Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (12): 3740-3754.doi: 10.13229/j.cnki.jdxbgxb.20230122

Previous Articles Next Articles

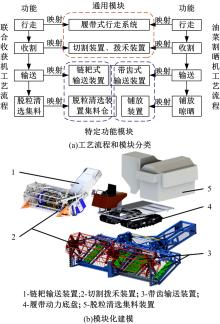

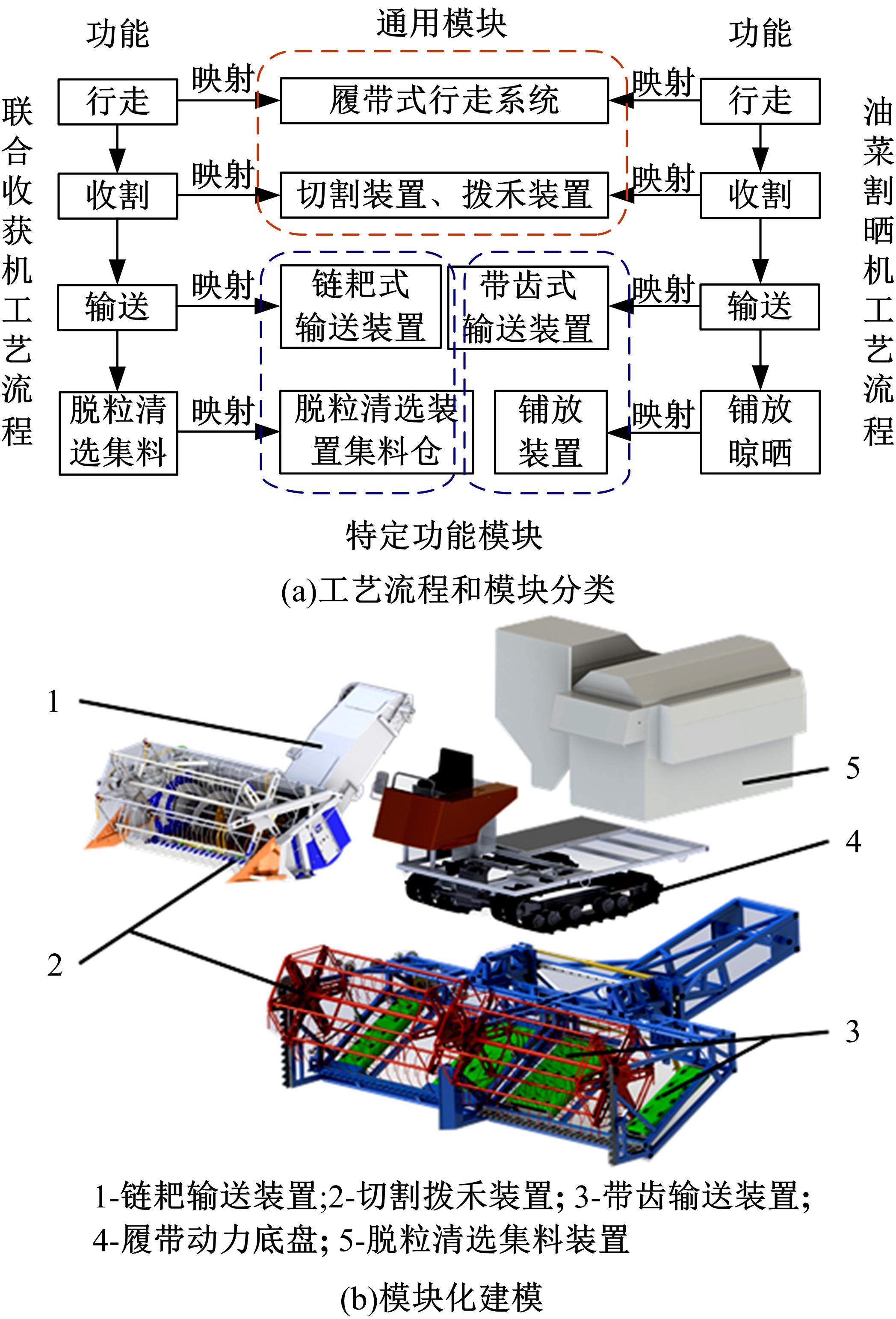

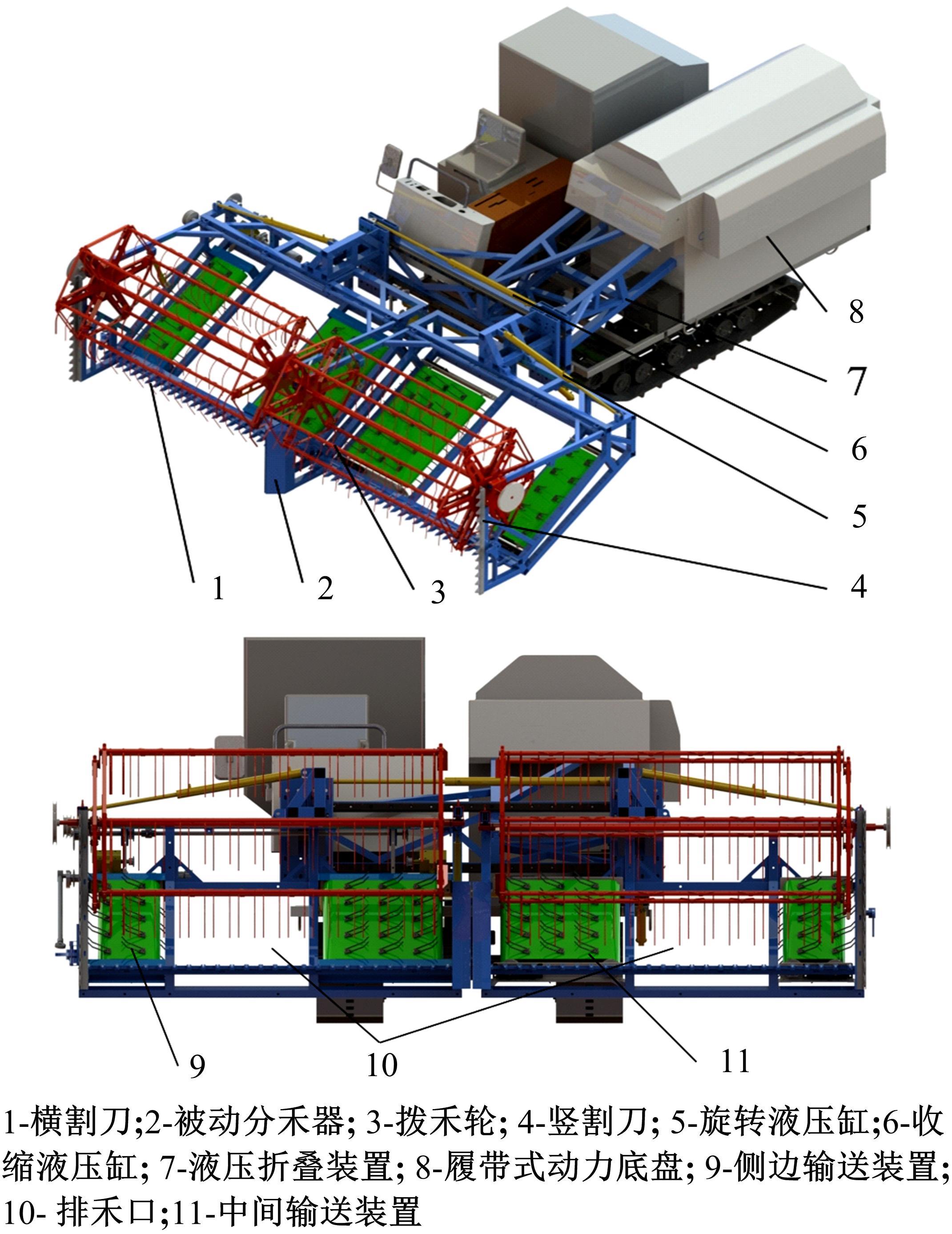

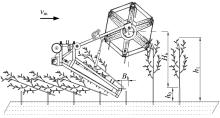

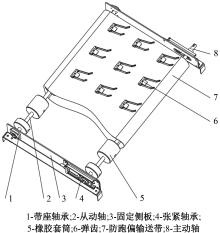

Design and experiment of wide folding rape windrower based on crawler type power chassis

Yun-tong LI1( ),Xing-yu WAN1,Qing-xi LIAO1,2,Yin-lei LIU1,Qing-song ZHANG1,2,Yi-tao LIAO1,2(

),Xing-yu WAN1,Qing-xi LIAO1,2,Yin-lei LIU1,Qing-song ZHANG1,2,Yi-tao LIAO1,2( )

)

- 1.College of Engineering,Huazhong Agricultural University,Wuhan 430070,China

2.Key Laboratory of Agricultural Equipment in Mid-lower Reaches of The Yangtze River,Ministry of Agriculture and Rural Affairs,Wuhan 430070,China

CLC Number:

- S223.2

| 1 | 汪波, 宋丽君, 王宗凯, 等. 我国饲料油菜种植及应用技术研究进展[J]. 中国油料作物学报, 2018, 40(5): 695-701. |

| Wang Bo, Song Li-jun, Wang Zong-kai, et al. Production and feeding technology of fodder-rapeseed in China[J]. Chinese Journal of Oil Crop Sciences, 2018, 40(5): 695-701. | |

