Journal of Jilin University(Engineering and Technology Edition) ›› 2020, Vol. 50 ›› Issue (5): 1698-1708.doi: 10.13229/j.cnki.jdxbgxb20190621

Interface failure mechanism and bonding strength calculation of CFRP tendons bonded anchorage system

Hua CHEN1,2( ),Yao-jia CHEN1,Bin XIE1,Peng-kai WANG1,Lang-ni DENG1(

),Yao-jia CHEN1,Bin XIE1,Peng-kai WANG1,Lang-ni DENG1( )

)

- 1.College of Civil and Architecture Engineering, Guangxi University of Science and Technology, Liuzhou 545006, China

2.College of Civil and Architecture Engineering, Nanning University,Nanning 530200,China

CLC Number:

- U444

| 1 | 叶列平, 冯鹏. FRP在工程结构中的应用与发展[J]. 土木工程学报, 2006, 39(3): 24-36. |

| Ye Lie-ping, Feng Peng. Application and development of fiber-reinforced polymer in engineering structures[J]. China Civil Engineering Journal, 2006, 39(3): 24-36. | |

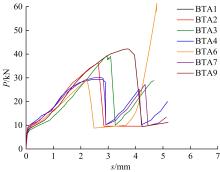

| 2 | 侯苏伟, 龙佩恒, 诸葛萍, 等. CFRP索股粘结型锚具锚固机理试验[J]. 中国公路学报, 2013, 26(5): 95-101. |

| Hou Su-wei, Long Pei-heng, Zhu-ge Ping, et al. Experiment on mechanism of bond-type anchor for CFRP cables[J]. China Journal of Highway and Transport, 2013, 26(5): 95-101. | |

| 3 | Mei K H, Sun S J, Li B, et al. Experimental investigation on the mechanical properties of a bond-type anchor for carbon fiber reinforced polymer tendons[J]. Composite Structures, 2018, 201: 193-199. |

| 4 | 蒋田勇, 方志. CFRP筋粘结式锚具锚固性能试验[J]. 中国公路学报, 2011, 24(1): 68-77. |

| Jiang Tian-yong, Fang Zhi. Experiment on anchorage performance of bond-type anchorage for CFRP tendon[J]. China Journal of Highway and Transport, 2011, 24(1): 68-77. | |

| 5 | Puigvert F, Crocombe A D, Gil L. Static analysis of adhesively bonded anchorages for CFRP tendons[J]. Construction and Building Materials, 2014, 61: 206-215. |

| 6 | Zhang B, Benmokrane B. Design and evaluation of a new bond-type anchorage system for fiber reinforced polymer tendons[J]. Canadian Journal of Civil Engineering, 2004, 31(1): 14-26. |

| 7 | Fang Z, Zhang K, Tu B, et al. Experimental investigation of a bond-type anchorage system for multiple FRP tendons[J]. Engineering Structures, 2013, 57: 364-373. |

| 8 | Jung W T, Keum M S, Kang J Y, et al. An experimental study on anchor performance of bare CFRP tendons with bond type anchor[J]. Advanced Materials Research, 2014, 1082: 408-411. |

| 9 | Zhang K, Fang Z, Nanni A, et al. Experimental study of a large-scale ground anchor system with FRP tendon and RPC grout medium[J]. Journal of Composites for Construction, 2015, 19(4): 1-30. |

| 10 | 方志, 余庭嘉, 方亚威, 等. CFRP绞线黏结式锚具静力性能试验研究[J]. 建筑结构学报, 2018, 39(6): 167-174. |

| Fang Zhi, Yu ting-jia, Fang Ya-wei, et al. Experimental study on static performance of bond-type anchorage for CFRP strand[J]. Journal of Building Structures, 2018, 39(6): 167-174. | |

| 11 | 方志, 龚畅, 杨剑, 等. CFRP预应力筋粘结式锚固系统的抗疲劳性能[J]. 公路交通科技, 2012, 29(7): 58-63. |

| Fang Zhi, Gong Chang, Yang Jian, et al. Fatigue behavior of bond-type anchorage with CFRP tendon[J]. Journal of Highway and Transportation Research and Development, 2012, 29(7): 58-63. | |

| 12 | 孙志刚. 碳纤维预应力筋及拉索锚固系统抗疲劳性能的试验研究[D]. 长沙: 湖南大学土木工程学院, 2002. |

| Sun Zhi-gang. Experimental study on the fatigue behavior of anchorage system for CFRP tendons[D]. Changsha: College of Civil Engineering, Hunan University, 2002. | |

| 13 | Xie G H, Tang Y S, Wang C M, et al. Experimental study on fatigue performance of adhesively bonded anchorage system for CFRP tendons[J]. Composites Part B: Engineering, 2018, 150: 47-59. |

