吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (12): 3379-3387.doi: 10.13229/j.cnki.jdxbgxb.20220099

• 车辆工程·机械工程 • 上一篇

冗余机械臂运动学逆解的求解优化方法

- 1.哈尔滨工程大学 智能科学与工程学院,哈尔滨 150001

2.中国工程物理研究院 化工材料研究所,四川 绵阳 621999

Optimized method for solving inverse kinematics of redundant manipulator

Zheng ZHANG1( ),Qi-dan ZHU1,Xiao-long LYU1,Xing FAN2

),Qi-dan ZHU1,Xiao-long LYU1,Xing FAN2

- 1.College of Intelligent Systems Science and Engineering,Harbin Engineering University,Harbin 150001,China

2.Institute of Chemical Materials,China Academy of Engineering Physics,Mianyang 621999,China

摘要:

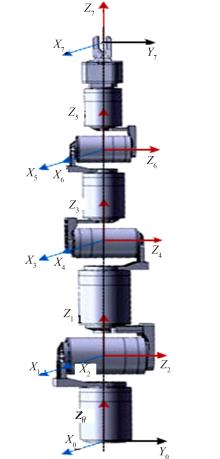

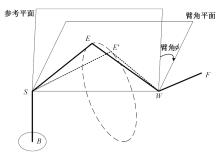

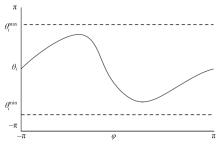

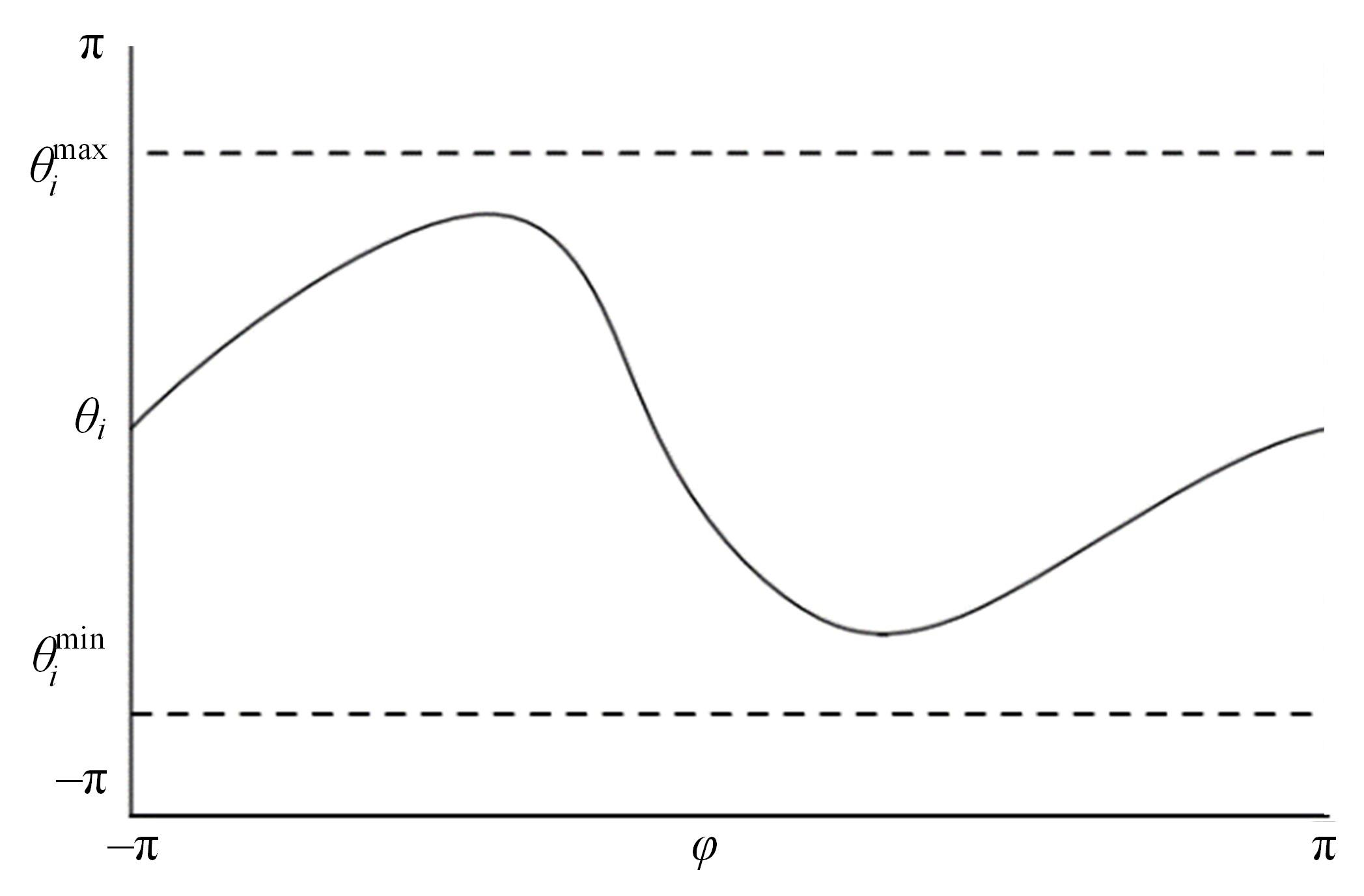

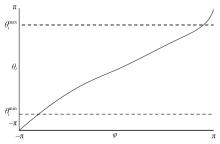

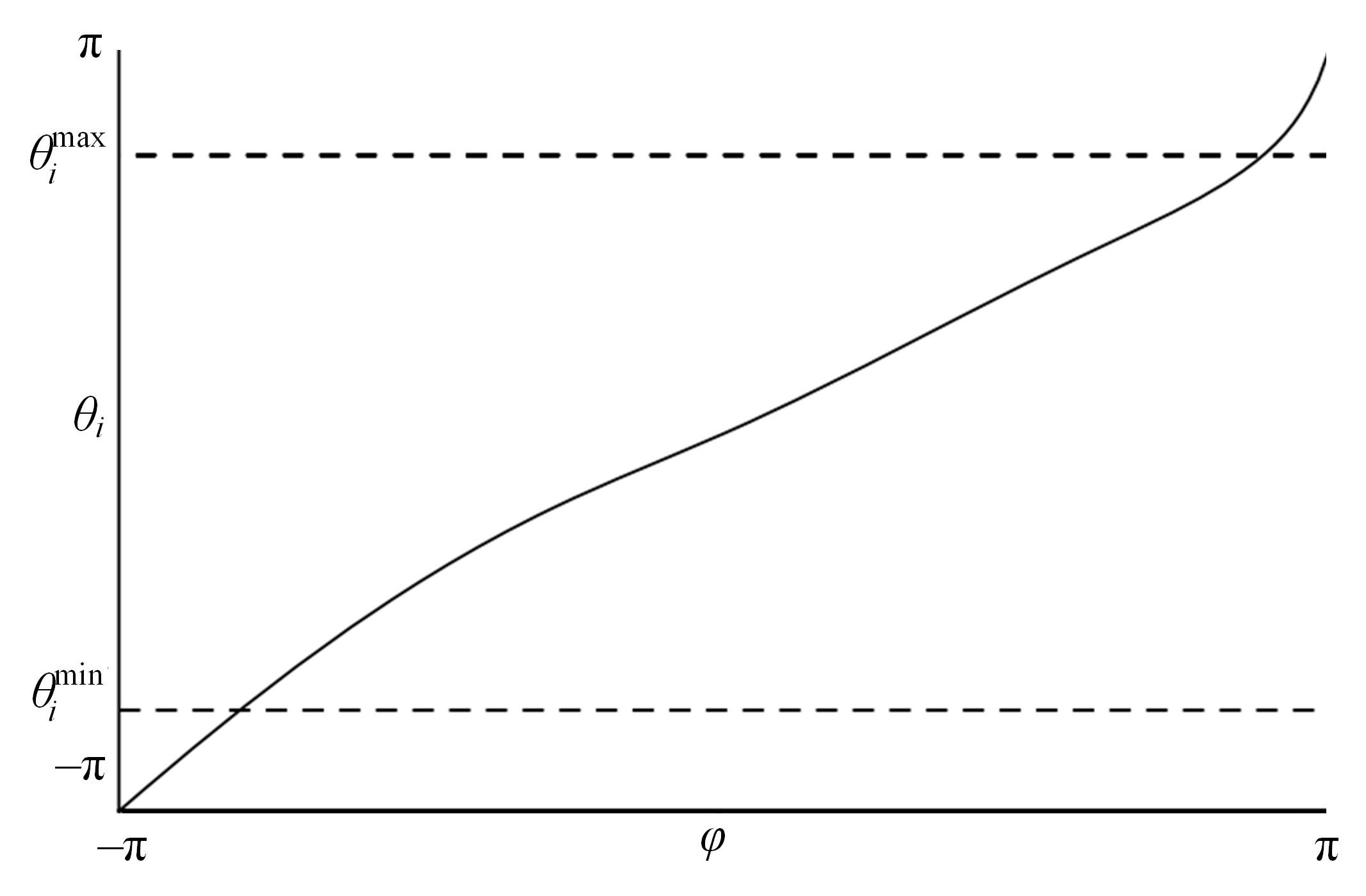

