Journal of Jilin University(Engineering and Technology Edition) ›› 2022, Vol. 52 ›› Issue (4): 970-980.doi: 10.13229/j.cnki.jdxbgxb20200882

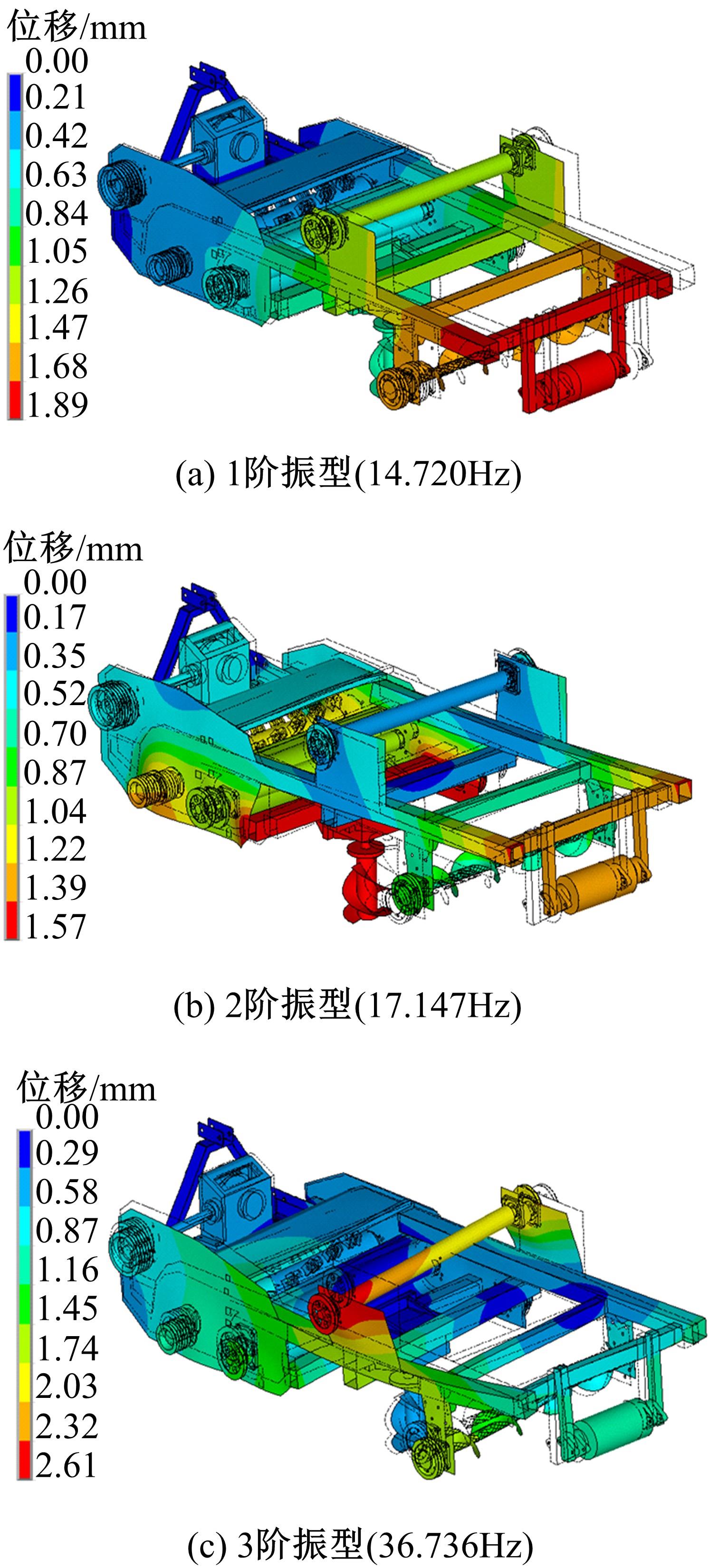

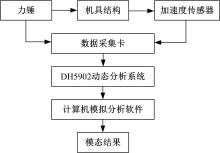

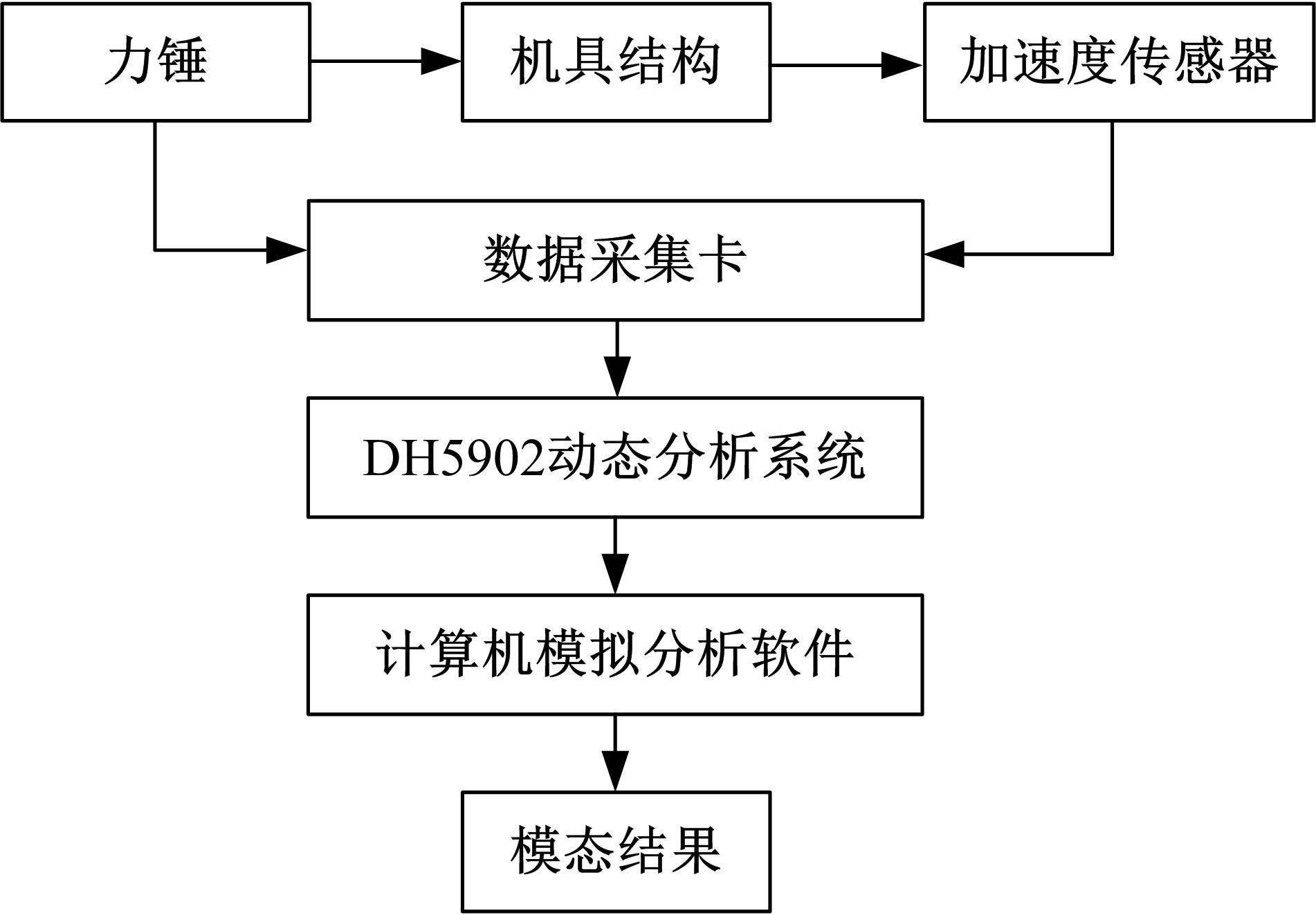

Vibration characteristics analysis and structural optimization of straw deep bury and returning machine

Wen-ying GAO( ),Jing LIN(

),Jing LIN( ),Bao-fa LI,Wei WANG,Shi-yan GU

),Bao-fa LI,Wei WANG,Shi-yan GU

- College of Engineering,Shenyang Agricultural University,Shenyang 110866,China

CLC Number:

- S222.4

| 1 | 田国成, 王钰, 孙路, 等. 秸秆焚烧对土壤有机质和氮磷钾含量的影响[J]. 生态学报, 2016, 36(2): 387-393. |

| Tian Guo-cheng, Wang Yu, Sun Lu, et al. Effects of wheat straw burning on content of soil organic matter, nitrogen, phosphorus and potassium[J]. Acta Ecologica Sinica, 2016, 36(2): 387-393. | |

| 2 | Chen J, Zheng M, Pang D, et al. Straw return and appropriate tillage method improve grain yield and nitrogen efficiency of winter wheat[J]. Journal of Integrative Agriculture, 2017, 16(8): 1708-1719. |

| 3 | Pureta V L, Pereira E I P, Wittwer R, et al. Improvement of soil structure through organic crop management conservation tillage and grass-clover ley[J]. Soil and Tillage Research, 2018, 180: 1-9. |

| 4 | 刘卉, 周清明, 黎娟. 秸秆还田对土壤改良及作物生长影响的研究进展[J]. 中国农学报, 2017, 33(32): 53-57. |

| Liu Hui, Zhou Qing-ming, Li Juan. Effect of straw returning on soil improvement and crop grows: research progress[J]. Chinese Agricultural Science Bulletin, 2017, 33(32): 53-57. | |

| 5 | Yang H S, Xu M M, Koide R T, et al. Effects of ditch-buried straw return on water percolation, nitrogen leaching and crop yields in a rice-wheat rotation system[J]. Journal of the Science of Food and Agriculture, 2016, 96(4): 1141-1149. |

| 6 | 王金武, 唐汉, 王金峰. 东北地区作物秸秆资源综合利用现状与发展分析[J]. 农业机械学报, 2017, 48(5) :1-21. |

| Wang Jin-wu, Tang Han, Wang Jin-feng. Comprehensive utilization status and development analysis of crop straw resource in Northeast China[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(5): 1-21. | |

| 7 | 韩瑞芸, 陈哲, 杨世琦. 秸秆还田对土壤氮磷及水土的影响研究[J]. 中国农学通报, 2016, 32(9): 148-154. |

| Han Rui-yun, Chen Zhe, Yang Shi-qi. Effect of straw-returning on nitrogen and phosphorus and water of soil[J]. Chinese Agricultural Science Bulletin, 2016, 32(9): 148-154. | |

| 8 | 宋健鹏, 林静, 马铁, 等. 旋转锹式玉米秸秆深埋还田机的设计[J]. 农机化研究, 2018, 40(2): 95-99. |

| Song Jian-peng, Lin Jing, Ma Tie, et al. Design and test rotating spade type maize straw returning root deep machine[J]. Journal of Agricultural Mechanization Research, 2018, 40(2): 95-99. | |

| 9 | 王金武, 王奇, 唐汉, 等. 水稻秸秆深埋整秆还田装置设计与试验[J]. 农业机械学报, 2015, 46(9): 112-117. |

| Wang Jin-wu, Wang Qi, Tang Han, et al. Design and experiment of rice straw deep buried and wholestraw returning device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(9): 112-117. | |

| 10 | 李真. 玉米整秆深埋还田试验[J]. 山西农业科学, 2014, 42(4): 349-352. |

| Li Zhen. Experiment of whole maize straw returned to deep furrow and buried under ridge[J]. Journal of Shanxi Agricultural Sciences, 2014, 42(4): 349-352. | |

| 11 | 王川, 邵陆寿, 施六林, 等. 秸秆深埋保护性耕作复合机具设计[J]. 中国农机化学报, 2014, 35(1): 117-120. |

| Wang Chuan, Shao Lu-shou, Shi Liu-lin, et al. Design of compound equipment with the deep straw and conservation tillage[J]. Journal of Chinese Agricultural Mechanization, 2014, 35(1): 117-120. | |

| 12 | 李永磊, 宋建农, 康小军, 等. 双辊秸秆还田旋耕机试验[J]. 农业机械学报, 2013, 44(6): 45-49. |

| Li Yong-lei, Song Jian-nong, Kang Xiao-jun, et al. Experiment on twin-roller cultivator for straw returning[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(6): 45-49. | |

| 13 | 章志强,何进,李洪文,等. 可调节式秸秆粉碎抛撒还田机设计与试验[J]. 农业机械学报, 2017, 48(9): 76-87. |

| Zhang Zhi-qiang, He Jin, Li Hong-wen, et al. Design and experiment on straw chopper cum spreader with adjustable spreading device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(9): 76-87. | |

| 14 | 王瑞丽, 杨鹏, Rabiu F J, 等. 秸秆深埋还田开沟灭茬机设计与试验[J]. 农业工程学报, 2017, 33(5): 40-47. |

| Wang Rui-li, Yang Peng, Rabiu F J, et al. Designand experiment of combine machine for deep furrowing, stubble, chopping, returning and burying of chopped straw[J]. Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(5): 40-47. | |

