Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (8): 2212-2218.doi: 10.13229/j.cnki.jdxbgxb.20211086

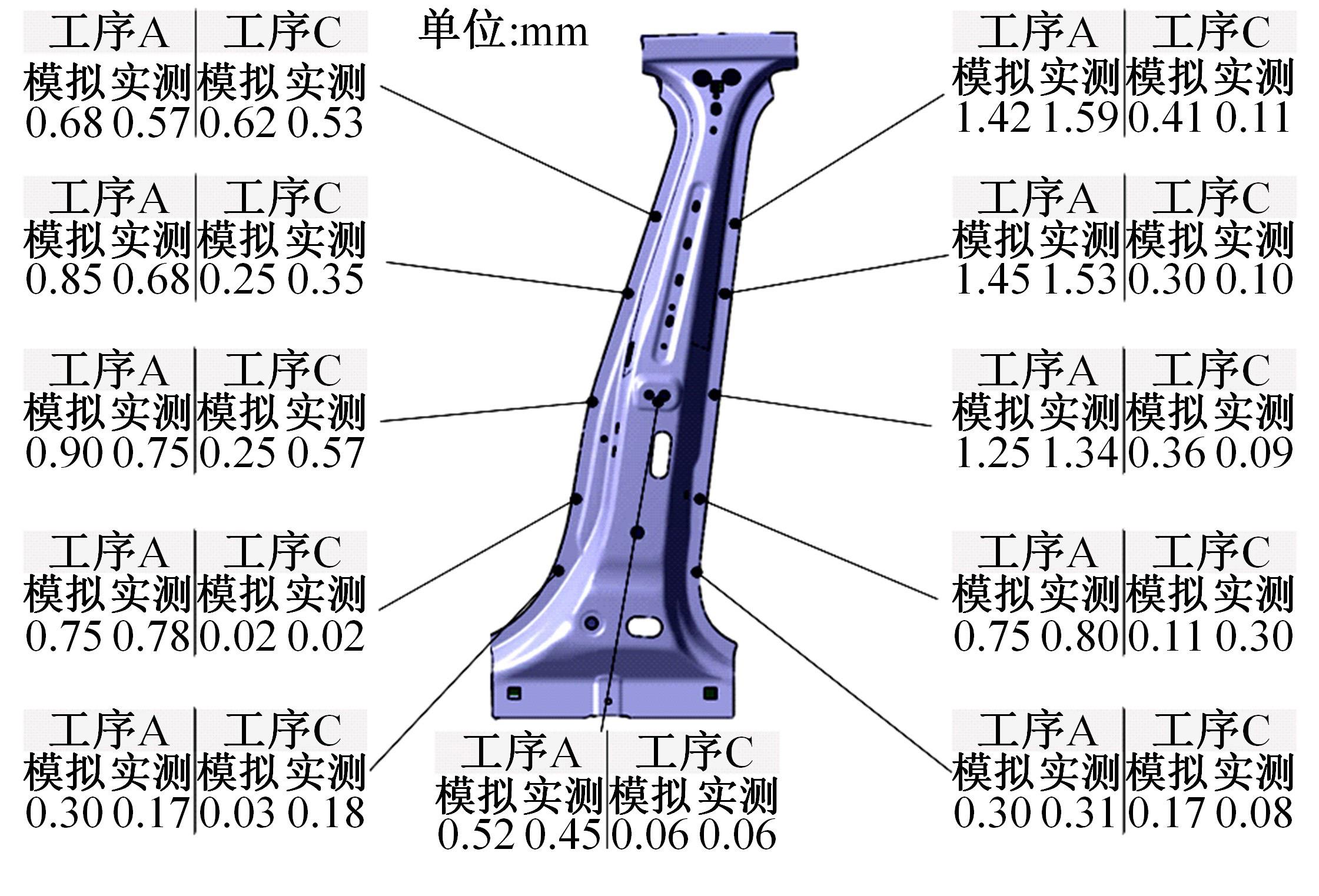

