吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (12): 3351-3357.doi: 10.13229/j.cnki.jdxbgxb.20221035

• 车辆工程·机械工程 • 上一篇

铝合金薄壁零件铣削加工颤振主动抑制方法

- 青岛理工大学 机械与汽车工程学院,山东 青岛 266520

Active flutter suppression method for aluminum alloy thin⁃walled parts milling

You-qiang WANG( ),Meng-jie LI,Tao ZHAO,Yu-ling ZHU,Yan HE

),Meng-jie LI,Tao ZHAO,Yu-ling ZHU,Yan HE

- School of Mechanical & Automotive Engineering,Qingdao University of Technology,Qingdao 266520,China

摘要:

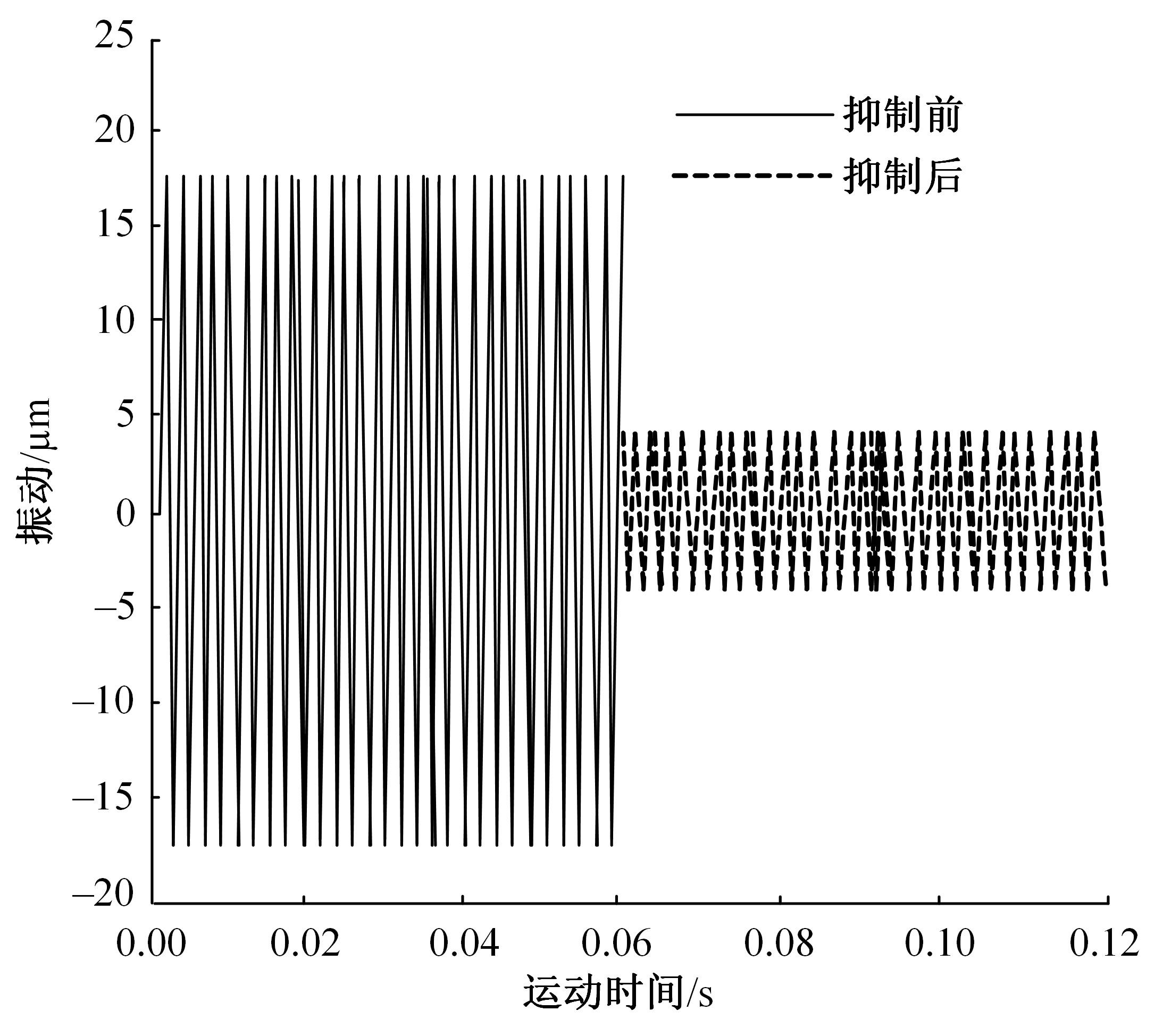

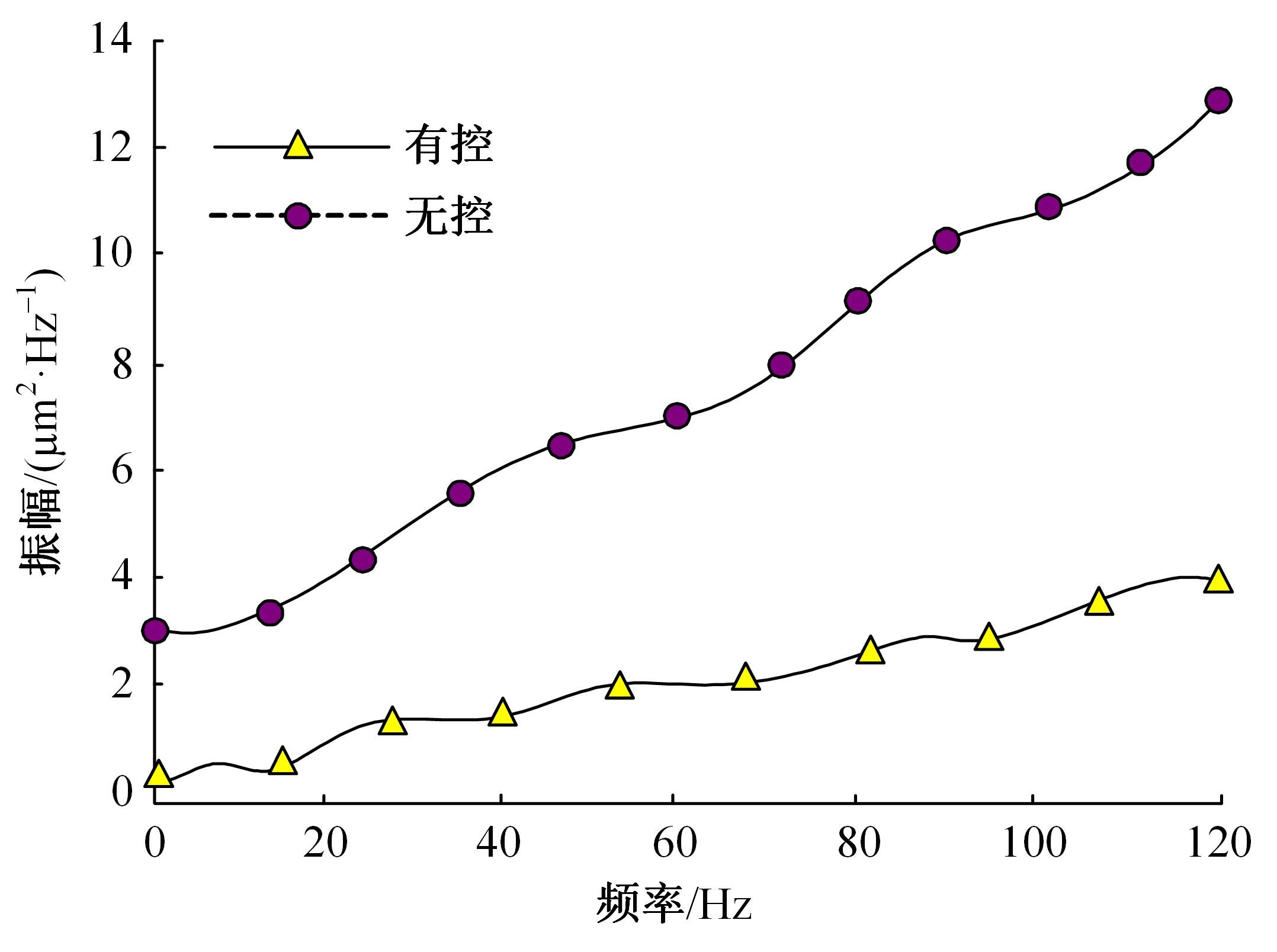

铝合金薄壁零件由于其刚性差,易受主轴转速、轴向切削深度、给进速度以及径向切削深度等因素的影响,导致其在铣削加工过程中极易出现颤振现象。为解决这一问题,设计了铝合金薄壁零件铣削加工颤振主动抑制方法。构建了基于圆柱螺旋立铣刀的铣削动力学模型,分析了x、y轴方向上的切削力变化,计算了切削时刀具刀齿的运行力学轨迹。利用小波神经网络比例积分微分控制算法,实现了零件铣削加工颤振的主动抑制。实验结果表明:该方法可在较高的刀具转速以及轴向切深下实现稳定的铣削加工,经抑制后的切削力与所设最佳切削力十分符合,且抑制后的振动控制在-5 μm~5 μm之间,可以减少加工中的变形和损伤,从而提高生产效率和产品寿命。

