Journal of Jilin University(Engineering and Technology Edition) ›› 2022, Vol. 52 ›› Issue (10): 2244-2255.doi: 10.13229/j.cnki.jdxbgxb20210307

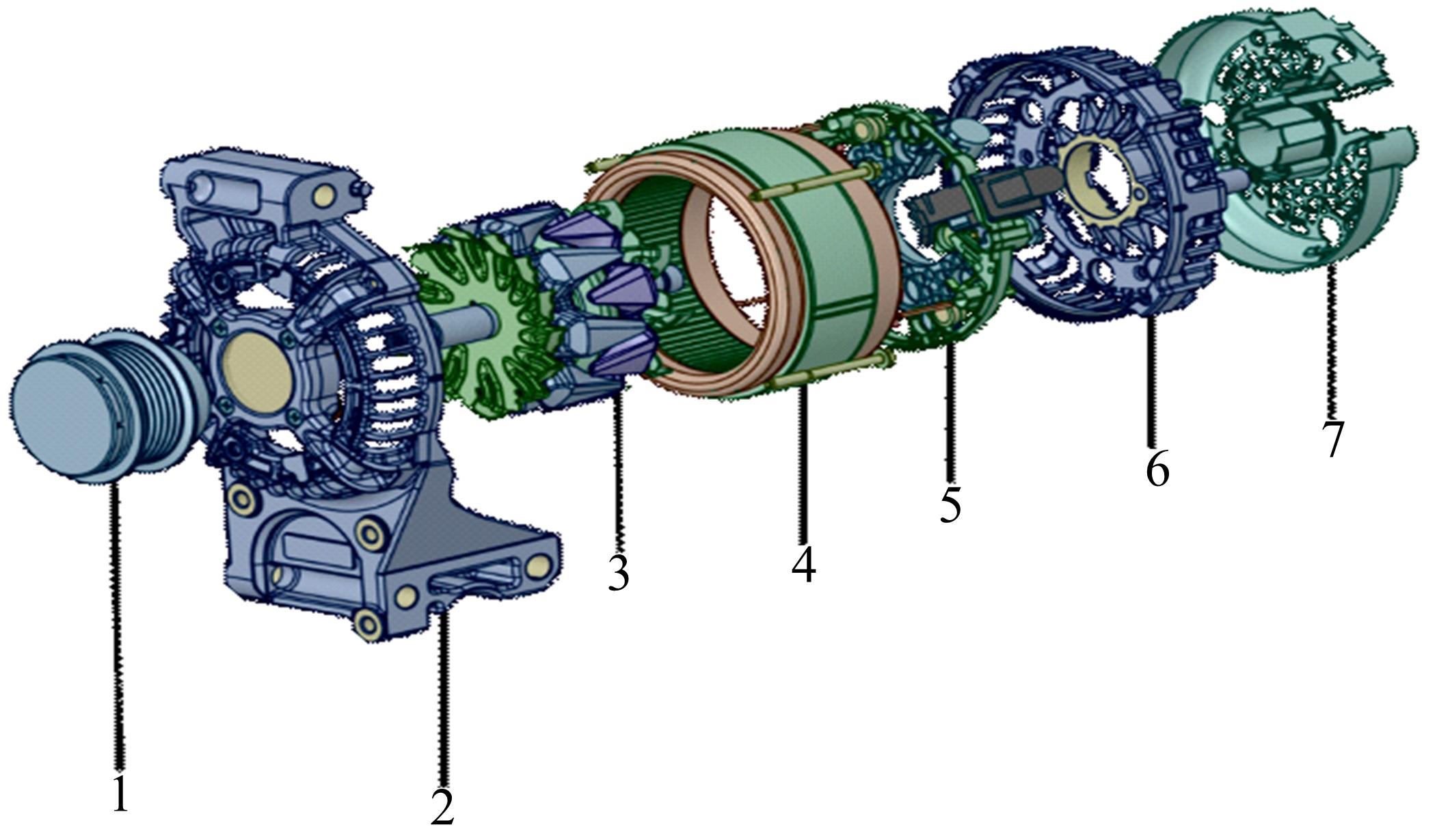

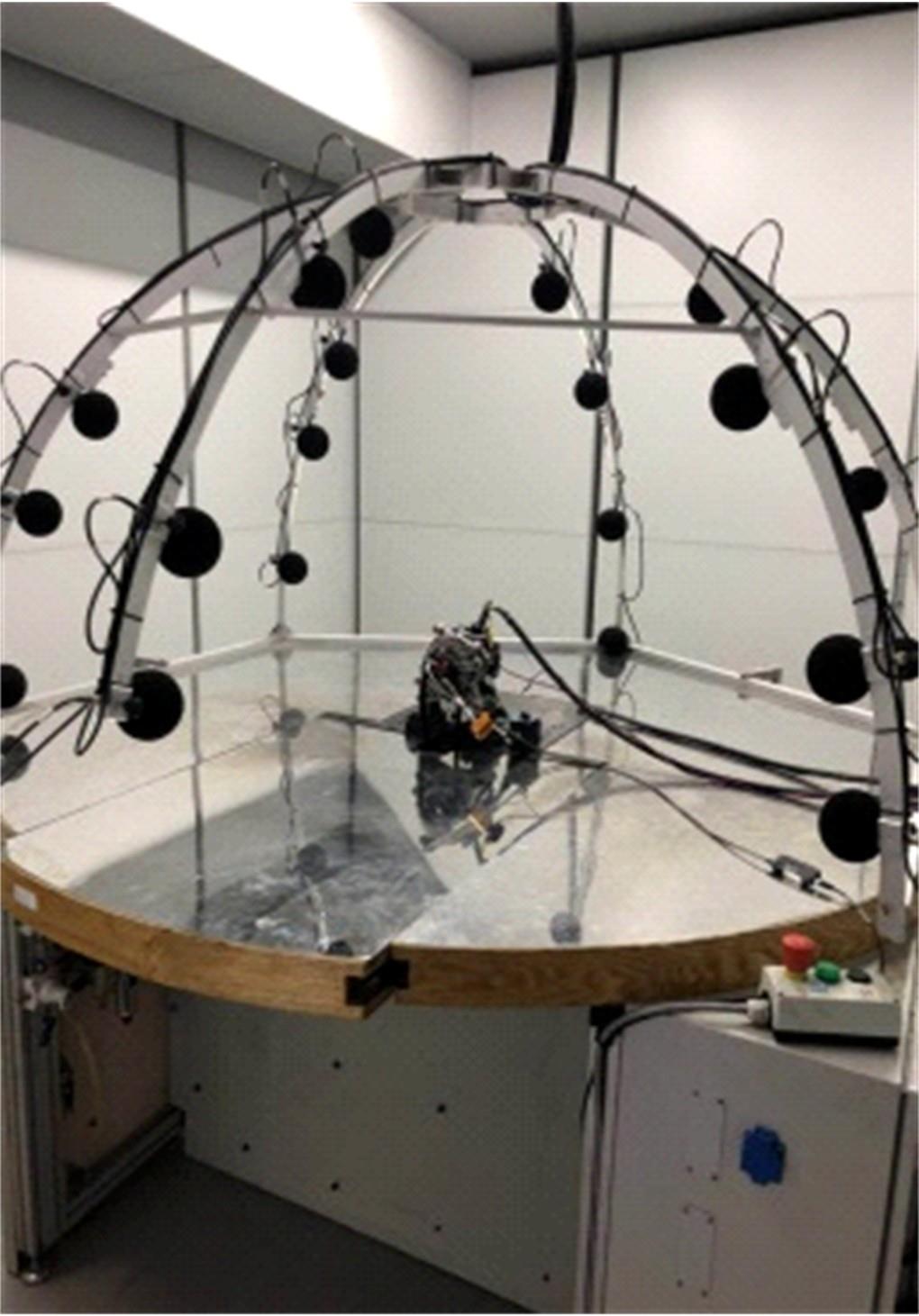

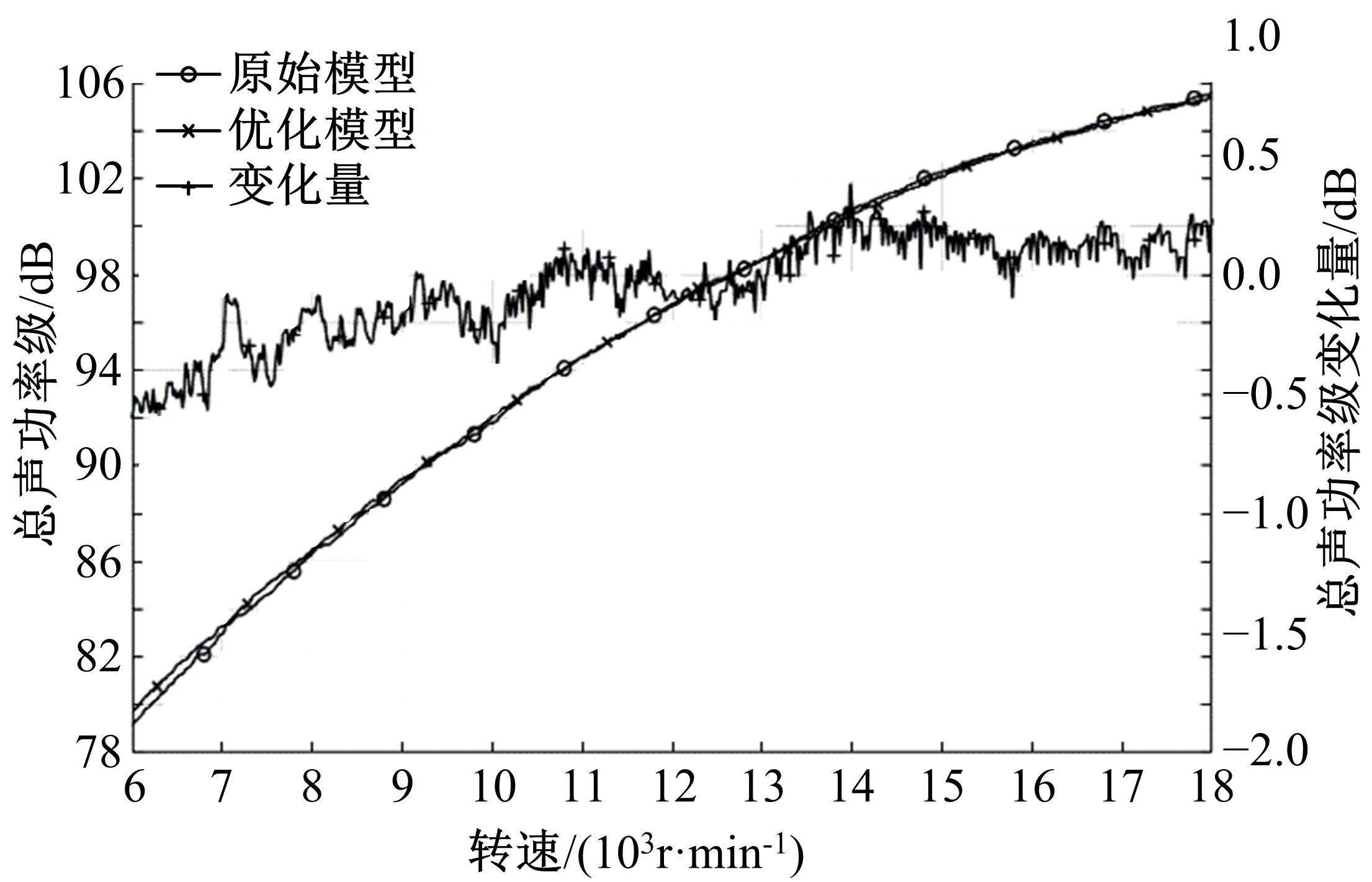

Aerodynamic noise optimization of vehicle claw-pole generator

Tai-ming HUANG1( ),Wei-ping LI2(

),Wei-ping LI2( ),Tao-tao HU2,Wan-hao YUE2,Nian-zhou JI2,Yu-bang LI3

),Tao-tao HU2,Wan-hao YUE2,Nian-zhou JI2,Yu-bang LI3

- 1.School of Mechanical Engineering,Hunan Institute of Science and Technology,Yueyang 414006,China

2.State Key Laboratory for Advanced Design and Manufacture of Automobile Body,Hunan University,Changsha 410082,China

3.School of Materials Science and Engineering,Central South University,Changsha 410083,China

CLC Number:

- U463.63

| 1 | Le Goff V, Vidal V, Fakes M, et al. Flow induced noise predictions of an automotive alternator using a lattice boltzmann method[C]∥Turbo Expo: Power for Land, Sea, and Air. American Society of Mechanical Engineers, Düsseldorf, Germany, 2014: 45578. |

| 2 | Kim W, Jeon W H, Hur N, et al. Development of a low-noise cooling fan for an alternator using numerical and doe methods[J]. International Journal of Automotive Technology, 2011, 12(2): 307-314. |

| 3 | Khelladi S, Kouidri S, Bakir F, et al. Predicting tonal noise from a high rotational speed centrifugal fan[J]. Journal of Sound and Vibration, 2008, 313(1/2): 113-133. |

| 4 | Hua C, Zhang Y, Dong D, et al. Aerodynamic noise numerical simulation and noise reduction study on automobile alternator[J]. Journal of Mechanical Science and Technology, 2017, 31(5): 2047-2055. |

| 5 | Zhang J H, Chu W L, Zhang H G, et al. Numerical and experimental investigations of the unsteady aerodynamics and aero-acoustics characteristics of a backward curved blade centrifugal fan[J]. Applied Acoustics, 2016, 110: 256-267. |

| 6 | 陈鑫, 王宁, 沈传亮, 等. 后视镜造型对前侧窗气动噪声的影响[J]. 吉林大学学报: 工学版, 2020, 50(2): 426-436. |

| Chen Xin, Wang Ning, Shen Chuan-liang, et al. Effect of rearview mirror modeling on aerodynamic noise of front window[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 426-436. | |

| 7 | Zheng W L, Yan C, Liu H K, et al. Comparative assessment of SAS and DES turbulence modeling for massively separated flows[J]. Acta Mechanica Sinica, 2016, 32(1): 12-21. |

| 8 | Kaltenbacher M, Escobar M, Becker S, et al. Numerical simulation of flow‐induced noise using LES/SAS and Lighthill's acoustic analogy[J]. International Journal for Numerical Methods in Fluids, 2010, 63(9): 1103-1122. |

| 9 | 杨博, 胡兴军, 王夫亮. 轻型客车侧窗区域气动噪声的数值模拟与验证[J]. 吉林大学学报: 工学版, 2010, 40(4): 915-919. |

| Yang Bo, Hu Xing-jun, Wang Fu-liang. Numerical simulation and verification of aerodynamic noise from side window region of minivan[J]. Journal of Jilin University(Engineering and Technology Edition), 2010, 40(4): 915-919. | |

| 10 | 高富东, 王德心, 王海东, 等. 基于射流冲击作用的舰机适配性数值分析与优化[J]. 中国机械工程, 2020, 31(12): 1425-1436. |

| Gao Fu-dong, Wang De-xin, Wang Hai-dong,et al. Numerical analysis and optimization of carrier/air vehicle integrations based on jet impingements[J]. China Mechanical Engineering, 2020, 31(12): 1425-1436. | |

| 11 | Zheng W L, Yan C, Liu H K, et al. Comparative assessment of SAS and DES turbulence modeling for massively separated flows[J]. Acta Mechanica Sinica, 2016, 32(1): 12-21. |

| 12 | 詹福良, 徐俊伟. Virtual.Lab Acoustics声学仿真计算从入门到精通[M]. 陕西:西北工业大学出版社,2013: 336-408. |

| 13 | Curle N. The influence of solid boundaries upon aerodynamic sound[J]. Proceedings of the Royal Society of London. Series A. Mathematical and Physical Sciences, 1955, 231(1187): 505-514. |

| 14 | Zheng Z G, Li R X. The application of numerical simulation technology in the external aerodynamic noise field of high-speed train[J]. Applied Mechanics and Materials, 2012(101/102): 197-201. |

| 15 | Zheng Z Y, Li R X. Application of numerical simulation technology to prediction of aerodynamic dipole acoustics source on automobile surface[C]∥The 2nd International Conference on Digital Manufacturing & Automation, Zhangjiajie, China, 2011: 216-220. |

