Journal of Jilin University(Engineering and Technology Edition) ›› 2021, Vol. 51 ›› Issue (5): 1749-1755.doi: 10.13229/j.cnki.jdxbgxb20200508

Design and performance of internal air supply conduit for dehumidification in main cables of suspension bridges

Wei CHEN1( ),Tian-bao WAN2,Zhong-bin WANG2,Xuan LI1,Rui-li SHEN1(

),Tian-bao WAN2,Zhong-bin WANG2,Xuan LI1,Rui-li SHEN1( )

)

- 1.School of Civil Engineering,Southwest Jiaotong University,Chengdu 610031,China

2.China Railway Major Bridge Reconnaissance & Design Institute Co. ,Ltd. ,Wuhan 430056,China

CLC Number:

- U443.8

| 1 | 白伦华, 沈锐利, 张兴标, 等. 自锚式悬索桥的面内稳定性[J]. 吉林大学学报: 工学版, 2019, 49(5): 1500-1508. |

| Bai Lun-hua, Shen Rui-li, Zhang Xing-biao, et al. In-plane stability of self-anchored suspension bridge[J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1500-1508. | |

| 2 | 王保群, 张强勇, 张凯, 等. 自锚式斜拉-悬吊协作体系桥梁动力性能[J]. 吉林大学学报: 工学版, 2009, 39(3): 686-690. |

| Wang Bao-qun, Zhang Qiang-yong, Zhang Kai, et al. Dynamic characteristics for self-anchored cablestayed suspension bridges[J]. Journal of Jilin University(Engineering and Technology Edition), 2009, 39(3): 686-690. | |

| 3 | Shoichi S, Kazuhiko F. Corrosion protection of suspension bridge cables[J]. Construction of Civil Engineering Structures, 2003(7): 35-37, 63. |

| 4 | Shunichi N, Keita S. Experimental study on repair methods of corroded bridge cables[J]. Journal of Bridge Engineering, 2012, 17(4): 720-727. |

| 5 | 陈小雨, 唐茂林. 悬索桥主缆钢丝腐蚀速率计算方法[J]. 公路交通科技, 2019, 36(2): 43-49. |

| Chen Xiao-yu, Tang Mao-lin. A method for calculating corrosion rate of main cable steel wires of suspension bridge[J]. Journal of Highway and Transportation Research and Development, 2019, 36(2): 43-49. | |