中图分类号:

- TH161

| 1 | 任宇强, 李国剑, 白浩. 大型薄壁硬质铝合金零件加工技术研究[J]. 工具技术, 2020, 54(4): 58-60. |

| Ren Yu-qiang, Li Guo-jian, Bai Hao. Research on machining techniques for large thin-walled components made of hard aluminum alloys[J]. Tool Engineering, 2020, 54(4): 58-60. | |

| 2 | 罗恒, 王优强, 张平. 基于单因素法对7A09铝合金铣削表面质量的研究[J]. 表面技术, 2020, 49(3): 327-333. |

| Luo Heng, Wang You-qiang, Zhang Ping. Study on surface quality of 7A09 aluminum alloy milling based on single factor method[J]. Surface Technology, 2020, 49(3): 327-333. | |

| 3 | 沈浩, 王全, 岳顺龙. 基于二次回归模型的铝合金弱刚性零件辅助支撑加工铣削温度预测[J]. 工具技术, 2022, 56(2): 30-34. |

| Shen Hao, Wang Quan, Yue Shun-long. Prediction of milling temperature for auxiliary support machining of aluminum alloy weakly rigid parts based on quadratic regression model[J]. Tool Engineering, 2022, 56(2): 30-34. | |

| 4 | 李茂月, 刘硕, 田帅, 等. 薄壁件铣削加工颤振的图像特征提取与识别[J]. 吉林大学学报: 工学版, 2022, 52(2): 425-432. |

| Li Mao-yue, Liu Shuo, Tian Shuai, et al. Image feature extraction and recognition of milling chatter of thin walled parts[J]. Journal of Jilin University (Engineering and Technology Edition), 2022, 52(2): 425-432. | |

| 5 | 聂雪媛, 郑冠男, 杨国伟. 变时滞间隙非线性机翼颤振主动控制方法[J]. 北京航空航天大学学报, 2020, 46(10): 1899-1906. |

| Nie Xue-yuan, Zheng Guan-nan, Yang Guo-wei. Flutter active control method of time-varying delayed aerofoil with free-play nonlinearity[J]. Journal of Beijing University of Aeronautics and Astronautics, 2020, 46(10): 1899-1906. | |

| 6 | 沐旭升, 邹奇彤, 黄锐, 等. 体自由度颤振主动抑制的多输入/多输出自抗扰控制律设计[J]. 振动工程学报, 2020, 33(5): 910-920. |

| Mu Xu-sheng, Zou Qi-tong, Huang Rui, et al. Design of multiple-input/multiple-output active disturbance rejection controller for body-freedom flutter suppression[J]. Journal of Vibration Engineering, 2020, 33(5): 910-920. | |

| 7 | 鲁治锴, 俞建超, 丁宇星. 加工参数对6061铝合金铣削振动的影响[J]. 工具技术, 2021, 55(9): 30-35. |

| Lu Zhi-kai, Yu Jian-chao, Ding Yu-xing. Influence of milling parameters on milling vibration of 6061 aluminum alloy[J]. Tool Engineering, 2021, 55(9): 30-35. | |

| 8 | 谭宇硕, 张文斌, 薛力峰, 等. 精铣削中抑制柔性工件颤振的阻尼器设计[J]. 液压与气动, 2022, 46(1): 124-129. |

| Tan Yu-shuo, Zhang Wen-bin, Xue Li-feng, et al. Design of damper for chatter suppression of flexible workpiece in fine milling[J]. Chinese Hydraulics & Pneumatics, 2022, 46(1): 124-129. | |

| 9 | 曹宏瑞, 李登辉, 刘金鑫, 等. 智能主轴高速铣削颤振的模糊控制方法研究[J]. 机械工程学报, 2021, 57(13): 55-62. |

| Cao Hong-rui, Li Deng-hui, Liu Jin-xin, et al. Research on fuzzy control for high speed milling chatter of intelligent spindle[J]. Journal of Mechanical Engineering, 2021, 57(13): 55-62. | |

