Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (10): 3026-3037.doi: 10.13229/j.cnki.jdxbgxb.20211332

Previous Articles Next Articles

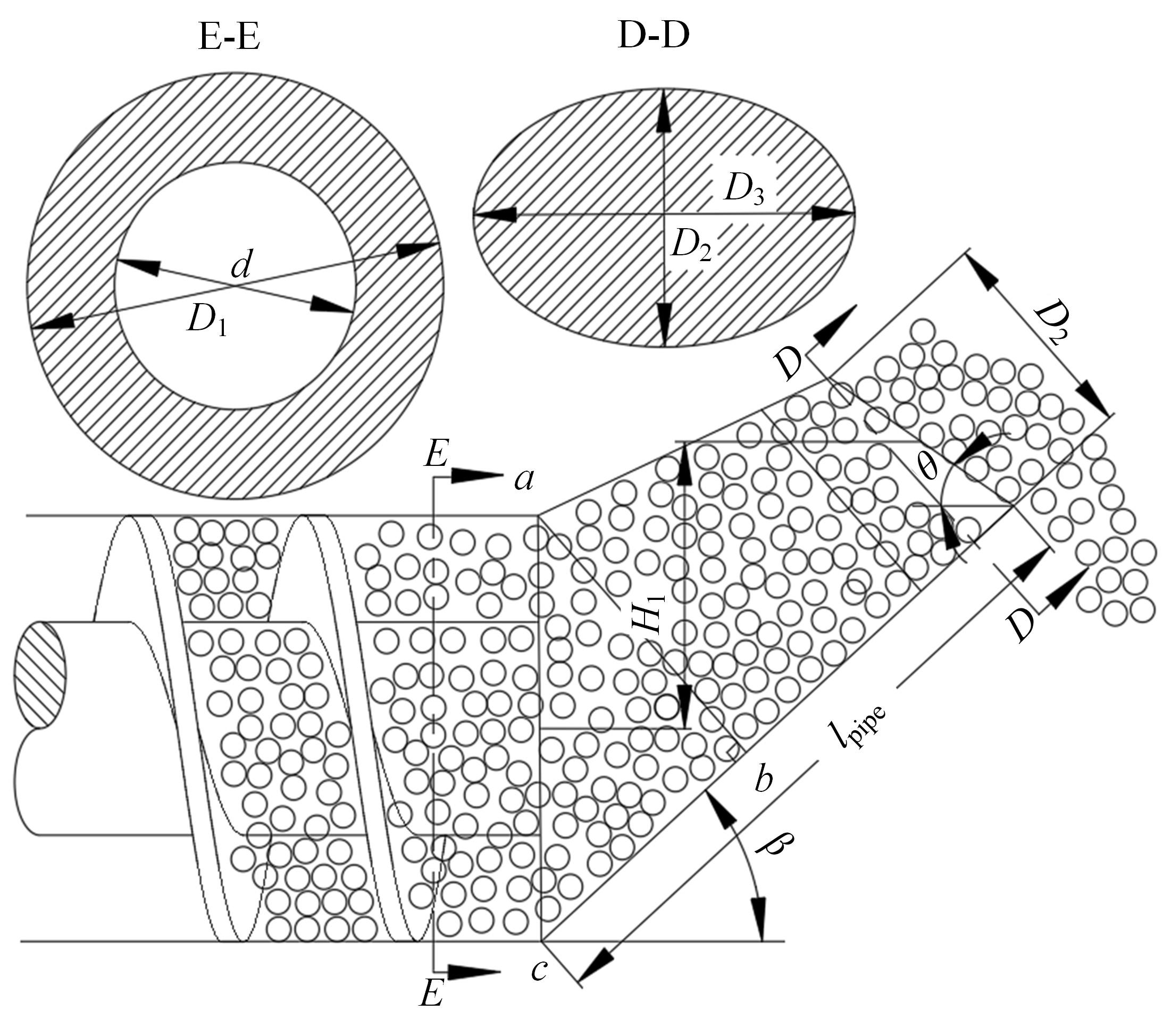

