吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (4): 1122-1132.doi: 10.13229/j.cnki.jdxbgxb.20210796

• 交通运输工程·土木工程 • 上一篇

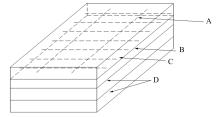

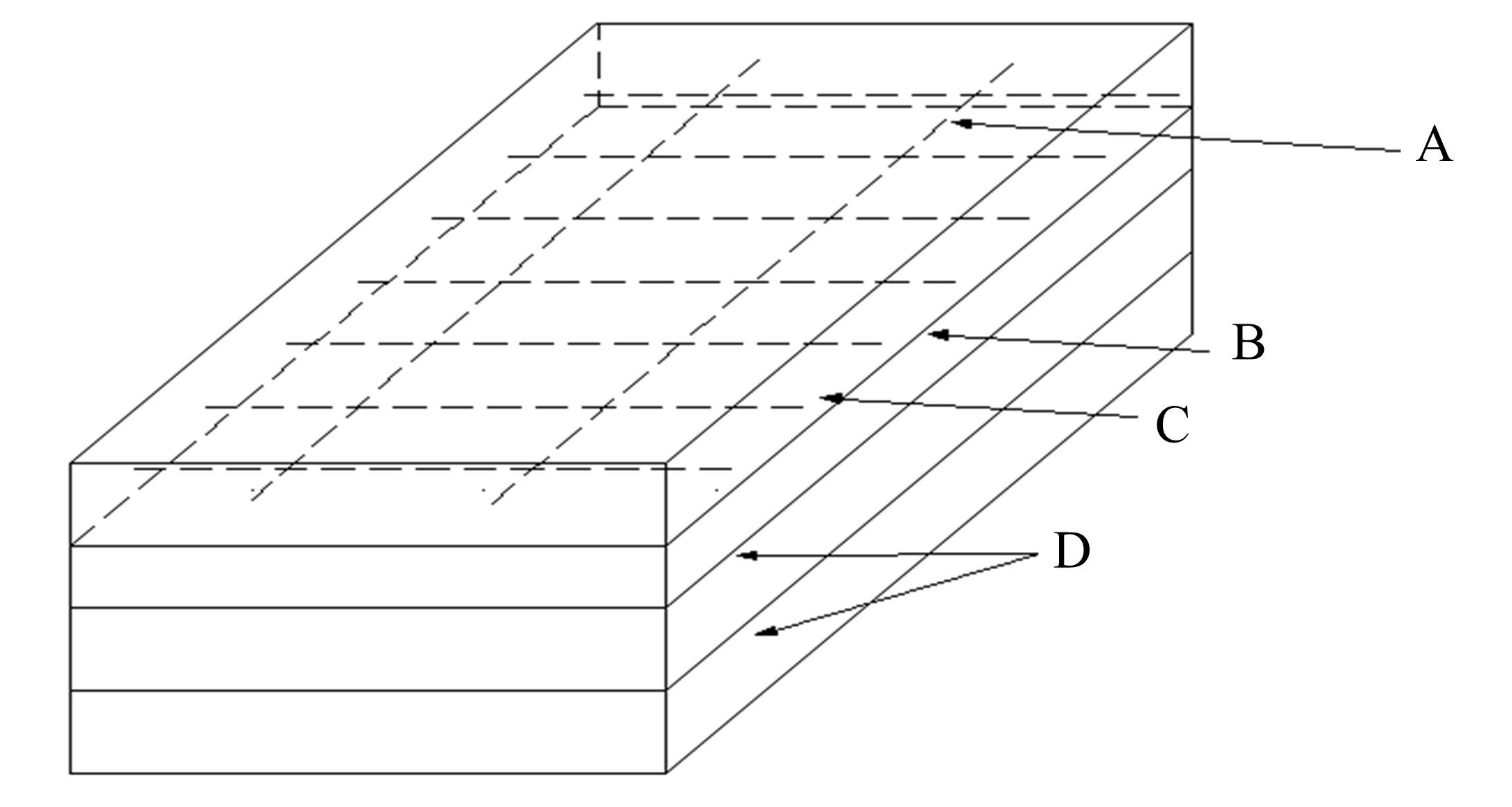

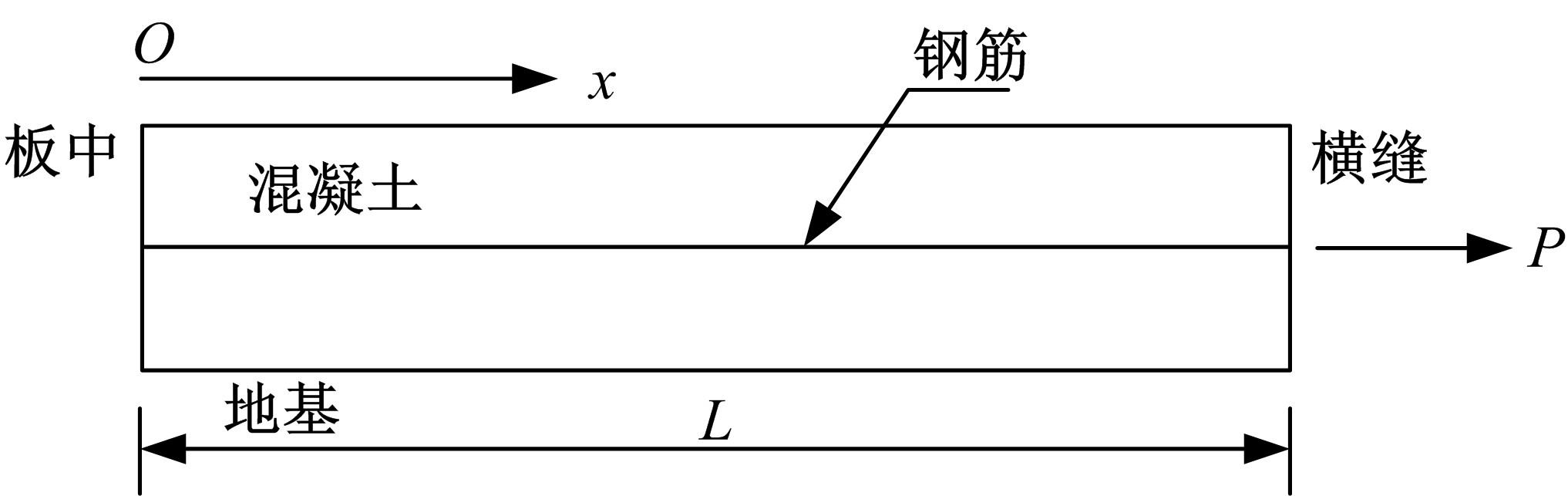

温缩作用下双层连续配筋混凝土路面配筋率设计参数对比分析

- 1.同济大学 道路与交通工程教育部重点实验室,上海 201804

2.亚琛工业大学 道路工程研究所,德国 亚琛 52074

3.长沙理工大学 公路养护技术国家工程实验室,长沙 410114

Numerical simulation of continuously reinforced concrete pavement with double⁃layer reinforcement under effect of temperature shrinkage

Fan YANG1( ),Chen-chen LI1,2,Sheng LI3(

),Chen-chen LI1,2,Sheng LI3( ),Hai-lun LIU1

),Hai-lun LIU1

- 1.Key Laboratory of Road and Traffic Engineering of the Ministry of Education,Tongji University,Shanghai 201804,China

2.Institute of Highway Engineering,RWTH Aachen University,Aachen 52074,Germany

3.State Engineering Laboratory of Highway Maintenance Technology,Changsha University of Science and Technology,Changsha 410114,China

摘要:

