Journal of Jilin University(Engineering and Technology Edition) ›› 2021, Vol. 51 ›› Issue (4): 1269-1276.doi: 10.13229/j.cnki.jdxbgxb20200235

Mechanical properties and micro analysis of AC-25 asphalt mixture based on vibration forming

Hai-bin WEI1( ),Xiang-yan WANG1,Fu-yu WANG1(

),Xiang-yan WANG1,Fu-yu WANG1( ),Yong ZHANG2

),Yong ZHANG2

- 1.College of Transportation,Jilin University,Changchun 130022,China

2.Jilin Province Highway Group Co. ,Ltd. ,Changchun 130025,China

CLC Number:

- U414

| 1 | Corum D K. Designing asphalt concrete mixes which are more readily compacted[J]. Journal of the Association of Asphalt Paving Technologists, 1998, 59(1): 341-359. |

| 2 | 杜群乐. 沥青路面损坏分析与GTM混合料设计方法的研究[D]. 上海: 同济大学交通运输工程学院, 2006. |

| Du Qun-le. Distress analysis of asphalt pavement and research on GTM design method of asphalt mixture[D]. Shanghai: School of Transportation Engineering, Tongji University, 2006. | |

| 3 | 陈浙江. 重交通道路沥青混合料压实标准及评价[J]. 交通标准化, 2014(1): 55-58. |

| Chen Zhe-jiang. Compaction criterion and evaluation of asphalt mixture for heavy-traffic road[J]. Transportation Standardization, 2014(1): 55-58. | |

| 4 | 姚林虎. 沥青混合料试件垂直振动成型方法研究[D].西安: 长安大学公路学院, 2012. |

| Yao Lin-hu. Research on vertical vibrocompression testing method for asphalt mixture specimen[D]. Xi'an: School of Highway, Chang'an University, 2012. | |

| 5 | 梁慧. ATB-30沥青混合料试件VTM方法及设计方法研究[D]. 西安: 长安大学材料科学与工程学院, 2013. |

| Liang Hui. Study on vertical vibration testing method and designing method for ATB-30 asphalt mixture[D]. Xi'an: School of Materials Science and Engineering, Chang'an University, 2013. | |

| 6 | Ksosla N P, Sadasivam S. Evaluation of the effects of mixture properties and compaction methods on the predicted performance of superpave mixtures[Z].Transportation Research Board, 2002:00980094. |

| 7 | 解晓光,马松林,王哲人. 沥青混合料马歇尔击实法与振动压实法成型工艺的比较研究[J]. 中国公路学报, 2001, 14(1): 9-12. |

| Xie Xiao-guang, Ma Song-lin, Wang Zhe-ren. Study of compacting properties of asphalt mixturewith MARSHALL and vibratory compaction method[J]. China Journal of Highway and Transport, 2001, 14(1): 9-12. | |

| 8 | 蒋应军,孔令飞,陈浙江. ATB-30沥青混合料VVCM与马歇尔设计对比[J]. 公路交通科技, 2015, 32(6): 6-11. |

| Jiang Ying-jun, Kong Ling-fei, Chen Zhe-jiang. Comparison of VVCM and Marshall method for ATB-30 asphalt mixture design[J]. Journal of Highway and Transportation Research and Development, 2015, 32(6): 6-11. | |

| 9 | 张毅,薛金顺,陈浙江,等. 成型方法对ATB-30混合料性能的影响[J]. 公路交通科技, 2014, 31(10): 1-6. |

| Zhang Yi, Xue Jin-shun, Zhang Zhe-jiang, et al. Effect of compaction methods on performance of ATB-30 asphalt mixture[J]. Journal of Highway and Transportation Research and Development, 2014, 31(10): 1-6. | |

| 10 | 薛金顺. SMA混合料振动压实试验方法及设计关键技术[D]. 西安: 长安大学公路学院, 2018. |

| Xue Jin-shun. Research on vertical vibration test method and key technology of SMA mixture[D]. Xi'an: School of Highway, Chang'an University, 2018. | |

| 11 | Ali Aslam, Mufleh Al Omari. Analysis of HMA permeability through microstructure characterization and simulation of fluid flow in X-ray CT images[D]. Texas A&M University, 2004. |