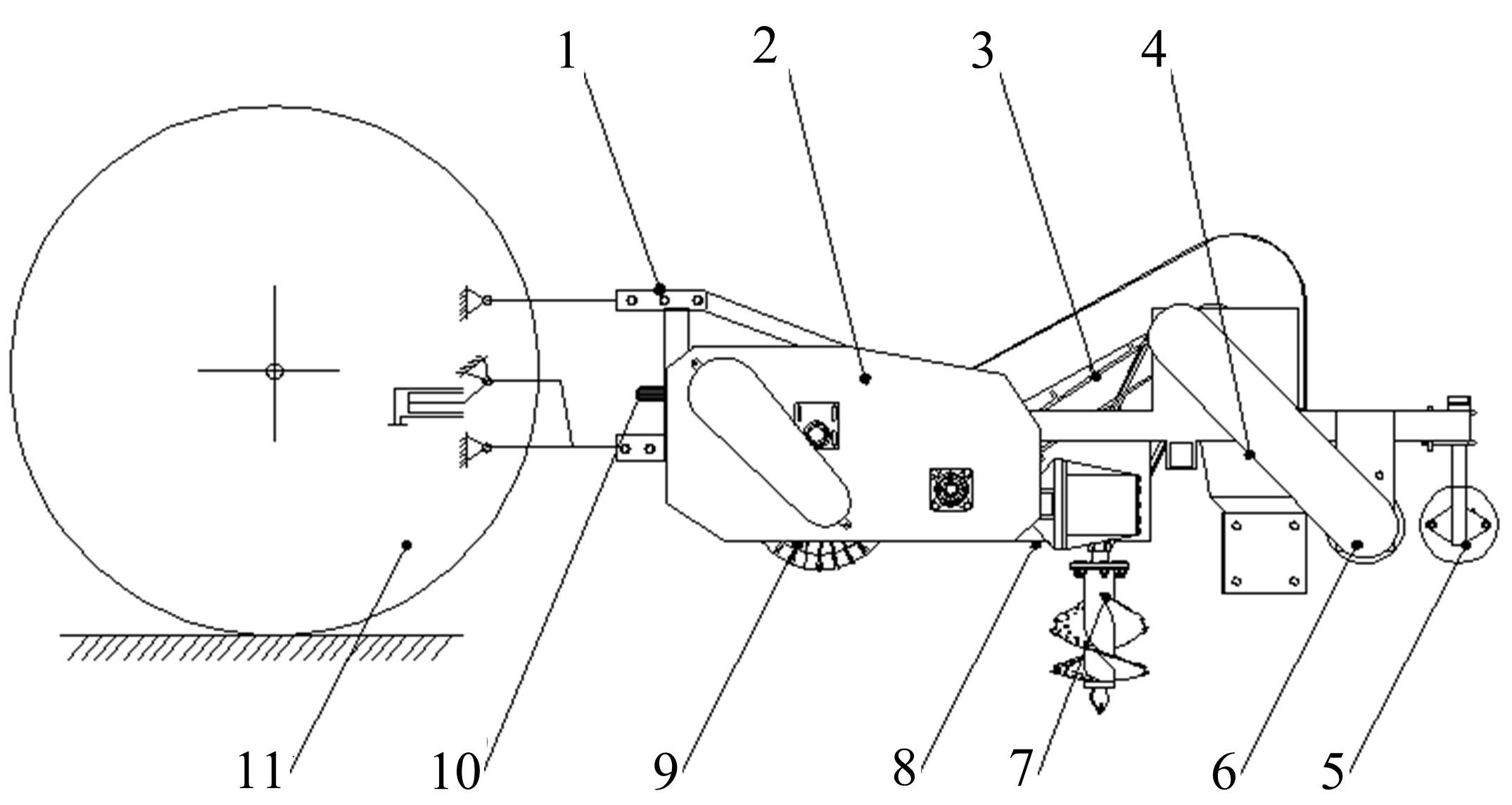

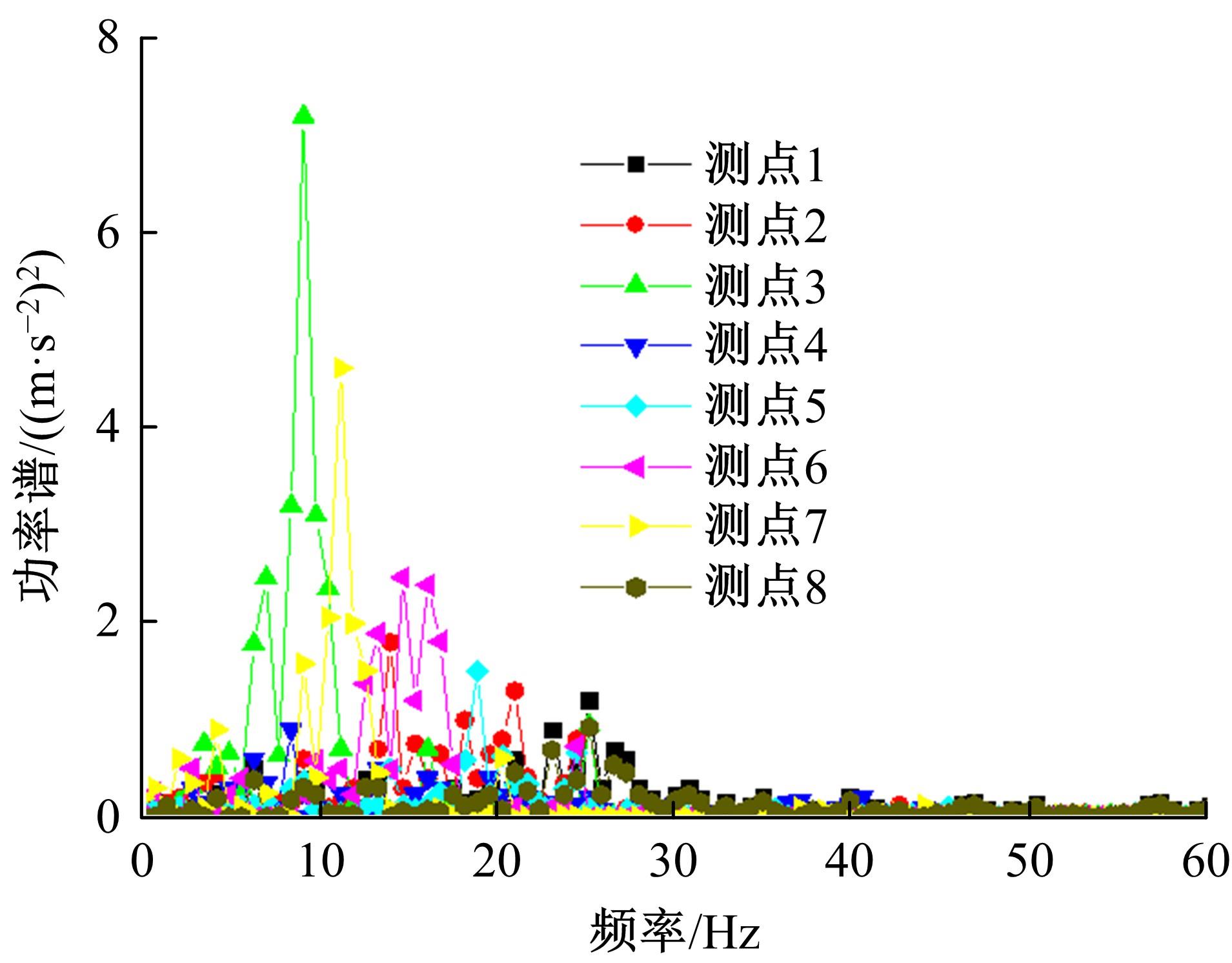

| 15 | 林静, 马铁, 李宝筏. 1JHL-2型秸秆深埋还田机设计与试验[J]. 农业工程学报, 2017, 33(20): 32-40. |

| Lin Jing, Ma Tie, Li Bao-fa. Design of 1 JHL-2 typestraw deep bury and returning machine[J]. Transactionsof the Chinese Society of Agricultural Engineering, 2017, 33(20): 32-40. | |