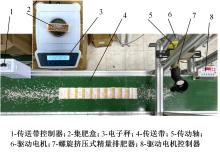

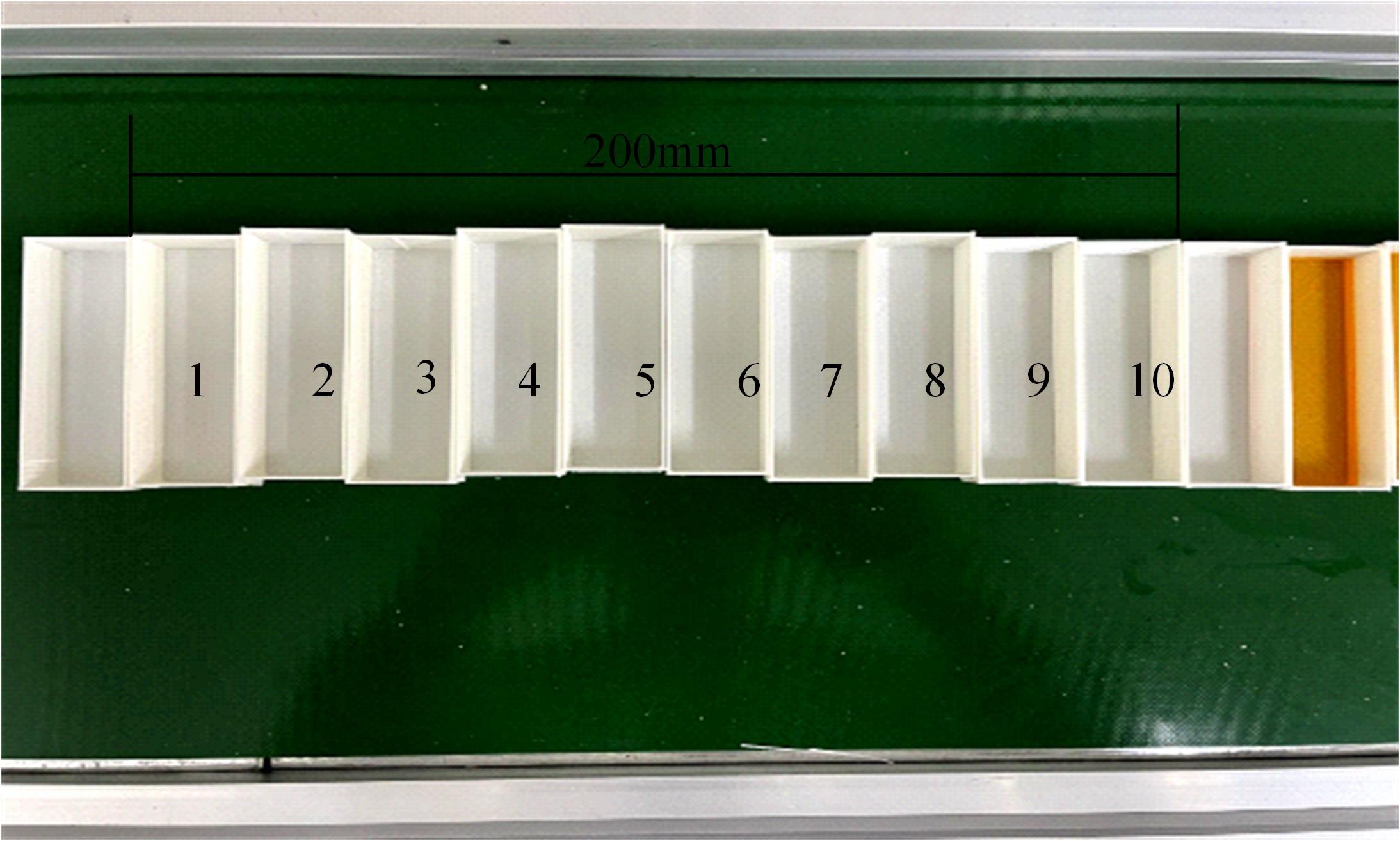

Simulation optimization and experiment of screw extrusion precision fertilizer ejector

