Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (11): 3103-3113.doi: 10.13229/j.cnki.jdxbgxb.20230427

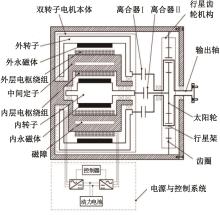

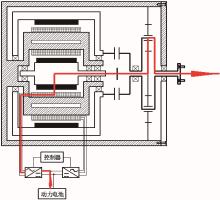

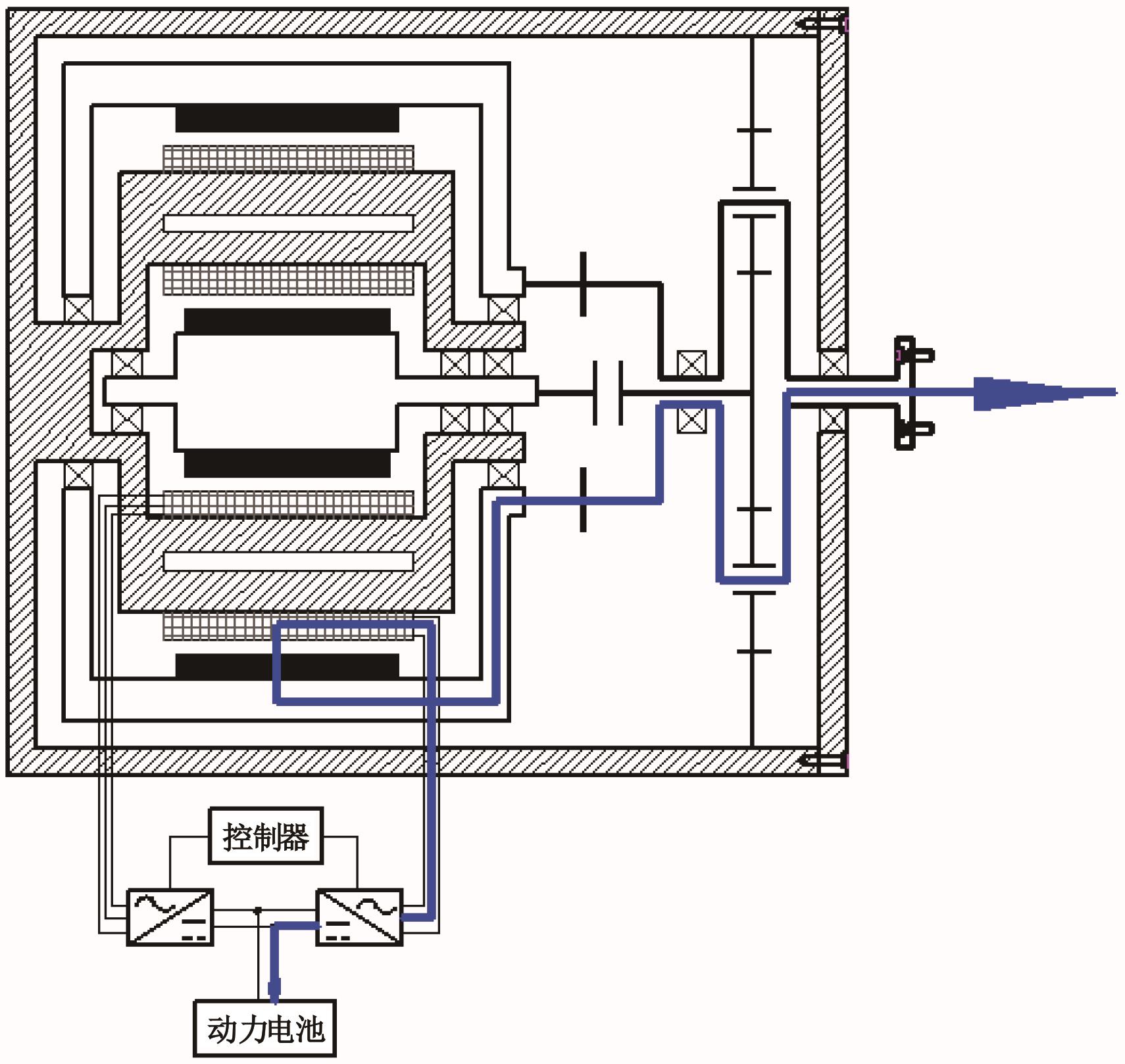

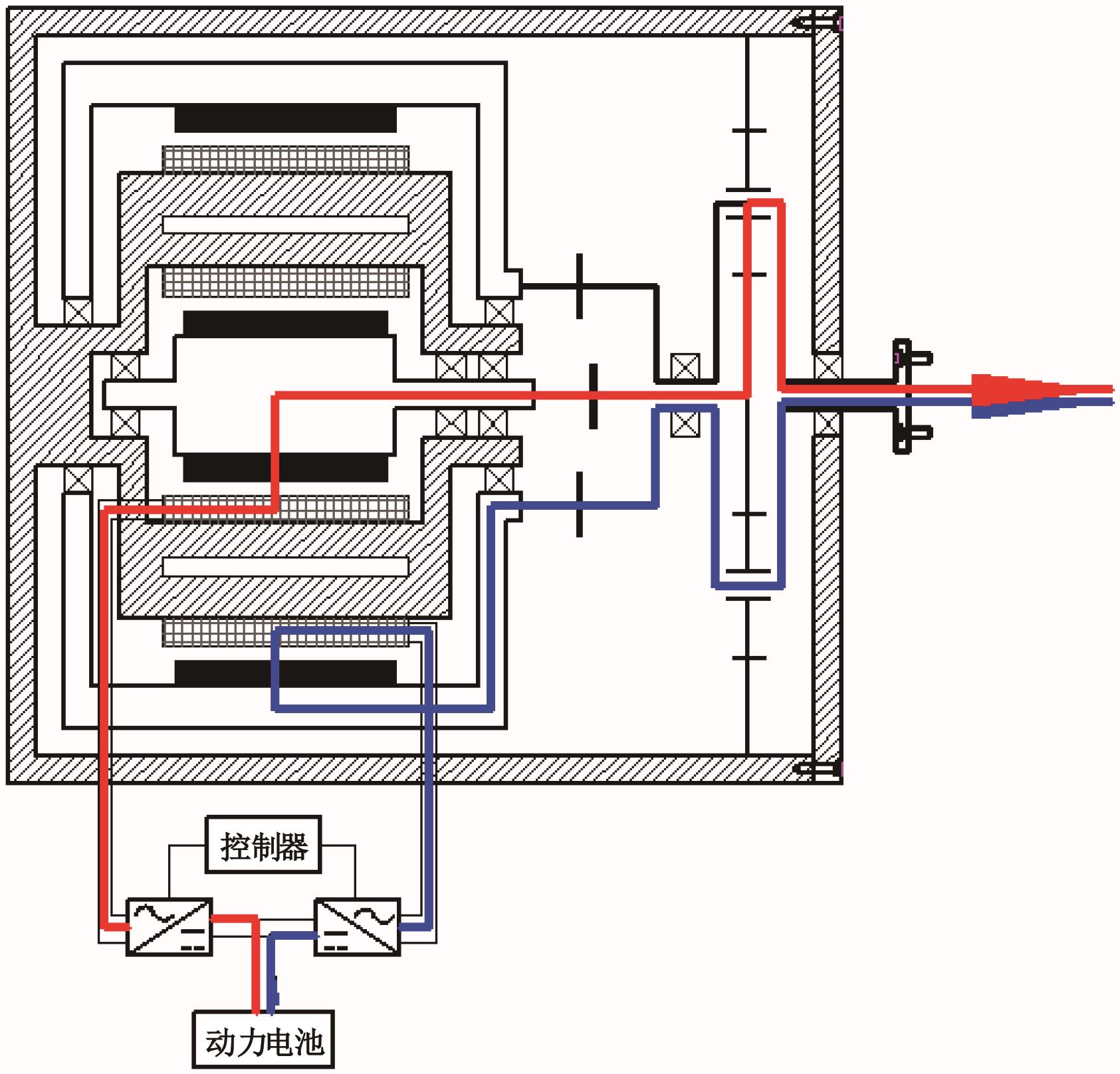

Energy management strategy of drive mode for dual-rotor in-wheel motor driven electric vehicle based on optimal system efficiency

