Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (8): 2219-2226.doi: 10.13229/j.cnki.jdxbgxb.20211164

Reliability sensitivity analysis of bolt pre-tightening connection

Xian-zhen HUANG1,2( ),Kai-bo SUN1,Xiao-gang LUAN1,Bing HU1

),Kai-bo SUN1,Xiao-gang LUAN1,Bing HU1

- 1.School of Mechanical Engineering and Automation,Northeastern University,Shenyang 110819,China

2.Key Laboratory of Vibration and Control of Aero-Propulsion Systems Ministry of Education of China,Northeastern University,Shenyang 110819,China

CLC Number:

- TH131.3

| 1 | Lin Q, Zhao Y, Sun Q, et al. Reliability evaluation method of anti-loosening performance of bolted joints[J]. Mechanical Systems and Signal Processing, 2022, 162(5): 108067. |

| 2 | Bozca M, Knt U. Reliability analysis of the mechanical properties of 30MnB4 high strength steel bolts under static loading conditions[J]. Ecological Restoration, 2020, 38(2): 495-512. |

| 3 | Öztekin E. Investigation of reliabilities of bolt distances for bolted structural steel connections by Monte Carlo simulation method[J]. Pamukkale University Journal of Engineering Sciences, 2015, 21(6): 213-223. |

| 4 | 山本晃. 螺纹联接的理论与计算[M]. 1版. 上海: 上海科学技术文献出版社, 1984. |

| 5 | Sopwith D G. The distribution of load in screw threads[J]. Proceedings of the Institution of Mechanical Engineers, 2006, 159: 373-383. |

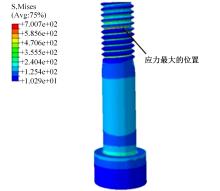

| 6 | Dragoni E. Effect of thread pitch and frictional coefficient on the stress concentration in metric nut-bolt connections[J]. Journal of Offshore Mechanics & Arctic Engineering, 1994, 116(1):21-27. |

| 7 | Zhao H. Stress concentration factors within bolt-nut connectors under elasto-plastic deformation[J]. International Journal of Fatigue, 1998, 20(9): 651-659. |

| 8 | Yokoyama T, Olsson M, Izumi S, et al. Investigation into the self-loosening behavior of bolted joint subjected to rotational loading[J]. Engineering Failure Analysis, 2012, 23(2): 35-43. |

| 9 | Dinger G, Friedrich C. Avoiding self-loosening failure of bolted joints with numerical assessment of local contact state[J]. Engineering Failure Analysis, 2011, 18(8): 2188-2200. |

