Journal of Jilin University(Engineering and Technology Edition) ›› 2019, Vol. 49 ›› Issue (4): 1081-1091.doi: 10.13229/j.cnki.jdxbgxb20180246

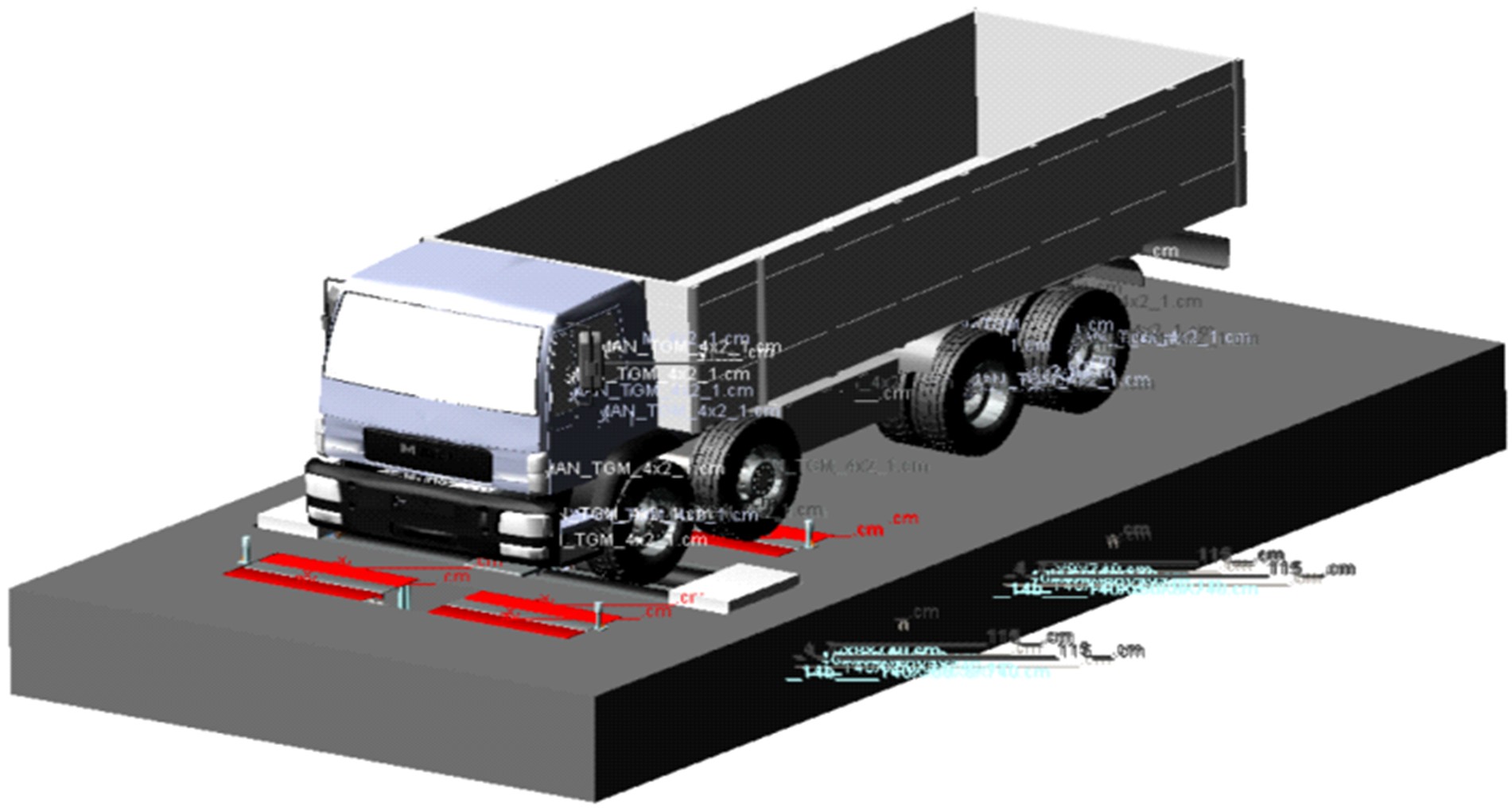

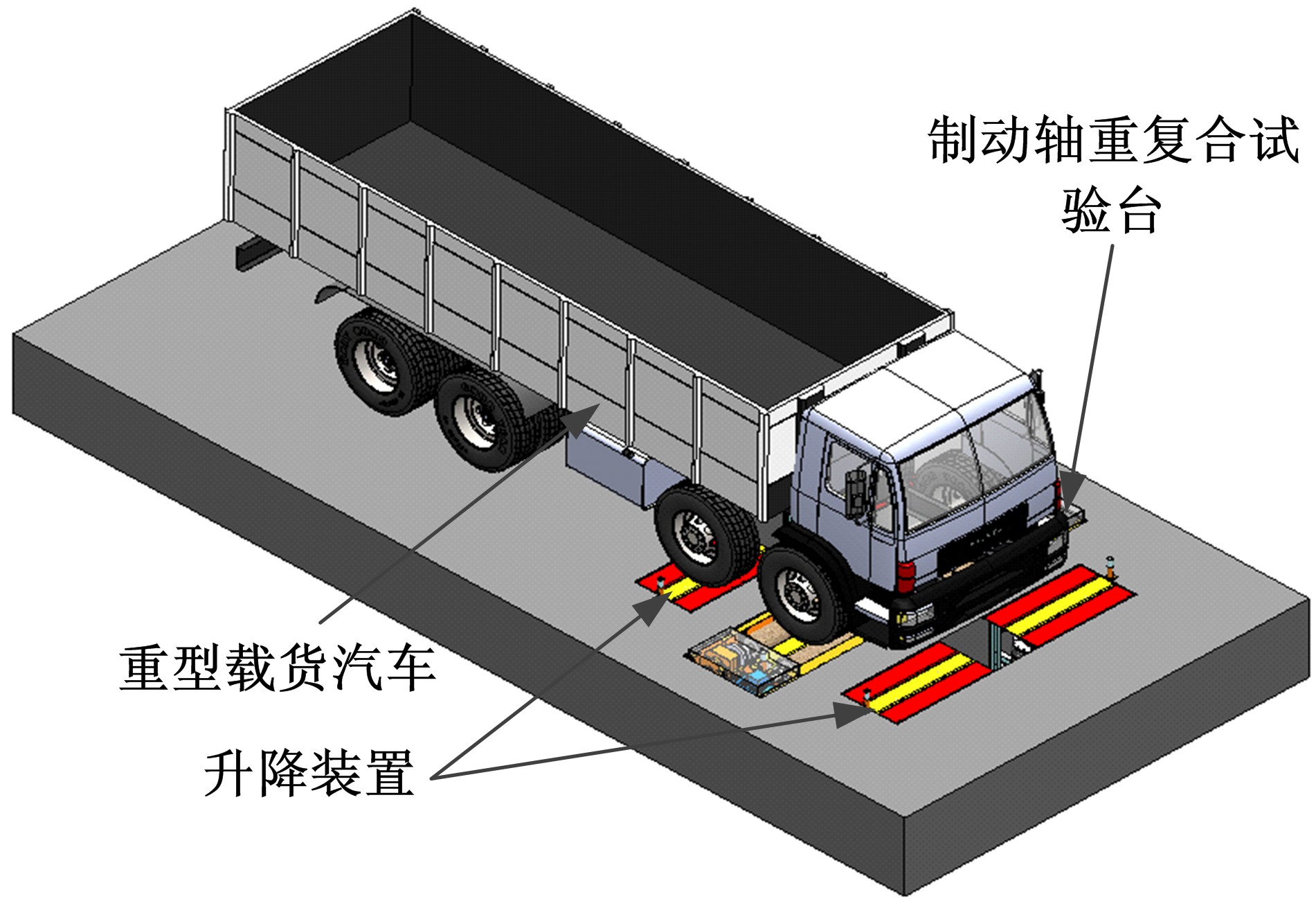