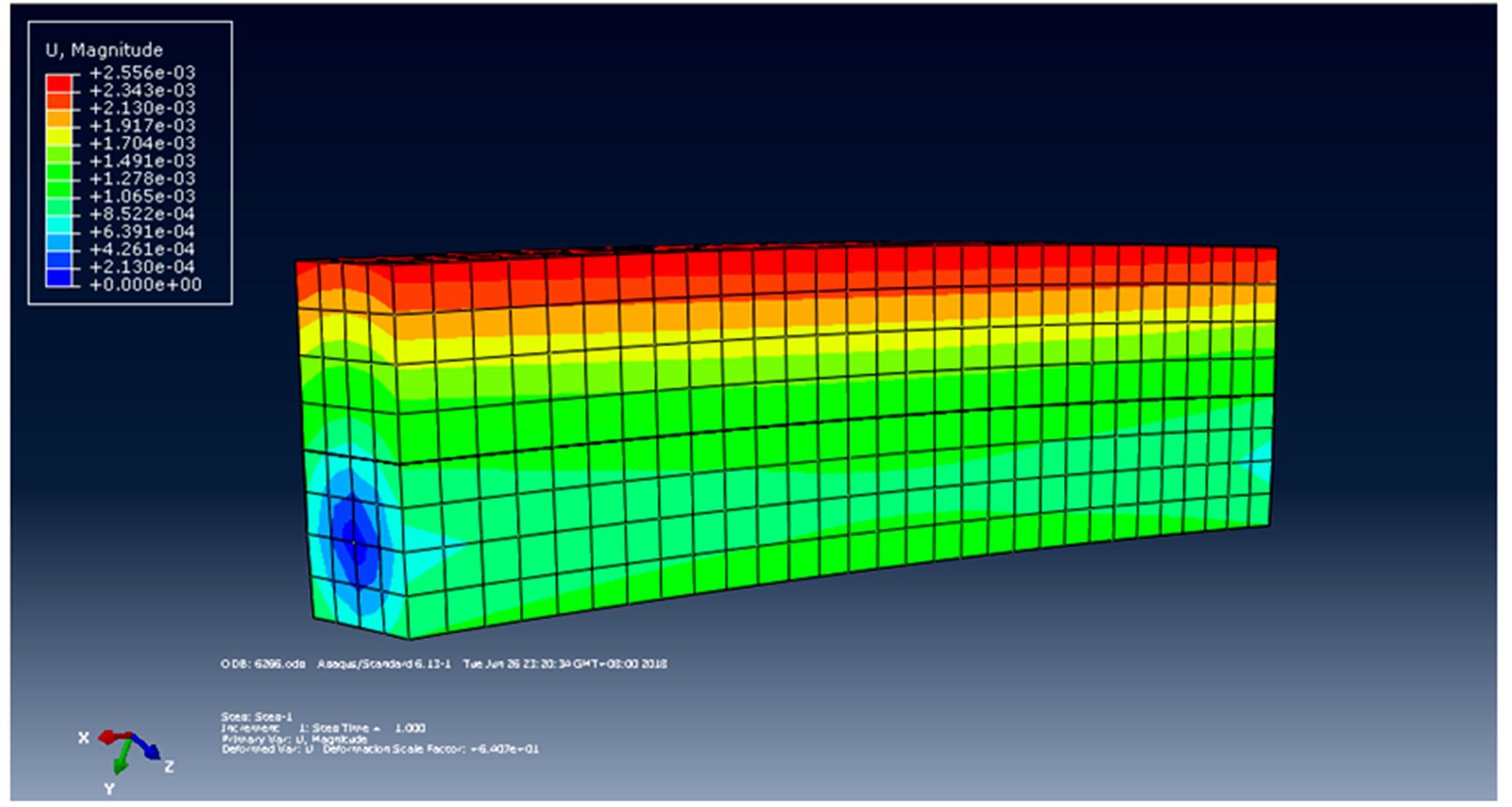

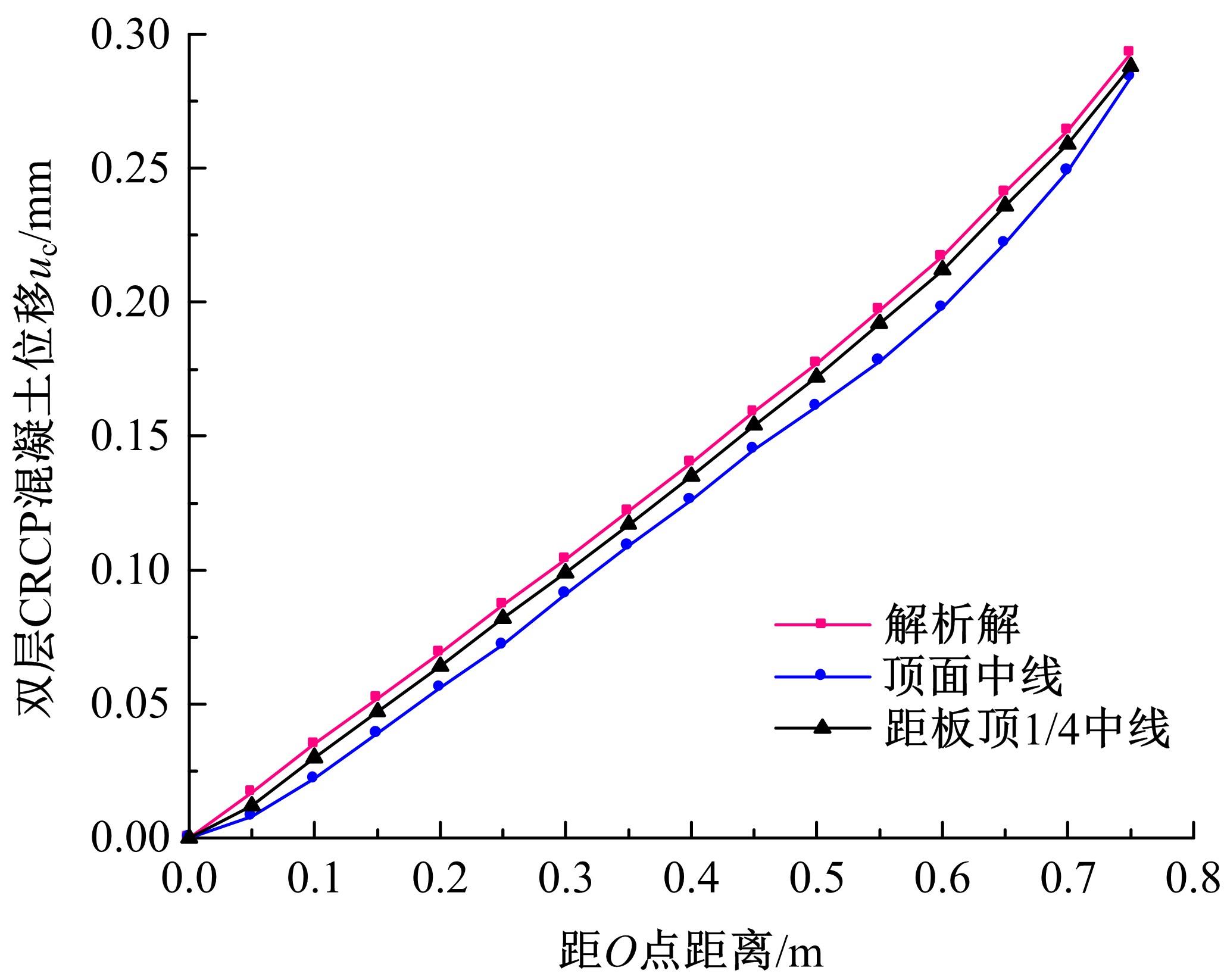

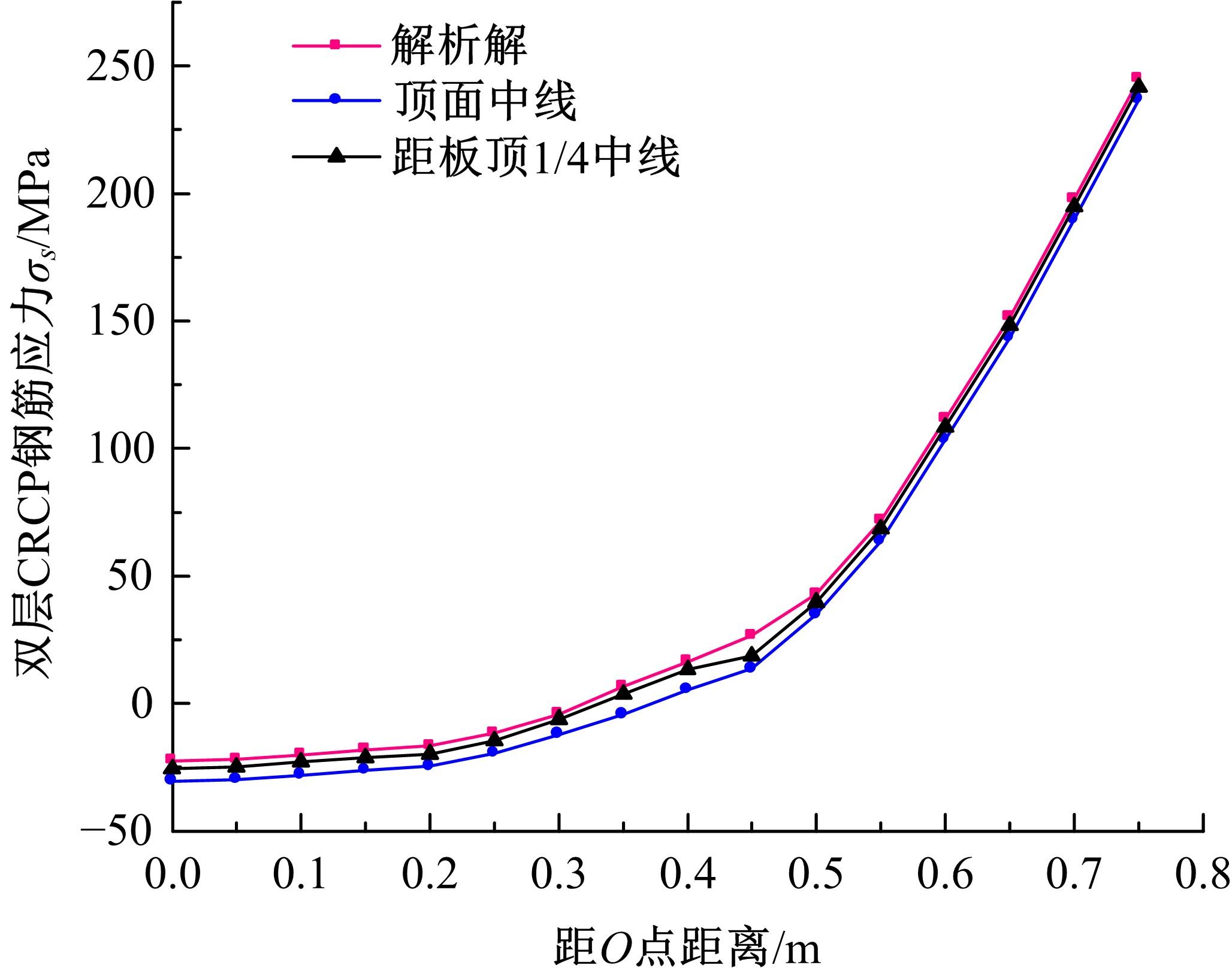

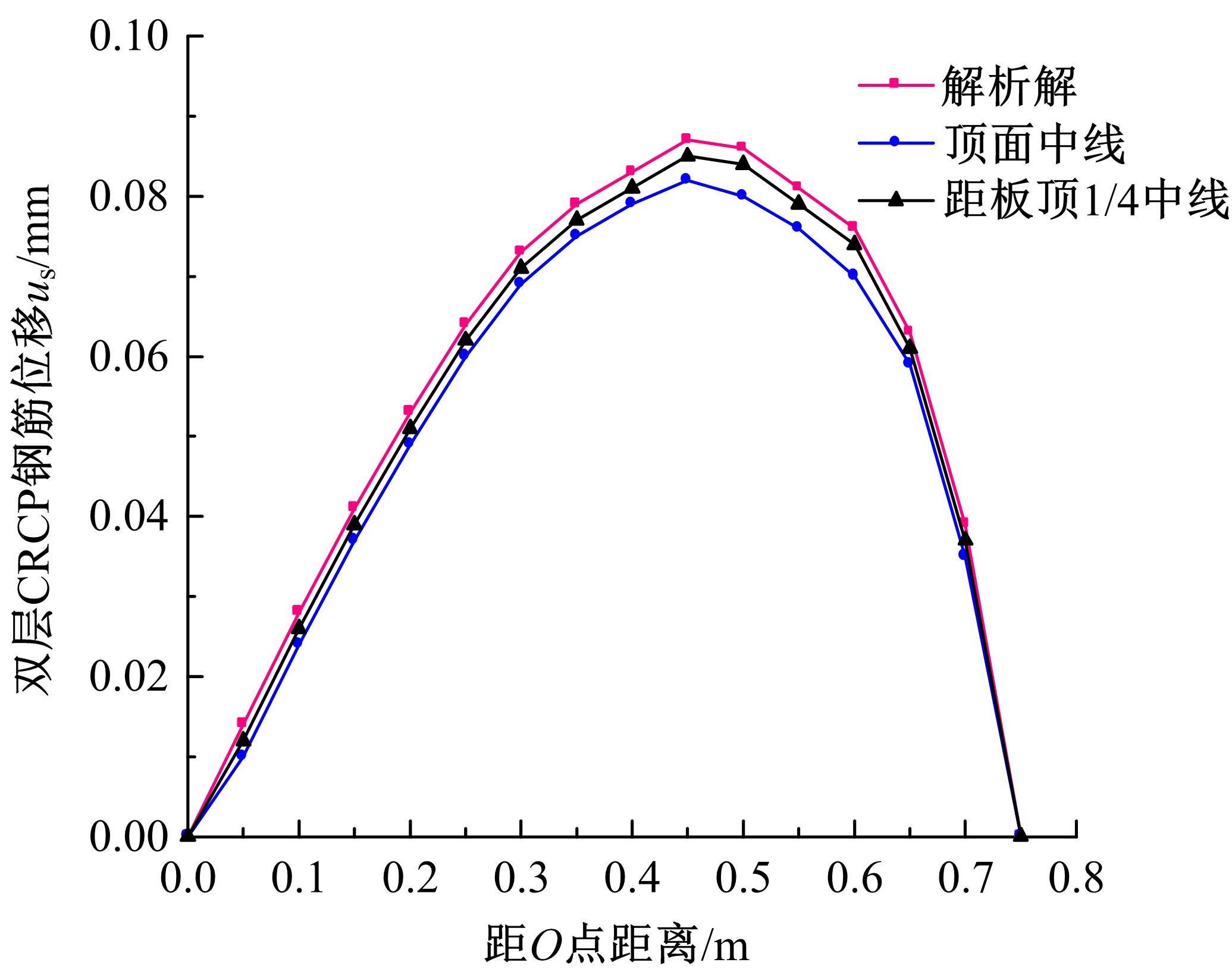

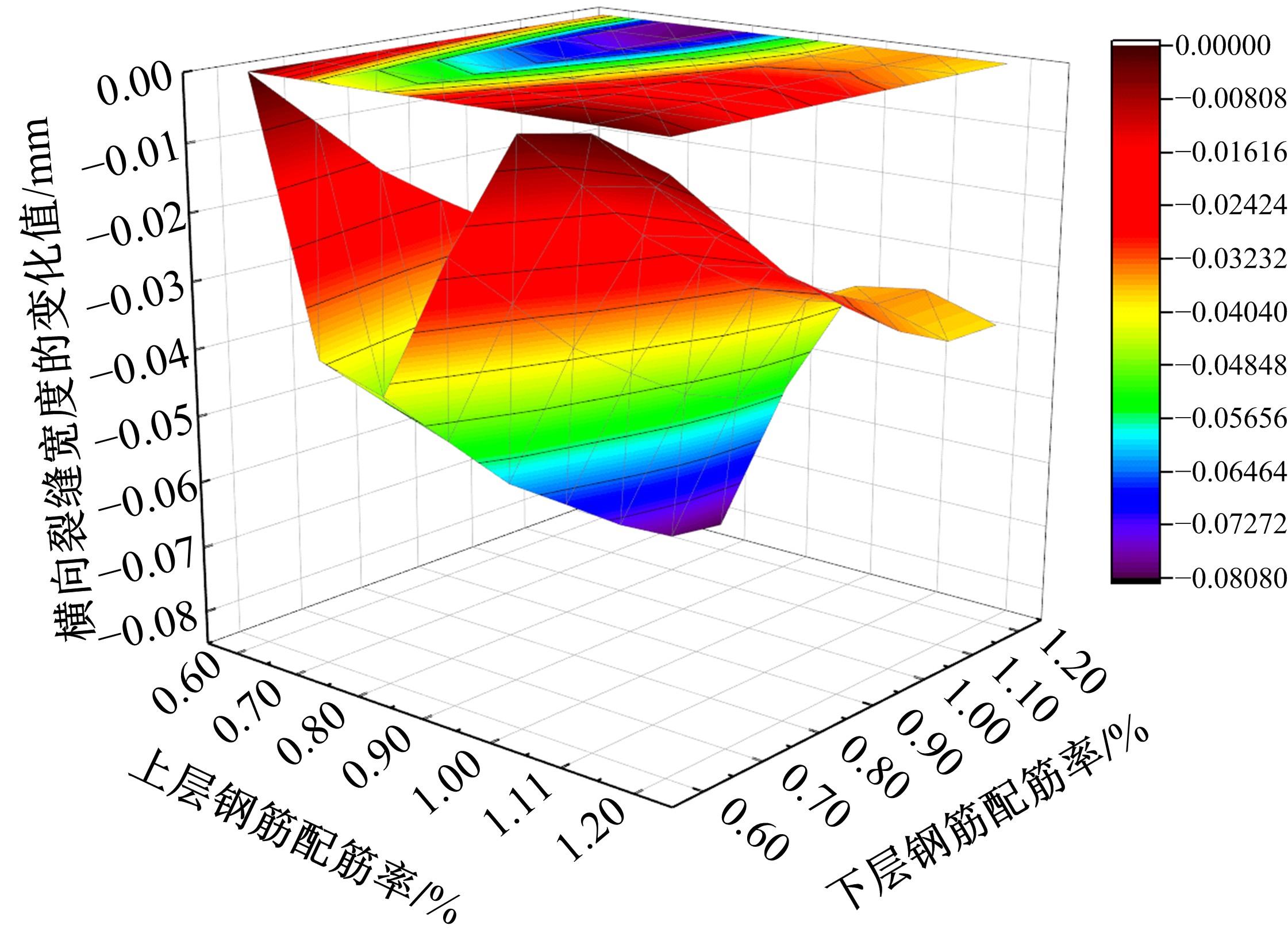

利用钢筋等效原理建立双层配筋CRCP在温缩作用下的数值模型并进行验证,在此基础上运用L50正交表设计数值仿真工况,以横向裂缝宽度bj、纵向钢筋应力极值σs,max和混凝土应力极值σc,max作为评价指标,对11项配筋设计参数进行敏感性分析和显著性排序。显著性分析表明,线膨胀系数、温降和配筋率、粘结刚度系数、钢筋弹性模量对CRCP力学响应影响较为显著,应作为双层配筋CRCP主要设计指标。在双层配筋CRCP的配筋率设计试算中,建议将配筋率ρ依次按照ρ∈[0.60%,0.80%]、ρ∈[0.80%,1.00%]、ρ∈[1.00%,1.20%]三个取值区间进行试算;将连续配筋混凝土(CRC)板体的1/3厚度处作为上层纵向钢筋和下层纵向钢筋的取值基点。