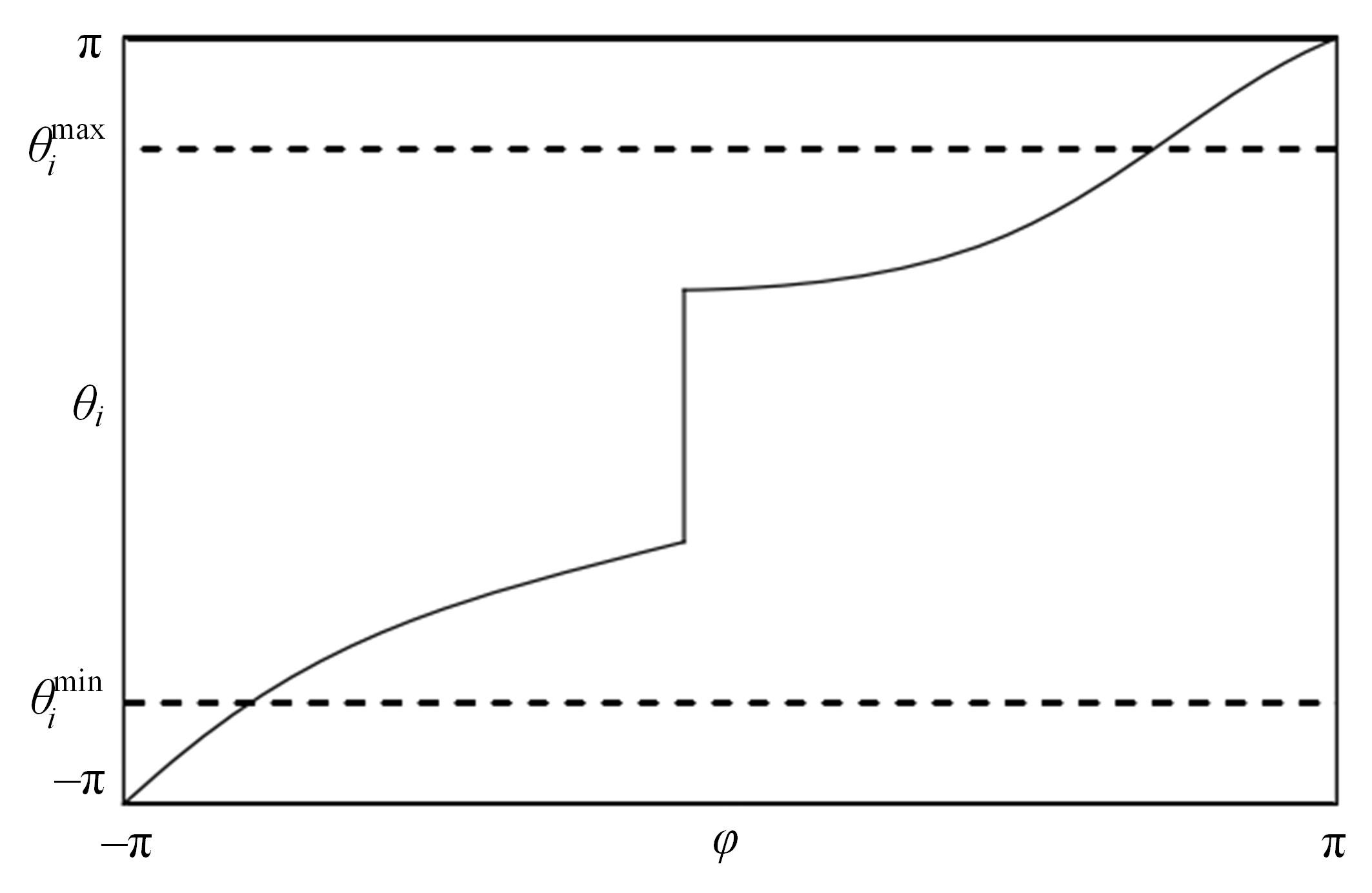

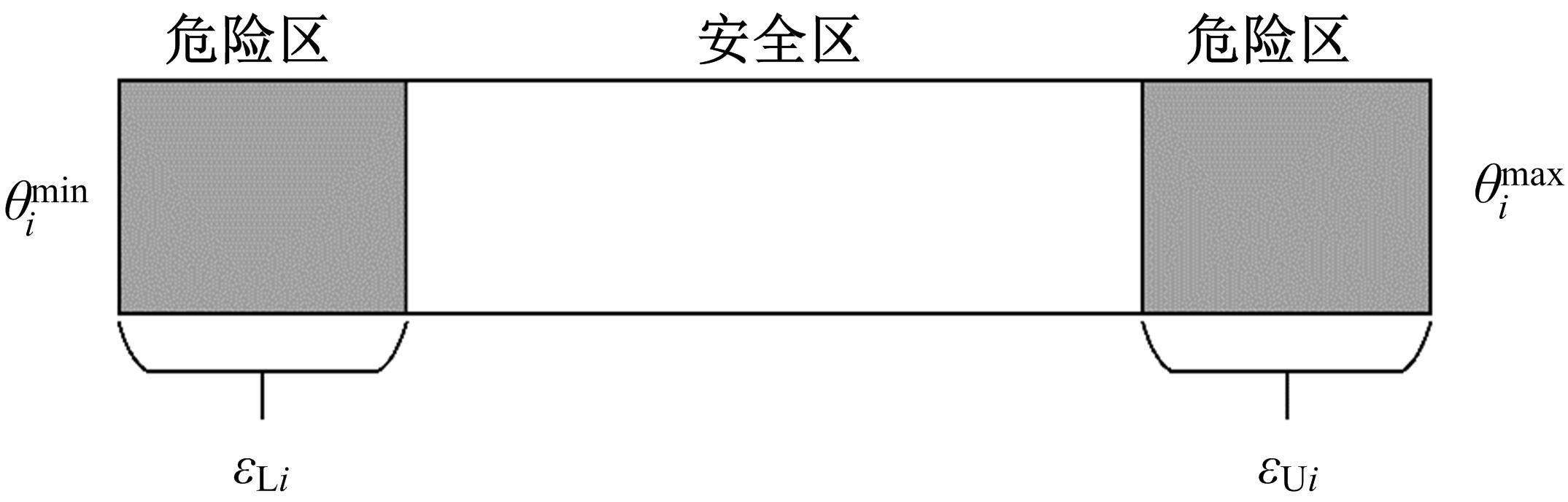

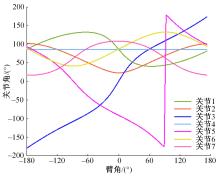

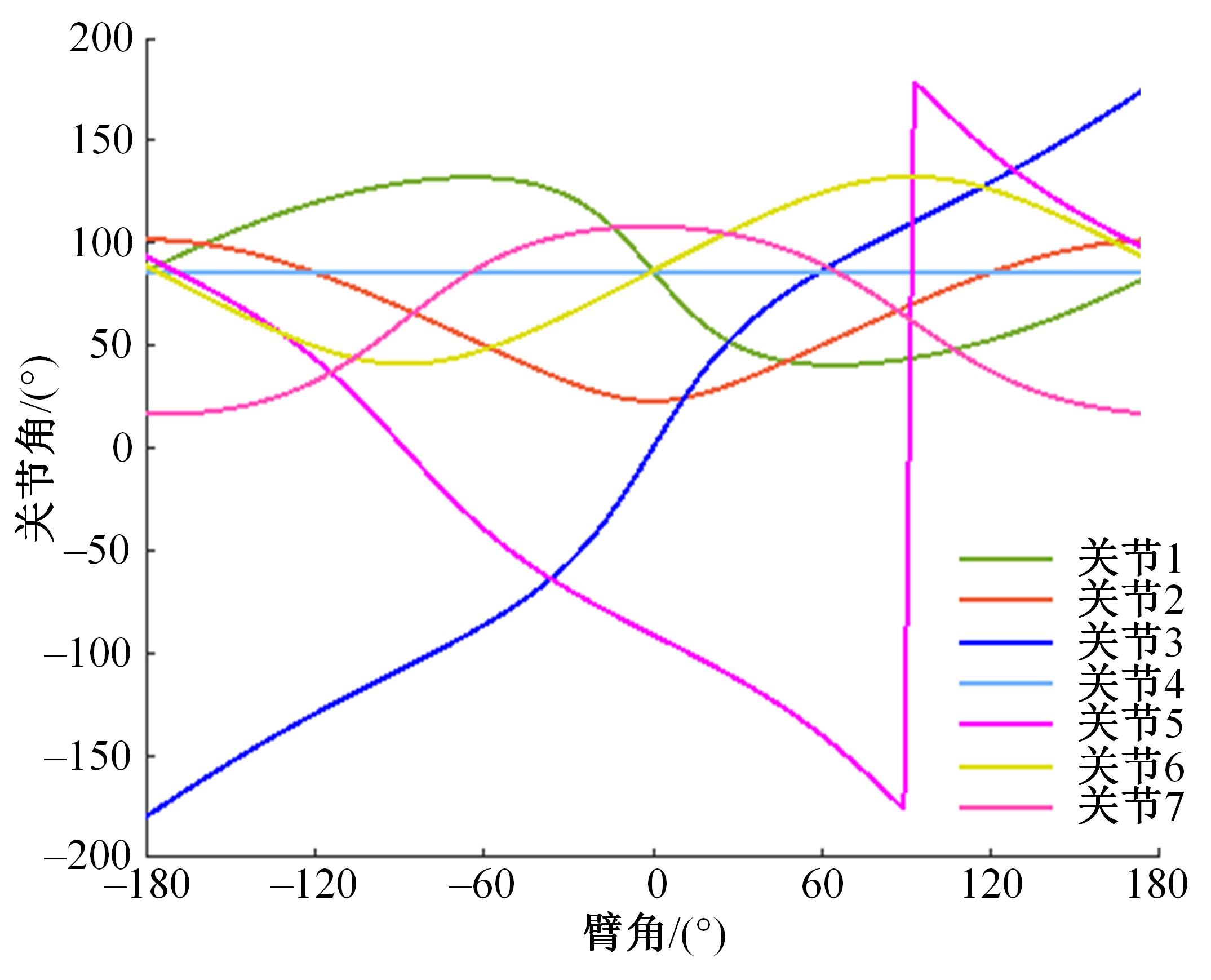

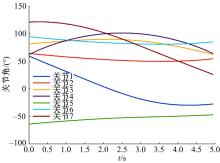

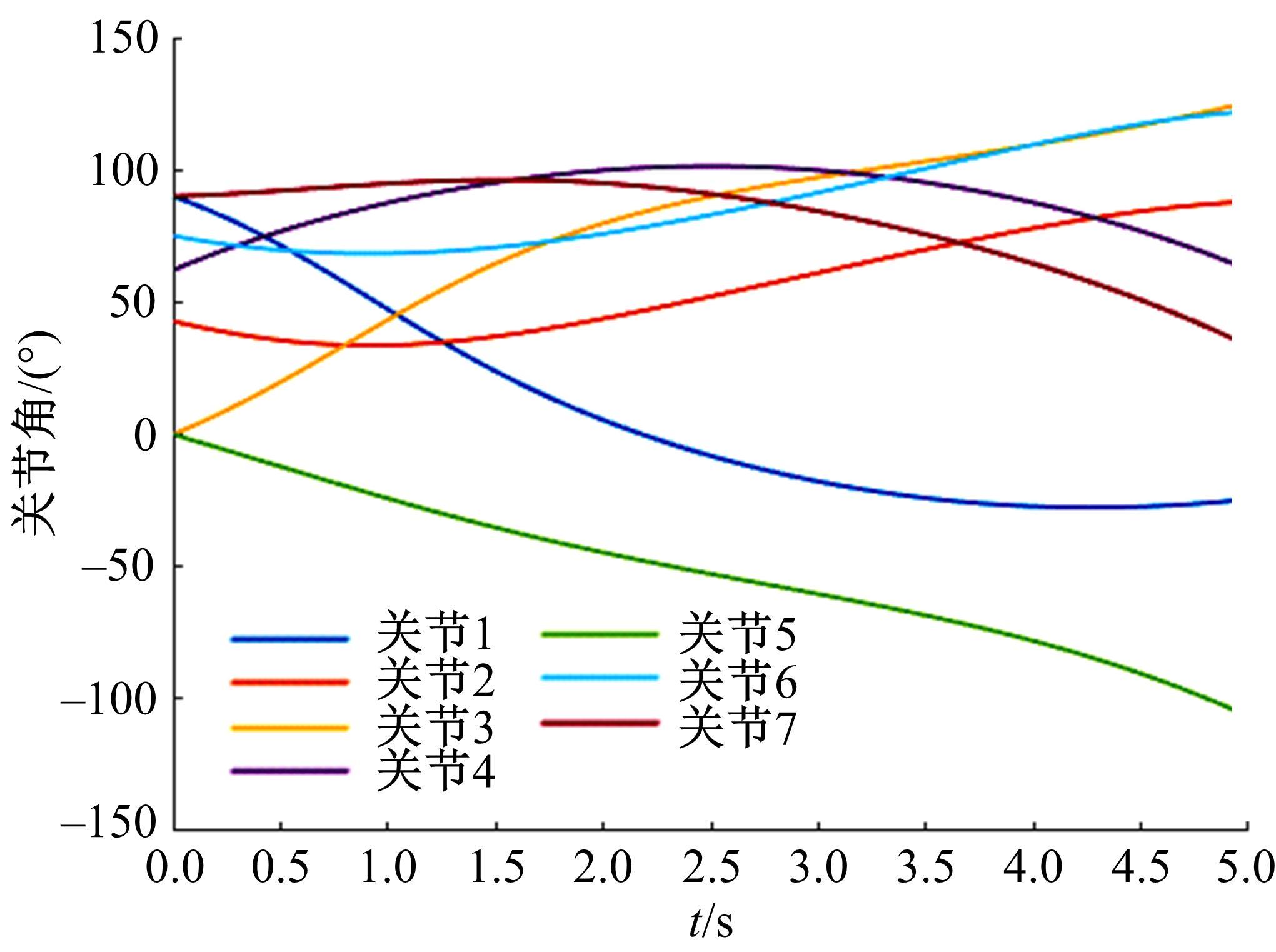

为解决仿人冗余机械臂逆运动学的求解问题,本文提出了一种逆运动学求解优化方法。通过引入臂角参数建立了逆解的解析解公式,根据关节限位进一步分析了不同形式解析解下的臂角可行区间。此外,提出了综合考虑关节避限和能耗最优的目标函数,通过自适应权重参数调节任务优先级,并引入粒子群优化算法得出最优解。实验结果表明,该算法能求出给定臂角的所有解,并且能选出满足关节避限和低能耗的最优解,对于冗余机械臂的轨迹规划有较好的应用意义。