| 16 | 汪怡平, 谷正气, 李伟平, 等. 汽车气动噪声数值计算分析[J]. 汽车工程, 2009, 31(4): 385-388. |

| Wang Yi-ping, Gu Zheng-qi, Li Wei-ping, et al. Numerical analysis of automobile aerodynamic noise[J]. Automotive Engineering, 2009, 31(4): 385-388. | |

| 17 | 胡坤, 顾中浩, 马海峰. ANSYS CFD疑难问题实例详解[M]. 北京:人民邮电出版社,2017. |

| 18 | Li W, Yue W, Huang T, et al. Optimizing the aerodynamic noise of an automobile claw pole alternator using a numerical method[J]. Applied Acoustics, 2020, 171: No. 107629. |

| 19 | Zuo S, Xie C, Wu X, et al. Numerical simulation and optimization of aerodynamic noise for claw pole alternator[J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2018, 233(3): 857-879. |

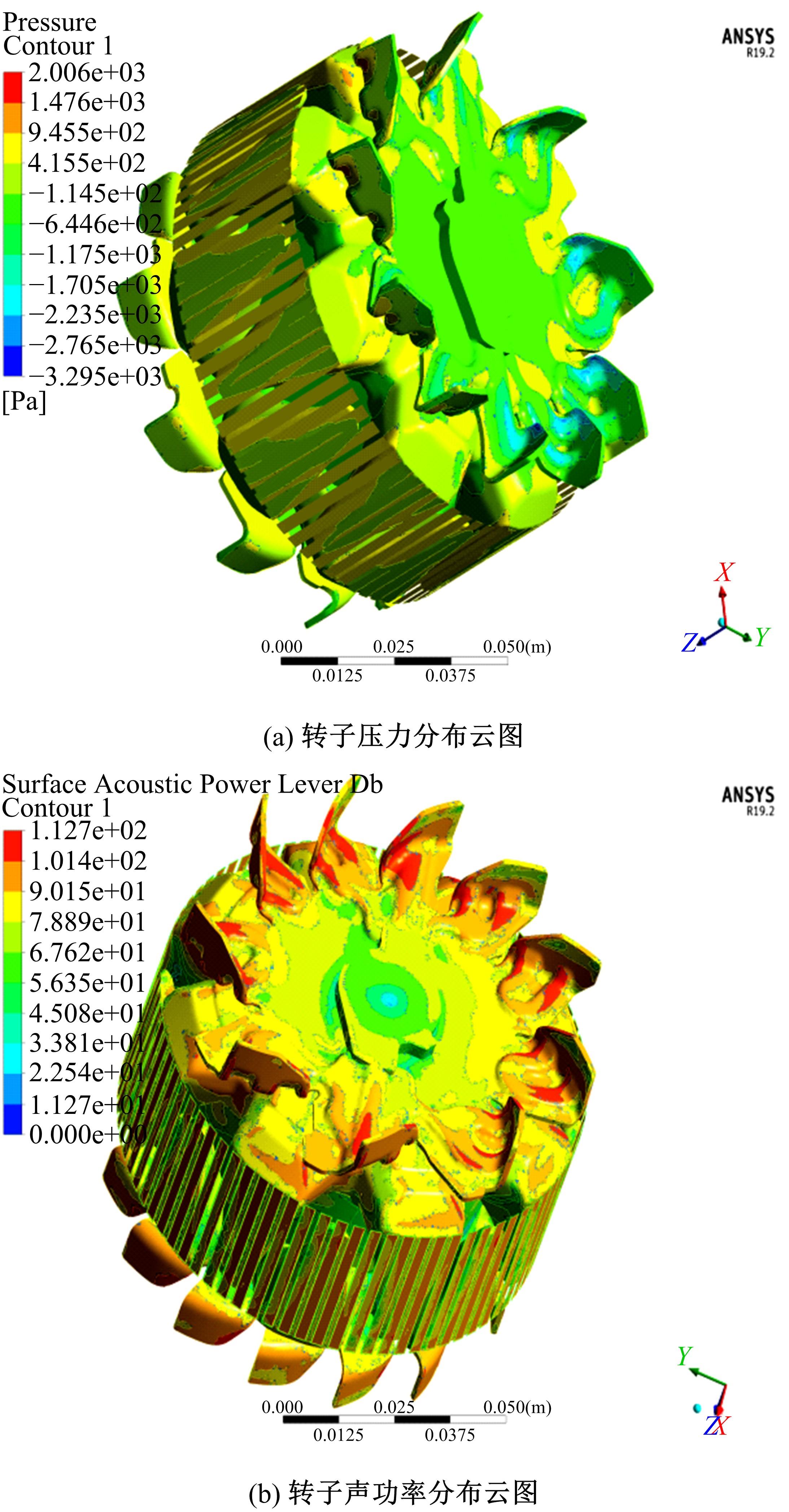

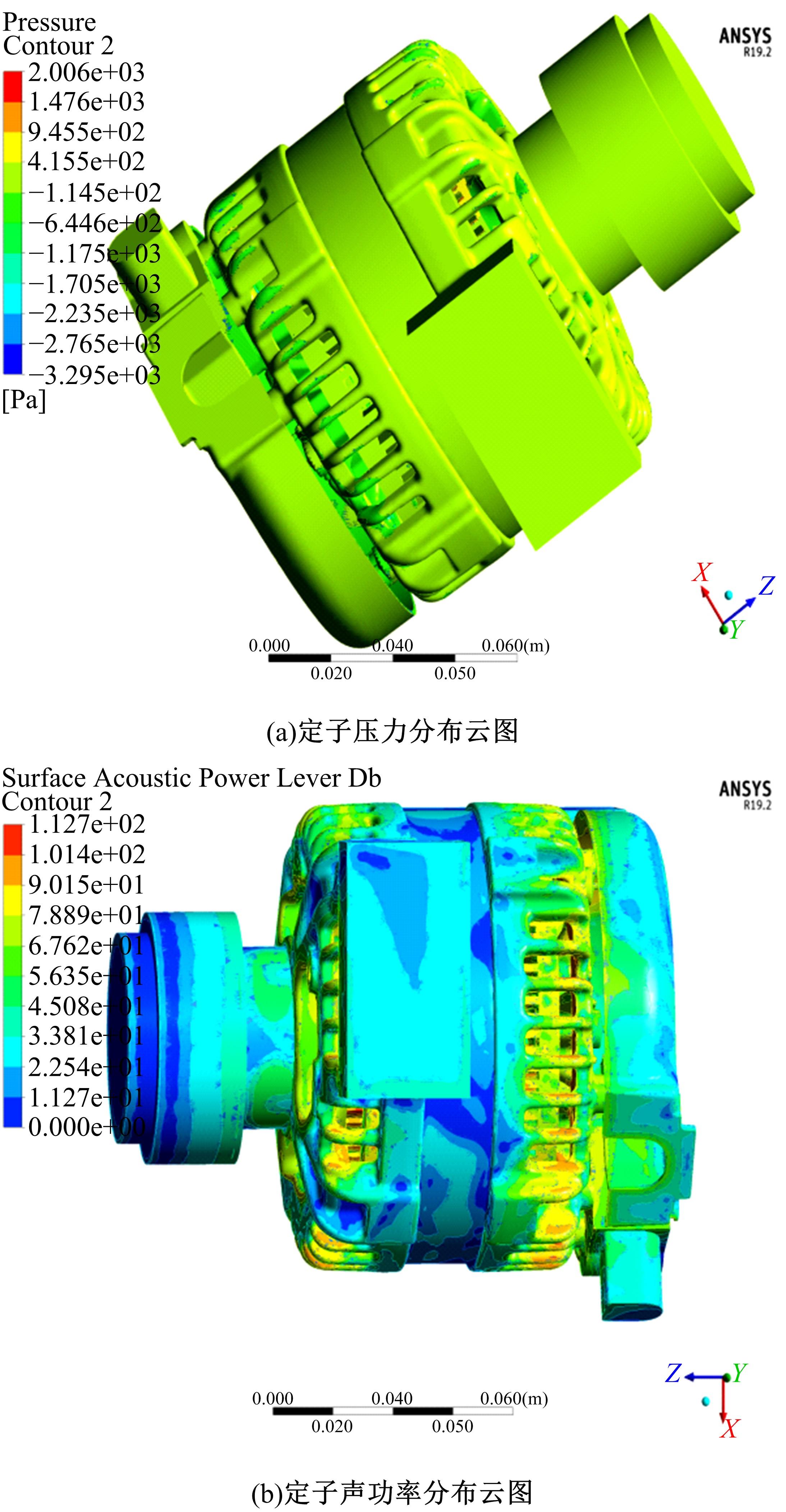

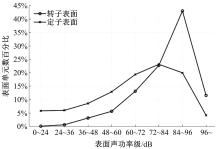

| 20 | 张亚东, 董大伟, 闫兵, 等. 车用交流发电机气动噪声数值分析[J]. 振动与冲击, 2016, 35(1): 174-182, 187. |

| Zhang Ya-dong, Dong Da-wei, Yan Bing, et al. Numerical simulation analysis for aerodynamic noise of a vehicle alternator[J]. Journal of Vibration and Shock, 2016, 35(1): 174-182, 187. |

| [1] | Ke-yong WANG,Da-tong BAO,Su ZHOU. Data-driven online adaptive diagnosis algorithm towards vehicle fuel cell fault diagnosis [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(9): 2107-2118. |

| [2] | Qi-ming CAO,Hai-tao MIN,Wei-yi SUN,Yuan-bin YU,Jun-yu JIANG. Hydrothermal characteristics of proton exchange membrane fuel cell start⁃up at low temperature [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(9): 2139-2146. |