| 16 | 林静, 马铁, 高文英, 等. 秸秆深埋还田机螺旋开沟装置的设计与试验[J] .沈阳农业大学学报,2018, 49(1): 41-48. |

| Lin Jing, Ma Tie, Gao Wen-ying, et al. Design and experiment of spiral milling cutter device of straw deep bury and returning machine [J]. Journal of Shenyang Agricultural University, 2018, 49(1): 41-48. | |

| 17 | 姚艳春, 赵雪彦, 杜岳峰, 等. 考虑质量时变的收获机械工作模态分析与试验[J]. 农业工程学报, 2018, 34(9): 83- 94. |

| Yao Yan-chun, Zhao Xue-yan, Du Yue-feng, et al. Operating modal analysis and test of harvester induced by mass-varying process[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(9): 83-94. | |

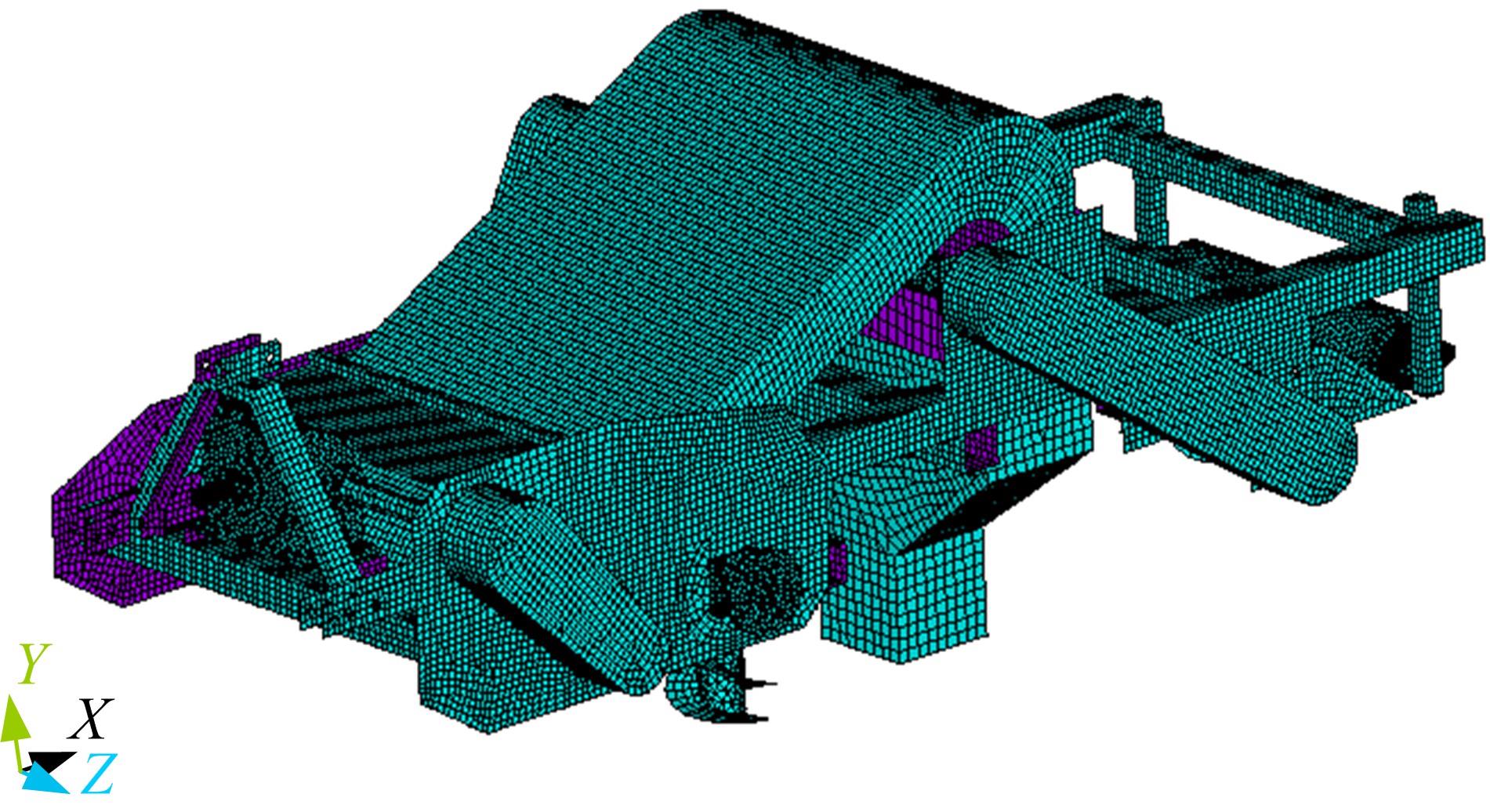

| 18 | 李耀明, 孙朋朋, 庞靖, 等. 联合收获机底盘机架有限元模态分析与试验[J]. 农业工程学报, 2013, 29(3): 38-46. |

| Li Yao-ming, Sun Peng-peng, Pang Jing, et al. Finite element mode analysis and experiment of combine harvester chassis[J]. Transactions of the Chinese Society of Agricultural Engineering, 2013, 29(3): 38-46. | |

| 19 | 徐立章, 李耀明, 孙朋朋, 等. 履带式全喂入水稻联合收获机振动测试与分析[J]. 农业工程学报, 2014, 30(8): 49-55. |

| Xu Li-zhang, Li Yao-ming, Sun Peng-peng, et al. Vibration measurement and analysis of tracked-whole feeding rice combine harvester[J]. Transactions of the Chinese Society of Agricultural Engineering, 2014, 30(8): 49-55. | |

| 20 | 姚艳春, 宋正河, 杜岳峰, 等. 玉米收获机车架应力及模态数值模拟焊点模型优选[J]. 农业工程学报, 2016, 32(24): 50-58. |

| Yao Yan-chun, Song Zheng-he, Du Yue-feng, et al. Optimum seeking of spot weld model on numerical simulation of stress and modal analysis for corn combine harvester frame[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(24): 50-58. | |