Guo-qiang DUN1( ),Wen-hui LIU1,Xing-peng WU1,Ning MAO1,Wen-yi JI2,Hong-yan MA3

),Wen-hui LIU1,Xing-peng WU1,Ning MAO1,Wen-yi JI2,Hong-yan MA3

- 1.College of Mechanical and Electrical Engineering,Northeast Forestry University,Harbin 150040,China

2.College of Engineering,Northeast Agricultural University,Harbin 150030,China

3.Heilongjiang Ruilong Innovation Technology Co. ,Ltd. ,Harbin 150050,China

CLC Number:

- S147.2

| 1 | 高晶晶, 彭超, 史清华. 中国化肥高用量与小农户的施肥行为研究——基于1995~2016年全国农村固定观察点数据的发现[J]. 管理世界, 2019, 35(10): 120-132. |

| Gao Jing-jing, Peng Chao, Shi Qing-hua. Study on the high chemical fertilizers consumption and fertilization behavior of small rural Househo in China: discovery from 1995~2016 national fixed point survey data[J]. Management World, 2019, 35(10): 120-132. | |

| 2 | 张维理, 徐爱国, 冀宏杰, 等. 中国农业面源污染形势估计及控制对策Ⅲ.中国农业面源污染控制中存在问题分析[J]. 中国农业科学, 2004(7): 1026-1033. |

| Zhang Wei-li, Xu Ai-guo, Ji Hong-jie, et al. Estimation of agricultural non-point source pollution in china and the alleviating strategies Ⅲ. a review of policies and practices for agricultural non-point source pollution control in China[J]. Scientia Agricultura Sinica, 2004(7): 1026-1033. | |

| 3 | 马常宝. 我国农业肥料施用发展趋势与展望[J]. 中国农技推广, 2016, 32(6): 6-10. |

| Ma Chang-bao. Development trends and prospects of agriculture fertilizer application in China[J]. China Agricultural Extension, 2016, 32(6):6-10. | |

| 4 | 付宇超, 袁文胜, 张文毅, 等. 我国施肥机械化技术现状及问题分析[J]. 农机化研究, 2017, 39(1): 251-255, 263. |

| Fu Yu-chao, Yuan Wen-sheng, Zhang Wen-yi, et al. The research and development of the falling tree fruits and nuts collect and pick-up technology[I]. Journal of Agricultural Mechanization Research, 2017, 39(1): 251-255, 263. | |

| 5 | 施印炎, 陈满, 汪小旵, 等. 稻麦精准变量施肥机排肥性能分析与试验[J]. 农业机械学报, 2017, 48(7): 97-103. |

| Shi Yin-yan, Chen Man, Wang Xiao-chan, et al. Analysis and experiment of fertilizing performance for precision fertilizer applicator in rice and wheat fields[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(7): 97-103. | |

| 6 | Anton F, Hubert Z, Georg B. Mass flowmeter for screw conveyors based on capactitive secsing[C]∥IEEE Instrumentation & Measurement Technology Conference, Warsaw, Poland, 2007. |

| 7 | 罗锡文, 廖娟, 胡炼, 等. 提高农业机械化水平促进农业可持续发展[J]. 农业工程学报, 2016, 32(1): 1-11. |

| Luo Xi-wen, Liao Juan, Hu Lian, et al. Improving agricultural mechanization level to promote agricultural sustainable development[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(1): 1-11. | |

| 8 | 兰志龙, Muhammad N K, Tanveer A S, 等. 25年长期定位不同施肥措施对关中塿土水力学性质的影响[J]. 农业工程学报, 2018, 34(24): 100-106. |