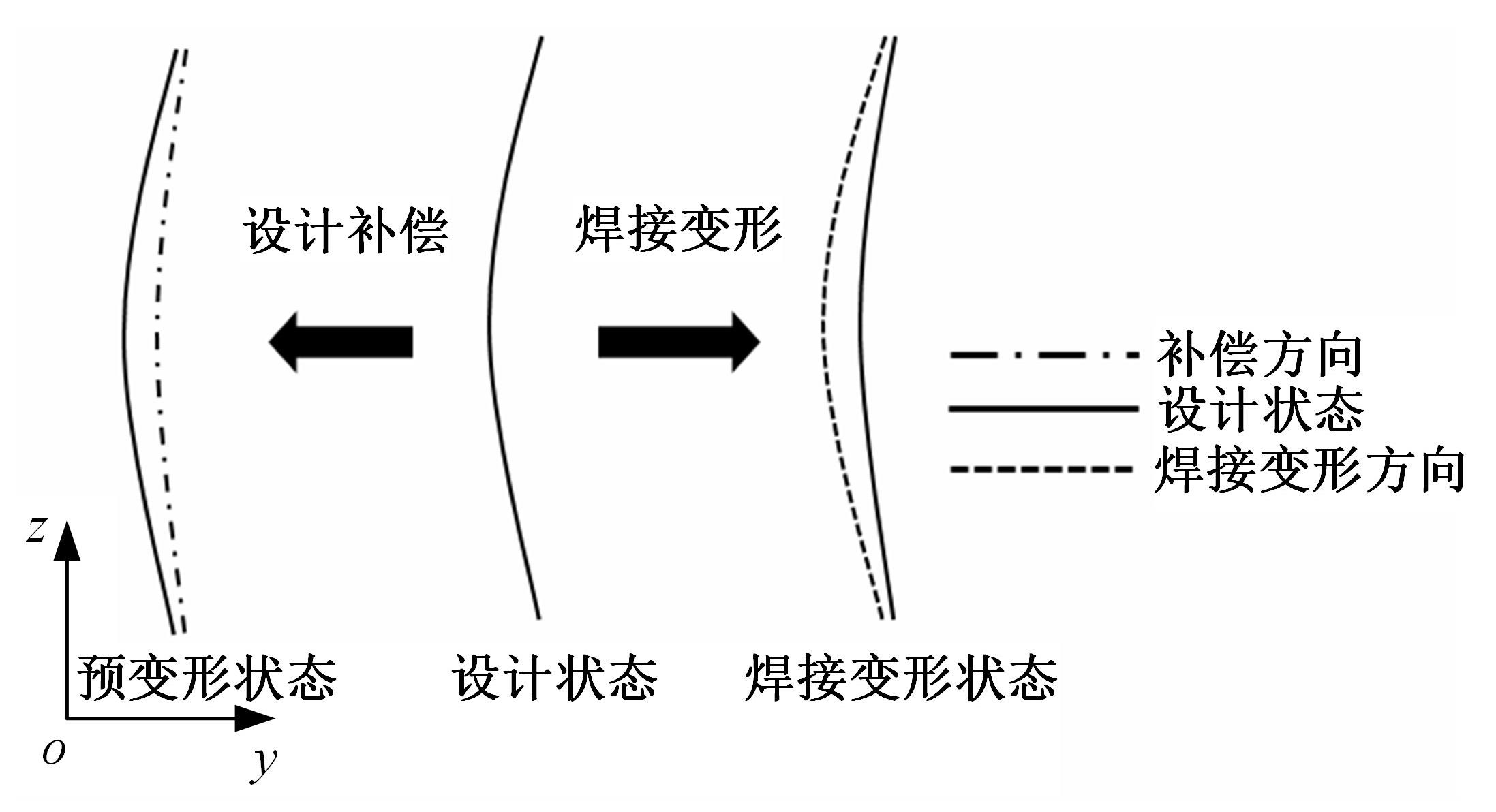

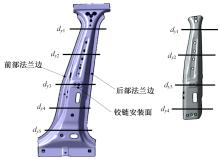

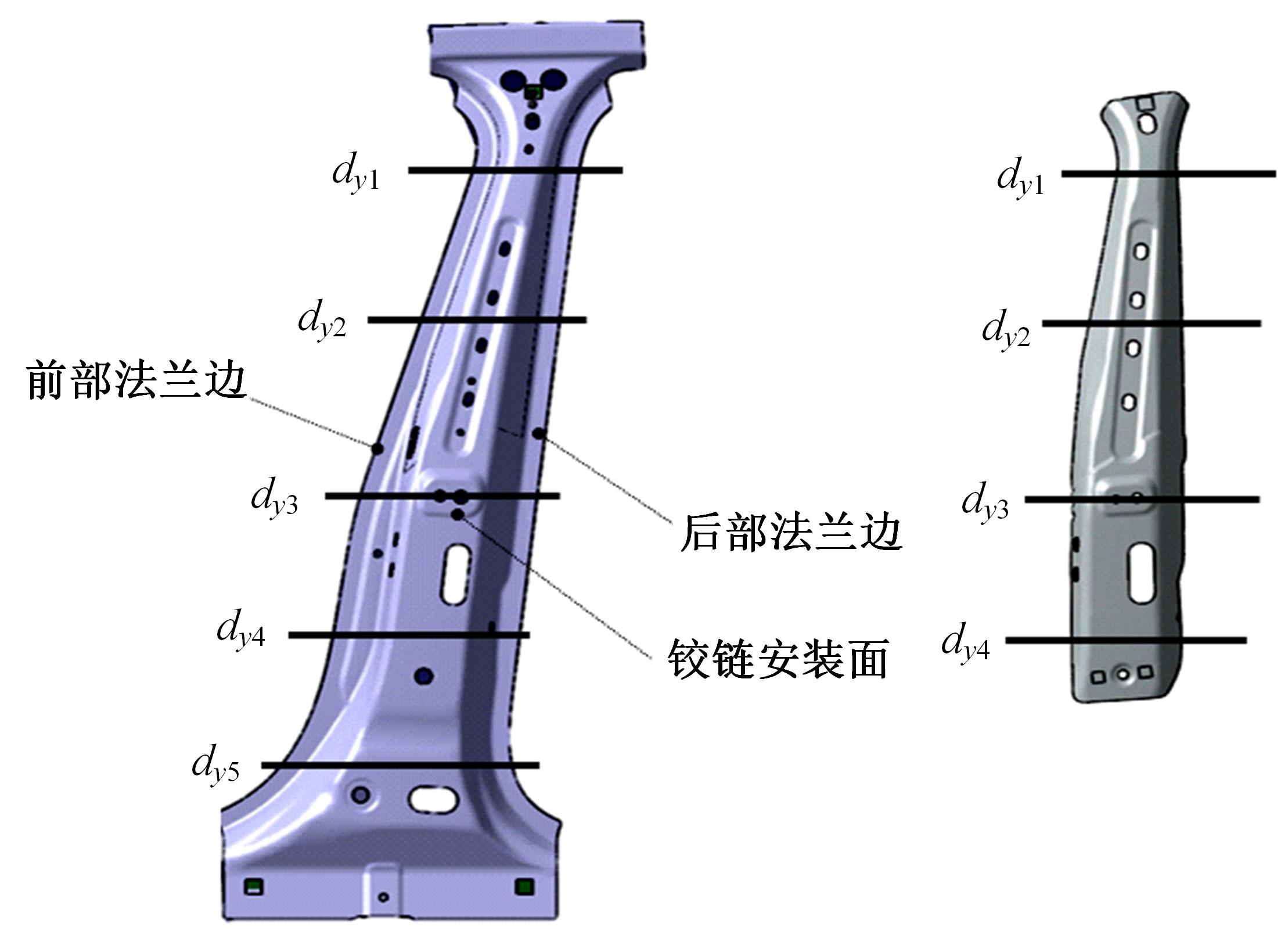

