Journal of Jilin University(Engineering and Technology Edition) ›› 2019, Vol. 49 ›› Issue (6): 1911-1919.doi: 10.13229/j.cnki.jdxbgxb20180922

Previous Articles Next Articles

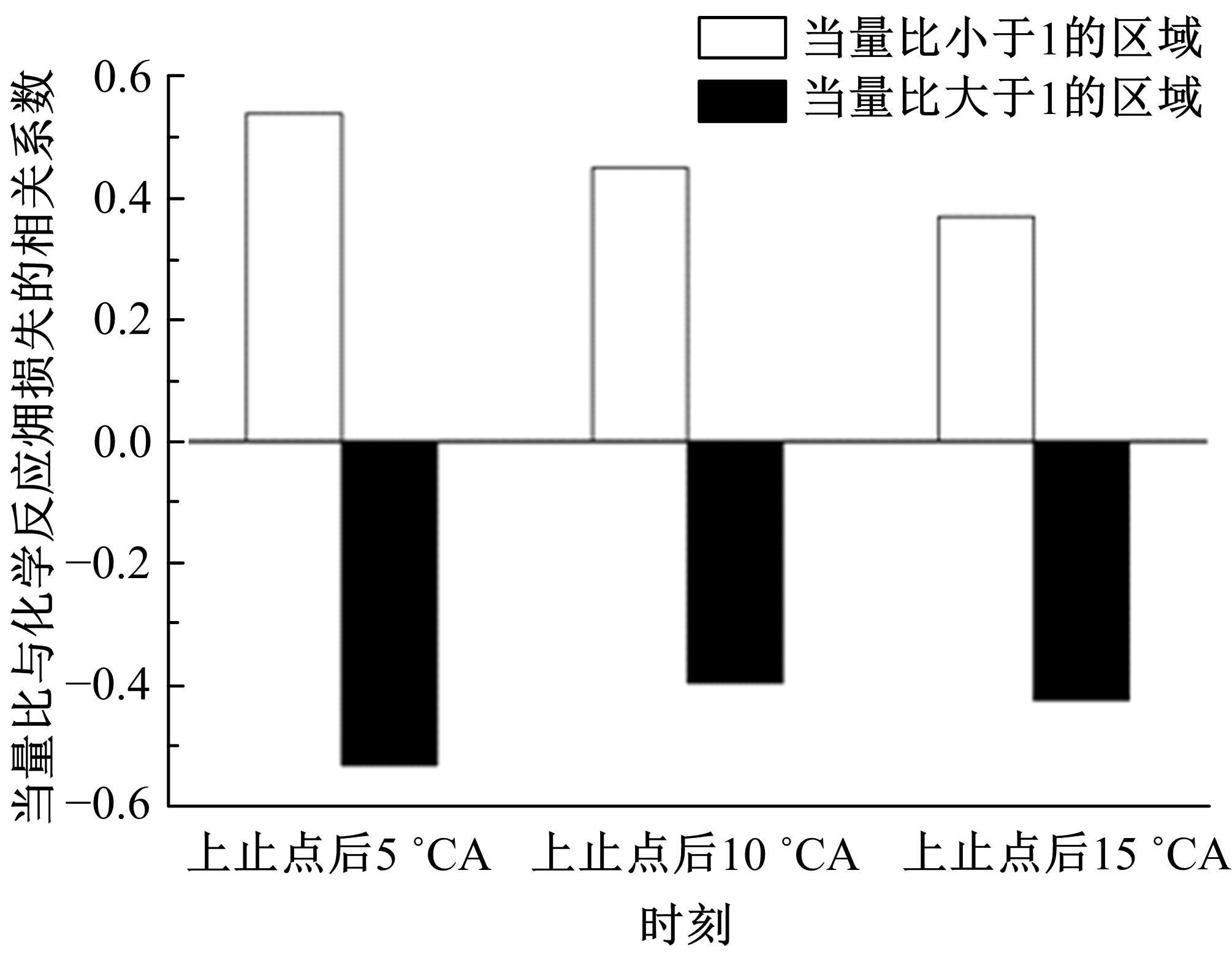

In⁃cylinder exergy destruction during combustion process ofheavy⁃duty turbocharged diesel engine