| 2 | 张哲, 殷艳, 刘芳, 等. 我国油菜多功能开发利用现状及发展对策[J]. 中国油料作物学报, 2018, 40(5): 618-623. |

| Zhang Zhe, Yin Yan, Liu Fang, et al. Current situation and development countermeasures of Chinese rapeseed multifunction development and utilization[J]. Chinese Journal of Oil Crop Sciences, 2018, 40(5): 618-623. | |

| 3 | 吴崇友, 丁为民, 石磊, 等. 油菜分段收获捡拾脱粒机捡拾损失响应面分析[J]. 农业机械学报, 2011, 42(8): 89-93. |

| Wu Chong-you, Ding Wei-min, Shi Lei, et al. Response surface analysis of pickup losses in two-stage harvesting for rapeseed[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(8): 89-93. | |

| 4 | 万星宇, 廖庆喜, 廖宜涛, 等. 油菜全产业链机械化智能化关键技术装备研究现状及发展趋势[J]. 华中农业大学学报, 2021, 40(2): 24-44. |

| Wan Xing-yu, Liao Qing-xi, Liao Yi-tao, et al. Situation and prospect of key technology and equipment in mechanization and intelligentization of rapeseed whole industry chain[J]. Journal of Huazhong Agricultural University, 2021, 40(2): 24-44. | |

| 5 | 刘德军, 赵秀荣, 高连兴, 等. 不同收获方式含水率对油菜收获物流损失的影响[J]. 农业工程学报, 2011, 27(10): 339-342. |

| Liu De-jun, Zhao Xiu-rong, Gao Lian-xing, et al. Effect of moisture content on rape harvest logistics losses under different harvest methods[J]. Transactions of the CSAE, 2011, 27(10): 339-342. | |