中图分类号:

- TP242

| 1 | 徐呈艺, 刘英, 贾民平, 等. 木板抓取冗余机械臂逆运动学求解[J]. 计算机集成制造系统, 2020, 26(12): 3368-3374. |

| Xu Cheng-yi, Liu Ying, Jia Min-ping, et al. Inverse kinematics solution of redundant robot arm in picking board[J]. Computer Integrated Manufacturing Systems, 2020, 26(12): 3368-3374. | |

| 2 | Gong M, Li X, Zhang L. Analytical inverse kinematics and self-motion application for 7-DOF redundant manipulator[J]. IEEE Access, 2019, 7: 18662-18674. |

| 3 | 段晋军, 甘亚辉, 戴先中, 等. 基于可操作度评价的冗余机器人逆解求解方法[J]. 华中科技大学学报, 2015, (): 45-48, 57. |

| Duan Jin-jun, Gan Ya-hui, Dai Xian-zhong, et al. Method of inverse kinematics solution for a redundant manipulator based on manipulability[J]. Journal of Huazhong University of Science and Technology, 2015, (Sup.1): 45-48, 57. | |

| 4 | 卢绍田. 空间冗余机械臂运动优化与轨迹跟踪控制研究[D]. 哈尔滨: 哈尔滨工业大学机电工程学院, 2019. |

| Lu Shao-tian. Research on motion optimization and trajectory tracking control of space redundant manipulator[D]. Harbin: College of Mechanical Engineering, Harbin Institute of Technology, 2019. | |

| 5 | Zhang X, Fan B, Wang C, et al. An improved weighted gradient projection method for inverse kinematics of redundant surgical manipulators[J]. Sensors, 2021, 21(21): No. 7362. |