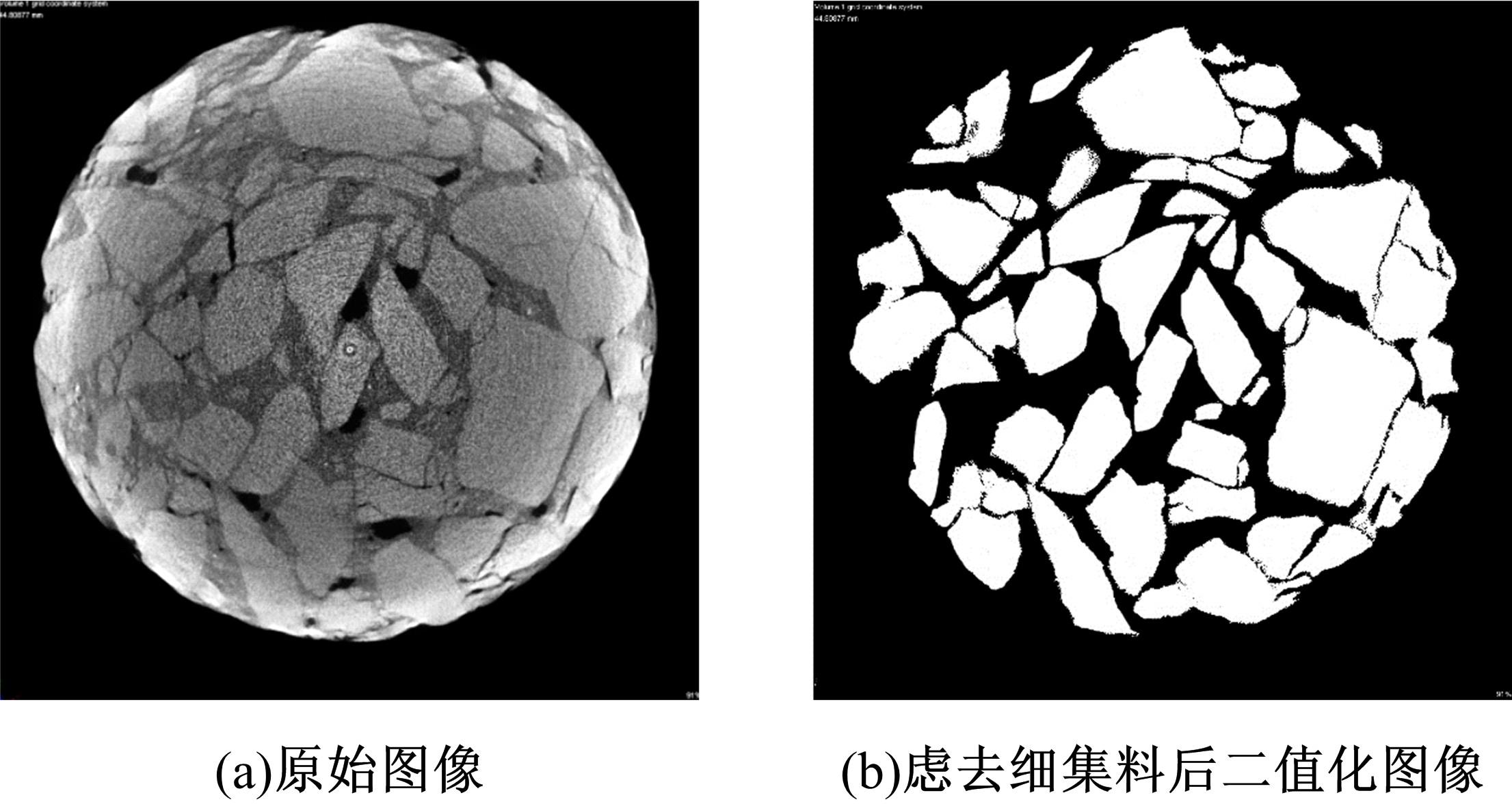

| 12 | 段跃华,张肖宁,李智,等. 基于工业 CT 的混凝土集料二维及三维轮廓表征方法[J]. 中国公路学报, 2011, 24(6): 9-15. |

| Duan Yue-hua, Zhang Xiao-ning, Li Zhi, et al. Methods about digital representation on surface profile of concrete aggregates from 2-D to 3-D based on X-ray computed tomography[J]. China Journal of Highway and Transport, 2011, 24(6): 9-15. | |