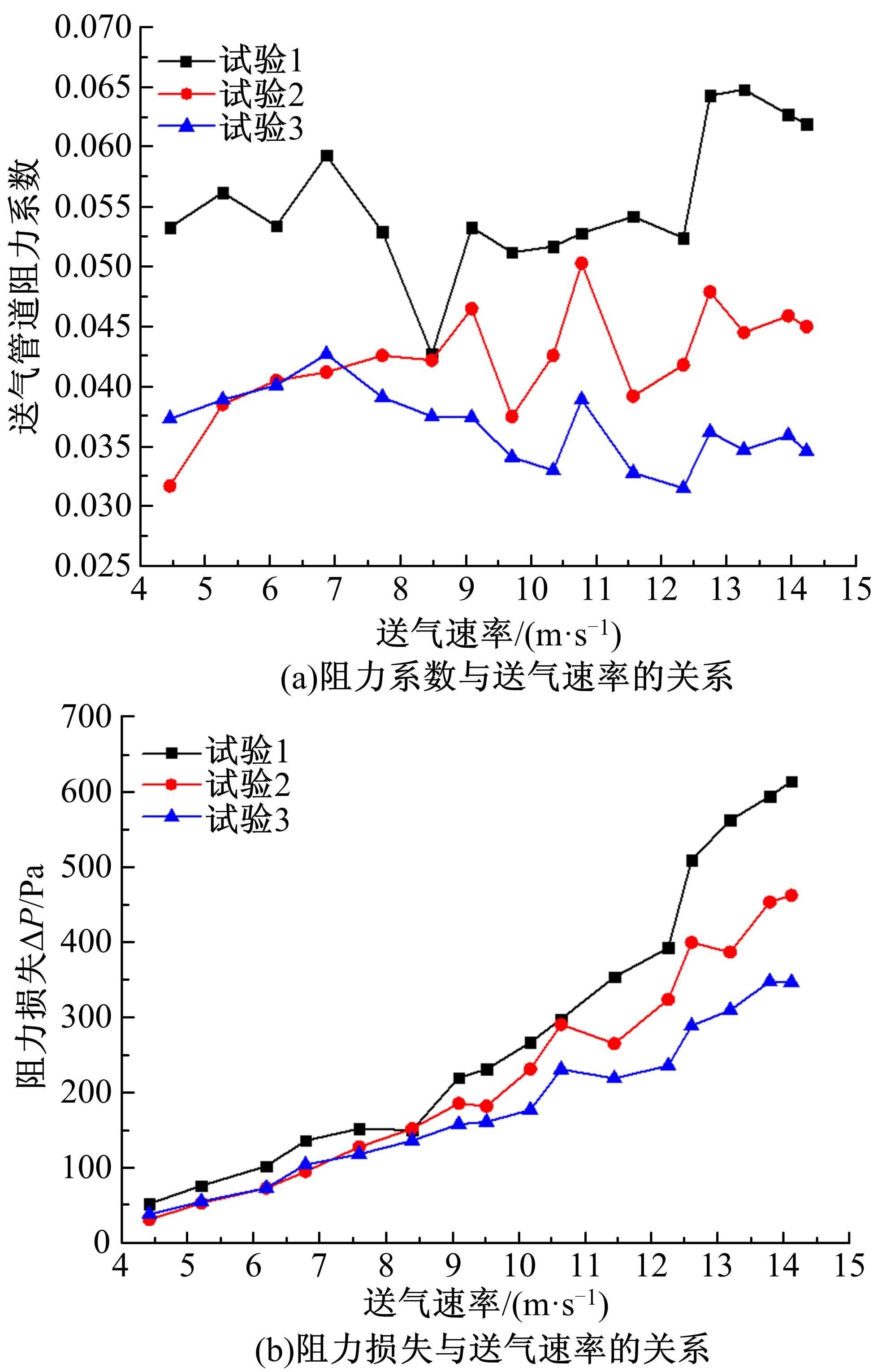

| 6 | 魏子杰, 彭福胜, 缪小平, 等. 悬索桥主缆通风除湿数值计算及实验研究[J]. 工程热物理学报, 2016, 37(12): 2495-2501. |

| Wei Zi-jie, Peng Fu-sheng, Miao Xiao-ping, et al. Numerical calculation and experiment on the dehumidification system for main cable of suspension bridge [J]. Journal of Engineering Thermophysics, 2016, 37(12): 2495-2501. | |

| 7 | 王鹏宇. 重庆几江长江大桥主桥设计[J]. 桥梁建设, 2017, 47(2): 72-77. |

| Wang Peng-yu. Design of main bridge of Jijiang Changjiang river bridge in chongqing[J]. Bridge Construction, 2017, 47(2): 72-77. | |

| 8 | 王凤存, 丁亚辉, 徐翾玄, 等. 清水河大桥主缆除湿系统安装施工技术[J]. 公路, 2018, 63(5): 120-124. |

| Wang Feng-cun, Ding Ya-hui, Xu Xuan-xuan, et al. Installation and construction technology of main cable dehumidification system of Qingshuihe Bridge[J]. Highway, 2018, 63(5): 120-124. | |

| 9 | 叶觉明, 李荣庆. 现代悬索桥主缆防护现状与展望[J]. 桥梁建设, 2009(6): 67-71. |

| Ye Jue-ming, Li Rong-qing. State-of-the-art and prospecting of main cable protection of modern suspension bridge[J]. Bridge Construction, 2009(6): 67-71. | |

| 10 | 李海. 润扬大桥悬索桥主缆除湿系统设计与施工[J]. 桥梁建设, 2005(1): 39-41. |

| Li Hai. Design and construction of dehumidification system for main cables of suspension bridge of Runyang Bridge[J]. Bridge Construction, 2005(1): 39-41. | |