中图分类号:

- U416.216

| 1 | Huang Y. Pavement Design and Analysis[M]. New York: Printice Hall, 2003. |

| 2 | 王秉纲. 水泥混凝土路面的配筋设计[J]. 公路, 2002, 46(8): 30-33. |

| Wang Bing-gang. Reinforcement design for cement concrete pavement[J]. Highway, 2002, 46(8): 30-33. | |

| 3 | 张洪亮, 左志武. 连续配筋混凝土路面[M].北京:人民交通出版社, 2010. |

| 4 | 王巍. 极重荷载下双层CRCP应力、应变及裂缝现场测试与分析[D]. 武汉: 华中科技大学土木与水利工程学院, 2016. |

| Wang Wei. Field test and analysis of stress, strain and crack of double-layer CRCP under extreme heavy load [D]. Wuhan: School of Civil and Hydraulic Engineering, Huazhong University of Science and Technology, 2016. | |

| 5 | 王晓帆. 温湿耦合对双层连续配筋混凝土路面纵向配筋率设计的影响研究[D]. 长沙: 长沙理工大学土木工程学院, 2017. |

| Wang Xiao-fan. Study on the influence of temperature humidity coupling on the design of longitudinal reinforcement ratio of double-layer continuous reinforced concrete pavement[D]. Changsha: College of Civil Engineering, Changsha University of Technology, 2017. | |

| 6 | Wu Fan, Dai Yi-Qing, Ni Fu-jian. Mid-depth punch-out research of continuously reinforced concrete pavement[C]∥The 17th COTA International Conference of Transportation Professionals, Shanghai, China, 2018. |

| 7 | Sun R J, Cobos L, Won M C. Behavior of the longitudinal construction joint of continuously reinforced concrete pavement[J]. Geotechnical Special Publication, 2011, 205(212): 200-207. |

