Journal of Jilin University(Engineering and Technology Edition) ›› 2022, Vol. 52 ›› Issue (2): 409-416.doi: 10.13229/j.cnki.jdxbgxb20211148

Optimal design of acceleration test of motorized spindle of numerical control Machine Tool considering parameter weight

Hong-xun ZHAO1,2( ),Zhao-jun YANG1,2,Chuan-hai CHEN1,2,3(

),Zhao-jun YANG1,2,Chuan-hai CHEN1,2,3( ),Hai-long TIAN1,2,Li-ping WANG4

),Hai-long TIAN1,2,Li-ping WANG4

- 1.Key Laboratory of Numerical Control Equipment Reliability,Ministry of Education,Jilin University,Changchun 130022,China

2.College of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

3.Chongqing Research Institute,Jilin University,Chongqing 400037,China

4.Department of Mechanical Engineering,Tsinghua University,Beijing 100084,China

CLC Number:

- TH17

| 1 | 杨兆军, 陈传海, 陈菲, 等. 数控机床可靠性技术的研究进展[J].机械工程学报, 2013, 49(20): 130-139. |

| Yang Zhao-jun, Chen Chuan-hai, Chen Fei, et al. Progress in the research of reliability technology of machine tools[J]. Journal of Mechanical Engineering, 2013, 49(20): 130-139. | |

| 2 | 杨佐卫, 殷国富, 尚欣, 等. 高速电主轴热态特性与动力学特性耦合分析模型[J]. 吉林大学学报: 工学版, 2011, 41(1): 100-105. |

| Yang Zuo-wei, Yin Guo-fu, Shang Xin, et al. Coupling analysis model of thermal and dynamic characteristics of high-speed motorized spindle[J]. Journal of Jilin University(Engineering and Technology Edition), 2011, 41(1): 100-105. | |

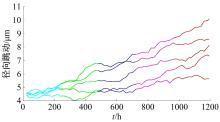

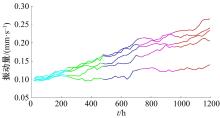

| 3 | 郑玉彬, 杨斌, 王晓峰, 等. 基于威布尔分布的电主轴加速寿命试验时间设计[J]. 吉林大学学报: 工学版, 2018, 48(3): 767-772. |

| Zheng Yu-bin, Yang Bin, Wang Xiao-feng, et al. Design of accelerated life test time of motorized spindle based on weibull distribution[J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(3): 767-772. | |

| 4 | Nelson W. Analysis of performance degradation data from accelerated tests[J]. IEEE Transactions on Reliability, 1981, 30(2): 149-155. |

| 5 | Nelson W. Accelerated Testing: Statistical Methods, Test Plans, and Data Analysis[M]. New York: John Wiley Press, 1990. |

| 6 | 葛蒸蒸, 姜同敏, 韩少华, 等. 基于D优化的多应力加速退化试验设计[J]. 系统工程与电子技术, 2012, 34(4): 846-853. |

| Ge Zheng-zheng, Jiang Tong-min, Han Shao-hua,et al. Design of accelerated degradation testing with multiple stresses based on D optimality[J]. Systems Engineering and Electronic Technology, 2012, 34(4): 846-853. | |

| 7 | 韩少华, 葛蒸蒸, 姜同敏, 等. 基于D优化方法的CSADT设计[J]. 装备环境工程, 2012, 9(4): 82-87. |

| Han Shao-hua, Ge Zheng-zheng, Jiang Tong-min, et al. CSADT design based on D optimization method [J]. Equipment Environmental Engineering, 2012, 9(4): 82-87. | |

| 8 | Zhang C F, Shi Y. Optimum simple accelerated life tests based on progressively Type-I hybrid censoring[J]. International Journal of System Assurance Engineering and Management, 2017, 8(2): 849-856. |

| 9 | Huang T, Jiang T. Optimum design of equivalent accelerated life testing plans based on proportional hazards-proportional odds model[J]. Journal of Systems Engineering and Electronics, 2011, 22: 871-878. |

| 10 | Toyoda M, Shen T. A receding horizon D-optimization approach for model identification-oriented input design and application in combustion engines[J]. Applied Mathematical Modelling, 2017, 42: 175-187. |

| 11 | Zhang C, Wang S, Wang Z, et al. An accelerated life test model for harmonic drives under a segmental stress history and its parameter optimization[J]. Chinese Journal of Aeronautics, 2015, 28(6):1758-1765. |