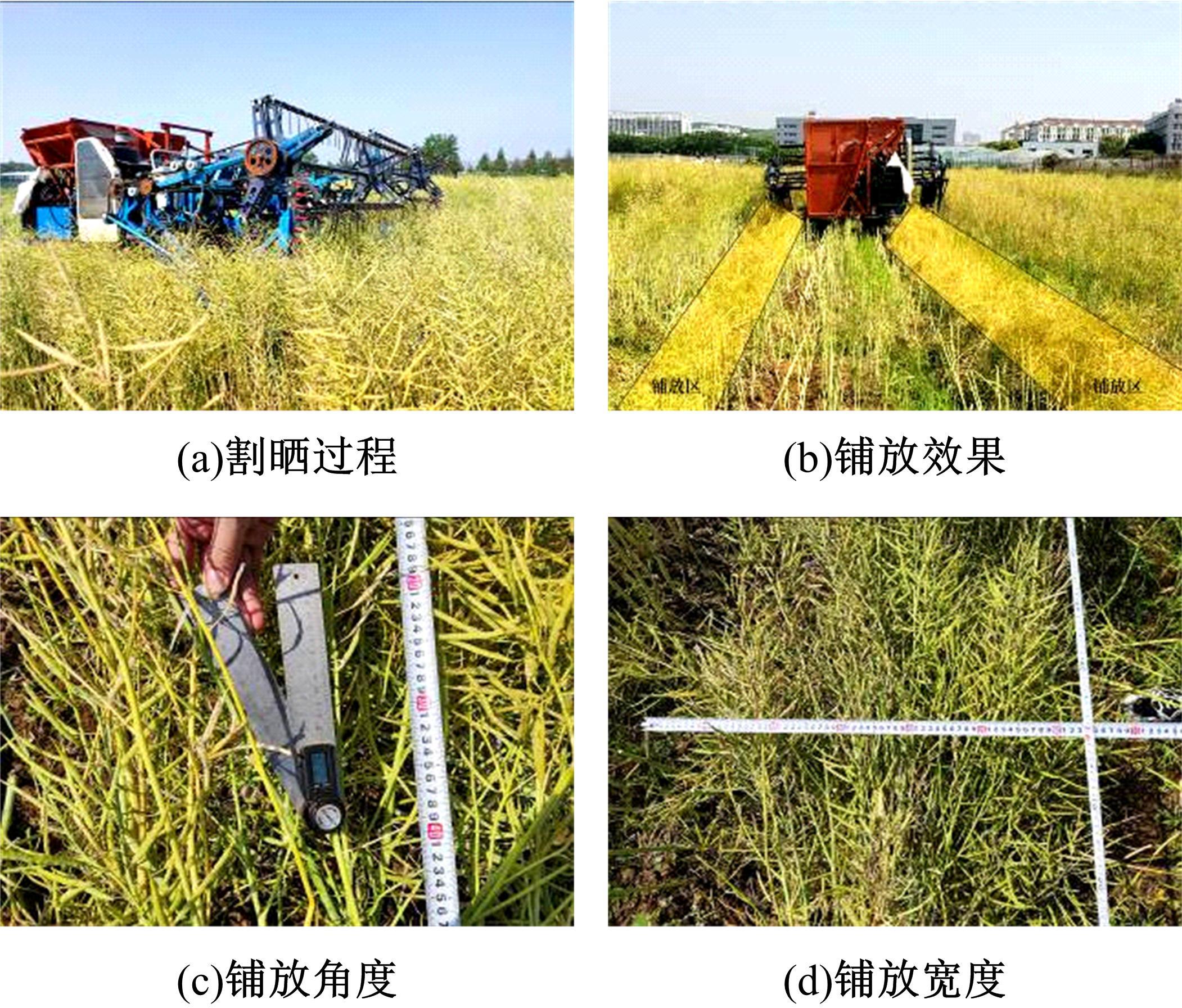

| 6 | 关卓怀, 江涛, 李海同, 等. 倾斜输送式油菜割晒机铺放质量分析与试验[J]. 农业工程学报, 2021, 37(4): 59-68. |

| Guan Zhuo-huai, Jiang Tao, Li Hai-tong, et al. Analysis and test of the laying quality of inclined transportation rape windrower[J]. Transactions of the CSAE, 2021, 37(4): 59-68. | |