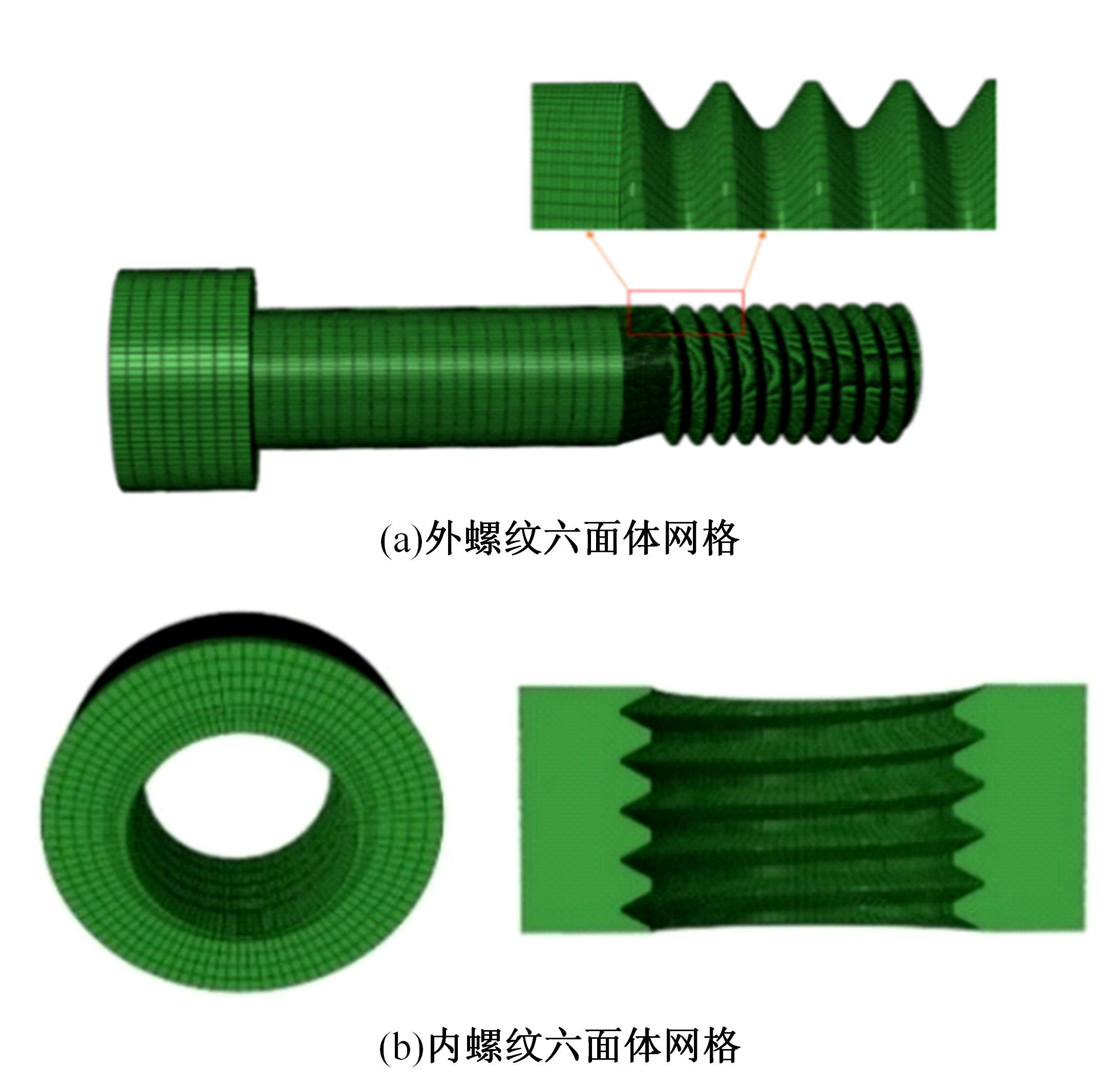

| 10 | Fukuoka T, Nomura M. Proposition of helical thread modeling with accurate geometry and finite element analysis[J]. Journal of Pressure Vessel Technology, 2008, 130(1): 135-140. |

| 11 | 胡大勇. 参数化三维螺纹实体建模技术及仿真研究[D]. 大连: 大连交通大学机械工程学院, 2005. |

| Hu Da-yong. Parametric 3D thread solid modeling technology and simulation research[D]. Dalian: School of Mechanical Engineering, Dalian Jiaotong University, 2005. | |

| 12 | 侯世远. 螺纹联接松动机理研究[D]. 北京: 北京理工大学机械与车辆学院, 2015. |

| Hou Shi-yuan. Research on the mechanism of thread connection looseness[D]. Beijing: School of Machinery and Vehicle, Beijing University of Technology, 2015. | |