| Lan Zhi-long, Muhammad N K, Tanveer A S, et al. Effects of 25-year located different fertilization measures on soil hydraulic properties of lou soil in Guanzhong area[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(24): 100-106. | |

| 9 | 余洪锋, 丁永前, 刘海涛, 等. 小田块变量施肥系统优化设计与应用[J]. 农业工程学报, 2018, 34(3):35-41. |

| Yu Hong-feng, Ding Yong-qian, Liu Hai-tao, et al. Optimization design and application of variable rate fertilization system for small-scaled fields[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(3): 35-41. | |

| 10 | 郝友莉, 唐正宁, 季婷婷. 粉体包装机密实输送螺杆的设计[J]. 轻工机械, 2017, 35(5): 12-15. |

| Hao You-li, Tang Zheng-ning, Ji Ting-ting. Design of compact conveying screw for powder packaging machine[J]. Light Industry Machinery, 2017, 35(5): 12-15. | |

| 11 | 都红云, 赵军. 圆管螺旋给料机的设计与制作[J]. 现代面粉工业, 2014, 28(2): 16-19. |

| Du Hong-yun, Zhao Jun. Design and fabrication of round tube screw feeder[J]. Modern Flour Industry, 2014, 28(2): 16-19. | |

| 12 | 陈汝超,陈小平,蔡佳莹,等. 粒煤螺旋输送特性试验研究[J]. 煤炭学报,2012,37(1):154-157. |

| Chen Ru-chao, Chen Xiao-ping, Cai Jia-ying, et al. Screw conveying characteristics of granular coal from screw conveyor[J]. Journal of China Coal Society, 2012, 37(1): 154-157. | |

| 13 | Moysey P A, Thompson M R. Modelling the solids inflow and solids conveying of single-screw extruders using the discrete element method[J]. Powder Technology, 2005, 153(2): 95-107. |

| 14 | 刘彪, 肖宏儒, 宋志禹, 等. 果园施肥机械现状及发展趋势[J]. 农机化研究, 2017, 39(11): 263-268. |

| Liu Biao, Xiao Hong-ru, Song Zhi-yu, et al. Present state and trends of fertilizing machine in orchard[J]. Journal of Agricultural Mechanization Research, 2017, 39(11): 263-268. | |

| 15 | 王强. 2CMG-4型马铃薯播种机排肥系统的设计研究[D]. 呼和浩特: 内蒙古农业大学机电工程学院, 2014. |

| Qiang Wng. Design and research on the 2CMG-4 potato planter distributing system[D]. Hohhot: College of Mechanical and Electrial Engineering, Inner Mongolia Agricultural University, 2014. | |

| 16 | 薛忠, 赵亮, 王凤花, 等. 基于离散元法的螺旋式排肥器性能模拟试验[J]. 湖南农业大学学报: 自然科学版, 2019, 45(5): 548-553. |

| Xue Zhong, Zhao Liang, Wang Feng-hua, et al. Performance simulation test of the spiral fertilizer distributor based on discrete element method[J]. Journal of Hunan Agricultural University(Natural Sciences),2019, 45(5): 548-553. | |

| 17 | Kretz D, Callau-Monje S, Hitschler M, et al. Discrete element method (DEM) simulation and validation of ascrew feeder system[J]. Powder Technology, 2015, 287: 131-138. |

| 18 | Dheeraj M, Abhishek S, Harsh P, et al. A review of granular flow in screw feeders and conveyors[J]. Powder Technology, 2020, 366: 369-381. |

| 19 | 张涛, 刘飞, 刘月琴, 等. 离散元模拟外槽轮排肥器排量分析[J]. 农机化研究, 2015, 37(9): 198-201. |

| Zhang Tao, Liu Fei, Liu Yue-qin, et al. Discrete element simulation of outer groove wheel type fertilizer discharging device capacity analysis[J].Journal of Agricultural Mechanization Research, 2015, 37(9): 198-201. | |