| 8 | 占逸, 吴瑞麟, 陈旭, 等. 基于ANSYS的双层配筋CRCP温度翘曲应力数值分析[J]. 土木工程与管理学报, 2019, 36(3): 177-182, 189. |

| Zhan Yi, Wu Rui-lin, Chen Xu, et al. Simulation analysis of the bilayer reinforcement CRCP's temperature warping stress based on ANSYS[J]. Journal of Civil Engineering and Management, 2019, 36(3): 177-182, 189. | |

| 9 | 吴瑞麟, 王巍, 杨梅梅, 等. 基于实测数据的双层CRCP横向裂缝研究[J]. 华中科技大学学报: 自然科学版, 2017, 45(1): 1-5. |

| Wu Rui-lin, Wang Wei, Yang Mei-mei, et al. Research on transverse cracks of bilayer CRCP based on actual data[J]. Journal of Huazhong University of Science and Technology (Nature Science Edition), 2017, 45(1): 1-5. | |

| 10 | 吴春蕾, 吴瑞麟, 占逸, 等. 板底脱空状态下车辆荷载对双层配筋CRCP钢筋应力的影响[J]. 土木工程与管理学报, 2018, 35(3): 173-178. |

| Wu Chun-lei, Wu Rui-lin, Zhan Yi, et al. Influence of vehicle load under slab hollow condition on bilayer continuous reinforced concrete pavement steel stress[J]. Journal of Civil Engineering and Management, 2018, 35(3): 173-178. | |

| 11 | 李盛, 杨帆, 刘萌, 等. 新型双层CRCP结构及在城市道路中的应用[J]. 中南大学学报: 自然科版, 2019, 50(4): 983-989. |

| Li Sheng, Yang Fan, Liu Meng, et al. Structure of continuously reinforced concrete pavement with double-layer reinforced and its application in urban road[J]. Journal of Central South University(Science and Technology), 2019, 50(4): 983-989. | |

| 12 | 左志武. 连续配筋混凝土路面横向裂缝分布和冲断预估研究[D]. 西安:长安大学公路学院, 2010. |

| Zuo Zhi-wu. Study on distribution of transverse cracks and punch out prediction of continuously reinforced concrete pavement[D]. Xi'an: School of Highway, Chang'an University, 2010. | |

| 13 | Kohler E R, Roesler J R. Repeated load behavior of continuously reinforced concrete pavements[J] Civil and Environmental Engineering, 2005,8(2): 621-638. |

| 14 | Beeldens A, Rens L. CRCP applications in Belgium: recent evolutions towards an optimised cracking pattern[C]∥Australian Society for Concrete Pavements Conference, Kingscliff, Australia, 2017. |

| 15 | 张翛, 胡圣能, 赵鸿铎, 等. 连续配筋混凝土路面裂缝间距特性[J].交通运输工程学报, 2013, 13(4): 1-7. |

| Zhang Xiao, Hu Sheng-neng, Zhao Hong-duo, et al. Characteristic of crack spacing for continuously reinforced concrete pavement[J]. Journal of Traffic and Transportation Engineering, 2013, 13(4): 1-7. | |

| 16 | AA .Guide for Design of Pavement Structure[S]. |

| 17 | 中交公路规划设计院. JTG D40-2011:公路水泥混凝土路面设计规范[M].北京:人民交通出版社, 2011. |

| 18 | 鲁昌河, 邱志雄, 蔡业青, 等. 双层与单层连续配筋混凝土路面设计与施工探讨[J]. 中外公路, 2006, 26(3): 83-86. |

| Lu Chang-he, Qiu Zhi-xiong, Cai Ye-qing. Discussion on design and construction of double-layer and single-layer continuously reinforced concrete pavement[J]. Journal of China & Foreign Highway, 2006, 26(3): 83-86. | |

| 19 | 陈小兵. 基于裂缝形成规律的连续配筋混凝土路面结构设计方法研究[D]. 南京: 东南大学交通学院, 2013. |

| Chen Xiao-bing. Structural design method of CRCP baesd on the chracteristics of cracking[D]. Nanjing: School of Transportation, Southeast University, 2013. | |

| 20 | 陈锋锋, 黄晓明, 单景松. 复合式路面CRCP疲劳损耗临界荷位处荷载应力研究[J]. 中国市政工程, 2008, 32(3): 4-6, 93. |

| Chen Feng-feng, Huang Xiao-ming, Shan Jing-song. Studies on load stress at loading position critical to fatigue loss on CRCP composite pavemen[J]. China Municipal Engineering, 2008, 32(3): 4-6, 93. | |

| 21 | 曹东伟. 连续配筋混凝土路面结构研究[D]. 西安:长安大学公路学院, 2001. |

| Cao Dong-wei. Study on the structure of continuous reinforced concrete pavement[D]. Xi'an: School of Highway, Chang'an University, 2010. | |