| [3] | Hai-lin KUI,Ze-zhao WANG,Jia-zhen ZHANG,Yang LIU. Transmission ratio and energy management strategy of fuel cell vehicle based on AVL⁃Cruise [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(9): 2119-2129. |

| [4] | Yan LIU,Tian-wei DING,Yu-peng WANG,Jing DU,Hong-hui ZHAO. Thermal management strategy of fuel cell engine based on adaptive control strategy [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(9): 2168-2174. |

| [5] | Cheng LI,Hao JING,Guang-di HU,Xiao-dong LIU,Biao FENG. High⁃order sliding mode observer for proton exchange membrane fuel cell system [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(9): 2203-2212. |

| [6] | Pei ZHANG,Zhi-wei WANG,Chang-qing DU,Fu-wu YAN,Chi-hua LU. Oxygen excess ratio control method of proton exchange membrane fuel cell air system for vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(9): 1996-2003. |

| [7] | Xun-cheng CHI,Zhong-jun HOU,Wei WEI,Zeng-gang XIA,Lin-lin ZHUANG,Rong GUO. Review of model⁃based anode gas concentration estimation techniques of proton exchange membrane fuel cell system [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(9): 1957-1970. |

| [8] | Yao-wang PEI,Feng-xiang CHEN,Zhe HU,Shuang ZHAI,Feng-lai PEI,Wei-dong ZHANG,Jie-ran JIAO. Temperature control of proton exchange membrane fuel cell thermal management system based on adaptive LQR control [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(9): 2014-2024. |