| 6 | Ito M, Kawatsu K, Shibata M. Kinematic control of redundant manipulators for admitting joint range of motion maximally[J]. IEEJ Journal of Industry Applications, 2017, 6(4): 278-285. |

| 7 | Ratajczak J. Design of inverse kinematics algorithms: extended Jacobian approximation of the dynamically consistent Jacobian inverse[J]. Archives of Control Sciences, 2015, 25(1): 35-50. |

| 8 | 谢宗武, 孙奎, 刘宏. 扩展雅克比方法的冗余度机器人逆运动学应用[J]. 哈尔滨工业大学学报, 2009(5): 34-36. |

| Xie Zong-wu, Sun Kui, Liu Hong. Application study on inverse kinematics algorithm of redundant manipulator based on extended Jacobian method[J]. Journal of Harbin Institute of Technology, 2009(5): 34-36. | |

| 9 | Wan J, Li D, Yao J, et al. A hybrid CHAOS-PSO algorithm for dimensional synthesis of a redundant manipulator based on tracking trajectories without or with singularities[J]. Production Engineering, 2018, 12(5): 579-587. |

| 10 | Xiang J, Zhong C, Wei W. General-weighted least-norm control for redundant manipulators[J]. IEEE Transactions on Robotics, 2010, 26(4): 660-669. |

| 11 | Chen P, Xiang J, Wei W. A unified weighted least norm method for redundant manipulator control[J]. International Journal of Advanced Robotic Systems, 2016, 13(1): No. 19. |

| 12 | 房立龙. 仿人双臂协作机器人设计研究[D]. 合肥: 中国科学技术大学工程科学学院, 2015. |

| Fang Li-long. Research on the design of human-like dual-arm collaborative robot[D]. Hefei: College of Mechatronic Engineering, University of Science and Technology of China, 2015. | |

| 13 | Wang X, Zhang D, Zhao C. Inverse kinematics of a 7R 6-DOF robot with nonspherical wrist based on transformation into the 6R robot[J]. Mathematical Problems in Engineering, 2017, 2017: 1-12. |

| 14 | Asfour T, Dillmann R. Human-like motion of a humanoid robot arm based on a closed-form solution of the inverse kinematics problem[C]∥Proceedings 2003 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2003), Washington, D C, USA, 2003: 1407-1412. |

| 15 | Shimizu M, Kakuya H, Yoon W K, et al. Analytical inverse kinematic computation for 7-DOF redundant manipulators with joint limits and its application to redundancy resolution[J]. IEEE Transactions on Robotics, 2008, 24(5): 1131-1142. |

| 16 | Yan L, Mu Z, Xu W. Analytical inverse kinematics of a class of redundant manipulator based on dual arm-angle parameterization[C]∥2014 IEEE International Conference on Systems, Man, and Cybernetics (SMC), Washington, D C, USA, 2014: 3744-3749. |

| 17 | Faria C, Ferreira F, Erlhagen W, et al. Position-based kinematics for 7-DoF serial manipulators with global configuration control, joint limit and singularity avoidance[J]. Mechanism and Machine Theory, 2018, 121(9): 317-334. |

| 18 | 霍希建, 刘伊威, 姜力, 等. 平面冗余自由度机器人自寻优运动优化方法[J]. 哈尔滨工程大学学报, 2015, 36(4): 528-533. |

| Huo Xi-jian, Liu Yi-wei, Jiang Li, et al. Self-optimizing kinematic optimization method of planar redundant robots[J]. Journal of Harbin Engineering University, 2015, 36(4): 528-533. | |

| 19 | 霍希建, 刘伊威, 姜力, 等. 具有关节限位的 7R 仿人机械臂逆运动学优化[J]. 吉林大学学报: 工学版, 2016, 46(1): 213-220. |

| Huo Xi-jian, Liu Yi-wei, Jiang Li, et al. Inverse kinematic optimization of 7R humanoid arm with joint limits[J]. Journal of Jilin University: Engineering Edition, 2016, 46(1): 213-220. | |

| 20 | Kuhlemann I, Schweikard A, Jauer P, et al. Robust inverse kinematics by configuration control for redundant manipulators with seven DoF[C]∥2016 2nd International Conference on Control, Automation and Robotics (ICCAR). Washington, D C, USA, 2016: 49-55. |