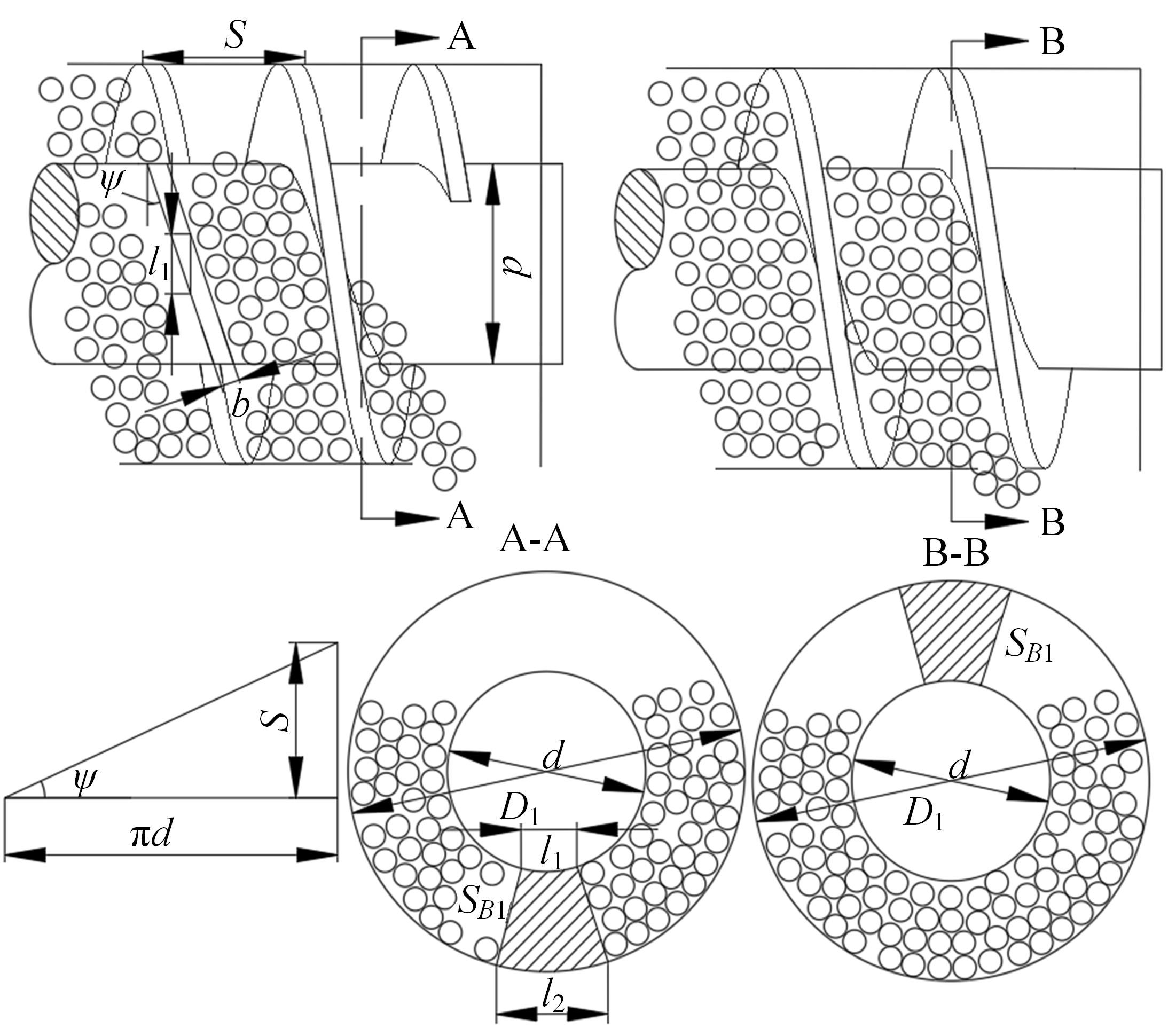

| 20 | 顿国强,于春玲,郭艳玲,等. 双齿轮式排肥器设计与试验[J]. 农业机械学报,2020,51(3):87-96. |

| Guo-qiang Dun, Yu Chun-ling, Guo Yan-ling, et al. Design and experiment of double-gear type fertilizer apparatus[J]. Transactions of the Chinese Society for Agricultural Machinery,2020,51(3):87-96. | |