| 12 | 李晓旭. 加工中心主轴系统可靠性综合应力加速模型研究[D]. 长春: 吉林大学机械与航空航天工程学院, 2019. |

| Li Xiao-xu. Study on reliability comprehensive stress acceleration model of spindle system of machining center[D]. Changchun: College of Mechanical and Aerospace Engineering, Jilin University, 2019. | |

| 13 | 程云鹏. 矩阵论[M]. 西安: 西北工业大学出版社,2006. |

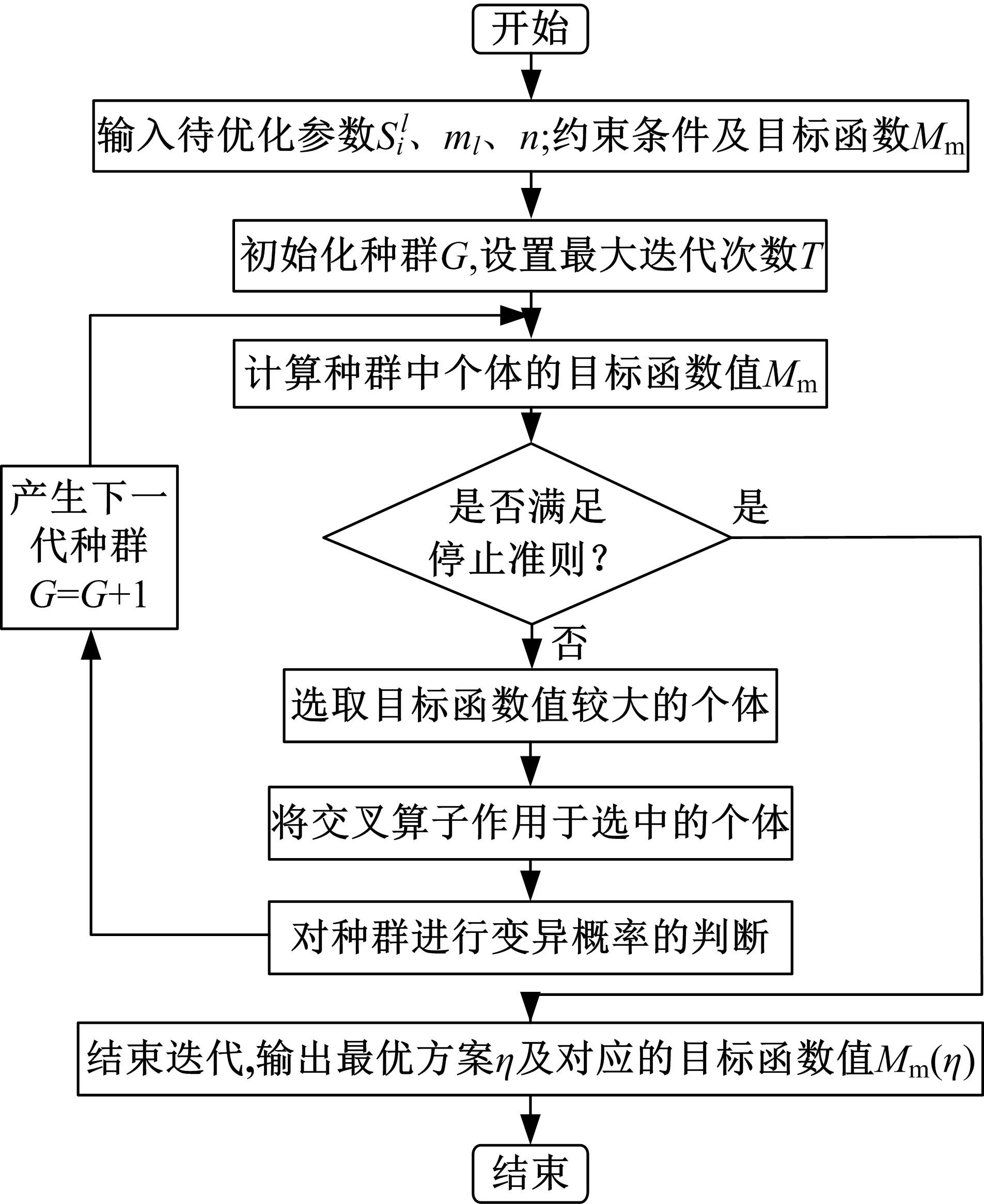

| 14 | Holland J. Adaptation in Natural and Artificial Systems[M]. Cambridge, MA: MIT Press, 1992. |