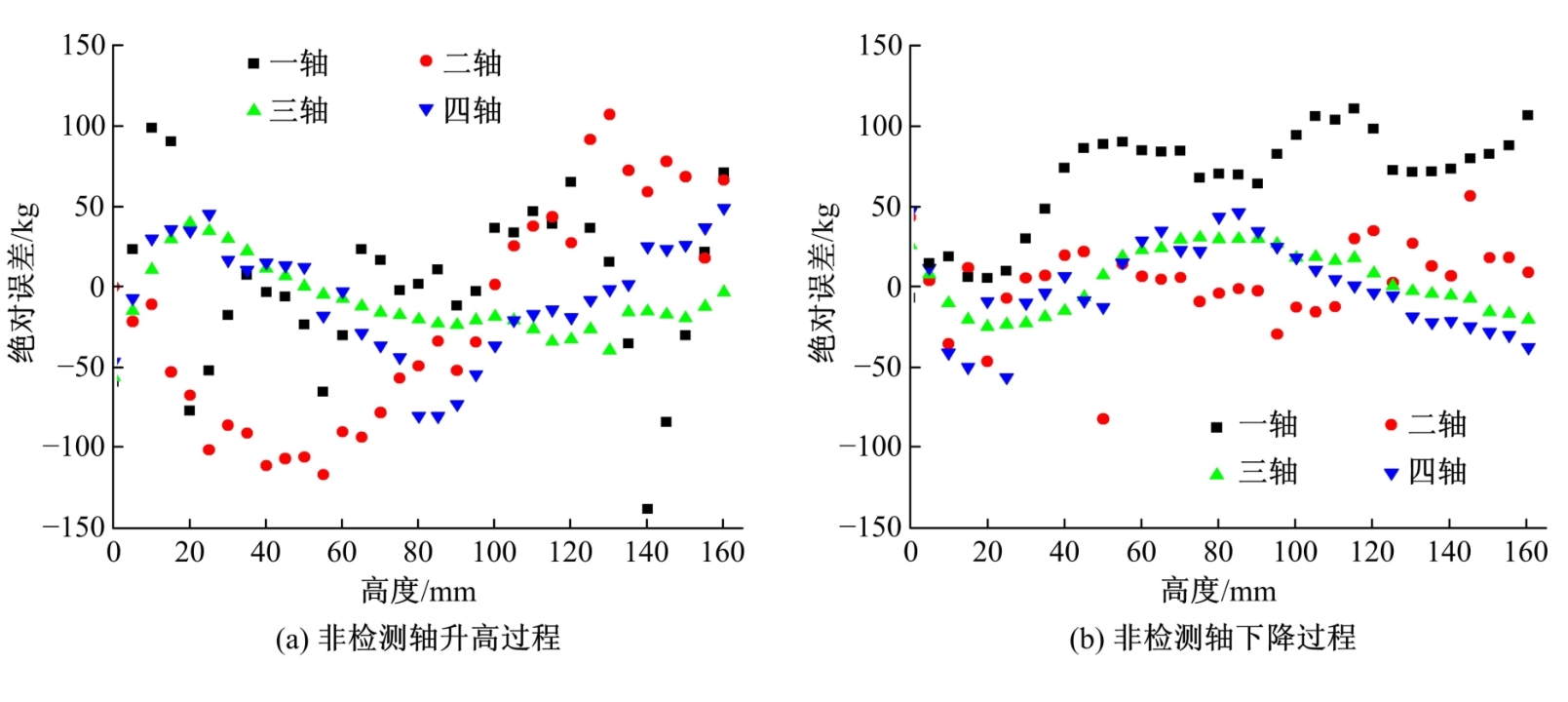

Design of axle load self⁃adjusting system for multi⁃axle vehicle based on brake tester

Li⁃bin ZHANG1( ),Dao WU1,Hong⁃ying SHAN2(

),Dao WU1,Hong⁃ying SHAN2( ),Xiang⁃jing DENG3

),Xiang⁃jing DENG3

- 1. College of Transportation,Jilin University,Changchun 130022,China

2. College of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

3. Engineering Research Institute,Beijing Electric Vehicle Co Ltd,Beijing 102606,China

CLC Number:

- U472.9

| 1 | Pernestål A , Nyberg M , Warnquist H . Modeling and inference for troubleshooting with interventions applied to a heavy truck auxiliary braking system[J]. Engineering Applications of Artificial Intelligence, 2012, 25(4): 705⁃ 719. |

| 2 | Xu G , Su J , Chen R , et al . Measurement performance assessment: dynamic calibration compared withstatic calibration method for roller tester of vehicle brake force[J]. Advances in Mechanical Engineering, 2014,6: 162435. |

| 3 | Bera T K , Bhattacharya K , Samantaray A K . Evaluation of antilock braking system with an integrated model of full vehicle system dynamics[J]. Simulation Modelling Practice and Theory, 2011, 19(10): 2131⁃2150. |

| 4 | GB21861-2014. 机动车安全技术检验项目和方法:[S]. |

| 5 | Fedotov A I , Młyńczak M . Analytical identification of parameters influencing measurement quality using flat brake tester[J]. Advances in Intelligent Systems and Computing, 2016, 470: 147⁃155. |

| 6 | Boć M , Vučetić A , Iliňić P , et al . Retrofit of a roller brake tester at famena[J]. Transactions of Famena, 2014, 38(3): 95⁃102. |

| 7 | 夏均忠, 王太勇, 李树珉 . 汽车制动试验台测试性能分析与应用[J]. 农业机械学报, 2005, 36(12): 13⁃16. |

| Xia Jun⁃zhong , Wang Tai⁃yong , Li Shu⁃min . Study on performance and application for vehicle brake tester[J]. Transactions of the Chinese Society of Agricultural Machinery, 2005, 36(12): 13⁃16. | |

| 8 | Senabre C , Velasco E , Valero S . Comparative analysis of vehicle brake data in the ministry of transport test on the roller brake tester and on flat ground[J]. International Journal of Automotive Technology, 2012, 13(5): 735⁃742. |

| 9 | Senabre C , Velasco E , Valero S . Comparative analysis of brake data of vehicles on two different ministry of transport brake roller testers[J]. Journal of Testing and Evaluation, 2012, 40(4): 104559. |

| 10 | 赵哲峰 . 可变滚筒轴距反力式制动检验台的研究[D]. 长春:吉林大学交通学院, 2008. |

| Zhao Zhe⁃feng . Research on auti⁃force changeable distance roller brake testing platform[D]. Changchun: College of Transportation, Jilin University, 2008. | |

| 11 | 黄万友, 于明进, 富文军, 等 . 汽车滚筒反力式制动台测量结果的影响因素分析[J]. 江苏大学学报:自然科学版, 2016, 37(5): 497⁃502. |

| Huang Wan⁃you , Yu Ming⁃jin , Fu Wen⁃jun , et al . Analysis of influencing factors on testing results of vehicle roller anti-force brake testing plarform[J]. Journal of Jiangsu University(Natural Science Edition), 2016, 37(5): 497⁃502. | |

| 12 | 陈南峰, 谷占勋, 应朝阳, 等 . 重型载货车辆行车制动性能加载检测的研究[J]. 汽车与安全, 2015(4):94⁃99. |

| Chen Nan⁃feng , Gu Zhan⁃xun , Ying Zhao⁃yang , et al . Research on heavy laden vehicle brake performance load testing[J]. Auto and Safety, 2015(4): 94⁃99. | |

| 13 | 陈书明, 王连会, 陈静, 等 . 一种滚筒反力式制动试验台制动轴荷再分配装置[P]. 中国:ZL 201510242804.7, 2015⁃07⁃29. |

| 14 | Surblys V , Sokolovskij E . Research of the vehicle brake testing efficiency[J]. Procedia Engineering, 2016, 134:452⁃458. |

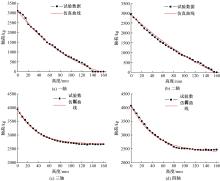

| 15 | 万振, 高峰, 丁靖, 等 . 多轴车制动的动力学模型及制动性能分析[J]. 中国机械工程, 2008, 19(3): 365⁃369. |

| Wan Zhen , Gao Feng , Ding Jing , et al . Dynamics model and braking performance analysis of multi⁃axle vehicle[J]. China Mechanical Engineering, 2008, 19(3): 365⁃369. | |