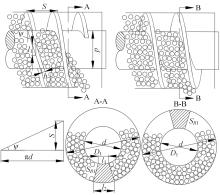

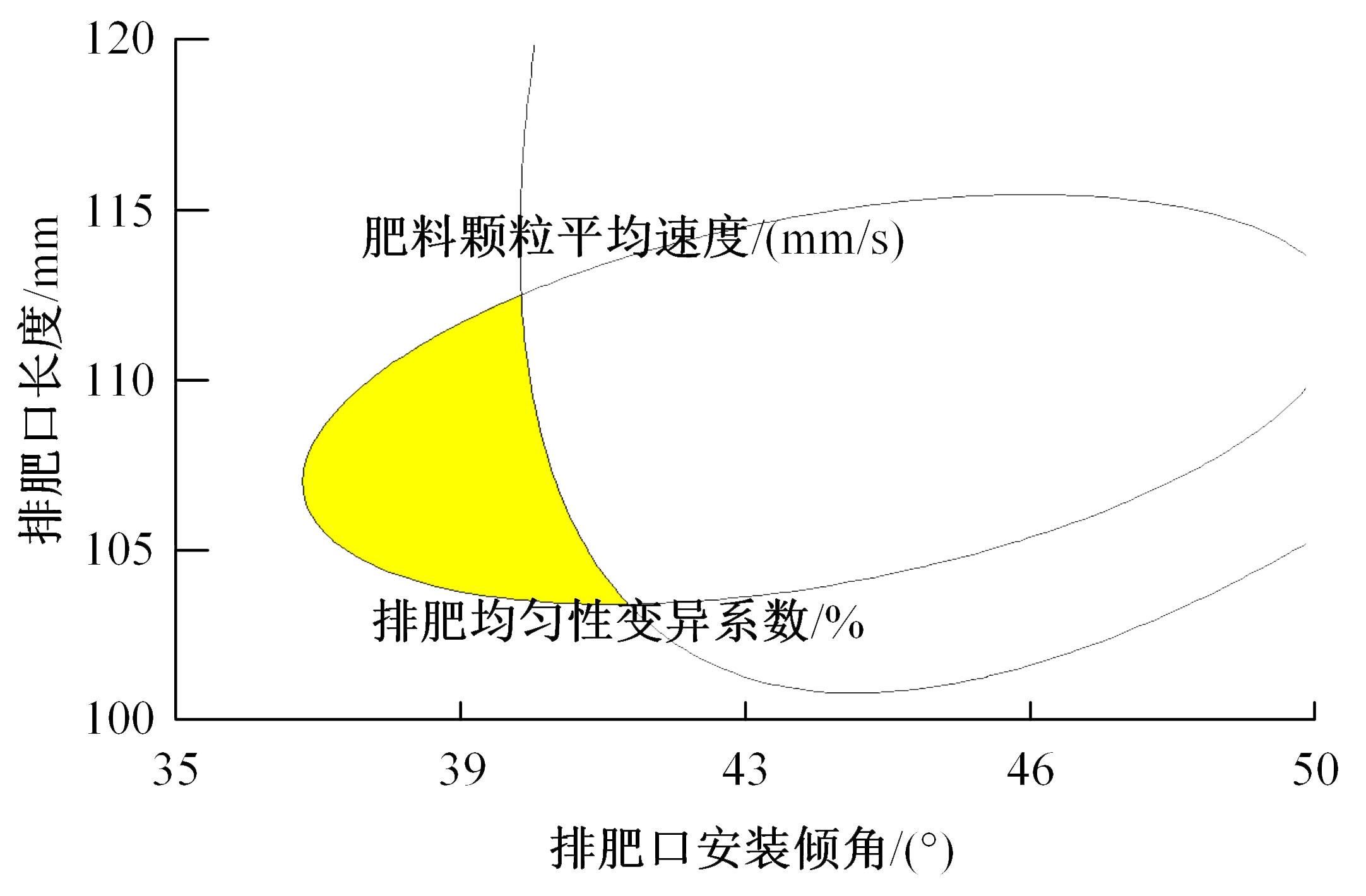

| 21 | 杨文武, 方龙羽, 罗锡文, 等. 螺旋排肥器排肥口参数对排肥性能影响的试验研究[J]. 农业工程学报, 2020, 36(17): 1-8. |

| Yang Wen-wu, Fang Long-yu, Luo Xi-wen, et al. Experimental study on the effect of the parameters of the spiral fertilizer feeder on the performance of the fertilizer[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(17): 1-8. | |

| 22 | 胡勇克, 戴莉莉, 皮亚南. 螺旋输送器的原理与设计[J]. 南昌大学学报: 工科版, 2000(4): 29-33, 91. |

| Hu Ke-yong, Dai Li-li, Pi Ya-nan. Theories and calculation of the auger-type conveyer[J]. Journal of Nanchang University(Engineering & Technology), 2000(4): 29-33, 91. | |

| 23 | 中华人民共和国国家质量监督检验检疫总局. 变量施肥播种机控制系统: GB/T35487-2017[M]. 北京: 中国标准出版社, 2017. |

| 24 | 袁全春, 徐丽明, 邢洁洁, 等. 机施有机肥散体颗粒离散元模型参数标定[J]. 农业工程学报, 2018, 34(18): 21-27. |

| Yuan Quan-chun, Xu Li-ming, Xing Jie-jie, et al. Parameter calibration of discrete element model of organic fertilizer particles for mechanical fertilization[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(18): 21-27. | |

| 25 | 李晓贤, 赵进, 任震宇, 等. 小型竖直螺旋式精量条施机的设计[J]. 农机化研究, 2018, 40(12): 75-79. |