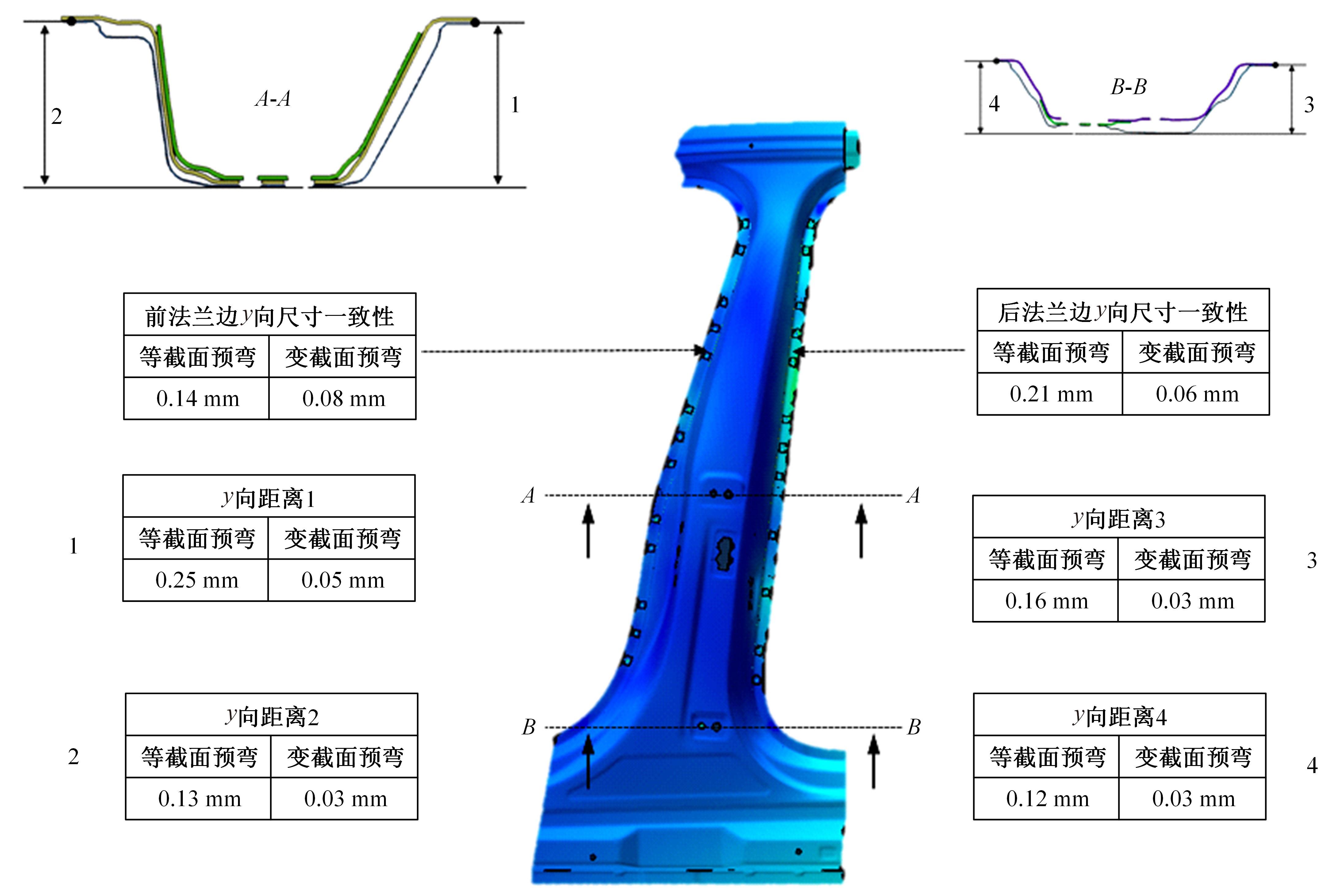

Welding deformation and compensation method of B-pillar in body-in-white

Xiao ZHOU( ),Yi-jie LIANG(

),Yi-jie LIANG( ),Zhong-xuan XI,Yu-tao WANG

),Zhong-xuan XI,Yu-tao WANG

- Vor Serien Center,FAW-Volkswagen Automotive Co. ,Ltd. ,Changchun 130011,China

CLC Number:

- TG404

| 1 | 王庆, 刘钊, 黄平华, 等. 白车身激光焊接过程的变形预测及几何补偿方法[J]. 上海交通大学学报, 2019, 53(1): 62-68. |

| Wang Qing, Liu Zhao, Huang Ping-hua, et al. Distortion prediction and geometry compensation method for laser welding-induced distortion of body-in-white[J]. Journal of Shanghai Jiao Tong University, 2019, 53(1): 62-68. | |

| 2 | 黄平华, 郭志强, 王一栋, 等. 车身B柱零件焊接变形链式仿真的实现及应用[C]∥第十七届中国CAE工程分析技术年会论文集, 海南, 中国, 2021: 328-331. |

| 3 | 董文超, 陆善平, 李殿中. 焊接顺序对大型薄板装甲钢结构焊接变形的影响[J]. 焊接学报, 2015, 36(7): 43-46. |

| Dong Wen-chao, Lu Shan-ping, Li Dian-zhong. Effect of welding sequence on welding distortion of large sized thin aasmor steel structure[J]. Transactions of China Welding Institution, 2015, 36(7): 43-46. | |

| 4 | 卢晶晶, 刑彦锋. 基于SYSWELD薄板焊接变形研究[J]. 热加工工艺, 2016, 45(11): 174-177. |

| Lu Jing-jing, Xing-Yan-feng. Study on welding deformation of thin plate using SYSWELD Software[J]. Hot Working Technology, 2016, 45(11): 174-177. | |

| 5 | 汪文芳. 轿车车身尺寸控制与夹具工艺设计分析[D].武汉: 武汉理工大学汽车工程学院, 2010. |

| Wang Wen-fang. Analysis of car body size control and fixture process design[D]. Wuhan: School of Automotive Engineering, Wuhan University of Technology, 2010. | |

| 6 | 汪建华, 陆皓, 魏良武. 固有应变有限元法预测焊接变形理论及其应用[J]. 焊接学报, 2002,23(6): 36-40. |

| Wang Jian-hua, Lu Hao, Liang-wu Wie. Theory and application of inherent strain finite element method in predicting welding deformation[J]. Transactions of China Welding Institution, 2002,23(6): 36-40. | |

| 7 | 李娅娜. 焊接变形预测与控制的数值方法研究及工程应用[D].大连: 大连交通大学机车车辆工程学院, 2010. |

| Li Ya-na. Research and engineering application on numerical method of welding deformation prediction and control[D]. Dalian: College of Locomotive and Rolling Stovk Engineering, Dalian Jiaotong University, 2010. | |

| 8 | 吴言高, 李午申, 邹宏军, 等. 焊接数值模拟技术发展现状[J]. 焊接学报, 2002, 23(3): 89-92. |

| Wu Yan-gao, Li Wu-shen, Zhou Hong-jun, et al. State-of-the-art of numerical simulation in welding[J]. Transactions of China Welding Institution, 2002, 23(3): 89-92. | |

| 9 | Dean D, Hidekazu M. Numerical simulation of temperature field and residual stress in multi-pass welds in stainless steel pipe and comparison with experimental measurements[J]. Computational Materials Science, 2006, 37(3):269-277. |

| 10 | 赵海燕, 吴骏巍, 陆向明, 等. 基于局部-整体有限元法的薄壁筒焊接变形计算[J]. 清华大学学报:自然科学版, 2017, 57(5): 449-453. |