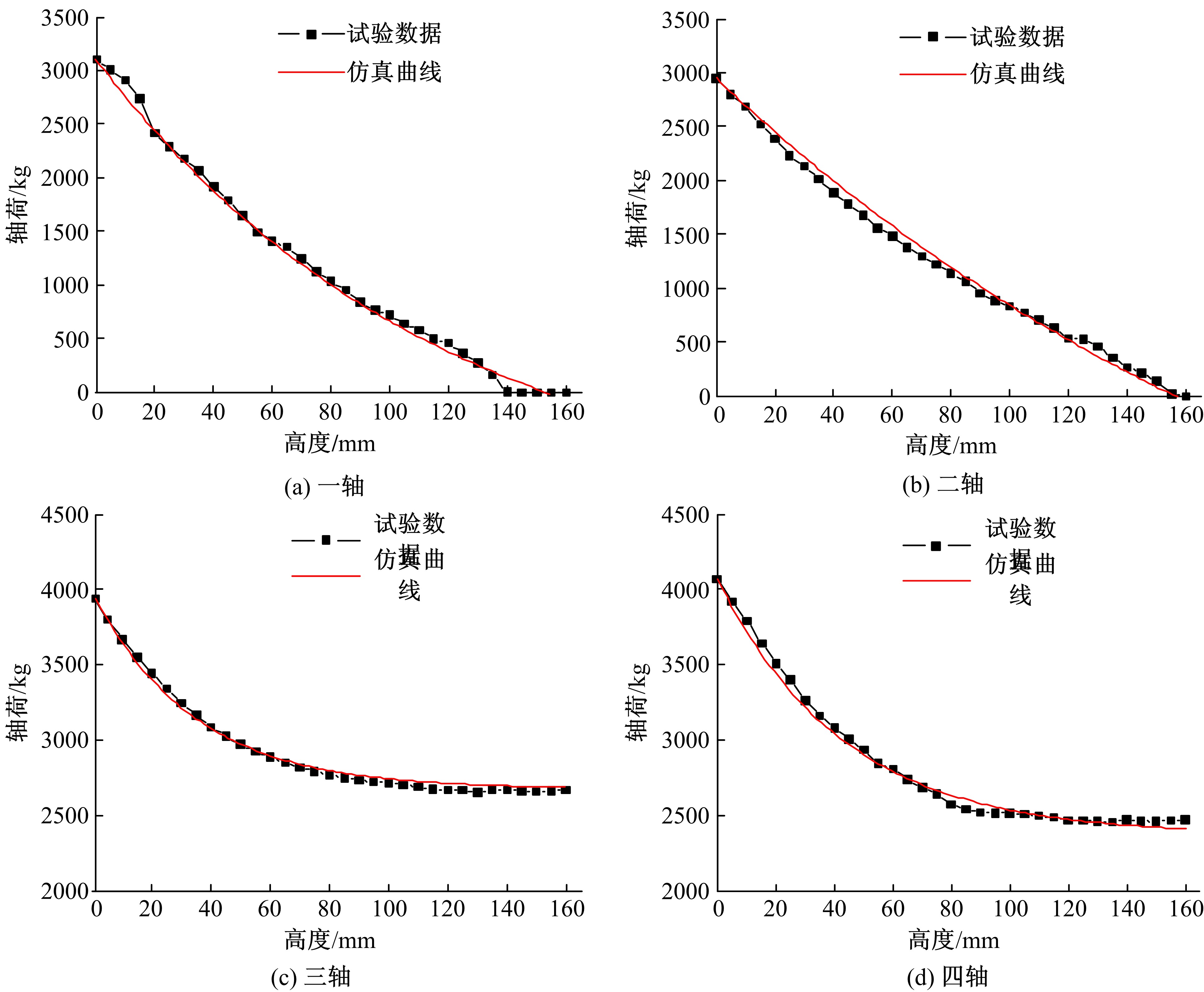

| 16 | 党潇正, 张连洪, 周良生, 等 . 多轴汽车负荷分配的建模验证与计算的研究[J]. 汽车工程, 2014, 36(9): 1122⁃1126. |

| Dang Xiao⁃zheng , Zhang Lian⁃hong , Zhou Liang⁃sheng , et al . A research on the modeling, verification and calculation of load distribution for multi⁃axle vehicles[J]. Automotive Engineering, 2014, 36(9): 1122⁃1126. | |