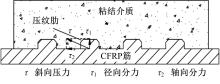

| 14 | 熊文, 蒋超, 肖汝诚, 等. 基于接触滑移理论的CFRP拉索黏结型锚具精细化仿真[J]. 东南大学学报: 自然科学版, 2014, 44(6): 1218-1223. |

| Xiong Wen, Jiang Chao, Xiao Ru-cheng, et al. Fine simulation of adhesive anchorage for CFRP cables based on contact-sliding theory[J]. Journal of Southeast University(Natural Science Edition), 2014, 44(6): 1218-1223. | |

| 15 | Wu J, Xian G, Li H. A novel anchorage system for CFRP cable: experimental and numerical investigation[J]. Composite Structures, 2018, 194: 555-563. |

| 16 | 朱元林, 刘礼华, 张继文, 等. 碳纤维复合材料筋粘结型锚固系统数值模拟及失效分析[J]. 复合材料学报, 2015, 32(5): 1414-1419. |

| Zhu Yuan-lin, Liu Li-hua, Zhang Ji-wen, et al. Numerical simulation and failure analysis of adhesive anchorage system for CFRP tendon[J]. Acta Materiae Compositae Sinica, 2015, 32(5): 1414-1419. | |

| 17 | 方志, 梁栋, 蒋田勇. 不同粘结介质中CFRP筋锚固性能的试验研究[J]. 土木工程学报, 2006, 39(6):47-51. |

| Fang Zhi, Liang Dong, Jiang Tian-yong, et al. Experimental investigation on the anchorage performance of CFRP tendon in different bond mediums [J]. China Civil Engineering Journal, 2006, 39(6): 47-51. | |

| 18 | 方志, 王常林, 张洪侨, 等. 碳纤维绞线在活性粉末混凝土中锚固性能的试验研究[J]. 中国公路学报, 2016, 29(6): 198-206. |

| Fang Zhi, Wang Chang-lin, Zhang Hong-qiao, et al. Experimental study on anchoring performance of CFRP strand in reactive powder concrete[J]. China Journal of Highway and Transport, 2016, 29(6): 198-206. | |

| 19 | 朱元林, 刘礼华, 张继文, 等. 碳纤维复合材料筋在不同锚固填料中的锚固性能试验研究[J]. 玻璃钢/复合材料, 2015(7): 78-82. |

| Zhu Yuan-lin, Liu Li-hua, Zhang Ji-wen. et al. Experiments research on the anchor age performance of CFRP tendon in different potting material[J]. Fiber Reinforced Plastics/Composites, 2015(7): 78-82. | |

| 20 | 蒋田勇, 方志. 极限状态时CFRP筋粘结式锚具粘结应力分布[J]. 公路交通科技, 2007, 24(12): 75-78, 92. |

| Jiang Tian-yong, Fang Zhi. Bond stress distribution of bond-type anchors for CFRP tendons under the ultimate tensile capacity[J]. Journal of Highway and Transportation Research and Development, 2007, 24(12): 75-78, 92. | |

| 21 | 王博, 白国良. 钢筋与再生混凝土黏结破坏过程的能量机制研究[J]. 混凝土, 2011(2): 32-35. |

| Wang Bo, Bai Guo-liang. Energy mechanism of the bonding failure process between the rebars and the recycled concrete[J]. Concrete, 2011(2): 32-35. | |

| 22 | Wu Z S, Yuan H, Niu H D. Stress transfer and fracture propagation in different kinds of adhesive joints[J]. Journal of Engineering Mechanics, 2002, 128(5): 562-573. |

| 23 | Faoro M. Bearing and deformation behaviour of structural components with reinforcements comprising resin bounded glass fibre bars and conventional ribbed steel bars[A]. Int Conf on Bond in Concrete, 1992: 145-162. |

