Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (9): 2495-2501.doi: 10.13229/j.cnki.jdxbgxb.20230458

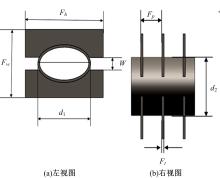

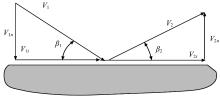

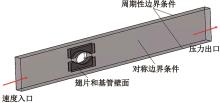

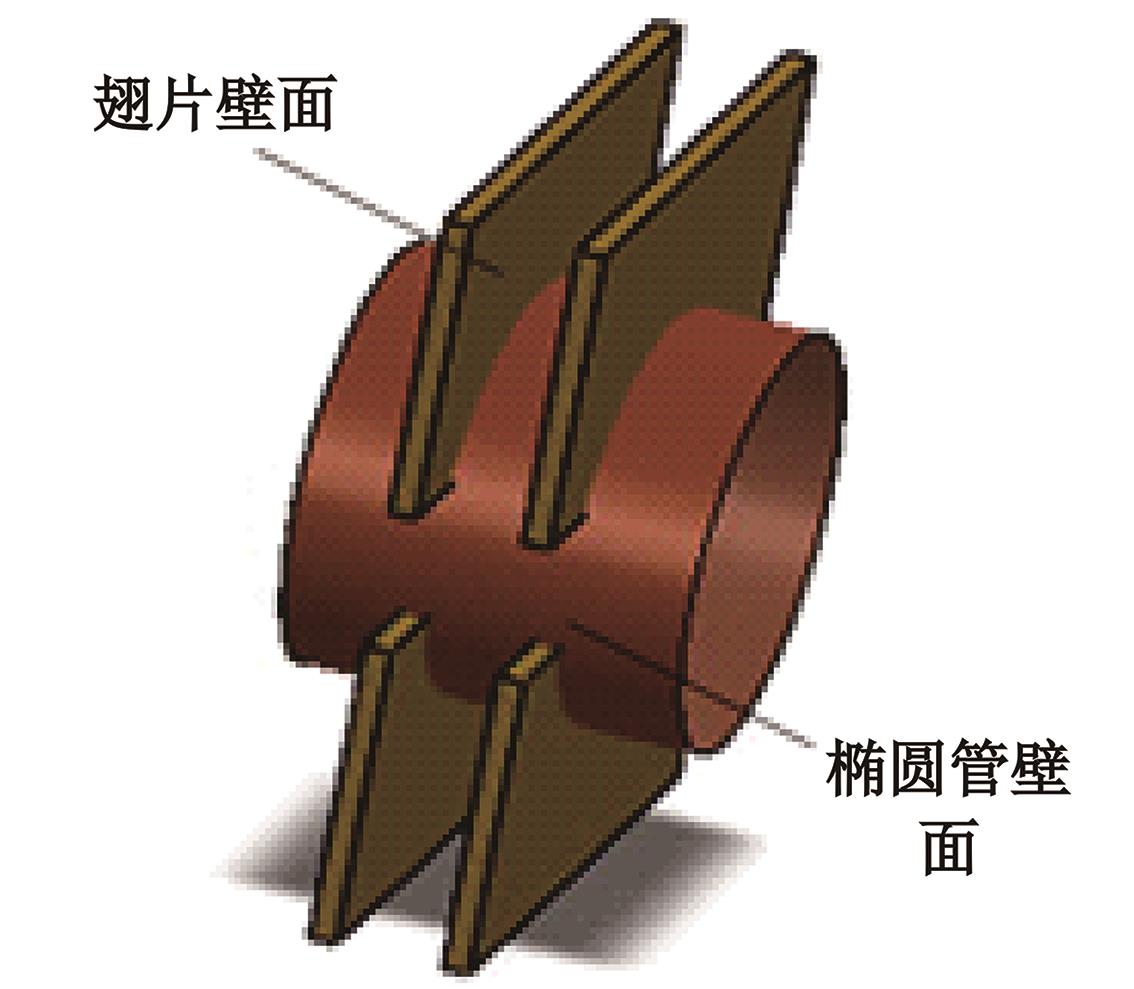

Numerical simulation of erosion characteristics of H-type finned elliptical tubes

Jin-xing WU( ),Yu-xiang MA,Jia-bang XIAO,Yao XU,Song-ge LI

),Yu-xiang MA,Jia-bang XIAO,Yao XU,Song-ge LI

- School of Mechanical and Power Engineering,Zhengzhou University,Zhengzhou 450001,China

CLC Number:

- TK172

| 1 | 黄丹,曾小义,杨建军,等. 超临界W火焰锅炉水冷壁管频繁拉裂泄漏事故原因分析[J]. 热加工工艺,2022,51(15):150-154, 158. |

| Huang Dan, Zeng Xiao-yi, Yang Jian-jun, et al. Analysis on causes of frequent rupture and leakage of water wall pipe of supercritical W Flame Boiler[J]. Hot Working Technology, 2022, 51(15): 150-154, 158. | |

| 2 | 张晓东,唐丽丽,翟璇,等. 燃煤发电机组烟气余热回收系统优化与经济性分析[J]. 锅炉技术,2022,53(4):74-78. |

| Zhang Xiao-dong, Tang Li-li, Zhai Xuan, et al. Optimization and economic analysis of flue gas wasteheat recovery system of coalfired power plants[J]. Boiler Technology, 2022, 53(4): 74-78. | |

| 3 | 徐承美,谢英柏,弓学敏. 燃煤锅炉烟气余热利用途径分析[J]. 热能动力工程,2020,35(8):151-157. |

| Xu Cheng-mei, Xie Ying-bai, Gong Xue-min. Analysis on waste heat utilization way of flue gas in coal-fired boiler[J]. Joumal of Engineering for Thermal Energy and Power, 2020, 35(8): 151-157. | |

| 4 | 李增亮,杜明超,董祥伟,等.固体颗粒冲蚀磨损模型的建立及有限元分析[J].计算机仿真,2018,35(6):275-281. |

| Li Zeng-liang, Du Ming-chao, Dong Xiang-wei, et al. Modeling and analysis of solid particle erosion process based on finite element method[J]. Computer Simulation, 2018, 35(6): 275-281. | |

| 5 | 叶侠丰,丁红蕾,潘卫国,等. 带拓展面椭圆管束的换热、积灰及磨损特性研究[J]. 中国电力,2018,51(6):26-32. |

| Ye Xia-feng, Ding Hong-lei, Pan Wei-guo, et al. Numerical study on the heat transfer, fouling and erosion characteristics of the elliptical tube bundle with different extended heating surfaces[J]. Electric Power, 2018, 51(6): 26-32. | |

| 6 | 叶侠丰,丁红蕾,潘卫国,等. 圆管束与椭圆管束换热、磨损及积灰特性的数值研究[J]. 中国电机工程学报,2018,38(11):3289-3294. |

| Ye Xia-feng, Ding Hong-lei, Pan Wei-guo, et al. Numerical study on heat transfer, wear and fouling performance of circular tube bundle and elliptical tube bundle[J]. Proceedings of the CSEE, 2018, 38(11): 3289-3294. | |

| 7 | 凌冬冬,李永光,马昕霞,等. 开缝宽度对H型椭圆翅片管束换热及流动的影响[J]. 上海电力学院学报, 2018,34(2): 106-110. |

| Ling Dong-dong, Li Yong-guang, Ma Xin-xia, et al. Influence of slot width on heat transfer and flow of h type elliptical finned tubes[J]. Journal of Shanghai University of Electric Power, 2018, 34(2): 106-110. | |

| 8 | 蒋涛.火力发电厂锅炉屏式过热器弯管泄漏失效原因分析及预防措施[J].铸造技术,2022,43(3):224-228. |

| Jiang Tao. Analysis and prevention of platen superheater elbow leakage of supercritical boiler in a coal-fired power plant[J]. Foundry Technology, 2022, 43(3): 224-228. | |

| 9 | 谌康,蔡文河,杜双明,等.电站锅炉水冷壁管的泄漏原因及应对措施[J].腐蚀与防护,2022,43(2):62-67. |

| Shen Kang, Cai Wen-he, Du Shuang-ming, et al. Cause analysis and treatment measures of water cooling wall pipe leakage ina power station boiler[J]. Corrosion & Protection, 2022, 43(2): 62-67. | |

| 10 | 闫廷庆,支卫峰. 对冲燃烧锅炉侧墙水冷壁高温腐蚀原因的空气动力研究[J]. 锅炉技术,2022,53(1):22-25, 31. |

| Yan Ting-qing, Zhi Wei-feng. Flow-field investigation of high-temperature corrosionon side waterwall of opposed firing boilers[J]. Boiler Technology, 2022, 53(1): 22-25, 31. | |

| 11 | 杨子江,袁益超,杨雨峤,等. 椭圆管H型翅片的翅片效率计算[J]. 锅炉技术,2019,50(3):18-23. |

| Yang Zi-jiang, Yuan Yi-chao, Yang Yu-giao,et al. Calculation for fin efficiency of H-type finned elliptical tube[J]. Boiler Technology, 2019, 50(3): 18-23. | |