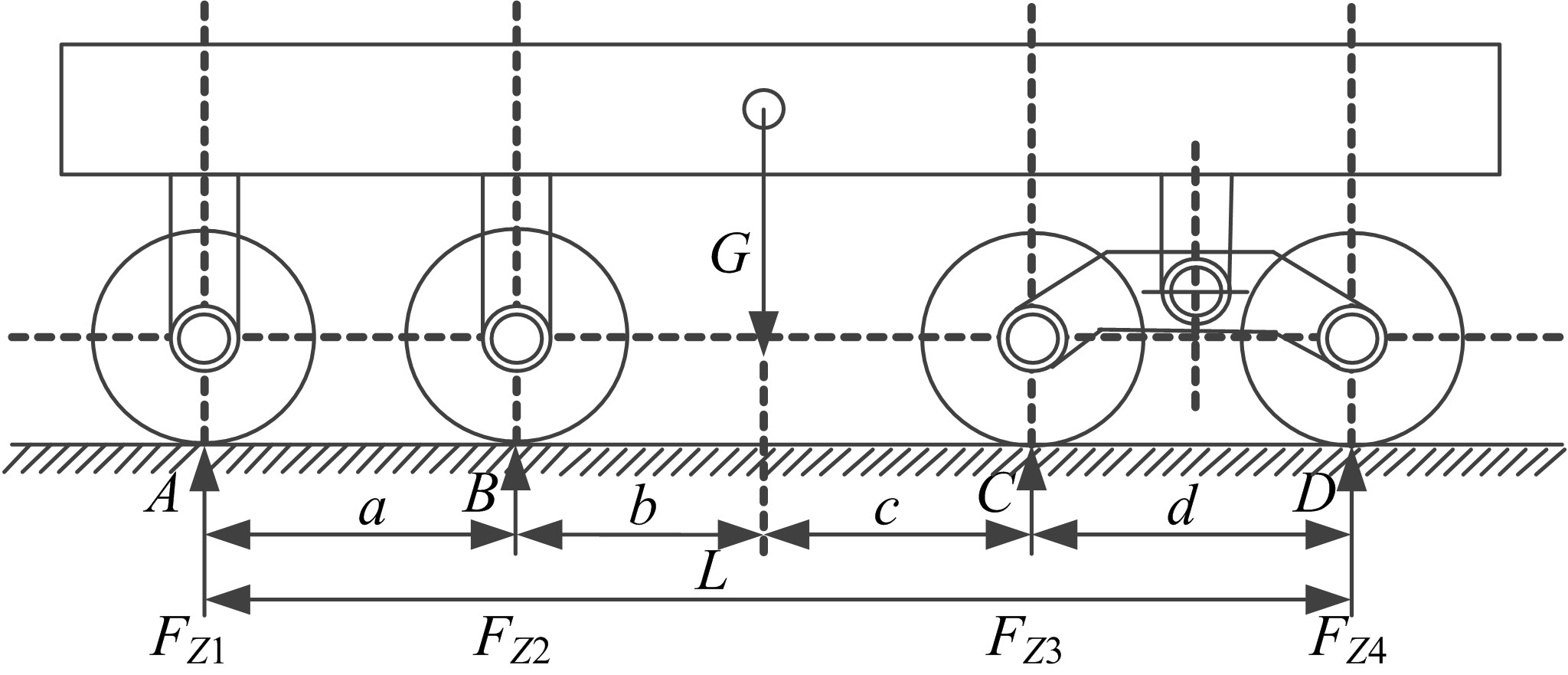

| 17 | 王宣锋, 梁迎春, 黄朝胜, 等 . 超静定多轴牵引车制动试验载荷参数的优化[J].吉林大学学报:工学版, 2011, 41(2): 316⁃320. |

| Wang Xuan⁃feng , Liang Ying⁃chun , Huang Chao⁃sheng , et al . Load parameter optimization of brake test on statically indeterminate multi⁃axle tractor[J]. Journal of Jilin University (Engineering and Technology Edition), 2011, 41(2): 316⁃320. | |

| 18 | 刚宪约, 王登峰, 苏学军, 等 . 基于位移法的多轴汽车轮胎载荷计算方法的研究[J]. 汽车工程, 2012, 34(1): 72⁃75. |

| Xian⁃yue Gang , Wang Deng⁃feng , Su Xue⁃jun , et al . A study on the tire load calculation for multi⁃axle vehicles based on displacement method[J]. Automotive Engineering, 2012, 34(1): 72⁃75. | |