| 21 | 王奇, 朱龙图, 李名伟, 等. 指夹式玉米免耕精密播种机振动特性及对排种性能的影响[J]. 农业工程学报, 2019, 35(9): 9-18. |

| Wang Qi, Zhu Long-tu, Li Ming-wei, et al. Vibration characteristics of corn no-tillage fillage finger-type precision planter and its effect on seeding performance [J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(9): 9-18. | |

| 22 | 张佳喜, 杨程, 张丽, 等. 玉米起茬机构的强度及振动特性分析与试验[J]. 农业工程学报, 2018, 34(12): 72-78. |

| Zhang Jia-xi, Yang Cheng, Zhang Li, et al. Analysis and experiment on strength and vibration characteristics of corn stubble plucking mechanism[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(12): 72-78. | |

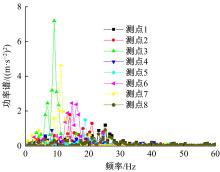

| 23 | 高志朋, 徐立章, 李耀明, 等. 履带式稻麦联合收获机田间收获工况下振动测试与分析[J]. 农业工程学报, 2017, 33(20): 48-55. |

| Gao Zhi-peng, Xu Li-zhang, Li Yao-ming, et al. Vibr-ation measure and analysis of crawler-type rice and wheat combine harvester in field harvesting condition[J]. Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(20): 48-55. | |

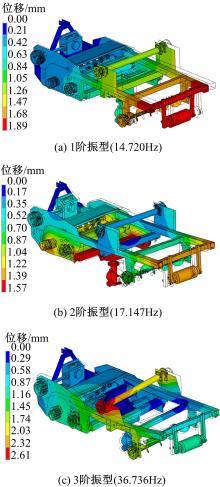

| 24 | 姚艳春, 杜岳峰, 朱忠祥, 等. 基于模态的玉米收获机车架振动特性分析与优化[J]. 农业工程学报, 2015, 31(19): 46-53. |

| Yao Yan-chun, Du Yue-feng, Zhu Zhong-xiang, et al. Vibration characteristics analysis and optimization of corn combine harvester frame using modal analysis method[J]. Transactions of the Chinese Society of Agricultural Engineering, 2015, 31(19): 46-53. | |