| Li Xiao-xian, Zhao Jin, Ren Zhen-yu, et al. The design of small vertical screw precision sliver[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2018, 40(12): 75-79. | |

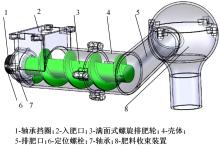

| 26 | 陈雄飞, 罗锡文, 王在满, 等. 两级螺旋排肥装置的设计与试验[J]. 农业工程学报, 2015, 31(3): 10-16. |

| Chen Xiong-fei, Luo Xi-wen, Wang Zai-man,et al. Design and experiment of fertilizer distribution apparatus with double-level screws[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(3): 10-16. | |

| 27 | 吕金庆, 王泽明, 孙雪松, 等. 马铃薯螺旋推进式排肥器研究与试验[J]. 农机化研究, 2015, 37(6): 194-196, 200. |

| Jin-qing Lü, Wang Ze-ming, Sun Xue-song, et al. Design and experimental study of fFeed screw potato planter propulsion[J]. Journal of Agricultural Mechanization Research, 2015, 37(6): 194-196, 200. | |

| 28 | Yu Yao-wei, Henrik Saxe N. Experimental and DEM study of segregation of ternary size particles in a blast furnace top bunker model[J]. Chemical Engineering Science, 2010, 65: 5237-5250. |

| 29 | 杨洲, 朱卿创, 孙健峰, 等. 基于EDEM和3D打印成型的外槽轮排肥器排肥性能研究[J]. 农机化研究, 2018, 40(5): 175-180. |

| Yang Zhou, Zhu Qing-chuang, Sun Jian-feng, et al. Study on the performance of fluted roller fertilizer distributor based on EDEM and 3D printing[J]. Journal of Agricultural Mechanization Research, 2018, 40(5): 175-180. | |