- 1.School of Automotive and Traffic Engineering,Jiangsu University,Zhenjiang 212003,China

2.School of Mechanical Engineering,Anyang Institute of Technology,Anyang 455000,China

CLC Number:

- U469.72

| 1 | Lu D B, Ouyang M G, Lu L G, et al. Theoretical performance of a new kind of range extended electric vehicle[J]. World Electric Vehicle Journal, 2011, 4(1): 655-661. |

| 2 | He R, Wang J C. Vertical vibration control of an in-wheel motor-driven electric vehicle using an in-wheel active vibration system[J]. Asian Journal of Control, 2020, 22(2): 879-896. |

| 3 | 王震坡, 孙逢春. 电动汽车能耗分配及影响因素分析[J]. 北京理工大学学报, 2004(4): 306-310. |

| Wang Zhen-po, Sun Feng-chun. Analysis of energy consumption distribution and factors of influence in electric vehicles[J]. Transactions of Beijing Institute of Technology, 2004(4): 306-310. | |

| 4 | Hoeijmakers M J, Rondel M. The electrical variable transmission in a city bus[C]∥ 35th IEEE Power Electronics Specialist Conference, Aachen, Germany, 2004: 2273-2278. |

| 5 | Eriksson S, Sadarangani C. A four-quadrant HEV drive system[C]∥ 56th Vehicular Technology Conference, Vancouver, Canada, 2002: 1510-1514. |

| 6 | Xu L, Zhang Y, Wen X. Multioperational modes and control strategies of dual-mechanical-port machine for hybrid electrical vehicles[J]. IEEE Transactions on Industry Applications, 2009, 45(2): 747-755. |

| 7 | 庄兴明, 宋强, 温旭辉, 等. 辐型磁钢双机械端口电机的解耦控制[J].中国电机工程学报, 2014, 34(33): 5925-5933. |

| Zhuang Xing-ming, Song Qiang, Wen Xu-hui, et al. Decoupling control of dual mechanical ports machine with spoke type permanent-magnet arrangement[J]. Proceedings of the CSEE, 2014, 34(33): 5925-5933. | |

| 8 | 陈云云, 全力, 朱孝勇, 等. 新型定子永磁式双转子电机运行模式分析与实验研究[J]. 中国电机工程学报, 2014, 34(33): 5895-5901. |

| Chen Yun-yun, Quan Li, Zhu Xiao-yong, et al. Analysis and experimental study on operational modes of a novel stator permanent magnet double rotor motor[J]. Proceedings of the CSEE, 2014, 34(33): 5895-5901. | |

| 9 | 莫丽红, 全力, 朱孝勇, 等. 定子永磁式双转子电机设计与实验研究[J]. 电工技术学报, 2014, 29(9): 74-82. |

| Mo Li-hong, Quan Li, Zhu Xiao-yong, et al. Optimal design and experiment of a novel double-rotor machine with PMs in stator[J]. Transactions of China Electrotechnical Society, 2014, 29(9): 74-82. | |

| 10 | Xiang Z X, Zhu X Y, Quan L, et al. Multi-level design optimization and operation of a brushless double mechanical ports flux-switching permanent magnet motor[J]. IEEE Transactions on Industrial Electronics, 2016, 63(10): 6042-6054. |

| 11 | 何仁, 胡东海. 基于双转子电机的电动轮及其控制方法[P]. 中国: ZL201410162607.X, 2016-03-02. |

| 12 | 何仁, 倪赟磊. 用于车辆轮毂驱动的双转子电机结构及其动力传递模式[P]. 中国: ZL201310659506.9, 2016-01-20. |

| 13 | 何仁, 杨祺. 四轮驱动电动汽车的双转子轮毂电机及其动力传递方法[P]. 中国: ZL201510453976.9, 2018-02-27. |

| 14 | 邢杰, 马士奔, 叶辉, 等. 用于电动汽车的双转子电机轮毂驱动系统[P]. 中国: CN106627101A, 2017-05-10. |

| 15 | 孟德建, 陈辛波, 张立军, 等. 一种双转子电机集成鼓式制动器的轮毂电机驱动系统[P]. 中国: CN109435676A, 2019-03-08. |