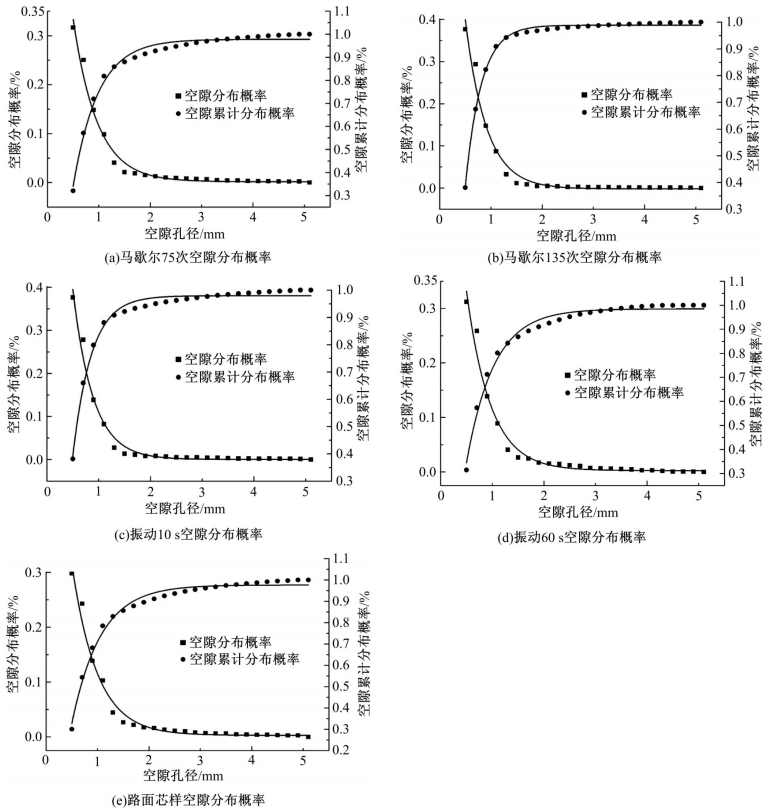

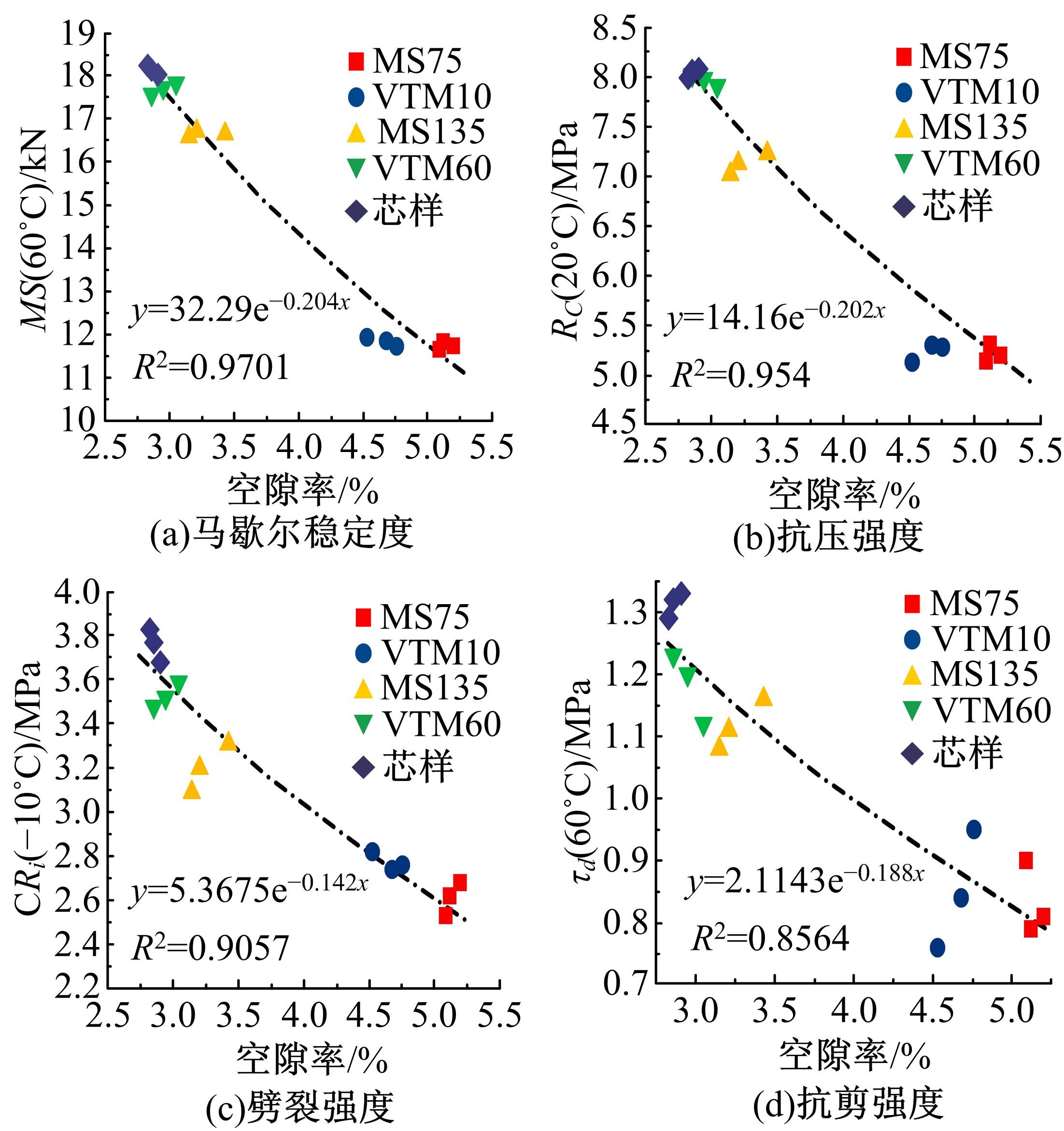

| 13 | 易富, 金艳, 苏剑. 两种压实方法下沥青混合料空隙分布特性细观分析[J]. 公路交通科技, 2014, 31(3): 26-31. |

| Yi Fu, Jin Yan, Su Jian. Mesoscopic analysis of air void distribution of asphalt mixture in two compaction methods[J]. Journal of Highway and Transportation Research and Development, 2014, 31(3): 26-31. | |

| 14 | 任俊达. 基于X-ray CT沥青混合料细观结构及力学性能研究[D]. 哈尔滨:哈尔滨工业大学交通运输工程学院, 2014. |

| Ren Jun-da. Research on mesoscopic structure and mechanical properties of asphalt mixture based on X-ray CT[D]. Harbin: School of Transportation Engineering, Harbin Institute of Technology, 2014. |

| [1] | Han-bing LIU,Xin GAO,Ya-feng GONG,Shi-qi LIU,Wen-jun LI. Influence of surface treatment on basalt fiber reactive powder concrete mechanical properties and fracture characteristics [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 936-945. |

| [2] | Yong PENG,Han-duo YANG,Xue-yuan LU,Yan-wei LI. Effect of void characteristics on virtual shear fatigue life of asphalt mixtures using discrete element method [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 956-964. |

| [3] | Yong-chun CHENG,He LI,Li-ding LI,Hai-tao WANG,Yun-shuo BAI,Chao CHAI. Analysis of mechanical properties of asphalt mixture affected by aggregate based on grey relational degree [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 925-935. |

| [4] | Jin-guo WANG,Zhi-qiang WANG,Shuai REN,Rui-fang YAN,Kai HUANG,Jin GUO. Effect of Ti addition on microstructure and mechanical properties of ductile iron [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1653-1662. |

| [5] | Hong-liang XIANG,Sheng-tao CHEN,Li-ping DENG,Wei ZHANG,Tu-sheng ZHAN. Microstructure and properties of microalloying 2205 duplex stainless steel [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1645-1652. |

| [6] | Ming LI,Hao-ran WANG,Wei-jian ZHAO. Experimental of loading-bearing capacity of one-way laminated slab with shear keys [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 654-667. |