| 22 | 陈锋锋, 黄晓明, 秦永春. 连续配筋混凝土路面横向裂缝分布模型的研究[J].公路交通科技, 2006, 23(6): 18-21. |

| Chen Feng-feng, Huang Xiao-ming, Qin Yong-chun. Study on the probability distribution model of continuously reinforced concrete pavement transverse cracks[J]. Journal of Highway and Transportation Research and Development, 2006, 23(6): 18-21. | |

| 23 | 黄优, 刘朝晖, 李盛. 不同层间结合状态下刚柔复合式路面的剪应力分析[J].公路交通科技, 2015, 32(6): 32-38, 61. |

| Huang You, Liu Zhao-hui, Li Sheng. Analysis of shear stress of rigid-flexible composite pavement under different interlaminar bonding conditions[J]. Journal of Highway and Transportation Research and Development, 2015, 32(6): 32-38, 61. | |

| 24 | 曹前, 刘青, 刘朝晖, 等. 双层连续配筋混凝土路面荷载应力分析[J]. 公路, 2016, 61(8): 22-26. |

| Cao Qian, Liu Qing, Liu Zhao-hui, et al. Load stress analysis of double-layer continuously reinforced concrete pavement[J]. Highway, 2016, 61(8): 22-26. | |

| 25 | 刘朝晖, 黄优, 李盛. 层间结合状态对刚柔复合式路面剪应力的影响分析[J].公路, 2015, 60(1): 1-6. |

| Liu Zhao-hui, Huang You, Li Sheng. Impact analysis of interlayer bonding condition on shear stress of rigid-flexible composite pavement[J]. Highway, 2015, 60(1): 1-6. |

| [1] | 关博文,邸文锦,王发平,吴佳育,张硕文,贾治勋. 干湿循环与交变荷载作用下混凝土硫酸盐侵蚀损伤[J]. 吉林大学学报(工学版), 2023, 53(4): 1112-1121. |

| [2] | 刘状壮,张有为,季鹏宇,Abshir Ismail Yusuf,李林,郝亚真. 电热型融雪沥青路面传热特性研究[J]. 吉林大学学报(工学版), 2023, 53(2): 523-530. |

| [3] | 魏海斌,马子鹏,毕海鹏,刘汉涛,韩栓业. 基于力学响应分析方法的导电橡胶复合路面铺装技术[J]. 吉林大学学报(工学版), 2023, 53(2): 531-537. |

| [4] | 时成林,王勇,吴春利,宋文祝. 路堤挡土墙主动土压力计算方法修正[J]. 吉林大学学报(工学版), 2022, 52(6): 1394-1403. |

| [5] | 郭庆林,刘强,吴春利,李黎丽,李懿明,刘富春. 导电沥青及混合料裂缝局部温度场及愈合效果[J]. 吉林大学学报(工学版), 2022, 52(6): 1386-1393. |

| [6] | 姚玉权,仰建岗,高杰,宋亮. 基于性能-费用模型的厂拌再生沥青混合料优化设计[J]. 吉林大学学报(工学版), 2022, 52(3): 585-595. |

| [7] | 夏全平,高江平,罗浩原,张其功,李志杰,杨飞. 用于高模量沥青砼的复合改性硬质沥青低温性能[J]. 吉林大学学报(工学版), 2022, 52(3): 541-549. |

| [8] | 叶奋,胡诗园. 考虑旧水泥路面接缝传荷能力的超薄罩面力学特性[J]. 吉林大学学报(工学版), 2022, 52(11): 2636-2643. |

| [9] | 于晓贺,罗蓉,柳子尧,黄婷婷,束裕. 沥青路面典型裂缝湿度场数值模拟[J]. 吉林大学学报(工学版), 2022, 52(10): 2343-2351. |

| [10] | 杨彦海,崔宏,杨野,张怀志,刘赫. 冻融循环作用对非饱和乳化沥青冷再生混合料性能的影响[J]. 吉林大学学报(工学版), 2022, 52(10): 2352-2359. |

| [11] | 冉武平,陈慧敏,李玲,冯立群. 干湿循环下粗粒土回弹模量演变规律及模型预估和修正[J]. 吉林大学学报(工学版), 2021, 51(6): 2079-2086. |

| [12] | 董伟智,张爽,朱福. 基于可拓层次分析法的沥青混合料路用性能评价[J]. 吉林大学学报(工学版), 2021, 51(6): 2137-2143. |

| [13] | 许哲谱,杨群. 基于实时路况地图的短期养护作业开始时间优化[J]. 吉林大学学报(工学版), 2021, 51(5): 1763-1774. |

| [14] | 文畅平,任睆遐. 基于Lade模型的生物酶改良膨胀土双屈服面本构关系[J]. 吉林大学学报(工学版), 2021, 51(5): 1716-1723. |

| [15] | 王元元,孙璐,刘卫东,薛金顺. 测量路面三维纹理双目重构算法的约束改进[J]. 吉林大学学报(工学版), 2021, 51(4): 1342-1348. |

|

||