| 12 | Om P, Arvind K, Basant S S. CFD modeling of slurry flow erosion wear rate through mitre pipe bend[J]. Proceedings of the Institution of Mechanical Engineers Part C-Journal of Mechanical Engineering Science, 2022, 236(5): 2256-2267. |

| 13 | 汪洋,郑志敏,张银森,等. 椭圆型管束的积灰特性数值研究[J]. 工程热物理学报,2022,43(3):720-728. |

| Wang Yang, Zheng Zhi-min Zhang Yin-sen, et al. Numerical study on ash deposition of the elliptical tube bundles[J]. Journal of Engineering Thermophysics, 2022, 43(3): 720-728. |

| [1] | Hua-fei HE,Zhao-ping LI,Rui-an FU,Shao-lin MA,Ming-li HUANG. Experiment on seismic performance of prefabricated sidewall joints considering strata restraint effect [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1601-1611. |

| [2] | Shu-mei LOU,Yi-ming LI,Xin LI,Peng CHEN,Xue-feng BAI,Bao-jia CHENG. Thermal deformation behavior of graphene nanosheets reinforced 7075Al based on BP neural network and Arrhenius constitutive equation [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1237-1245. |

| [3] | Qiu ZHAO,Peng CHEN,Yu-wei ZHAO,Ao YU. Overall mechanical performance of jointless bridges with arch structure behind abutment [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(4): 1016-1027. |

| [4] | Yi-gang WANG,Yu-peng WANG,Hao ZHANG,Si-an ZHAO. Identification and analysis of aerodynamic noise sources in the bogie area of high⁃speed trains [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 346-355. |

| [5] | Wei-hua ZHANG,Jia-ming LIU,Li-peng XIE,Heng DING. Lane⁃changing model of autonomous vehicle in weaving area of expressway in intelligent and connected mixed environment [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 469-477. |

| [6] | Xing WEI,Ya-jie GAO,Zhi-rui KANG,Yu-chen LIU,Jun-ming ZHAO,Lin XIAO. Numerical simulation of residual stress field of stud girth weld in low temperature environment [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(1): 198-208. |

| [7] | Zhi ZHENG,Pei YUAN,Xuan-hui JIN,Si-si WEI,Bo GENG. Experimental on composite flexible anti⁃collision fender of bridge pier [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2581-2590. |

| [8] | Feng WANG,Shuang-rui LIU,Jia-ying WANG,Jia-ling SONG,Jun WANG,Jiu-peng ZHANG,Xiao-ming HUANG. Size and shape effects of wind drag coefficients for porous structures [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1677-1685. |

| [9] | Chun-li WU,Shi-ming HUANG,Kui LI,Zheng-wei GU,Xiao-ming HUANG,Bing-tao ZHANG,Run-chao YANG. Analysis of pier action effect under flood based on numerical simulation and statistical analysis [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1612-1620. |

| [10] | Zheng-wei GU,Pan ZHANG,Dong-ye LYU,Chun-li WU,Zhong YANG,Guo-jin TAN,Xiao-ming HUANG. Earthquake⁃induced residual displacement analysis of simply supported beam bridge based on numerical simulation [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1711-1718. |

| [11] | Hai-bin WEI,Shuan-ye HAN,Hai-peng BI,Qiong-hui LIU,Zi-peng MA. Intelligent sensing road active ice and snow removal system and experimental technology [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1411-1417. |

| [12] | Jing-fu JIN,Xin-ju DONG,Zhi-cheng JIA,Kang WANG,Lian-bin HE,Meng ZOU,Ying-chun QI. Optimization of the tread plate-spring structure of flexible metal wheel with plate-spring [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 964-972. |

| [13] | Zhuang-zhuang LIU,You-wei ZHANG,Peng-yu JI,Abshir Ismail Yusuf,Lin LI,Ya-zhen HAO. Study on heat transfer characteristics of electric heating snow melting asphalt pavement [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 523-530. |

| [14] | Fang-xi XIE,Shi-jie ZHAO,Zi-sen WANG,Shuang LIU,Xiao-ping LI,Cheng ZHANG. Simulation analysis of influencing factors of flash boiling spray collapse of porous injector [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(12): 3314-3325. |

| [15] | Li-zhao DAI,Liang ZHOU,Xiao-wen YANG,Lei WANG. Meso-scale numerical simulation of interfacial bond behavior of corroded RC beams based on connector element [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(10): 2886-2896. |

|

||