Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (6): 1528-1536.doi: 10.13229/j.cnki.jdxbgxb.20221223

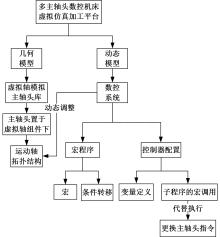

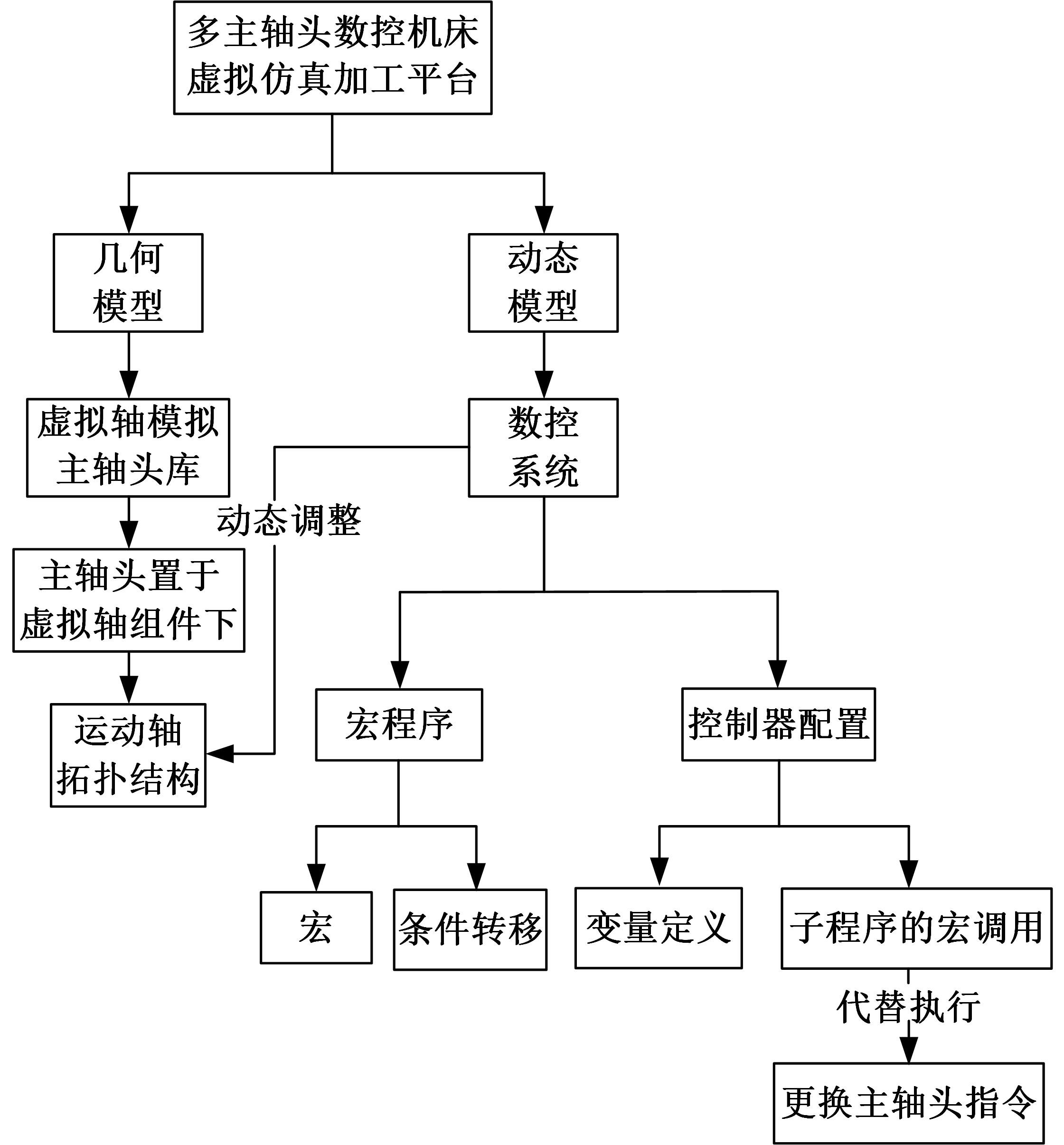

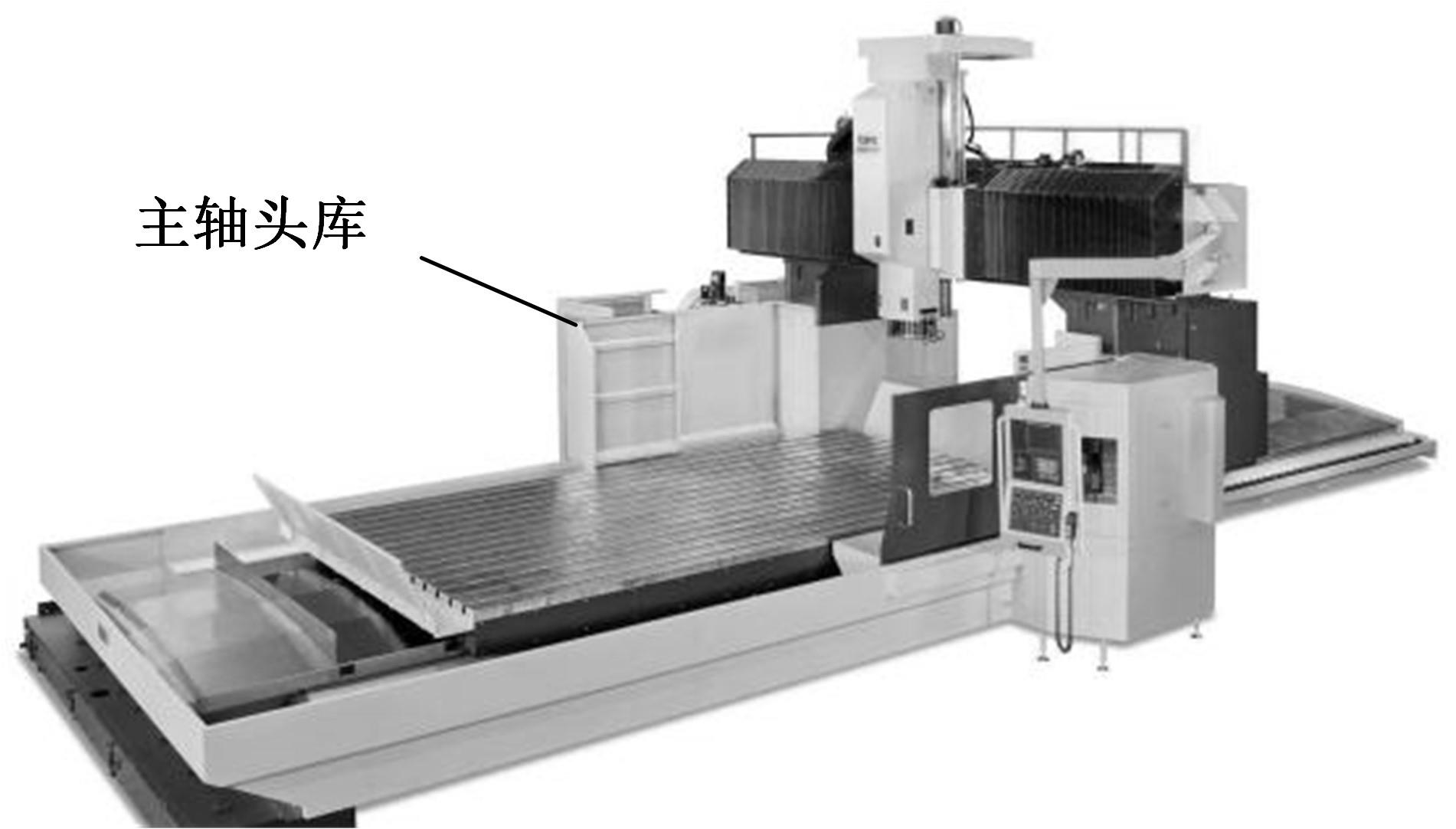

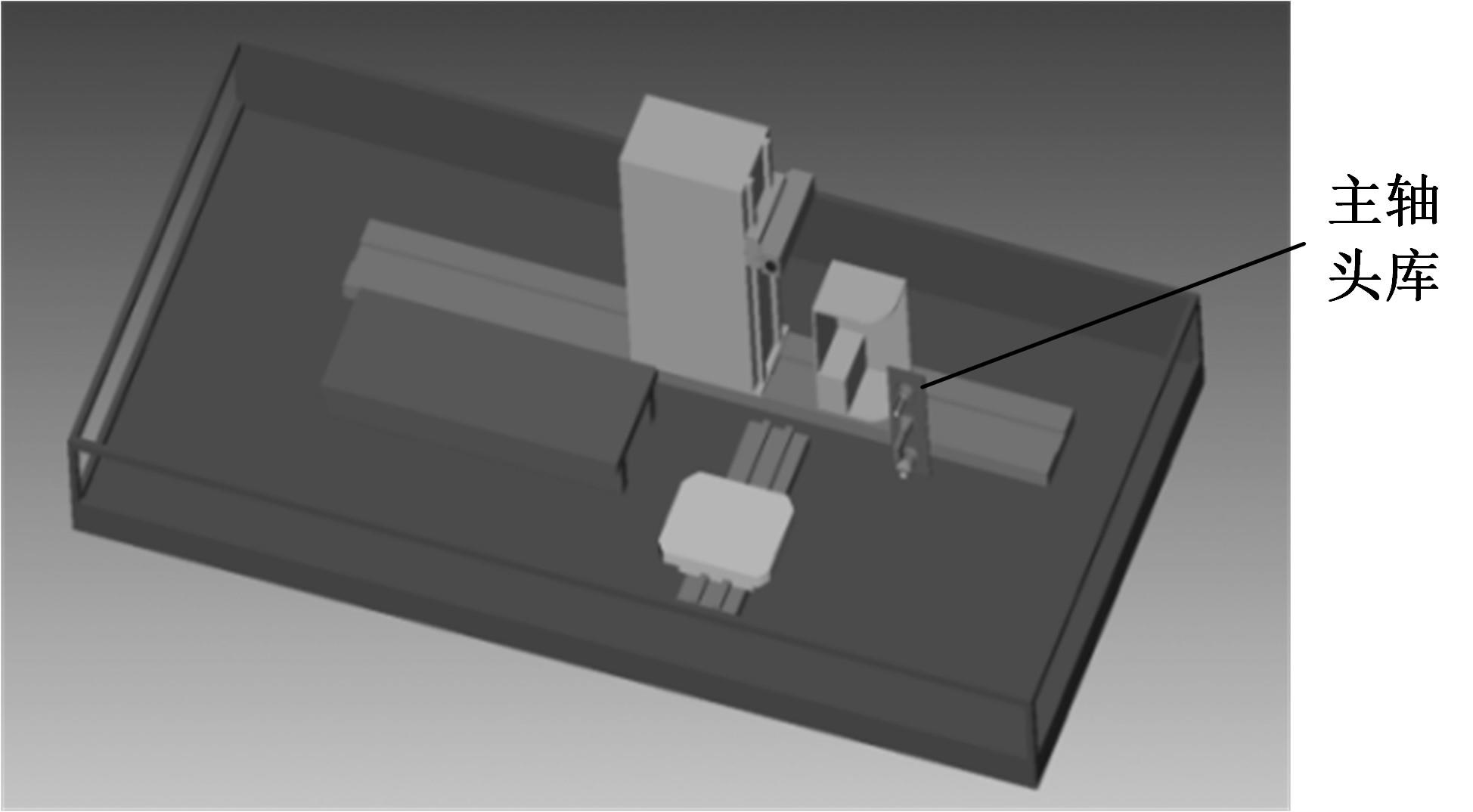

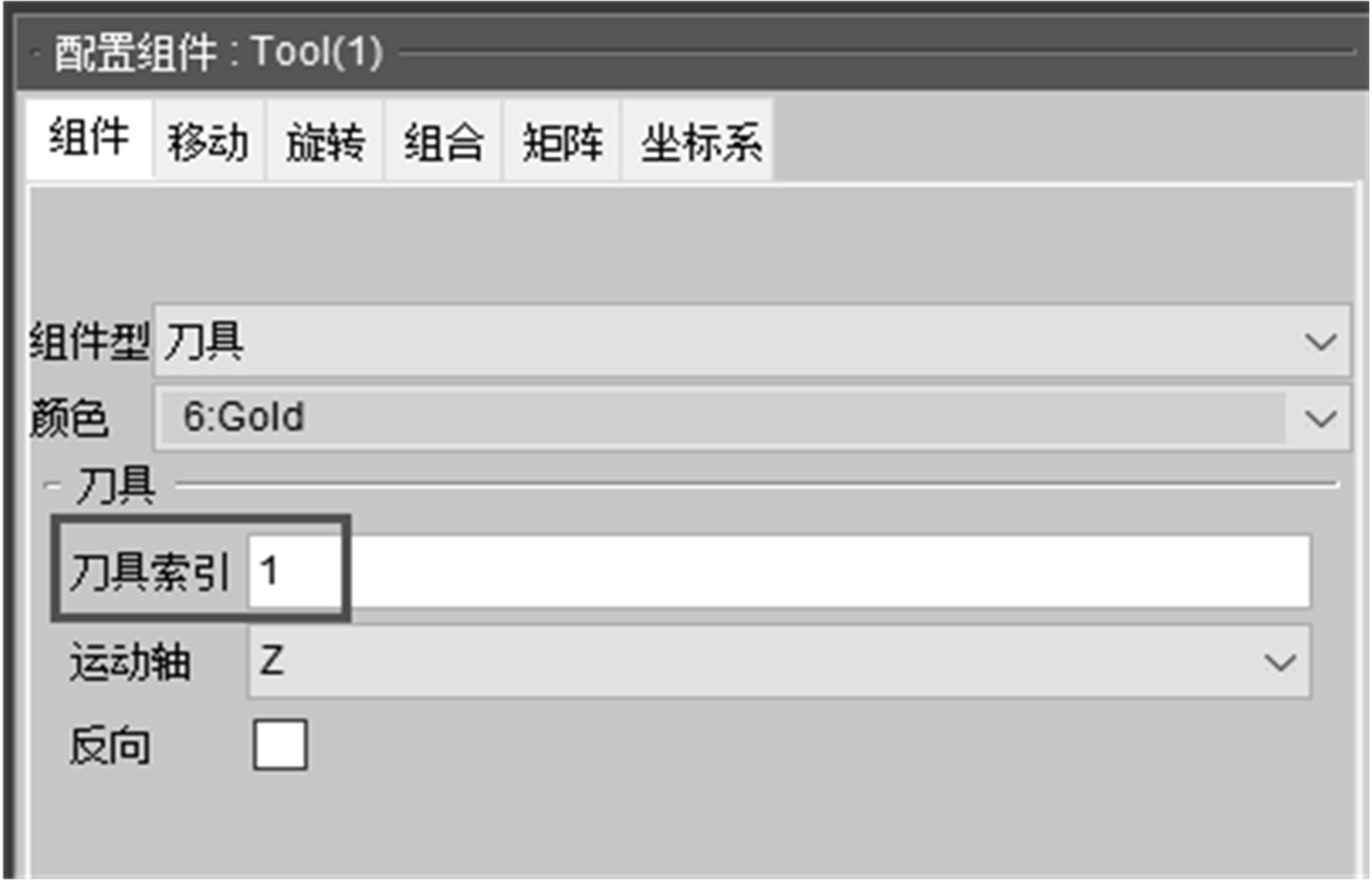

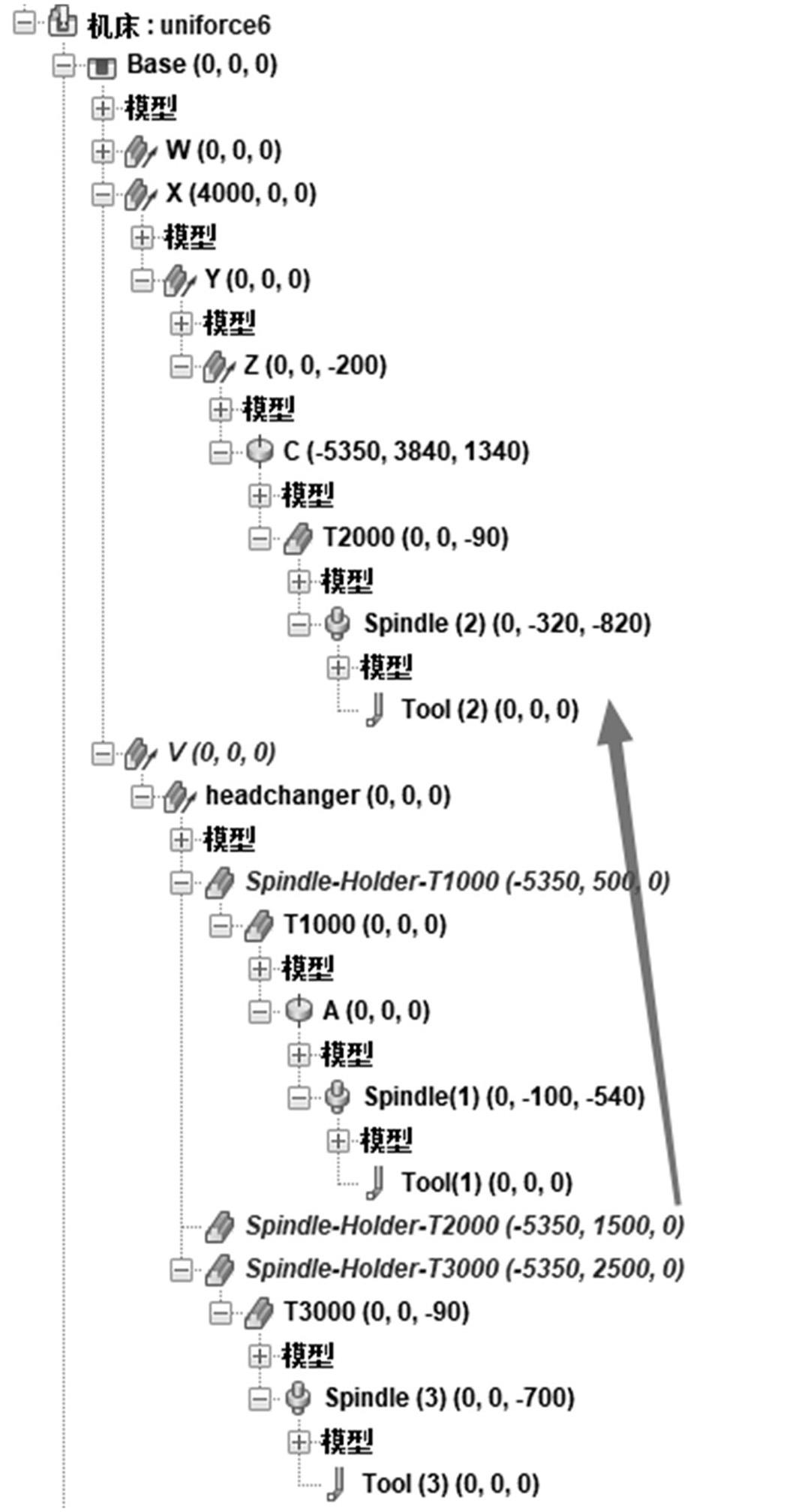

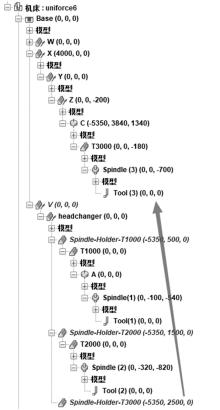

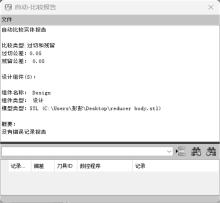