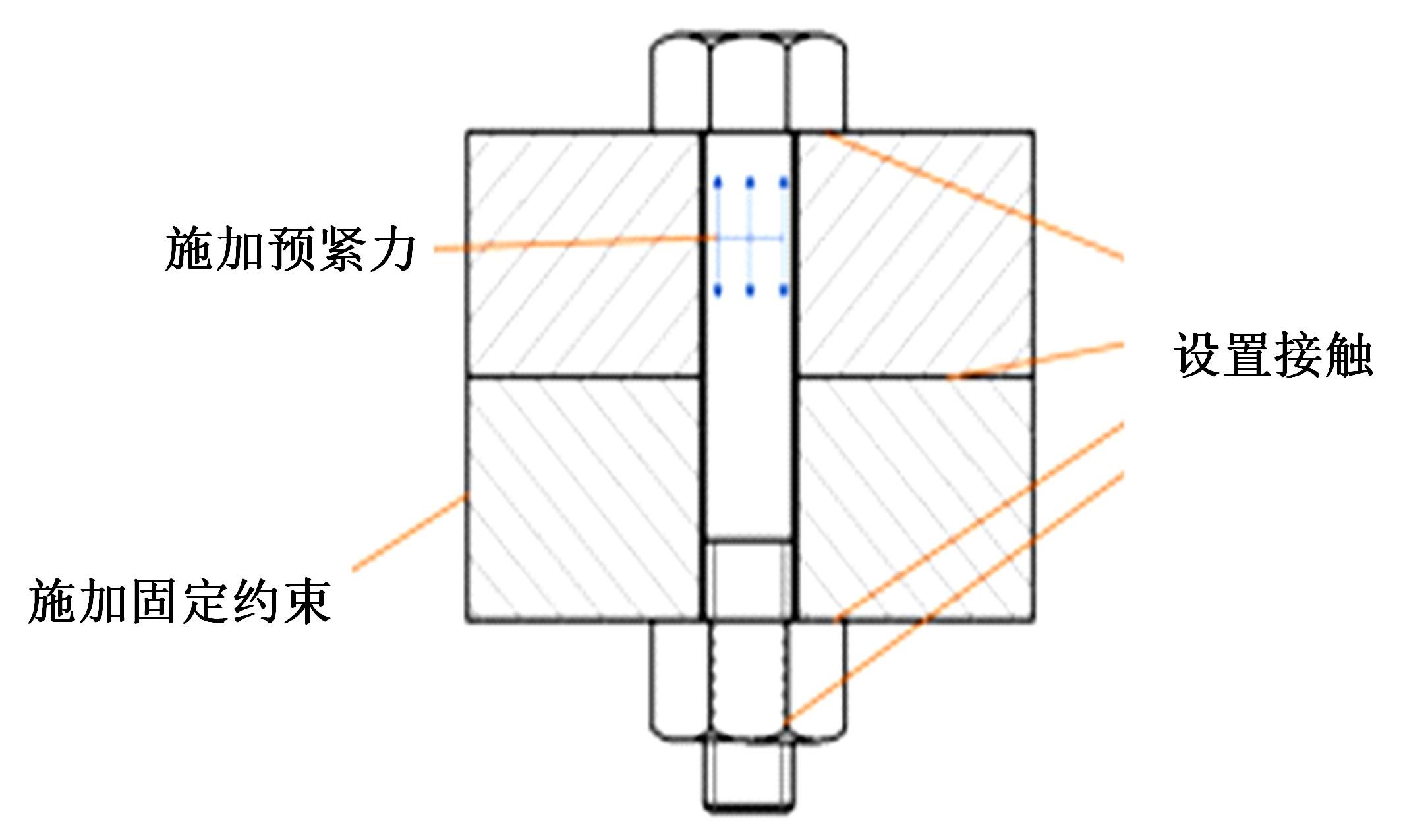

| 13 | 陆秉权, 王海龙, 周小飞, 等. 应用有限元技术计算螺栓联接的方法研究[J]. 黑龙江电力, 2004, 26(2): 100-102. |

| Lu Bing-quan, Wang Hai-long, Zhou Xiao-fei, et al. Research on the method of calculating bolted connections using finite element technology[J]. Heilongjiang Electric Power, 2004, 26 (2): 100-102. | |

| 14 | 李军, 杨洁明, 高俊云. 大型风力机组塔架螺栓连接应力分析[J]. 钢结构, 2011, 26(7): 22-25. |

| Li Jun, Yang Jie-ming, Gao Jun-yun. Stress analysis of bolt connections in large wind turbine tower frames[J]. Steel Structures, 2011, 26(7): 22-25. | |

| 15 | 邱继伟, 罗海胜. 基于混合不确定性的螺旋锥齿轮结构可靠性分析[J]. 吉林大学学报: 工学版, 2022, 52(2): 466-473. |

| Qiu Ji-wei, Luo Hai-sheng. Reliability analysis of spiral bevel gear structure based on mixed uncertainty [J]. Journal of Jilin University (Engineering and Techndogy Edition), 2022, 52(2): 466-473. | |

| 16 | Jamia N, Jalali H, Taghipour J, et al. An equivalent model of a nonlinear bolted flange joint[J]. Mechanical Systems and Signal Processing, 2021, 153(25/26): 107507. |

| 17 | Izumi S, Yokoyama T, Kimura M, et al. Loosening-resistance evaluation of double-nut tightening method and spring washer by three-dimensional finite element analysis[J]. Engineering Failure Analysis, 2009, 16(5): 1510-1519. |

| 18 | Zou Q, Sun T S, Nassar S A, et al. Effect of lubrication on friction and torque-tension relationship in threaded fasteners[J]. Tribology Transactions, 2007, 50(1): 127-136. |

| 19 | 李成, 朱红红, 铁瑛,等. 单搭胶/螺栓混合连接结构的应力分布与载荷分配[J]. 吉林大学学报: 工学版, 2013, 43(4): 933-938. |

| Li Cheng, Zhu Hong-hong, Ying Tie, et al. Stress distribution and load distribution of single adhesive/bolt hybrid connection structure[J]. Journal of Jilin University(Engineering and Technology Edition), 2013, 43(4): 933-938. | |