| [9] | Guang-di HU,Hao JING,Cheng LI,Biao FENG,Xiao-dong LIU. Multi⁃objective sliding mode control based on high⁃order fuel cell model [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(9): 2182-2191. |

| [10] | Feng-xiang CHEN,Qi WU,Yuan-song LI,Tian-de MO,Yu LI,Li-ping HUANG,Jian-hong SU,Wei-dong ZHANG. Matching,simulation and optimization for 2.5 ton fuel cell/battery hybrid forklift [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(9): 2044-2054. |

| [11] | Xiao-hua WU,Zhong-wei YU,Zhang-ling ZHU,Xin-mei GAO. Fuzzy energy management strategy of fuel cell buses [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(9): 2077-2084. |

| [12] | Qing GAO,Hao-dong WANG,Yu-bin LIU,Shi JIN,Yu CHEN. Experimental analysis on spray mode of power battery emergency cooling [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1733-1740. |

| [13] | Kui-yang WANG,Ren HE. Recognition method of braking intention based on support vector machine [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1770-1776. |

| [14] | Jun-cheng WANG,Lin-feng LYU,Jian-min LI,Jie-yu REN. Optimal sliding mode ABS control for electro⁃hydraulic composite braking of distributed driven electric vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1751-1758. |

| [15] | Han-wu LIU,Yu-long LEI,Xiao-feng YIN,Yao FU,Xing-zhong LI. Multi⁃point control strategy optimization for auxiliary power unit of range⁃extended electric vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1741-1750. |

|

||