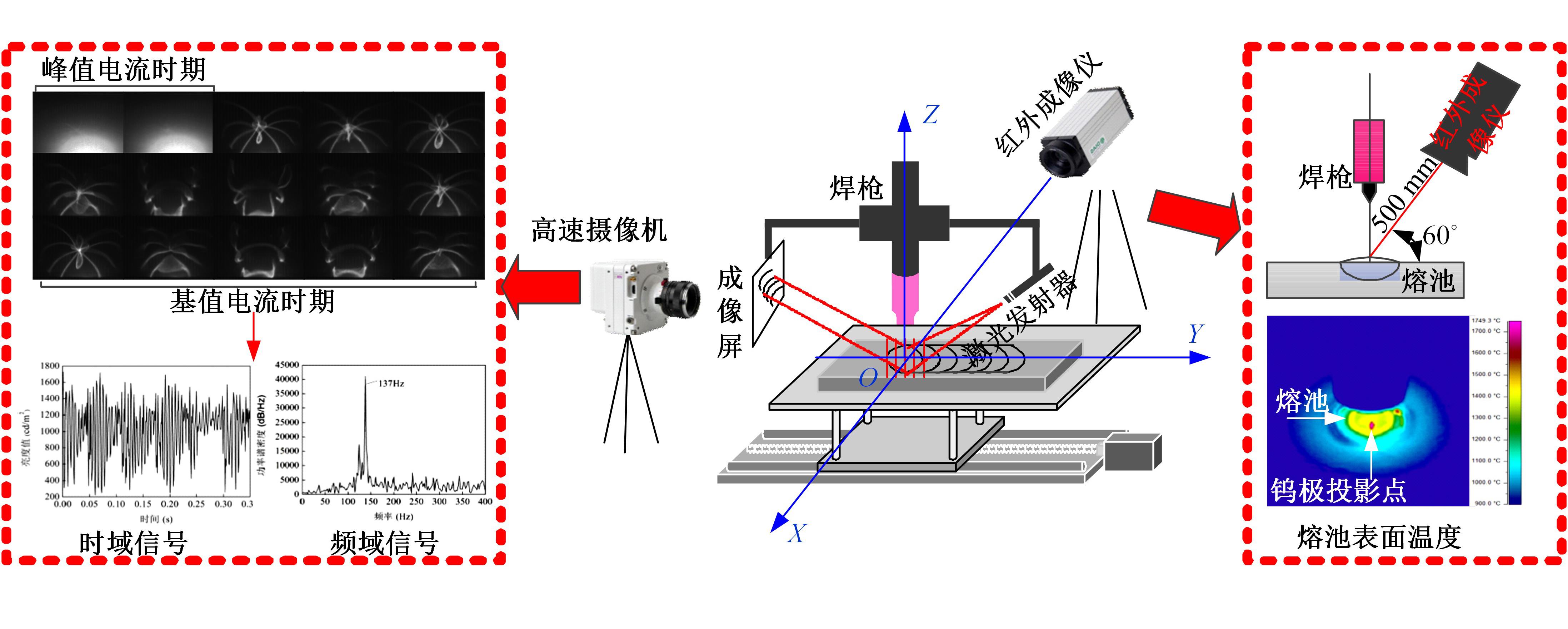

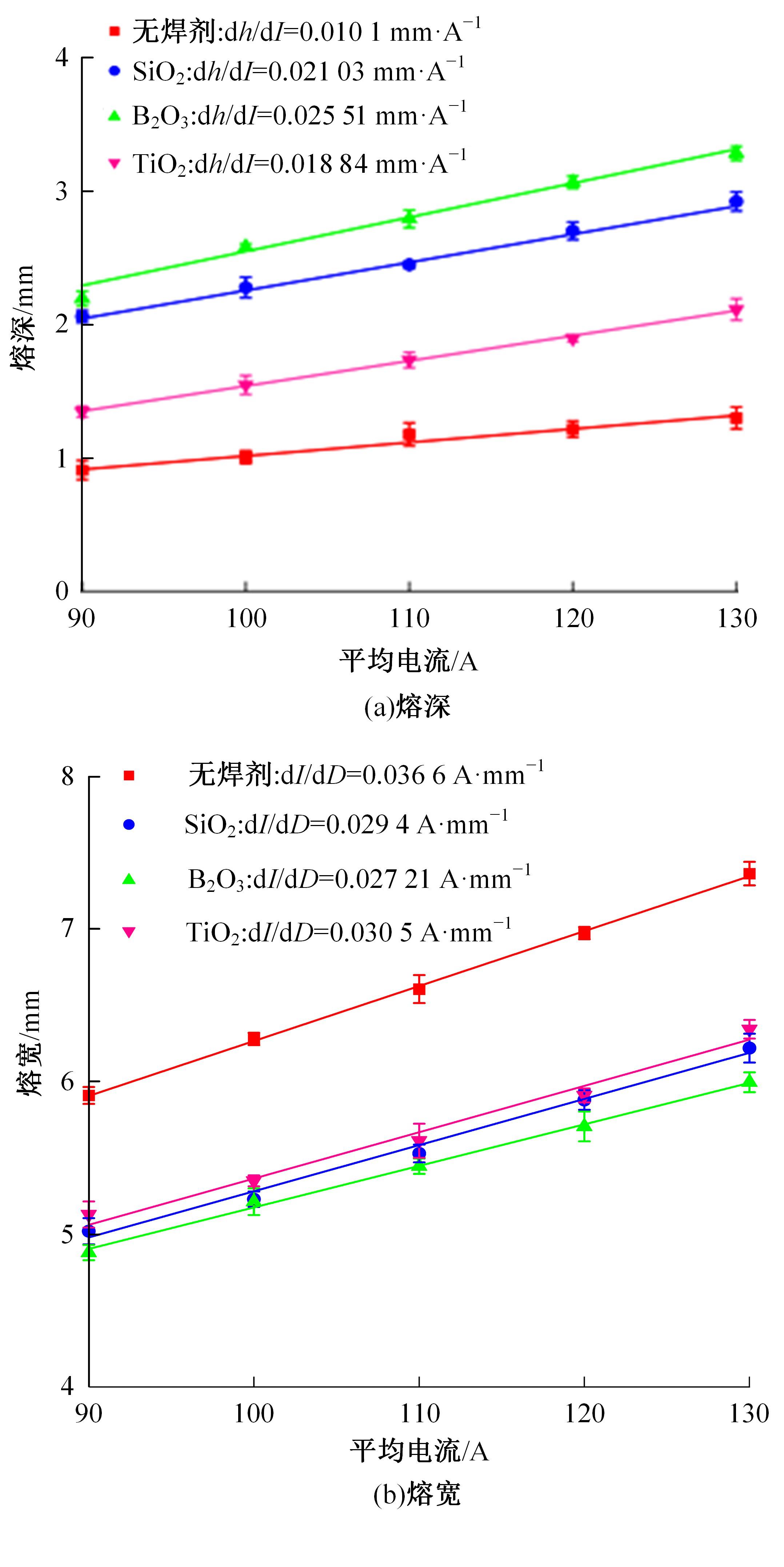

Effect of flux on surface tension of liquid metal in welding pool

Chun-kai LI( ),Yue DAI,Jia-xin WANG,Yu-fen GU,Yu SHI,Bao-long XI

),Yue DAI,Jia-xin WANG,Yu-fen GU,Yu SHI,Bao-long XI

- State Key Laboratory of Advanced Processing and Reuse of Nonferrous Metals,Lanzhou University of Technology,Lanzhou 730050,China

CLC Number:

- TG444

| 1 | Wakimoto T, Katoh K, Ueda Y, et al. Measurement of dynamic surface tension for liquid metal by capillary jet method[J]. International Journal of Heat and Fluid Flow, 2017, 66: 243-248. |

| 2 | Farzadi A, Esfahani M M, Zaree A S R. Theoretical and experimental investigation of gas metal arc weld pool in commercially pure aluminum: effect of welding current on geometry[J]. Journal of Central South University, 2017, 24(11): 2556-2564. |

| 3 | Yu F, Wei Y. Effect of surface tension anisotropy and welding parameters on initial instability dynamics during solidification: a phase-field study[J]. Metallurgical and Materials Transactions a-Physical Metallurgy and Materials Science, 2018, 49A (8): 3293-3305. |

| 4 | Yang M, Liu H, Qi B. The surface depression and temperatures in molten pool with pulsed arc welding [J]. Journal of Manufacturing Processes, 2019, 37: 130-138. |

| 5 | Kim C K, Kim J H, Hong H U, et al. Behavior of weld pool convection and columnar-to-equiaxed grain transition in gas tungsten arc welds of ferritic stainless steels with different aluminum contents[J]. Journal of Materials Processing Technology, 2021, 289:No.116496. |

| 6 | Kurtulmus M. Effects of welding parameters on penetration depth in mild steel A-TIG welding[J]. Scientia Iranica, 2019, 26(3): 1400-1404. |

| 7 | Pandya D, Badgujar A, Ghetiya N. A novel perception toward welding of stainless steel by activated TIG welding: a review[J]. Materials and Manufacturing Processes, 2021, 36 (8): 877-903. |

| 8 | Chu Q, Zhang M, Li J, et al. Intermetallics in CP-Ti/X65 bimetallic sheets filled with Cu-based flux-cored wires[J]. Materials & Design, 2016, 90: 299-306. |

| 9 | 商延赓,孙大千,郎波,等.金属间化合物对Sn-Ag-Cu无铅钎料钎焊接头性能的影响[J].吉林大学学报:工学版, 2006, 36(6): 846-850. |

| Shang Yan-geng, Sun Da-qian, Lang Bo, et al. Effects of intermetallic compounds on the properties of Sn-Ag-Cu lead-free solder joints[J]. Journal of Jilin University (Engineering and Technology Edition), 2006, 36(6): 846-850. | |

| 10 | Wang X X, Huang J K, Huang Y, et al. Investigation of heat transfer and fluid flow in activating TIG welding by numerical modeling[J]. Applied Thermal Engineering, 2017, 113: 27-35. |

| 11 | Zhao C X, Steijn V V, Richardson I M, et al. Unsteady interfacial phenomena during inward weld pool flow with an active surface oxide[J]. Science and Technology of Welding and Joining, 2009, 14(2): 132-140. |

| 12 | Huang Y M, Zhang F, Yuan J, et al. Investigation on surface morphology and microstructure of double-wire+arc additive manufactured aluminum alloys based on spectral analysis[J]. Journal of Manufacturing Processes, 2022, 84: 639-651. |

| 13 | Li C K, Shi Y, Gu Y F, et al. Monitoring weld pool oscillation using reflected laser pattern in gas tungsten arc welding[J]. Journal of Materials Processing Technology, 2018, 255: 876-885. |

| 14 | Shi Y, Li C K, Du L M, et al. Frequency characteristics of weld pool oscillation in pulsed gas tungsten arc welding[J]. Journal of Manufacturing Processes, 2016, 24: 145-151. |

| 15 | Liu G H, Liu M H, Yi Y Y, et al. Activated flux tungsten inert gas welding of 8 mm-thick AISI 304 austenitic stainless steel[J]. Journal of Central South University, 2015, 22(3): 800805. |

| 16 | 刘凤尧, 杨春利, 林三宝,等. 活性化TIG焊熔深增加机理的研究[J]. 金属学报, 2003(6): 661-665. |

| Liu Feng-yao, Yang Chun-li, Lin San-bao, et al. Mechanism of incerasing A-TIG welding penetration [J]. Acta Metallurgica Sinica, 2003(6): 661-665. | |

| 17 | 赵玉珍, 雷永平, 史耀武. A-TIG焊中氧含量对熔池流动方式影响的数值模拟[J]. 金属学报, 2004, 40(10): 1085-1092. |