| 21 | Omisore O M, Han S, Ren L, et al. Deeply-learnt damped least-squares (DL-DLS) method for inverse kinematics of snake-like robots[J]. Neural Networks, 2018, 107: 34-47. |

| 22 | Lv X, Tan Z, Chen K, et al. Improved recurrent neural networks for online solution of Moore‐Penrose inverse applied to redundant manipulator kinematic control[J]. Asian Journal of Control, 2020, 22(3): 1188-1196. |

| 23 | Dereli S, Köker R. IW-PSO approach to the inverse kinematics problem solution of a 7-DOF serial robot manipulator[J]. International Journal of Natural and Engineering Sciences, 2018, 36(1): 75-85. |

| 24 | 许杉, 李高峰, 刘景泰, 等. 基于点触任务的可变形臂逆运动学求解[J]. 机器人, 2017, 39(4): 23-32. |

| Xu Shan, LI Gao-feng, Liu Jing-tai, et al. Inverse kinematics solution of deformable manipulator for point touching task[J]. Robot, 2017, 39(4): 23-32. |

| [1] | 谭国金,孔庆雯,何昕,张攀,杨润超,朝阳军,杨忠. 基于动力特性和改进粒子群优化算法的桥梁冲刷深度识别[J]. 吉林大学学报(工学版), 2023, 53(6): 1592-1600. |

| [2] | 孙琪凯,张楠,刘潇,周子骥. 基于Timoshenko梁理论的钢-混组合梁动力折减系数[J]. 吉林大学学报(工学版), 2023, 53(2): 488-495. |

| [3] | 秦静,郑德,裴毅强,吕永,苏庆鹏,王膺博. 基于PSO-GPR的发动机性能与排放预测方法[J]. 吉林大学学报(工学版), 2022, 52(7): 1489-1498. |

| [4] | 朱思峰,赵明阳,柴争义. 边缘计算场景中基于粒子群优化算法的计算卸载[J]. 吉林大学学报(工学版), 2022, 52(11): 2698-2705. |

| [5] | 金顺福,郄修尘,武海星,霍占强. 基于新型休眠模式的云虚拟机分簇调度策略及性能优化[J]. 吉林大学学报(工学版), 2020, 50(1): 237-246. |

| [6] | 王宏志,姜方达,周明月. 基于遗传粒子群优化算法的认知无线电系统功率分配[J]. 吉林大学学报(工学版), 2019, 49(4): 1363-1368. |

| [7] | 陈东良,臧睿,段鹏,赵伟鹏,翁旭涛,孙杨,唐艺鹏. 基于新月鱼尾推进理论的多连杆鱼骨仿生设计[J]. 吉林大学学报(工学版), 2019, 49(4): 1246-1257. |

| [8] | 刘颖, 张凯, 于向军. 基于代理模型的中空轴式大型静压轴承多目标优化[J]. 吉林大学学报(工学版), 2017, 47(4): 1130-1137. |

| [9] | 黄璇, 郭立红, 李姜, 于洋. 改进粒子群优化BP神经网络的目标威胁估计[J]. 吉林大学学报(工学版), 2017, 47(3): 996-1002. |

| [10] | 张家旭, 李静. 基于混合优化方法的UniTire轮胎模型参数辨识[J]. 吉林大学学报(工学版), 2017, 47(1): 15-20. |

| [11] | 卢英, 王慧琴, 秦立科. 高大空间建筑火灾精确定位方法[J]. 吉林大学学报(工学版), 2016, 46(6): 2067-2073. |

| [12] | 祁若龙, 张伟, 王铁军, 李正. 仿人头颈部机器人跟踪运动控制[J]. 吉林大学学报(工学版), 2016, 46(5): 1595-1601. |

| [13] | 邵鹏, 吴志健, 周炫余. 基于反向学习的粒子群算法对线性相位低通FIR滤波器的优化[J]. 吉林大学学报(工学版), 2015, 45(3): 907-912. |

| [14] | 邱宁佳, 隋振, 李明哲, 郑承香. 六自由度机器人空间划线轨迹规划算法[J]. 吉林大学学报(工学版), 2013, 43(05): 1307-1313. |

| [15] | 孔英秀, 赵丁选, 杨彬, 李天宇, 韩京元. 基于PSO-DE和LMI的鲁棒静态输出反馈控制[J]. 吉林大学学报(工学版), 2013, 43(05): 1375-1380. |

|

||