| [7] | Chun-feng ZHU,Yong-chun CHENG,Chun-yu LIANG,Bo XIAO. Road performance experiment of diatomite⁃basalt fiber composite modified asphalt mixture [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 165-173. |

| [8] | Ying WANG,Ping LI,Teng-fei NIAN,Ji-bin JIANG. Short-term water damage characteristics of asphalt mixture based on dynamic water scour effect [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 174-182. |

| [9] | Xin TONG,Ya-jiao ZHANG,Yu-shan HUANG,Zheng-zheng HU,Qing WANG,Zhi-hui ZHANG. Microstructure and mechanical properties of 304L stainless steel processed by selective laser melting [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1615-1621. |

| [10] | Yong PENG,Hua GAO,Lei WAN,Gui-ying LIU. Numerical simulation of influence factors of splitting strength of asphalt mixtures [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1521-1530. |

| [11] | Ming LI,Hao-ran WANG,Wei-jian ZHAO. Mechanical properties of laminated slab with shear keys [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1509-1520. |

| [12] | Na WU,Jian ZHUANG,Ke⁃song ZHANG,Hui⁃xin WANG,Yun⁃hai MA. Compression mechanical properties and fracture mechanism of Scapharca Subcrenata shell [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 897-902. |

| [13] | JIANG Qiu-yue,YANG Hai-feng,TAN Cai-wang. Strengthening properties of welded joints of 22MnB5 super high strength steel [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1806-1810. |

| [14] | LUO Rong, ZENG Zhe, ZHANG De-run, FENG Guang-le, DONG Hua-jun. Moisture stability evaluation of asphalt mixture based on film pressure model of Wilhelmy plate method [J]. 吉林大学学报(工学版), 2017, 47(6): 1753-1759. |

| [15] | SI Wei, MA Biao, REN Jun-ping, WANG Hai-nian, GE-Sang Ze-ren. Analysis of asphalt pavement performance under freeze-thaw cycles using reliability method [J]. 吉林大学学报(工学版), 2016, 46(1): 126-132. |

|

||