Chang-cheng LIU( ),Zhong-chang LIU,Jing TIAN(

),Zhong-chang LIU,Jing TIAN( ),Yun XU,Ze-yu YANG

),Yun XU,Ze-yu YANG

- State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

CLC Number:

- TK421

|

| [1] | Ren HE,Kun TU. Electromagnetic brake with changed⁃temperature air gap width [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1777-1785. |

| [2] | Qiao WANG,Wan-chen SUN,Liang GUO,Peng CHENG,Lu-yan FAN,Guo-liang LI. Effects of butanol/diesel blends on combustion and particulate emission characteristics of compression ignition engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1920-1928. |

| [3] | Chang-qing SONG,Wen-miao CHEN,Jun LI,Da-wei QU,Hao CUI. Effects of single and dual ignition on combustion characteristics of natural gas under different equivalence ratios [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1929-1935. |

| [4] | Yi-xiao ZHU,Xiao-min HE,Yi JIN. Effects of radial strut width on flow structure ofsingle⁃cavity trapped vortex combustor [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1936-1944. |

| [5] | Xiao-yu HU,Guo-xiang LI,Shu-zhan BAI,Ke SUN,Si-yuan LI. Modified boiling heat transfer model considering roughness and material of heating surface [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1945-1950. |

| [6] | Chun-zheng DUAN,Fang-yuan ZHANG,Wen-neng KOU,Bin WEI. Martensitic transformation of surface white layer in high speed hard cutting [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1575-1583. |

| [7] | Guang YAN,Jian-zhong LU,Kai-yu ZHANG,Fan-yong MENG,Lian-qing ZHU. Temperature decoupling large range fiber Bragg grating strain sensor [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1682-1688. |

| [8] | Guo⁃feng QIN,Jing⁃xin NA,Wen⁃long MU,Wei TAN,Jian⁃ze LUAN,Hao SHEN. Degradation failure of adhesively bonded CFRP/aluminum alloy subjected to high temperature environment [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1063-1071. |

| [9] | De⁃jun WANG,Zhi⁃chao LYU,Qi⁃ming WANG,Jian⁃rui ZHANG,Jian⁃nan DING. Cylinder pressure identification based on EKF and frequency⁃amplitude modulation Fourier series [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1174-1185. |

| [10] | Yan-qin ZHANG,Ya-nan FENG,Peng-rui KONG,Xiao-dong YU,Xiang-bin KONG. Temperature field and experiment of hydrostatic bearing oil film based on hot oil carrying [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1203-1211. |

| [11] | Peng⁃fei ZANG,Zhe WANG,Yang GAO,Chen⁃le SUN. Investigation of integrated control strategy for stable operation of linear generator/engine system [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 798-804. |

| [12] | Yu⁃peng LI,Da⁃qian SUN,Wen⁃biao GONG. Temperature fields in bobbin⁃tool friction stir welding for 6082⁃T6 aluminum alloy sheet [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 836-841. |

| [13] | LI Yi,LIU Li-ping,SUN Li-jun. Prediction model on rutting equivalent temperature for asphalt pavement at different depth [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1703-1711. |

| [14] | JIANG Tao,LIN Xue-dong,LI De-gang,YANG Miao,TANG Xue-lin. Effect of control parameters on heat release rate with ANN method [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1747-1754. |

| [15] | LI Zhi-jun, WANG Hao, HE Li, CAO Li-juan, ZHANG Yu-chi, ZHAO Xin-shun. Soot distribution features and its influence factors in catalytic diesel particulate filte [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1466-1474. |

|