| 15 | 鲍俊. 基于步进双应力加速退化试验的电主轴可靠性建模研究[D]. 长春: 吉林大学机械与航空航天工程学院, 2018. |

| Bao Jun. Research on reliability modeling of motorized spindle based on stepping double stress accelerated degradation test[D]. Changchun: School of Mechanical and Aerospace Engineering, Jilin University, 2018. | |

| 16 | 蔡忠义, 陈云翔, 张诤敏, 等. 非线性步进加速退化数据的可靠性评估方法[J]. 北京航空航天大学学报, 2016, 42(3): 576-582. |

| Cai Zhong-yi, Chen Yun-xiang, Zhang Zheng-min, et al. Reliability assessment method of nonlinear step-stress accelerated degradation data[J]. Journal of Beijing University of Aeronautics and Astronautics, 2016, 42(3): 576-582. |

| [1] | Xin-tian LIU,Mu-zhou MA,Jia-long HE. Reliability prediction method of machining precision of machine tool parts based on fuzzy coupling [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 377-383. |

| [2] | Li-jie ZHANG,Xi-ta A,Xiao TIAN,Wen LI. Multi⁃objective optimization design of accelerated degradation test based on Gamma process [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 361-367. |

| [3] | Chuan-hai CHEN,Cheng-gong WANG,Zhao-jun YANG,Zhi-feng LIU,Hai-long TIAN. Research status and development trend analysis of reliability modeling of CNC machine tools [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 253-266. |

| [4] | Li-ping WANG,Bin ZHU,Jun WU,Zi-han TAO. Fault analysis of circular tool magazine based on Bayesian network [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 280-287. |

| [5] | Zi-ling ZHANG,Xiong HU,Yin QI,Wei WANG,Zhi-qiang TAO,Zhi-feng LIU. An approach for error allocation of machine tool based on vector projection response surface method [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 384-391. |

| [6] | Xue-ping FAN,Guang-hong YANG,Zhi-peng SHANG,Xiao-xiong ZHAO,Qing-kai XIAO,Yue-fei LIU. Dynamic reliability fusion prediction of long-span bridge girder considering structural serviceability [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 144-153. |

| [7] | Guo-fa LI,Ze-quan CHEN,Jia-long HE. New adaptive sampling strategy for structural reliability analysis [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 1975-1981. |

| [8] | Zun-ling DU,Yi-min ZHANG. Reliability analysis of piston pump under random flow rate [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 1967-1974. |

| [9] | Xue-ping FAN,Guang-hong YANG,Qing-kai XIAO,Yue-fei LIU. Optimal R-vine copula information fusion for failure probability analysis of long-span bridge girder [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1296-1305. |

| [10] | Hao-tian WU,Rui-feng GUO,A-zhen PENG,Pin WANG. A low power scheduling algorithm based on constant bandwidth server considering reliability [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1802-1808. |

| [11] | Qiao-bin LIU,Wen-ku SHI,Zhi-yong CHEN,Lian-meng LUO,Zhi-yong SU,Kai-jun HUANG. Parameter estimation of mixed reliability model based on kernel density optimal grouping and gravity search algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1818-1825. |

| [12] | GUO Hao-tian,XU Tao,LIANG Xiao,YU Zheng-lei,LIU Huan,MA Long. Optimization on thermal surface with rib turbulator inspired by turbulence of alopias' gill in simplified gas turbine transition piece [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1793-1798. |

| [13] | YU Fan-hua, LIU Ren-yun, ZHANG Yi-min, ZHANG Xiao-li, SUN Qiu-cheng. Swarm intelligence algorithm of dynamic reliability-based robust optimization design of mechanic components [J]. 吉林大学学报(工学版), 2017, 47(6): 1903-1908. |

| [14] | WU Jiao-rong, WANG Yu-qin, WEI Ming, LIN Bin. Impact of length of road-side bus lane on bus operational reliability [J]. 吉林大学学报(工学版), 2017, 47(1): 82-91. |

| [15] | ZHANG Ying-zhi, LIU Jin-tong, SHEN Gui-xiang, QI Xiao-yan, LONG Zhe. Reliability modeling of CNC machine tools system based on failure correlation analysis [J]. 吉林大学学报(工学版), 2017, 47(1): 169-173. |

|

||