| 19 | Wang Xuan⁃feng , Liang Ying⁃chun , Shi Guang , et al . A study on the asynchronous brake lock⁃up of a statically indeterminate tractor with an air suspension[J]. Proceedings of the Institution of Mechanical Engineers, 2012, 226(4): 507⁃516. |

| 20 | 段亮, 杨树凯, 宋传学, 等 . 某多轴商用车平衡悬架高精度建模与分析[J]. 汽车工程, 2016, 38(2): 229⁃233. |

| Duan Liang , Yang Shu⁃kai , Song Chuan⁃xue , et al . High⁃accuracy modeling and analysis of balanced suspension in a multi⁃axle commercial vehicle[J]. Automotive Engineering, 2016, 38(2): 229⁃233. |

| [1] | Jing LI,Qiu⁃jun SHI,Peng LIU,Ya⁃wei HU. Neural network sliding mode control of commercial vehicle ABS based on longitudinal vehicle speed estimation [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1017-1025. |

| [2] | Shun YANG,Yuan⁃de JIANG,Jian WU,Hai⁃zhen LIU. Autonomous driving policy learning based on deep reinforcement learning and multi⁃type sensor data [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1026-1033. |

| [3] | Xin CHEN,Ming LI,Xin⁃jian RUAN,Ning WANG,Jia⁃ning WANG. Investigation of vortical structures in wake of Ahmed body by delayed detached⁃eddy simulation turbulence model using immersed boundary method [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1034-1042. |

| [4] | Hua ZHOU,Zhi⁃gang YANG,Hui ZHU. Aerodynamic calculation of MIRA model correlated with wind tunnel test [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1043-1053. |

| [5] | Run⁃dong LIU,Jun MAO,Yan⁃hong XI,Hong⁃yu ZHANG,Fei PENG. Pressure pulse on windbreak impacting by cross⁃wind coupling with high⁃speed trains passing each other [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1054-1062. |

| [6] | Guo⁃feng QIN,Jing⁃xin NA,Wen⁃long MU,Wei TAN,Jian⁃ze LUAN,Hao SHEN. Degradation failure of adhesively bonded CFRP/aluminum alloy subjected to high temperature environment [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1063-1071. |

| [7] | Ji⁃qing CHEN,Meng⁃meng LIU,Feng⁃chong LAN. Experiment on overcharge safety of NCM battery and battery pack [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1072-1080. |

| [8] | CHANG Cheng,SONG Chuan-xue,ZHANG Ya-ge,SHAO Yu-long,ZHOU Fang. Minimizing inverter capacity of doubly-fed machine driving electric vehicles [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1629-1635. |

| [9] | XI Li-he,ZHANG Xin,SUN Chuan-yang,WANG Ze-xing,JIANG Tao. Adaptive energy management strategy for extended range electric vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1636-1644. |

| [10] | HE Ren,YANG Liu,HU Dong-hai. Design and analysis of refrigeration system supplied by solar auxiliary power of refrigerator car [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1645-1652. |

| [11] | NA Jing-xin,MU Wen-long,FAN Yi-sa,TAN Wei,YANG Jia-zhou. Effect of hygrothermal aging on steel-aluminum adhesive joints for automotive applications [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1653-1660. |

| [12] | LIU Yu-mei,LIU Li,CAO Xiao-ning,XIONG Ming-ye,ZHUANG Jiao-jiao. Construction on collision avoidance model of bogie dynamic simulation test bench [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1661-1668. |

| [13] | ZHAO Wei-qiang, GAO Ke, WANG Wen-bin. Prevention of instability control of commercial vehicle based on electric-hydraulic coupling steering system [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1305-1312. |

| [14] | SONG Da-feng, WU Xi-tao, ZENG Xiao-hua, YANG Nan-nan, LI Wen-yuan. Life cycle cost analysis of mild hybrid heavy truck based on theoretical fuel consumption model [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1313-1323. |

| [15] | ZHU Jian-feng, ZHANG Jun-yuan, CHEN Xiao-kai, HONG Guang-hui, SONG Zheng-chao, CAO Jie. Design modification for automotive body structure based on seat pull safety performance [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1324-1330. |

|

||