Construction method of virtual simulation machining platform for CNC machine tools with multi-spindle heads

An-jiang CAI( ),Pei-peng WANG,Chen-xi WANG,Ling LI

),Pei-peng WANG,Chen-xi WANG,Ling LI

- School of Mechanical and Electrical Engineering,Xi 'an University of Architecture and Technology,Xi' an 710055,China

CLC Number:

- TG659

| 1 | 胡涞,查俊,朱永生,等.基础装备制造及高档集成数控机床研究进展[J].中国机械工程,2021,32(16):1891-1903. |

| Hu Lai, Zha Jun, Zhu Yong-sheng, et al. Research progress in basic equipment manufacturing and high-grade integrated CNC machine tools[J]. China Mechanical Engineering, 2021,32(16): 1891-1903. | |

| 2 | 崔榕芳,陈蔚芳,潘立剑,等.基于遗传算法的多主轴头加工空行程轨迹规划[J].计算机集成制造系统,2022,28(2):507-517. |

| Cui Rong-fang, Chen Wei-fang, Pan Li-jian, et al. Empty travel trajectory planning of multi-spindle head processing based on genetic algorithm[J]. Computer Integrated Manufacturing System, 2022,28(2): 507-517. | |

| 3 | 吴志清.VERICUT虚拟机床技术在五轴加工中的应用研究[J].机床与液压,2016,44(16):66-68, 76. |

| Wu Zhi-qing. Application of VERICUT virtual machine tool in five axis processing[J]. Machine Tool and Hydraulic Pressure, 2016,44(16): 66-68, 76. | |

| 4 | Yu D Y, Ding Z. Post-processing algorithm of a five-axis machine tool with dual rotary tables based on the TCS method[J]. The International Journal of Advanced Manufacturing Technology, 2019,102(9): 3937-3944. |

| 5 | Chen Y D, Wei H X, Wang T M. Three-dimensional tool radius compensation for a 5-Axis peripheral milling[J]. Advanced Science Letters, 2011, 4(8): 3093-3096. |

| 6 | Tang J Y, Yang X Y. Research on manufacturing method of planing for spur face-gear with 4-axis CNC planer[J]. The International Journal of Advanced Manufacturing Technology, 2016,82(5): 847-858. |

| 7 | Yang J H, Zhang D H, Wu B H, et al. A path planning method for error region grinding of aero-engine blades with free-form surface[J]. The International Journal of Advanced Manufacturing Technology, 2015,81(1): 717-728. |

| 8 | 杨胜群,杨伟群,唐秀梅,等.VERICUT数控加工仿真技术[M].北京:清华大学出版社,2013:103-115. |

| 9 | 唐清春,尹韶辉,王永强,等.非模态回转轴旋转角的优化方法[J].机械工程学报,2018,54(3):178-185. |

| Tang Qing-chun, Yin Shao-hui, Wang Yong-qiang, et al. Optimization method of rotation angle of nonmodal rotary axis[J]. Journal of Mechanical Engineering, 2018,54(3):178-185. | |