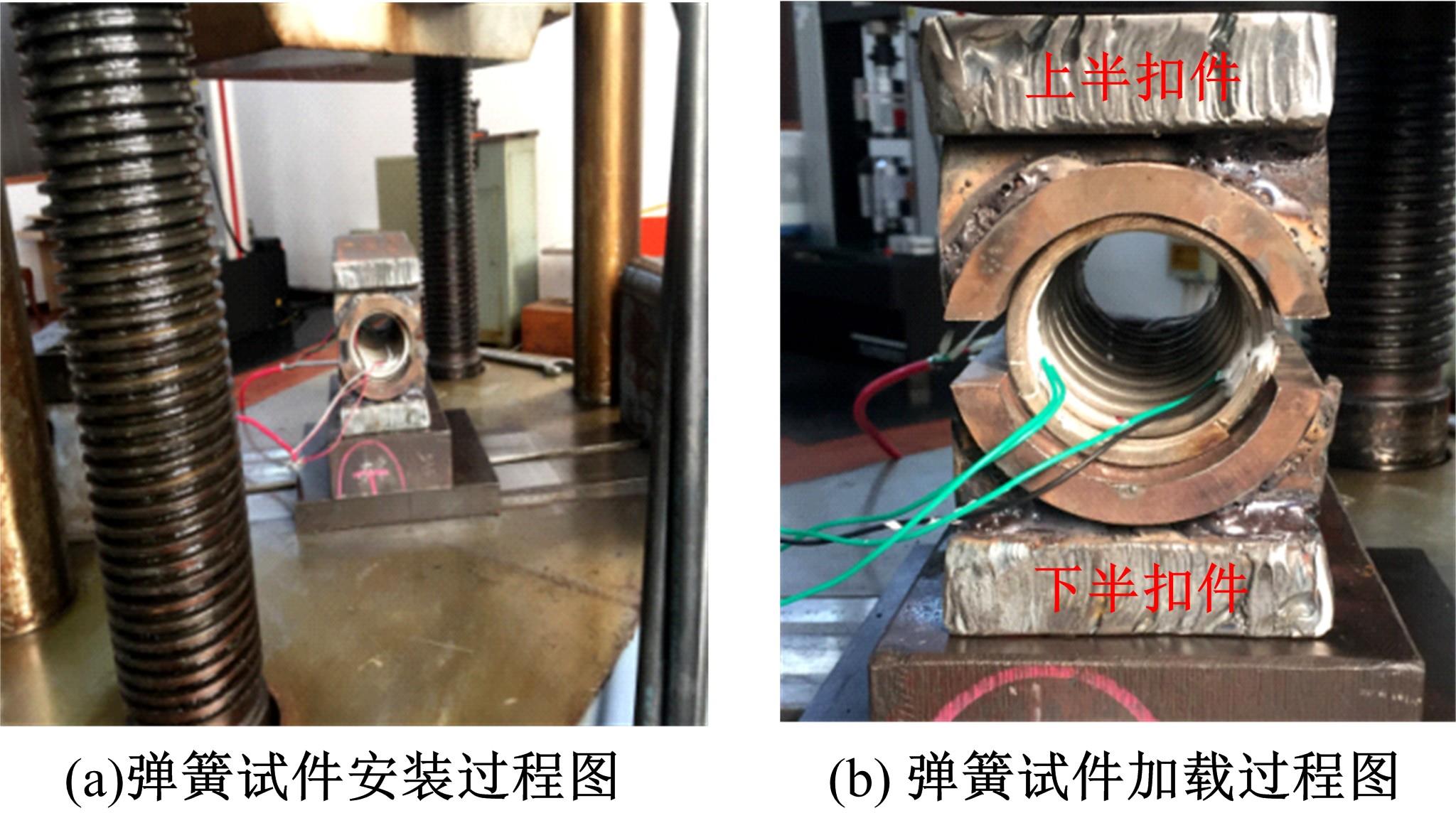

| 11 | Miao R S, Shen R L, Wang L, et al. Theoretical and numerical studies of the slip resistance of main cable clamp composed of an upper and a lower part[J]. Advances in Structural Engineering, 2020, 24(4): 691-705. |