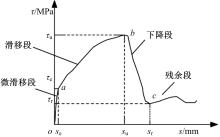

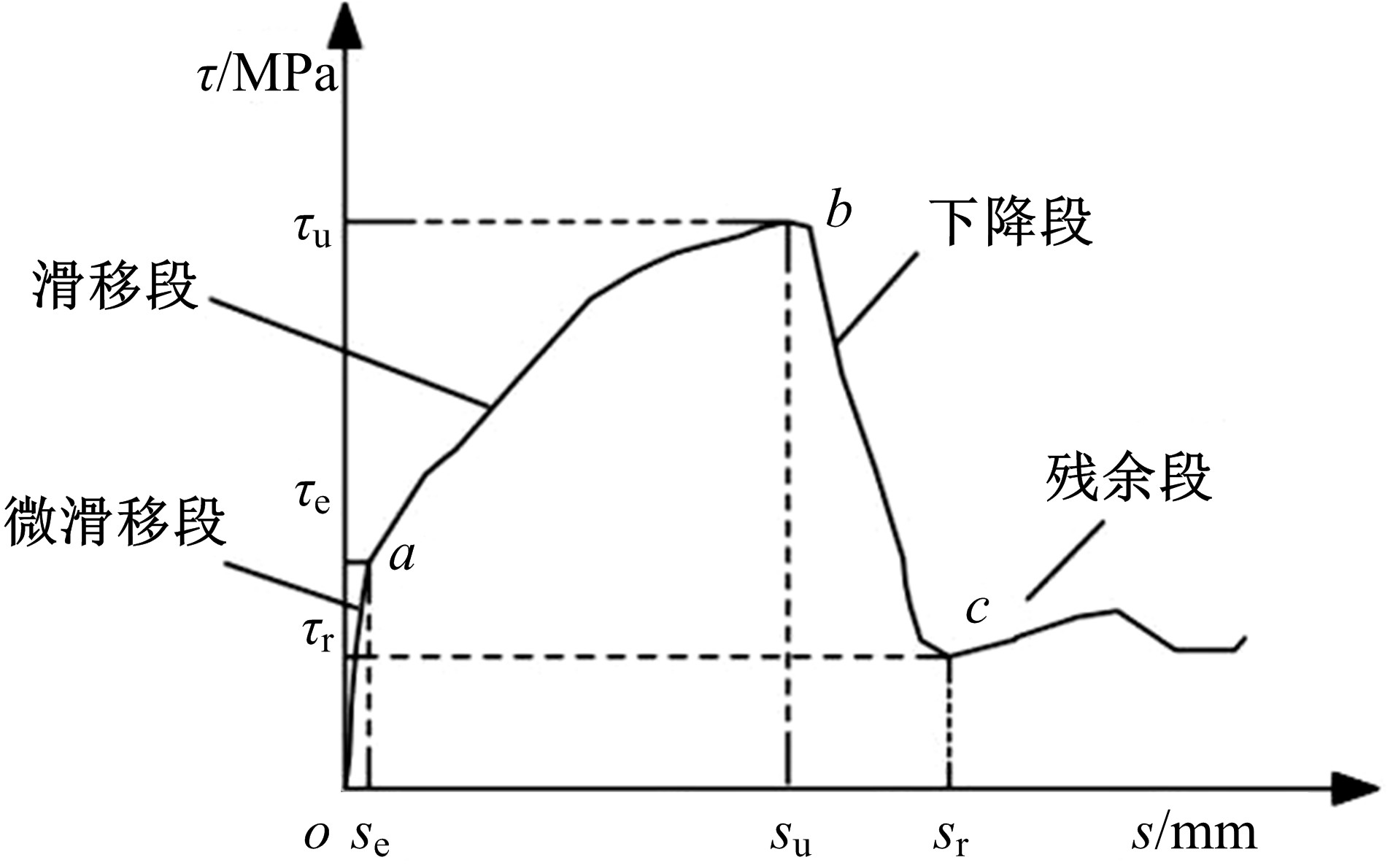

| 24 | 高丹盈, 朱海堂, 谢晶晶. 纤维增强塑料筋混凝土粘结滑移本构模型[J]. 工业建筑, 2003, 33(7): 41-43, 82. |

| Gao Dan-ying, Zhu Hai-tang, Xie Jing-jing. The constitutive models for bong slip relation between FRP rebars and concrete[J]. Industrial Construction, 2003, 33(7): 41-43, 82. | |