| 10 | 韦洪新,王智森,程发武.基于控制分布角的球面螺旋加工法研究[J].现代制造工程,2022,501(6):39-42. |

| Wei Hong-xin, Wang Zhi-sen, Cheng Fa-wu. Study on spherical helix processing method based on control distribution angle[J]. Modern Manufacturing Engineering, 2022,501 (6): 39-42. |

| [1] | Chang-bin DONG,Long-kun LI,Yong-ping LIU,Wang-peng PEI. Numerical simulation and experiment of non-circular gear transmission error and backlash [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(4): 865-873. |

| [2] | Fei WU,Hao-ye NONG,Chen-hao MA. Tool wear prediction method based on particle swarm optimizationlong and short time memory model [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 989-997. |

| [3] | Lin SONG,Li-ping WANG,Jun WU,Li-wen GUAN,Zhi-gui LIU. Reliability analysis based on cyber⁃physical system and digital twin [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 439-449. |

| [4] | Guo-long LI,Xiao-hui TAO,Kai XU,Zhe-yu LI. Rapid measurement and identification of position dependent geometric errors of CNC machine tool turntable [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 458-467. |

| [5] | Yun-wei ZHAO,De-xu GENG,Xiao-min LIU,Qi LIU. Implementation and stability on turning with constant radius of pneumatic flexible hexapod robot [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 472-482. |

| [6] | Chun-zheng DUAN,Fang-yuan ZHANG,Wen-neng KOU,Bin WEI. Martensitic transformation of surface white layer in high speed hard cutting [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1575-1583. |

| [7] | QU Xing-tian, ZHAO Yong-bing, LIU Hai-zhong, WANG Xin, YANG Xu, CHEN Hang-de. Modeling and experiment of spatial geometric errors of hybrid serial-parallel machine tool [J]. 吉林大学学报(工学版), 2017, 47(1): 137-144. |

| [8] | ZHANG Peng, KOU Shu-qing, ZHAO Yong, LIN Bao-jun. Ananlsis of three rollers axial knurling process of assembled camshaft [J]. 吉林大学学报(工学版), 2016, 46(6): 1953-1960. |

| [9] | REN Shu-nan, YANG Xiang-dong, WANG Guo-lei, LIU Zhi, CHEN Ken. Base position planning of mobile manipulator for large parts painting [J]. 吉林大学学报(工学版), 2016, 46(6): 1995-2002. |

| [10] | WEI Xiao-hui, LI Xiang, LI Hong-liang, LI Cong, ZHUANG Yuan, YU Hong-mei. Flexible Online MapReduce model and topology protocols supporting large-scale stream data processing [J]. 吉林大学学报(工学版), 2016, 46(4): 1222-1231. |

| [11] | SHEN Zhi-huang, YAO Bin, LU Ru-sheng, FENG Wei, ZHANG Xiang-lei, WANG Meng-meng. Form grinding error analysis of precision screw rotor profiles [J]. 吉林大学学报(工学版), 2016, 46(3): 831-838. |

| [12] | GUO Li-bin, ZHANG Bin, CUI Hai, ZHANG Zhi-hang. Structural parameters of 3D roughness for micro wire electrical discharge machining surface [J]. 吉林大学学报(工学版), 2015, 45(3): 851-856. |

| [13] | DENG Cheng-jiang, HE Xiao-cong, XING Bao-ying, WANG Yu-qi, ZENG Kai, DING Yan-fang. Mechanical properties of self-piercing riveted lap joints in dissimilar metal sheets of aluminum and copper [J]. 吉林大学学报(工学版), 2015, 45(2): 473-480. |

| [14] | HONG Zhao-bin, YANG Zhao-jun, ZHANG Xue-cheng, WANG Bai-chao. Milling simulation analysis of spiral bevel gear based on tooth generating line [J]. 吉林大学学报(工学版), 2013, 43(02): 334-339. |

| [15] | LI Guo-fa, ZHANG Dong-lin, GONG Jin-long, WANG Li-bin. Laser-assisted machining technique for zirconia ceramics [J]. , 2012, (06): 1409-1414. |

|

||