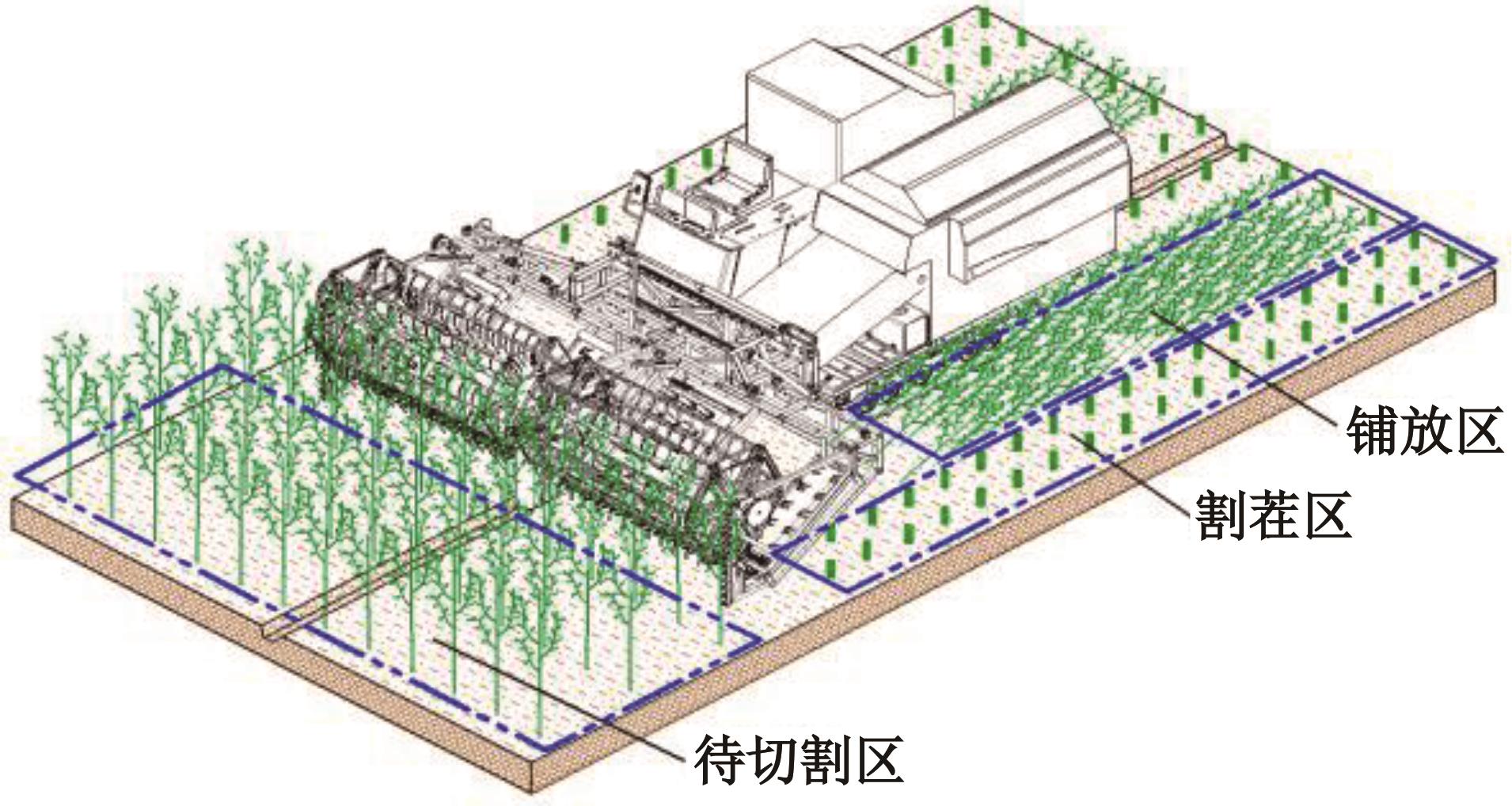

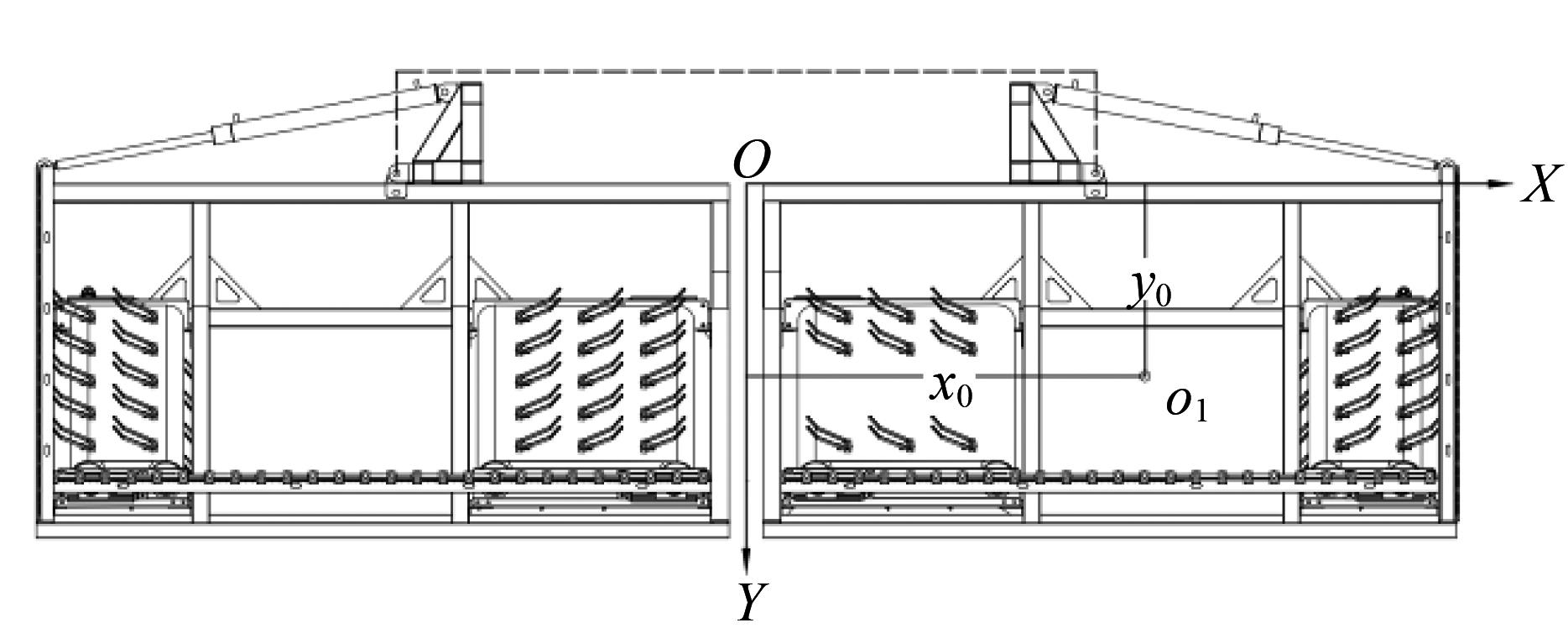

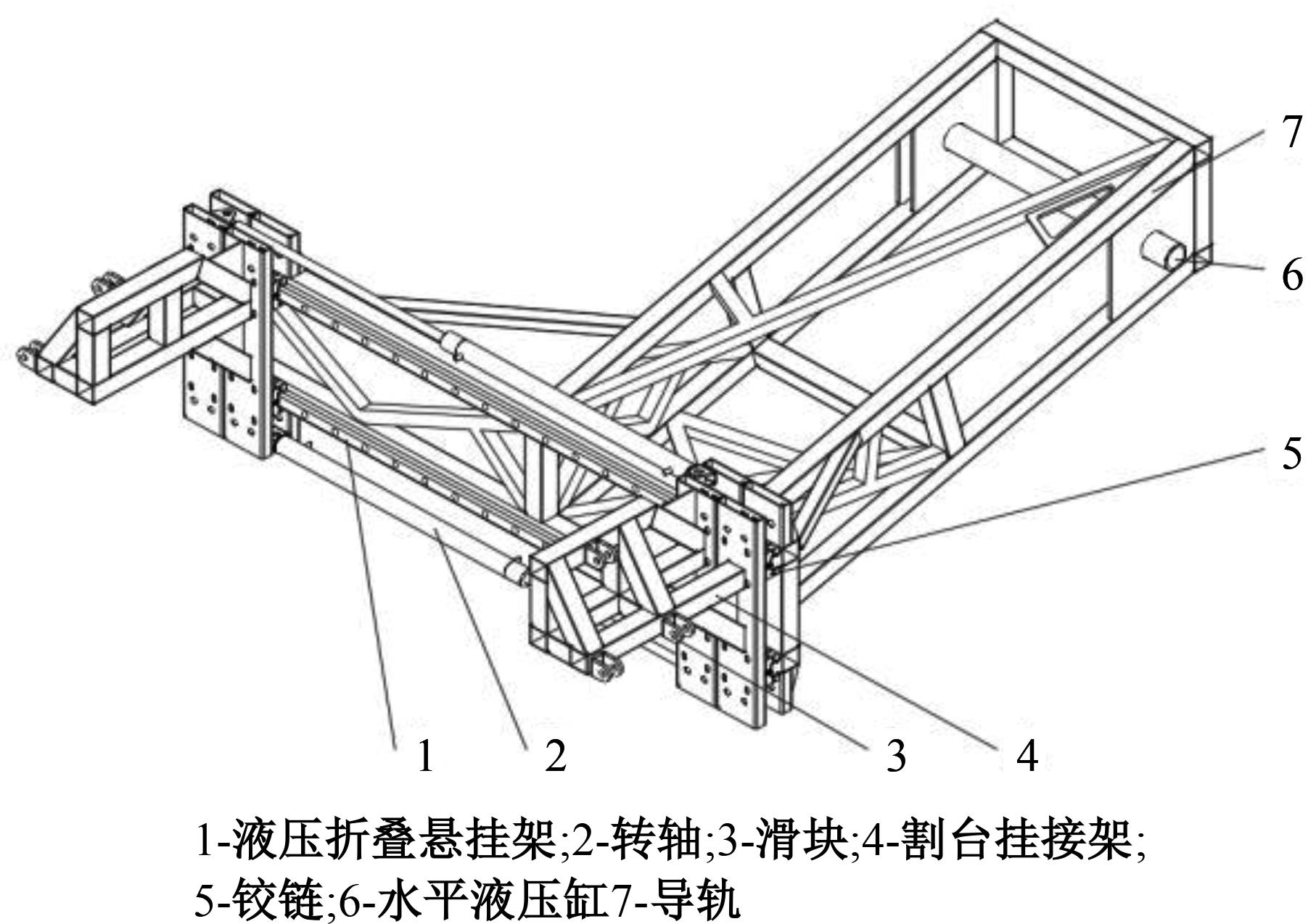

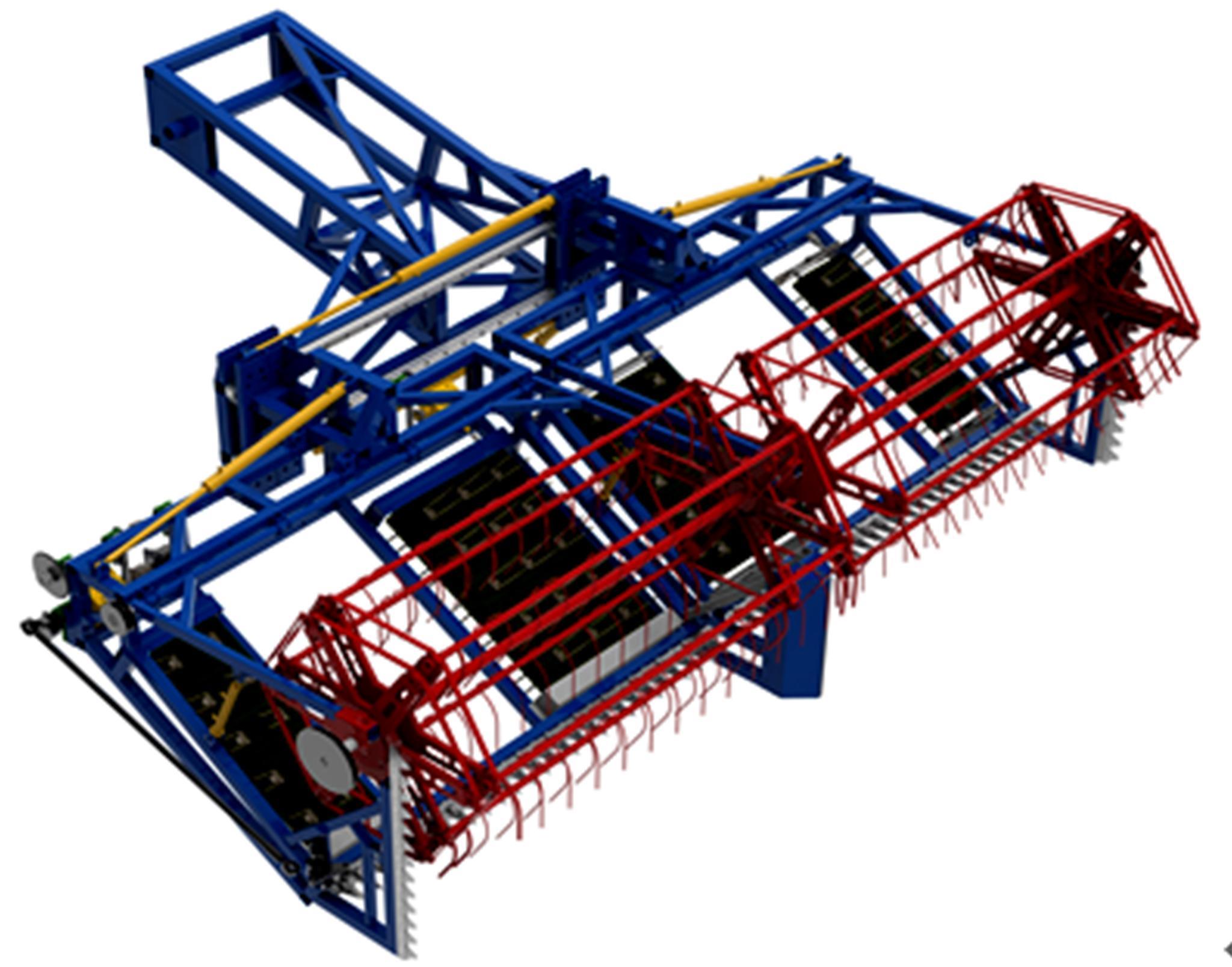

| 7 | 万星宇, 舒彩霞, 廖庆喜, 等. 高地隙履带自走式中间条铺油菜割晒机设计与试验[J]. 农业机械学报, 2022, 53(9): 109-121. |

| Wan Xing-yu, Shu Cai-xia, Liao Qing-xi, et al. Design and experiment of self-propelled middle-placement rape windrower[J]. Transactions of the Chinese Society for Agricultural Machinery, 2022, 53(9): 109-121. | |