| 25 | 王博, 白国良, 代慧娟, 等. 再生混凝土与钢筋粘结滑移性能的试验研究及力学分析[J]. 工程力学, 2013, 30(10): 54-64. |

| Wang Bo, Bai Guo-liang, Dai Hui-juan, et al. Experimrntal and mechanical analysis of bond-slip performance between recycled concrete and rebar[J]. Engineering Mechanics, 2013, 30(10): 54-64. | |

| 26 | 孙芳芳. 浅议灰色关联度分析方法及其应用[J]. 科技信息, 2010, 2(17): 780-782. |

| Sun Fang-fang. Grey relational analysis method and its application[J]. Science & Technology Information, 2010, 2(17): 780-782. |

| [1] | Yun-long ZHANG,Yang-yang GUO,Jing WANG,Dong LIANG. Natural frequency and mode of vibration of steel⁃concrete composite beam [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 581-588. |

| [2] | Qian-hui PU,Jing-wen LIU,Gang-yun ZHAO,Meng YAN,Xiao-bin LI. Theoretical analysis of bearing capacity of concrete eccentric compressive column reinforced by HTRCS [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 606-612. |

| [3] | Miao ZHANG,Yong-jiu QIAN,Fang ZHANG,Shou-qin ZHU. Experimental analysis of spatial force performance of concrete-reinforced stone arch bridge based on enlarged section method [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 210-215. |

| [4] | Bo-xin WANG,Hai-tao YANG,Qing WANG,Xin GAO,Xiao-xu CHEN. Bridge vibration signal optimization filtering method based on improved CEEMD⁃multi⁃scale permutation entropy analysis [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 216-226. |

| [5] | Chun-ling ZHONG,Dong LIANG,Yun-long ZHANG,Jing WANG. Calculation of natural vibration frequency of simply supported beam strengthened by external prestressing [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1884-1890. |

| [6] | Yi JIA,Ren-da ZHAO,Yong-bao WANG,Fu-hai LI. Sensitivity analysis of viscous damper parameters for multi⁃span and long⁃unit continuous girder bridges [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1871-1883. |

| [7] | Lun-hua BAI,Rui-li SHEN,Xing-biao ZHANG,Lu WANG. In-plane stability of self-anchored suspension bridge [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1500-1508. |

| [8] | Jin⁃gang ZHAO,Ming ZHANG,Yu⁃lin ZHAN,Ming⁃zhi XIE. Damage criterion of reinforced concrete pier based on plastic strain energy density [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1124-1133. |

| [9] | Shi⁃cheng WAN,Qiao HUANG,Jian GUAN,Zhao⁃yuan GUO. Strengthening of continuous steel⁃concrete composite beams in negative moment region using prestressed carbon fiber⁃reinforced polymer plates [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1114-1123. |

| [10] | Wan⁃heng LI,Lin SHEN,Shao⁃peng WANG,Shang⁃chuan ZHAO. Damage assessment of bridge construction based onmulti⁃stage subregion mobile test [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 773-780. |

| [11] | HUI Ying-xin,MAO Ming-jie,LIU Hai-feng,ZHANG Shang-rong. Influence of structural seismic response of bridges crossing active fault [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1725-1734. |

| [12] | ZHENG Yi-feng, ZHAO Qun, BAO Wei, LI Zhuang, YU Xiao-fei. Wind resistance performance of long-span continuous rigid-frame bridge in cantilever construction stage [J]. 吉林大学学报(工学版), 2018, 48(2): 466-472. |

| [13] | GONG Ya-feng, HE Yu-long, TAN Guo-jin, SHEN Yang-fan. Anti-overturning stability analysis for three-span continuous curved girder bridge with single column pier [J]. 吉林大学学报(工学版), 2018, 48(1): 133-140. |

| [14] | WEI Zhi-gang, LIU Han-bing, SHI Cheng-lin, GONG Ya-feng. Calculation of transverse distribution coefficient of simply supported beam bridge with effect of bridge deck pavement [J]. 吉林大学学报(工学版), 2018, 48(1): 105-112. |

| [15] | WEI Zhi-gang, SHI Cheng-lin, LIU Han-bing, ZHANG Yun-long. Dynamic characteristics of steel-concrete composite simply supported beam under vehicles [J]. 吉林大学学报(工学版), 2017, 47(6): 1744-1752. |

|

||