| Zhao Hai-yan, Wu Jun-wei, Lu Xiang-ming, et al. Calculation of welding deformation of thin-walled tube based on local-global finite element method[J]. Journal of Tsinghua University (Natural Science Edition), 2017, 57(5): 449-453. | |

| 11 | 薛忠明, 顾兰, 张彦华. 激光焊接温度场数值模拟[J]. 焊接学报, 2003, 24(2): 79-82. |

| Xue Zhong-ming, Gu Lan, Zhang Yan-hua. Numerical simulation of temperature field in laser welding[J]. Transactions of China Welding Institution, 2003, 24(2): 79-82. |

| [1] | Xin CHEN,Guan-chen ZHANG,Kang-ming ZHAO,Jia-ning WANG,Li-fei YANG,De-rong SITU. Influence of lap welds on the lightweight design of welded aluminum structures [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1282-1288. |

| [2] | Hai-bo LONG,Jia-qi YANG,Liang YIN,Xue-yu ZHAO,Zi-quan XIANG. Multi-objective decision-making on emergency material distribution under uncertain demand based on robust optimization [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1078-1084. |

| [3] | Ying HE,Jun-song FAN,Wei WANG,Geng SUN,Yan-heng LIU. Joint optimization of secure communication and trajectory planning in unmanned aerial vehicle air⁃to⁃ground [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(3): 913-922. |

| [4] | Han-wu LIU,Yu-long LEI,Xiao-feng YIN,Yao FU,Xing-zhong LI. Multi⁃point control strategy optimization for auxiliary power unit of range⁃extended electric vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1741-1750. |

| [5] | Zhao-ming CHEN,Jin-song ZOU,Wei WANG,Ming-quan SHI. Multi-objective optimization of casting-forging dynamic forming based on improved particle swarm neural network and finite element analysis [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(7): 1524-1533. |

| [6] | Yong-jie MA,Min CHEN. Dynamic multi⁃objective optimization algorithm based on Kalman filter prediction strategy [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(6): 1442-1458. |

| [7] | Bin-xiang JIANG,Tong-tong JIANG,Yong-lei WANG. Optimization of consensus algorithm for drug detection block chain based on cultural genetic algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 684-692. |

| [8] | Han HUANG,Qing-hao YAN,Zhi-xin XIANG,Xin-tao YANG,Jin-bao CHEN,Shu-cai XU. Crashworthiness investigation and optimization of bionic multi⁃cell tube based on shrimp chela [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 716-724. |

| [9] | Li-jie ZHANG,Xi-ta A,Xiao TIAN,Wen LI. Multi⁃objective optimization design of accelerated degradation test based on Gamma process [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 361-367. |

| [10] | Bao-feng SUN,Xin-xin REN,Zai-si ZHENG,Guo-yi Li. Multi⁃objective flow shop optimal scheduling considering worker's load [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 900-909. |

| [11] | Bing-hai ZHOU,Zhao-xu HE. Static semi⁃kitting strategy⁃based multi⁃objective just⁃in⁃time material distribution scheduling [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 910-916. |

| [12] | Ji-cheng HUANG,Cheng SHEN,Ai-min JI,Xian-wang LI,Bin ZHANG,Kun-peng TIAN,Hao-lu LIU. Optimization of cutting⁃conveying key working parameters of hemp harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 772-780. |

| [13] | Bing-hai ZHOU,Qiong WU. Balancing and bi⁃objective optimization of robotic assemble lines [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 720-727. |

| [14] | Fang-wu MA,Li HAN,Liang WU,Jin-hang LI,Long-fan YANG. Damping optimization of heavy⁃loaded anti⁃vibration platform based on genetic algorithm and particle swarm algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1608-1616. |

| [15] | Xue-shen CHEN,Tao CHEN,Tao WU,Xu MA,Ling-chao ZENG,Lin-tao CHEN. Design and experiment on harvester for winter planting potato of straw coverage [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 749-757. |

|

||