| 16 | 陈龙, 朱斌, 孙晓东, 等. 基于模型预测控制的多电机驱动系统能量最优分配策略[J]. 农业机械学报, 2018, 49(10): 403-409. |

| Chen Long, Zhu Bin, Sun Xiao-dong, et al. Optimal allocation strategy for multi-motor drive system based on model predictive control[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(10): 403-409. |

| [1] | Jun-long QU,Wen-ku SHI,Sheng-yi XUAN,Zhi-yong CHEN. Parameter design method of multiple dynamic vibration absorbers for suppressing multi-frequency resonance of automotive powertrain [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(2): 444-455. |

| [2] | Xin CHEN,Xiang-yuan ZHANG,Zi-tao WU,Gui-shen YU,Li-fei YANG. Effect of process sequence on tensile shear properties of PFSSW joints for automotive aluminum sheets [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(2): 468-475. |

| [3] | Hong-yu HU,Zheng-guang ZHANG,You QU,Mu-yu CAI,Fei GAO,Zhen-hai GAO. Driver behavior recognition method based on dual-branch and deformable convolutional neural networks [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 93-104. |

| [4] | Jun-nian WANG,Yu-jing CAO,Zhi-ren LUO,Kai-xuan LI,Wen-bo ZHAO,Ying-yi MENG. Online detection algorithm of road water depth based on binocular vision [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 175-184. |

| [5] | Cao TAN,Hao-xin REN,Wen-qing GE,Ya-dong SONG,Jia-yu LU. Improved active disturbance rejection control for hydraulic vibration stages based on the direct-drive valve [J]. Journal of Jilin University(Engineering and Technology Edition), 2025, 55(1): 84-92. |

| [6] | Shou-tao LI,Lu YANG,Ru-yi QU,Peng-peng SUN,Ding-li YU. Slip rate control method based on model predictive control [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2687-2696. |

| [7] | Liang WU,Yi-fan GU,Biao XING,Fang-wu MA,Li-wei NI,Wei-wei JIA. Steering four-wheel distributed integrated control method based on LQR [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2414-2422. |

| [8] | Yu-hai WANG,Xiao-zhi LI,Xing-kun LI. Predictive energy saving algorithm for hybrid electric truck under high-speed condition [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2121-2129. |

| [9] | Sheng CHANG,Hong-fei LIU,Nai-wei ZOU. H∞ loop shaping robust control of vehicle tracking on variable curvature curve [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2141-2148. |

| [10] | Jian-ze LIU,Jiang LIU,Min LI,Xin-jie ZHANG. Vehicle speed decoupling road identification method based on least squares [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(7): 1821-1830. |

| [11] | Xian-yi XIE,Ming-jun ZHANG,Li-sheng JIN,Bin ZHOU,Tao HU,Yu-fei BAI. Artificial bee colony trajectory planning algorithm for intelligent vehicles considering comfortable [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1570-1581. |

| [12] | Ling HUANG,Zuan CUI,Feng YOU,Pei-xin HONG,Hao-chuan ZHONG,Yi-xuan ZENG. Vehicle trajectory prediction model for multi-vehicle interaction scenario [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1188-1195. |

| [13] | Hong-yan GUO,Lian-bing WANG,Xu ZHAO,Qi-kun DAI. Joint estimation of vehicle mass and road slope considering lateral motion [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1175-1187. |

| [14] | Yu-kai LU,Shuai-ke YUAN,Shu-sheng XIONG,Shao-peng ZHU,Ning ZHANG. High precision detection system for automotive paint defects [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1205-1213. |

| [15] | Shao-hua WANG,Qi-rui ZHANG,De-hua SHI,Chun-fang YIN,Chun LI. Analysis of nonlinear vibration response characteristics of hybrid transmission system with dual-planetary gear sets [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(4): 890-901. |

|

||