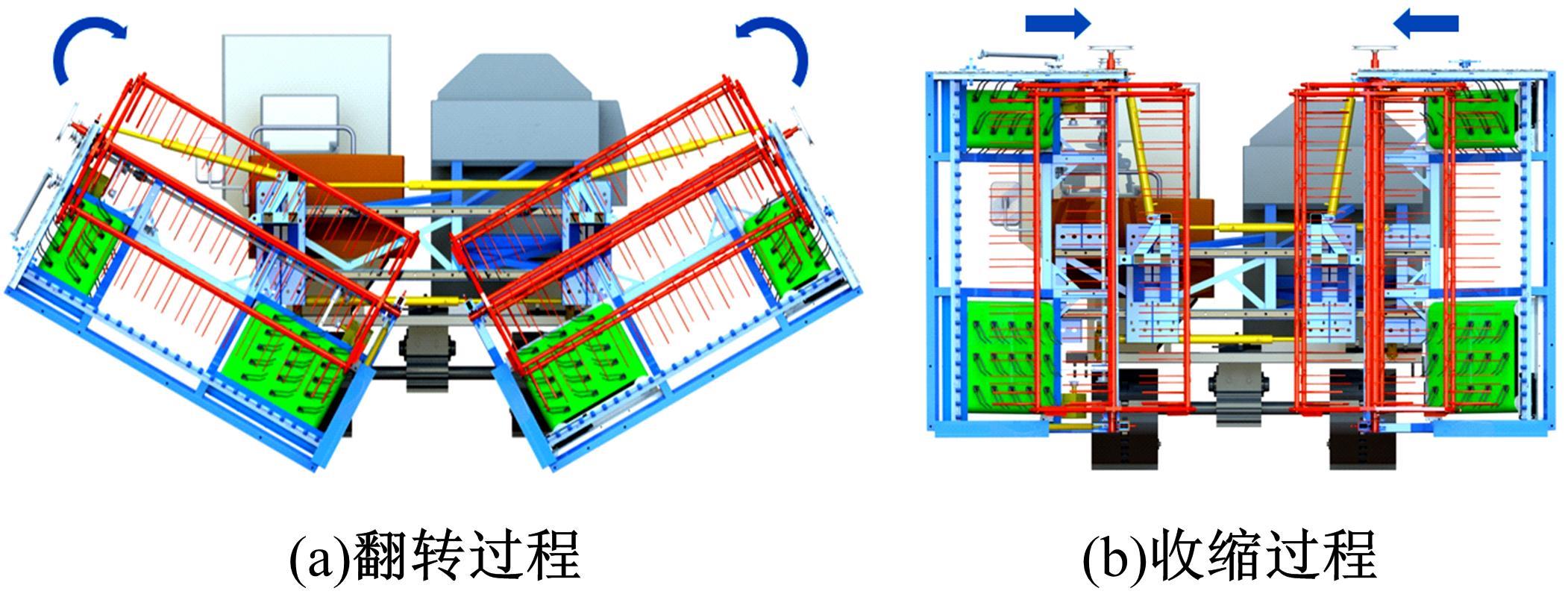

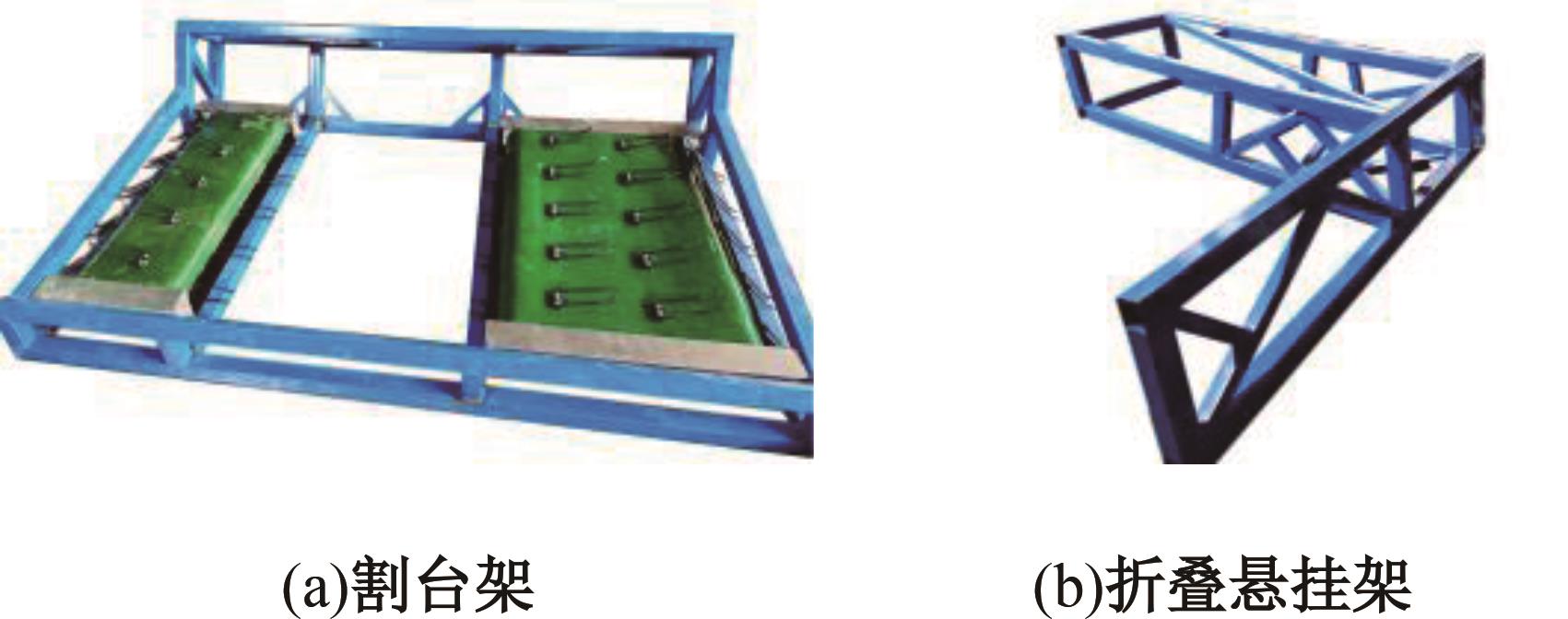

| 8 | 陈延鑫. 玉米收获机折叠式割台的试验与研究[D]. 淄博:山东理工大学农业工程与食品科学学院, 2012. |

| Chen Yan-xin. Experiment and research on the foldable header of corn harvester[D]. Zibo: College of Agricultural Engineering and Food Science, Shandong University of Technology, 2012. | |

| 9 | 陈延鑫, 张道林, 许振冻, 等. 折叠式玉米收获机割台的试验[J]. 农机化研究, 2013, 35(2): 117-120. |

| Chen Yan-xin, Zhang Dao-lin, Xu Zhen-dong, et al. Experiment of the foldable header of corn harvester[J]. Journal of Agricultural Mechanization Research, 2013, 35(2): 117-120. | |