| 30 | 徐中儒. 回归分析与试验设计[M]. 北京: 中国农业出版社, 1998. |

| 31 | 潘丽军. 试验设计与数据处理[M]. 南京: 东南大学出版社, 2008. |

| [1] | Rui-jie SHI,Fei DAI,Wu-yun ZHAO,Fa-rong YANG,Feng-wei ZHANG,Yi-ming ZHAO,Hao QU,Tian-fu WANG,Jun-hai GUO. Design and experiments of self⁃propelled quinoa combine harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2686-2694. |

| [2] | Si-lin CAO,Jian-hua XIE,Yu-xin YANG,Yong-rui LIU,Yong-tao LU,Bo SUN. Design and experiment of side row cotton straw returning and residual film recovery combined machine [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1514-1528. |

| [3] | Xue-jun ZHANG,Shuang HUANG,Zeng-lu SHI,Yong-liang YU,Xin-cheng ZHOU,Wei JIN,Yong CHEN,Jia HONG. Design and test of the remaining film picking and baling machine [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1220-1230. |

| [4] | Xin RONG,Hong-hai LIU,Zuo-yao YIN,Hai-xiang LIN,Qing-hua BIAN. On-line detection method of aggregate gradation based on image processing [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(10): 2847-2855. |

| [5] | Rui-jie SHI,Fei DAI,Wu-yun ZHAO,Xiao-long LIU,Jiang-fei QU,Feng-wei ZHANG. Optimization and experiment of operation parameters of hilly area flax combine harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2746-2755. |

| [6] | Zhi-hui LI,Ya-qian SUN,Peng-fei TAO,Hai-tao LI,Xin LIU. Prediction method of traffic operation risk level after traffic accident [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 127-135. |

| [7] | Duan-yang GENG,Xiao-dong MU,Guo-dong ZHANG,Zong-yuan WANG,Jun-ke ZHU,Hai-gang XU. Analysis and optimization of cleaning mechanism of wheat combine harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 219-230. |

| [8] | Bin ZHANG,Guo-zan CHENG,Hao-cen HONG,Chun-xiao ZHAO,Da-peng BAI,Hua-yong YANG. Structure optimization of triangular groove of valve plate in axial piston pump based on SVR [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1213-1221. |

| [9] | Ji-cheng HUANG,Cheng SHEN,Ai-min JI,Xian-wang LI,Bin ZHANG,Kun-peng TIAN,Hao-lu LIU. Optimization of cutting⁃conveying key working parameters of hemp harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 772-780. |

| [10] | Xue-shen CHEN,Tao CHEN,Tao WU,Xu MA,Ling-chao ZENG,Lin-tao CHEN. Design and experiment on harvester for winter planting potato of straw coverage [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 749-757. |

| [11] | Yuan-li GU, Yuan ZHANG, Xiao-ping RUI, Wen-qi LU, Meng LI, Shuo WANG. Short⁃term traffic flow prediction based on LSSVMoptimized by immune algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1852-1857. |

| [12] | LI Jing, DING Ming-hui, LI Li-gang, CHEN Li-jun. Dynamic characteristics analysis and optimization of air spring based on the piston shape [J]. 吉林大学学报(工学版), 2018, 48(2): 355-363. |

| [13] | MA Kai, GAO Ji-dong, YAN Lei, XU Tao. Dummy material parameter optimization based on calibration experiment of chest pressure in collision [J]. 吉林大学学报(工学版), 2017, 47(5): 1498-1503. |

| [14] | HUANG Xuan, GUO Li-hong, LI Jiang, YU Yang. Target threat assessment based on BP neural network optimized by modified particle swarm optimization [J]. 吉林大学学报(工学版), 2017, 47(3): 996-1002. |

| [15] | WANG Qing-nian, WANG Guang-ping, WANG Peng-yu, HAN Biao, LI Feng. Parameter matching for plug-in hybrid electric vehicle based on cost optimization [J]. 吉林大学学报(工学版), 2016, 46(2): 340-347. |

|

||