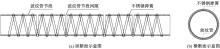

| 12 | 沈锐利, 陈巍, 陈鑫, 等. 一种高承压高伸长管道结构[P]. 中国: CN210088192U, 2020-02-18. |

| 13 | 苑磊. 山区公路大管径钢波纹管涵洞受力特征分析与工程应用[D]. 重庆: 重庆交通大学土木工程学院, 2016. |

| Yuan Lei. Force characteristics of mountain highway and engineering application of large diameter steel bellows Culvert[D]. Chongqing: School of Civil Engineering, Chongqing Jiaotong University, 2016. | |

| 14 | Elie P, Benoît T, Marc L. Irradiation-assisted stress corrosion cracking susceptibility and mechanical properties related to irradiation-induced microstructures of 304L austenitic stainless steel[J]. Journal of Nuclear Materials, 2020, 528: 151880. |

| 15 | 彭关中, 缪小平, 贾代勇, 等. 悬索桥主缆通风除湿系统的设计[J]. 深圳大学学报: 理工版, 2013, 30(2): 179-185. |

| Peng Guan-zhong, Miao Xiao-ping, Jia Dai-yong, et al. Design research on dehumidification system for main cable of suspension bridge[J]. Journal of Shenzhen University(Science & Engineering), 2013, 30(2): 179-185. |

| [1] | Kai GAO,Gang LIU. Effective strength improvement of global critical strength branch and bound method [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 597-603. |

| [2] | Ya-feng GONG,Jia-xiang SONG,Guo-jin TAN,Hai-peng BI,Yang LIU,Cheng-xin SHAN. Multi⁃vehicle bridge weigh⁃in⁃motion algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 583-596. |

| [3] | Qing-wen KONG,Guo-jin TAN,Long-lin WANG,Yong WANG,Zhi-gang WEI,Han-bing LIU. Analysis of free vibration characteristics of cracked box girder bridge based on finite element method [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 225-232. |

| [4] | Hua CHEN,Yao-jia CHEN,Bin XIE,Peng-kai WANG,Lang-ni DENG. Interface failure mechanism and bonding strength calculation of CFRP tendons bonded anchorage system [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1698-1708. |

| [5] | Ya-feng GONG,Jia-xiang SONG,Hai-peng BI,Guo-jin TAN,Guo-hai HU,Si-yuan LIN. Static test and finite element analysis of scale model of fabricated box culvert [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1728-1738. |

| [6] | Hao GAO,Jun-jie WANG,Hui-jie LIU,Jian-ming WANG. Design criterion and applied devices for controlled seismic behavior of continuous girder bridges [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1718-1727. |

| [7] | Qian-hui PU,Jing-wen LIU,Gang-yun ZHAO,Meng YAN,Xiao-bin LI. Theoretical analysis of bearing capacity of concrete eccentric compressive column reinforced by HTRCS [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 606-612. |

| [8] | Yun-long ZHANG,Yang-yang GUO,Jing WANG,Dong LIANG. Natural frequency and mode of vibration of steel⁃concrete composite beam [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 581-588. |

| [9] | Bo-xin WANG,Hai-tao YANG,Qing WANG,Xin GAO,Xiao-xu CHEN. Bridge vibration signal optimization filtering method based on improved CEEMD⁃multi⁃scale permutation entropy analysis [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 216-226. |

| [10] | Miao ZHANG,Yong-jiu QIAN,Fang ZHANG,Shou-qin ZHU. Experimental analysis of spatial force performance of concrete-reinforced stone arch bridge based on enlarged section method [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 210-215. |

| [11] | Yi JIA,Ren-da ZHAO,Yong-bao WANG,Fu-hai LI. Sensitivity analysis of viscous damper parameters for multi⁃span and long⁃unit continuous girder bridges [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1871-1883. |

| [12] | Chun-ling ZHONG,Dong LIANG,Yun-long ZHANG,Jing WANG. Calculation of natural vibration frequency of simply supported beam strengthened by external prestressing [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1884-1890. |

| [13] | Lun-hua BAI,Rui-li SHEN,Xing-biao ZHANG,Lu WANG. In-plane stability of self-anchored suspension bridge [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1500-1508. |

| [14] | Jin⁃gang ZHAO,Ming ZHANG,Yu⁃lin ZHAN,Ming⁃zhi XIE. Damage criterion of reinforced concrete pier based on plastic strain energy density [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1124-1133. |

| [15] | Shi⁃cheng WAN,Qiao HUANG,Jian GUAN,Zhao⁃yuan GUO. Strengthening of continuous steel⁃concrete composite beams in negative moment region using prestressed carbon fiber⁃reinforced polymer plates [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1114-1123. |

|

||