| 10 | 廖中源, 王英俊, 王书亭. 基于拓扑优化的变密度点阵结构体优化设计方法[J]. 机械工程学报, 2019, 55(8): 65-72. |

| Liao Zhong-yuan, Wang Ying-jun, Wang Shu-ting. Graded-density lattice structure optimization design based on topology optimization[J]. Journal of Mechanical Engineering, 2019, 55(8): 65-72. | |

| 11 | 张明, 刘文斌, 李闯, 等. 优化驱动的起落架结构设计方法[J]. 航空学报, 2015, 36(3): 857-864. |

| Zhang Ming, Liu Wen-bin, Li Chuang, et al. Optimization-driven design method of landing gear structure[J]. Acta Aeronautica Et Astronautica Sinica, 2015, 36(3): 857-864. | |

| 12 | 李天箭, 丁晓红, 李郝林. 机床结构轻量化设计研究进展[J]. 机械工程学报, 2020, 56 (21): 186-198. |

| Li Tian-jian, Ding Xiao-hong, Li Hao-lin. Research progress on lightweight design of machine tool structure[J]. Journal of Mechanical Engineering, 2020, 56 (21): 186-198. | |

| 13 | 才胜, 罗颖辉, 李青林. 农业机械轻量化技术研究现状与发展趋势[J]. 机械工程学报, 2021, 57(17): 35-52. |

| Cai Sheng, Luo Ying-hui, Li Qing-lin. State of the art of lightweight technology in agricultural machinery and its development trend[J]. Journal of Mechanical Engineering, 2021, 57(17): 35-52. | |

| 14 | 吴伟斌, 廖劲威, 洪添胜, 等. 山地果园轮式运输机车架结构分析与优化[J]. 农业工程学报, 2016, 32(11): 39-47. |

| Wu Wei-bin, Liao Jing-wei, Hong Tian-sheng, et al. Analysis and optimization of frame structure for wheeled transporter in hill orchard[J]. Transactions of the CSAE, 2016, 32(11): 39-47. | |

| 15 | 谢斌, 温昌凯, 杨子涵, 等. 基于实测载荷的蔬菜田间动力机械车架结构优化[J]. 农业机械学报, 2018, 49(): 463-469. |

| Xie Bin, Wen Chang-kai, Yang Zi-han, et al. Structure optimization of frame for field vegetable power machinery based on measured load data[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(Sup.): 463-469. | |

| 16 | 中华人民共和国交通部. 超限运输车辆行驶公路管理规定[J]. 中华人民共和国国务院公报, 2000(23): 33-36. |

| 17 | 李平, 廖庆喜, 李磊, 等. 4SY-1.8改进型油菜割晒机主要装置设计与试验[J]. 农业机械学报, 2014, 45(1): 53-58. |

| Li Ping, Liao Qing-xi, Li Lei, et al. Design and experiment of the main device of 4SY-1.8 modified rape windrower[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(1): 53-58. | |

| 18 | 王伟, 吕晓兰, 王士林, 等. 茎叶类蔬菜机械化收获技术研究现状与发展[J]. 中国农业大学学报, 2021, 26(4): 117-127. |

| Wang Wei, Xiao-lan Lyu, Wang Shi-lin, et al. Current status and development of stem and leaf vegetable mechanized harvesting technology[J]. Journal of China Agricultural University, 2021, 26(4): 117-127. | |

| 19 | 李海同, 吴崇友, 沐森林, 等. 基于ANSYS-ADAMS的立式油菜割晒机铺放角形成机理[J]. 农业工程学报, 2020, 36(14): 96-105. |

| Li Hai-tong, Wu Chong-you, Mu Sen-lin, et al. Formation mechanism of laying angle of vertical rape windrower based on ANSYS-ADAMS[J]. Transactions of the CSAE, 2020, 36(14): 96-105. | |

| 20 | 廖宜涛, 廖庆喜, 周宇, 等. 饲料油菜薹期收获茎秆破碎离散元仿真参数标定[J]. 农业机械学报, 2020, 51(6): 73-82. |

| Liao Yi-tao, Liao Qing-xi, Zhou Yu, et al. Parameters calibration of discrete element model of fodder rape crop harvest in bolting stage[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(6): 73-82. | |

| 21 | 李仲恺, 谢方平, 刘科, 等. 油菜收获圆盘式切割器的设计与性能试验[J]. 湖南农业大学学报:自然科学版, 2014, 40(1): 83-88. |

| Li Zhong-kai, Xie Fang-ping, Liu Ke, et al. Design and performance evaluation of a disc cutter for rape harvest[J]. Journal of Hunan Agricultural University(Natural Sciences), 2014, 40(1): 83-88. | |

| 22 | 廖宜涛, 陈传节, 舒彩霞, 等. 4SY-1.8型手扶式油菜割晒机设计与试验[J]. 农业机械学报, 2014, 45(): 94-100. |

| Liao Yi-tao, Chen Chuan-jie, Shu Cai-xia, et al. Design and experiment of 4SY-1.8 rape walking windrower[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(Sup.1): 94-100. | |

| 23 | 李平, 廖庆喜, 舒彩霞, 等. 油菜割晒机茎秆铺放质量的故障成因分析与参数匹配研究[J]. 应用基础与工程科学学报, 2016, 24(1): 197-209. |

| Li Ping, Liao Qing-xi, Shu Cai-xia, et al. Fault analysis of stem windrowing quality and parameters match on the rape windrower[J]. Journal of Basic Science and Engineering, 2016, 24(1): 197-209. | |

| 24 | 金文明, 李华军, 寇淑清, 等. 装配式凸轮轴悬臂式数控装配机的机架模态分析[J]. 吉林大学学报:工学版, 2009, 39(): 319-323. |

| Jin Wen-ming, Li Hua-jun, Kou Shu-qing, et al. Modal analysis of frame of cantilever NC assembling machine for assembled camshaft[J]. Journal of Jilin University (Engineering and Technology Edition) 2009, 39(Sup.2): 319-323. | |

| 25 | 汪泉, 陈进, 王君, 等. 气动载荷作用下复合材料风力机叶片结构优化设计[J]. 机械工程学报, 2014, 50(9): 114-121. |

| Wang Quan, Chen Jin, Wang Jun, et al. Structural optimization of composite wind turbine blade under aerodynamic loads[J]. Journal of Mechanical Engineering, 2014, 50(9): 114-121. | |