| 25 | 高文英, 林静, 李宝筏, 等. 玉米秸秆深埋还田机螺旋开沟装置参数优化与试验[J]. 农业机械学报, 2018, 49(9): 45-54. |

| Gao Wen-ying, Lin Jing, Li Bao-fa, et al. Parameter optimization and experiment for spiral type opener device of maize straw deep bury and returning machine[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(9): 45-54. | |

| 26 | 刘习军, 贾启芬, 张素侠. 振动理论及工程应用[M]. 北京:机械工业出版社, 2017. |

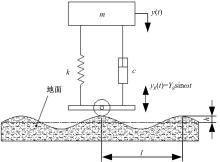

| 27 | 张晓冬,李成华,李建桥,等. 铲式玉米精密播种机振动特性模型建立与试验[J]. 农业机械学报, 2014, 45(2): 88-93. |

| Zhang Xiao-dong, Li Cheng-hua, Li Jian-qiao, et, al. Mathematic vibration model of spade punch planter of maize [J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(2): 88-93. |

| [1] | Jie LI,Tao CHEN,Wen-cui GUO,Qi ZHAO. Pseudo excitation method of vehicle non-stationary random vibration in space domain and its application [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 738-744. |

| [2] | Xue-mei LI,Chun-yang WANG,Xue-lian LIU,Da XIE. Time delay estimation of linear frequency-modulated continuous-wave lidar signals via SESTH [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 950-958. |

| [3] | Jian-po LI,Mei-lin LI,Tao YANG,Peng XUE. Low-complexity Wiener filter channel estimation algorithm in massive MIMO-OFDM system [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 211-218. |

| [4] | Chang-jun ZHONG,Zhong-bin WANG,Chen-yang LIU. Influencing factors and structural optimization of main cable saddle bearing capacity of suspension bridge [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 2068-2078. |

| [5] | Rong-qing LIANG,Bo ZHONG,He-wei MENG,Zhi-min SUN,Za KAN. Design of 4QJ⁃3 type pickup header of silage oat [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1887-1896. |

| [6] | Hong-wei ZHAO,Zi-jian ZHANG,Jiao LI,Yuan ZHANG,Huang-shui HU,Xue-bai ZANG. Bi⁃direction segmented anti⁃collision algorithm based on query tree [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1830-1837. |

| [7] | Jia-cheng YUAN,Chang WANG,Kun HE,Xing-yu WAN,Qing-xi LIAO. Effect of components mass ratio under sieve on cleaning system performance for rape combine harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1897-1907. |

| [8] | Hai-bin WEI,Xiang-yan WANG,Fu-yu WANG,Yong ZHANG. Mechanical properties and micro analysis of AC-25 asphalt mixture based on vibration forming [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1269-1276. |

| [9] | Jian YANG,Qi XIA,Hai-chao ZHOU,Guo-lin WANG. Noise reduction mechanism of truck radial tire based on modified carcass string contour design [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1198-1203. |

| [10] | Wei LI,Huai-liang ZHANG,Wei QU. Design method of hydraulic straight pipe under random vibration [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1222-1229. |

| [11] | Ping YU,Te MU,Li-hui ZHU,Zi-ye ZHOU,Jie SONG. Nonlinear dynamic analysis and stability control of drilling tool conveying mechanism [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 820-830. |

| [12] | Qing-wen KONG,Guo-jin TAN,Long-lin WANG,Yong WANG,Zhi-gang WEI,Han-bing LIU. Analysis of free vibration characteristics of cracked box girder bridge based on finite element method [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 225-232. |

| [13] | Ming-wei HU,Hong-guang WANG,Xin-an PAN. Global structural optimization design of collaborative robots using orthogonal design [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 370-378. |

| [14] | Fang-wu MA,Li HAN,Liang WU,Jin-hang LI,Long-fan YANG. Damping optimization of heavy⁃loaded anti⁃vibration platform based on genetic algorithm and particle swarm algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1608-1616. |

| [15] | Hao-tian WU,Rui-feng GUO,A-zhen PENG,Pin WANG. A low power scheduling algorithm based on constant bandwidth server considering reliability [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1802-1808. |

|

||