| 20 | Liu J H, Ouyang H J, Peng J F, et al. Experimental and numerical studies of bolted joints subjected to axial excitation[J]. Wear, 2016, 346(1): 66-77. |

| 21 | Yang X, Nassar S A, Wu Z, et al. Nonlinear Behavior of preloaded bolted joints under a cyclic separating load[J]. Journal of Pressure Vessel Technology, 2012, 134(1): 011206. |

| 22 | 闫明, 张义民, 孙志礼, 等. 机械零件相关失效可靠度及灵敏度计算的Monte Carlo方法[J]. 东北大学学报: 自然科学版, 2011, 32(6): 834-837. |

| Yan Ming, Zhang Yi-min, Sun Zhi-li, et al. The Monte Carlo method for calculating the reliability and sensitivity of mechanical component related failures[J]. Journal of Northeast University(Natural Science Edition), 2011, 32(6): 834-837. | |

| 23 | Jiang C, Qiu H, Gao L, et al. Real-time estimation error-guided active learning Kriging method for time-dependent reliability analysis[J]. Applied Mathematical Modelling, 2020, 77(1): 82-98. |

| [1] | Zhi-qiang HAN,Gang XIE,Yong-jun ZHOU,Shi-zhong LIU,Min-jie JIN. Numerical analysis method of vehicle⁃bridge coupling vibration of curved bridge [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 515-522. |

| [2] | Xu CHEN,Chao-fei CAO,Jing SHANG,Ming-xing HUANG,Chang-fa AI,Dong-ya Ren. Evaluation of influence of gradation segregation on pavement moisture damage under action of dynamic and static water environment [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(1): 210-219. |

| [3] | Zi-rong YANG,Yan LI,Xue-feng JI,Fang LIU,Dong HAO. Sensitivity analysis of operating parameters for proton exchange membrane fuel cells [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(9): 1971-1981. |

| [4] | Xin-tian LIU,Mu-zhou MA,Jia-long HE. Reliability prediction method of machining precision of machine tool parts based on fuzzy coupling [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 377-383. |

| [5] | Hong-xun ZHAO,Zhao-jun YANG,Chuan-hai CHEN,Hai-long TIAN,Li-ping WANG. Optimal design of acceleration test of motorized spindle of numerical control Machine Tool considering parameter weight [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 409-416. |

| [6] | Chuan-hai CHEN,Cheng-gong WANG,Zhao-jun YANG,Zhi-feng LIU,Hai-long TIAN. Research status and development trend analysis of reliability modeling of CNC machine tools [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 253-266. |

| [7] | Lin SONG,Li-ping WANG,Jun WU,Li-wen GUAN,Zhi-gui LIU. Reliability analysis based on cyber⁃physical system and digital twin [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 439-449. |

| [8] | Ji-wei QIU,Hai-sheng LUO. Structure reliability analysis of spiral bevel gear based on hybrid uncertainties [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 466-473. |

| [9] | Li-ping WANG,Bin ZHU,Jun WU,Zi-han TAO. Fault analysis of circular tool magazine based on Bayesian network [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 280-287. |

| [10] | Zi-ling ZHANG,Xiong HU,Yin QI,Wei WANG,Zhi-qiang TAO,Zhi-feng LIU. An approach for error allocation of machine tool based on vector projection response surface method [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 384-391. |

| [11] | Lu LIU,Hua-xi ZHOU,Chuan-hai CHEN,Meng-hui GONG,Hu-tian FENG,Chang-guang ZHOU. Reliability design model of ball screws based on competition failure [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 458-465. |

| [12] | Xue-ping FAN,Guang-hong YANG,Zhi-peng SHANG,Xiao-xiong ZHAO,Qing-kai XIAO,Yue-fei LIU. Dynamic reliability fusion prediction of long-span bridge girder considering structural serviceability [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 144-153. |

| [13] | Yu-xuan WEI,Ming ZHANG,Jia LIU,Shuo LIU,Ming-yu LU,Hong-yu WANG. Buckling performance of variable stiffness composite cylindrical shells based on mode imperfections [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 91-100. |

| [14] | Zun-ling DU,Yi-min ZHANG. Reliability analysis of piston pump under random flow rate [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 1967-1974. |

| [15] | Guo-fa LI,Ze-quan CHEN,Jia-long HE. New adaptive sampling strategy for structural reliability analysis [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 1975-1981. |

|

||