| 26 | 张娜娜, 赵匀, 刘宏新. 高速水稻插秧机车架的轻量化设计[J]. 农业工程学报, 2012, 28(3): 55-59. |

| Zhang Na-na, Zhao Yun, Liu Hong-xin. Light design of frame for self-propelled chassis rice transplanter[J]. Transactions of the CSAE, 2012, 28(3): 55-59. | |

| 27 | 邱白晶, 何耀杰, 盛云辉, 等. 喷雾机喷杆有限元模态分析与结构优化[J]. 农业机械学报, 2014, 45(8): 112-116. |

| Qiu Bai-jing, He Yao-jie, Sheng Yun-hui, et al. Finite element modal analysis and structure optimization of spray boom[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(8): 112-116. | |

| 28 | 廖庆喜, 何坤, 万星宇, 等. 履带联合收获机式动力平台油菜直播机设计与试验[J]. 农业机械学报, 2021, 52(12): 54-64. |

| Liao Qing-xi, He Kun, Wan Xing-yu, et al. Devices for rapeseed direct seeder on tracked combined harvesting power platform[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(12): 54-64. | |

| 29 | 王利鹤, 赵永来, 崔红梅, 等. 基于ANSYS Workbench的深松机机架静力学分析及轻量化设计[J]. 重庆理工大学学报:自然科学, 2019,33(2): 87-93. |

| Wang Li-he, Zhao Yong-lai, Cui Hong-mei, et al. Static analysis and lightweight design of subsoiler frame based on ANSYS Workbench[J]. Journal of Chongqing University of Technology(Natural Science), 2019, 33(2): 87-93. | |

| 30 | 李耀明, 孙朋朋, 庞靖, 等. 联合收获机底盘机架有限元模态分析与试验[J]. 农业工程学报, 2013, 29(3): 38-46. |

| Li Yao-ming, Sun Peng-peng, Pang Jing, et al. Finite element mode analysis and experiment of combine harvester chassis[J]. Transactions of the CSAE, 2013, 29(3): 38-46. | |

| 31 | 金诚谦, 尹文庆, 吴崇友. 4SY-2型油菜割晒机铺放质量数学模型与影响因素分析[J]. 农业工程学报, 2012, 28(2): 45-48. |

| Jin Cheng-qian, Yin Wen-qing, Wu Chong-you. Mathematical model and influencing factors analysis for windrow quality of 4SY-2 rape windrower[J]. Transactions of the CSAE, 2012, 28(2): 45-48. | |

| 32 | 金诚谦, 尹文庆, 吴崇友. 油菜割晒机拨指输送链式输送装置研制与试验[J]. 农业工程学报, 2013, 29(21): 11-18. |

| Jin Cheng-qian, Yin Wen-qing, Wu Chong-you. Development and experiment of rape windrower transportation device with poke finger conveyor chain[J]. Transactions of the CSAE, 2013, 29(21): 11-18. |

| [1] | Chen WANG,Te LUO,Qian-qian HUI,Zhong-hao WANG,Fang-fang WANG. Design and verification of electromechanical system for docking and locking of modular flying vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2130-2140. |

| [2] | Cai-xia SHU,Jia YANG,Qing-xi LIAO,Xing-yu WAN,Jia-cheng YUAN. Design and experiment of diversion type double-cylinder cyclone separation system for rapeseed combine harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1807-1820. |

| [3] | Jian-xing YU,Ming-xiu WEI,Yang YU,Yu-peng CUI,Yu PAN. Reliability-based topology optimization and engineering design of stiffened plates [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(10): 2781-2791. |

| [4] | Huan-lin ZHOU,Xin GUO,Xuan WANG,Li-xue FANG,Kai LONG. Topology optimization design of multiphase porous structures considering geometric nonlinearity [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(10): 2754-2763. |

| [5] | Shuai MA,Li-ming XU,Shu-cai XU,Cong NIU,Cheng-gong YAN,Hao-chao TAN. Design and experiment of grapevine cold⁃proof soil cleaner with combined scraping and brushing [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(1): 294-312. |

| [6] | Lin-rong SHI,Wu-yun ZHAO. Design and test of rolling spoon type flaxes precision hole sower for caraway in northwest cold and arid agricultural region [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2706-2717. |

| [7] | Chao-jian FANG,Xin-rong HU. Privacy-sensitive data filtering algorithm based on fuzzy approximation [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1174-1180. |

| [8] | Shu-yang SUN,Wei-bin CHENG,Hao-zhen ZHANG,Xiang-ping DENG,Hong QI. Deep-learning-based two-stage approach for real-time explicit topology optimization [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(10): 2942-2951. |

| [9] | Guo-liang WEI,Qing-song ZHANG,Biao WANG,Kun HE,Qing-xi LIAO. Analysis and experiment on parameters of plough body of rapeseed direct seeder [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(7): 1709-1718. |

| [10] | Xing-yu WAN,Qing-xi LIAO,Ya-jun JIANG,Yi-yin SHAN,Yu ZHOU,Yi-tao LIAO. Discrete element simulation and experiment of mechanized harve- sting and chopping process for fodder rape crop harvest [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2735-2745. |

| [11] | Jia-cheng YUAN,Chang WANG,Kun HE,Xing-yu WAN,Qing-xi LIAO. Effect of components mass ratio under sieve on cleaning system performance for rape combine harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1897-1907. |

| [12] | Gang WANG,Hui-li LIU,Hong-lei JIA,Chun-jiang GUO,Yong-jian CONG,Ming-hao QU. Design and experiment of touching-positioning weeding device for inter-row maize (Zea Mays L.) [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1518-1527. |

| [13] | WANG Deng-feng, ZHANG Shuai, WANG Yong, CHEN Hui. Optimization design of assembled wheel based on performance of fatigue and 13° impact [J]. 吉林大学学报(工学版), 2018, 48(1): 44-56. |

| [14] | SHI Wen-ku, ZU Qing-hua, CHEN Zhi-yong, MAO Yang, HE Bang-ying, FU Ji-yun, LI Xiao-yan. Noise diagnosis of in idle automotive air conditioning compressor and topology optimization [J]. 吉林大学学报(工学版), 2016, 46(3): 725-731. |

| [15] | ZHU Jian-feng, LIN Yi, CHEN Xiao-kai, SHI Guo-biao. Structural topology optimization based design of automotive transmission housing structure [J]. 吉林大学学报(工学版), 2013, 43(03): 584-589. |

|