| Zhao Yu-zhen, Lei Yong-ping, Shi Yao-wu. Modeling of the effects of oxygen content on flow patterns in A-TIG welding[J]. Acta Metallurgica Sinica, 2004, 40(10): 1085-1092. |

| [1] | Li HUI,Lei JIN,Wan-wan SONG,Song ZHOU,Jin-lan AN. Crack growth rate of SMA490BW steel in different welding areas for bogie [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(3): 650-656. |

| [2] | Yin-shui HE,He XIAO,Cang-hai LUO,Yu ZHANG,Zhuo-hua YU,Hai-tao YUAN. Autonomous decision⁃making of welding positions based on analytic hierarchy process in T⁃joint arc welding [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(3): 657-662. |

| [3] | Xiao ZHOU,Yi-jie LIANG,Zhong-xuan XI,Yu-tao WANG. Welding deformation and compensation method of B-pillar in body-in-white [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(8): 2212-2218. |

| [4] | Di WU,Wen-hua GENG,Hong-mei LI,Da-qian SUN. Electron backscattered diffraction analysis on interface of aluminum/steel joints produced by plasma arc welding⁃brazing [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1331-1337. |

| [5] | Xin CHEN,Guan-chen ZHANG,Kang-ming ZHAO,Jia-ning WANG,Li-fei YANG,De-rong SITU. Influence of lap welds on the lightweight design of welded aluminum structures [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1282-1288. |

| [6] | Gui-shen YU,Xin CHEN,Zi-tao WU,Yi-xiong CHEN,Guan-chen ZHANG. Analysis of microstructure and mechanical properties of probeless friction stir spot welding joint in AA6061⁃T6 aluminum thin plate [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1338-1344. |

| [7] | Xiao-hong LU,Jin-hui QIAO,Yu ZHOU,Chong MA,Guo-chuan SUI,Zhuo SUN. Research progress of temperature field in friction stir welding [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(1): 1-17. |

| [8] | Li HUI,Jia-chen LU,Song ZHOU,Jin-lan AN,Guan-yan ZHOU,Xiao-peng LIU. Effect of heat treatment on fatigue properties of TC4 titanium alloy by laser double beam welded joint [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(1): 105-110. |

| [9] | Hai-yan XING,Chao LIU,Cheng XU,Yu-huan CHEN,Song-hong-ze WANG. Quantitative metal magnetic memory classification model of weld grades based on particle swarm optimization fuzzy C⁃means [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 525-532. |

| [10] | Lei WANG,Bing-han HUANG,Jia-hui CONG,Li HUI,Song ZHOU,Yong-zhen XU. Effect of ultrasonic impact on fatigue performance of friction stir weld [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2542-2548. |

| [11] | Wen-quan WANG,Yan-xin WANG,Hong-xiao WANG,Xin LI,Peng WU. Defects repair technology of SUS301L stainless steel laser weld [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 79-90. |

| [12] | Xin CHEN,Gui-shen YU,Biao ZHANG,Kai-xuan PAN,Li-fei YANG. Equivalent modeling of tensile-shear behavior for friction stir spot welding joints [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1190-1197. |

| [13] | Xiao-yan GU,Cheng-long SUI,Xing DI,Zheng-yu MENG,Kai-xuan ZHU,Chang-chun CHU. Effect of welding energy on performance of Cu/Ti joints obtained by ultrasonic welding [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1669-1676. |

| [14] | Yin-bao TIAN,Jun-qi SHEN,Sheng-sun HU,Jian GOU. Effect of EP/EN Balance on droplet transfer and weld formation of Al alloy by VP⁃CMT [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1663-1668. |

| [15] | Wen-biao GONG,Rui ZHU,Xin-zhe QIE,Heng CUI,Ming-yue GONG. Microstructure and properties of 6082 aluminum alloyultra⁃thick plate preparated by friction stir weld [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 512-519. |

|

||