| 10 | 米洁, 穆希望, 杨庆东, 等. 铣削加工颤振稳定域影响参数研究及优化[J].机床与液压,2020,48(10):154-159. |

| Mi Jie, Mu Xi-wang, Yang Qing-dong, et al. Research and optimization of influence parameters of chatter stability domain in milling process[J]. Machine Tool & Hydraulics, 2020, 48(10): 154-159. | |

| 11 | 赵国龙, 信连甲, 李亮, 等. 高硅铝合金的金刚石涂层刀具铣削损伤机理研究[J]. 中国机械工程, 2022, 33(2): 153-159. |

| Zhao Guo-long, Xin Lian-jia, Li Liang, et al. Study on damage mechanism of high-volume fraction silicon aluminum alloy milled with diamond coated cutting tools[J]. China Mechanical Engineering, 2022, 33(2): 153-159. | |

| 12 | 陈云, 侯亮, 刘文志, 等. 基于时域仿真法的断续铣削颤振预测[J]. 机械工程学报, 2021, 57(3): 98-106. |

| Chen Yun, Hou Liang, Liu Wen-zhi, et al. Chatter stability prediction in low immersion milling based on time-domain simulation[J]. Journal of Mechanical Engineering, 2021, 57(3): 98-106. | |

| 13 | 籍永建, 王西彬, 刘志兵, 等. 包含刀具-工件多重交互与速度效应的铣削颤振稳定性分析[J].振动与冲击, 2021, 40(17): 14-24, 54. |

| Ji Yong-jian, Wang Xi-bin, Liu Zhi-bing, et al. Stability analysis of milling chatter with tool-workpiece multiple interactions and velocity effects[J]. Journal of Vibration and Shock, 2021, 40(17): 14-24, 54. | |

| 14 | 沈宇峰. 基于ABAQUS铝合金铣削过程中毛刺形成机制的研究[J]. 轻合金加工技术, 2021, 49(9): 57-61. |

| Shen Yu-feng. Study on mechanism of burr formation in milling process of aluminum alloy based on ABAQUS[J]. Light Alloy Fabrication Technology, 2021, 49(9): 57-61. | |

| 15 | 尚歌, 王雁飞. 生态型机械加工过程设备叠加振动检测仿真[J]. 计算机仿真, 2021, 38(11): 197-200, 393. |

| Shang Ge, Wang Yan-fei. Simulation of overlay vibration detection of equipment in ecotype machining process[J]. Computer Simulation, 2021, 38(11): 197-200, 393. |

| [1] | 陈鑫,张冠宸,赵康明,王佳宁,杨立飞,司徒德蓉. 搭接焊缝对铝合金焊接结构轻量化设计的影响[J]. 吉林大学学报(工学版), 2023, 53(5): 1282-1288. |

| [2] | 吴迪,耿文华,李洪梅,孙大千. 铝/钢等离子弧熔⁃钎焊接头界面电子背散射衍射分析[J]. 吉林大学学报(工学版), 2023, 53(5): 1331-1337. |

| [3] | 王磊,黄秉汉,丛家慧,回丽,周松,徐永臻. 超声冲击对搅拌摩擦焊缝疲劳性能的影响[J]. 吉林大学学报(工学版), 2022, 52(11): 2542-2548. |

| [4] | 庄蔚敏,王鹏跃,高瑞娟,解东旋. 温热成形对AA5754铝合金静态力学性能的影响[J]. 吉林大学学报(工学版), 2021, 51(3): 847-854. |

| [5] | 罗开玉,陈俊成,王长雨,鲁金忠. 光斑直径对激光冲击强化铝合金腐蚀性能的影响[J]. 吉林大学学报(工学版), 2021, 51(2): 501-510. |

| [6] | 梁继才,廖雁飞,滕菲,梁策,李义. 矩形截面型材三维多点拉弯成形减薄率[J]. 吉林大学学报(工学版), 2021, 51(1): 163-171. |

| [7] | 田银宝,申俊琦,胡绳荪,勾健. EP/EN模数对铝合金VP-CMT焊熔滴过渡及焊道成形的影响[J]. 吉林大学学报(工学版), 2020, 50(5): 1663-1668. |

| [8] | 宫文彪,朱芮,郄新哲,崔恒,宫明月. 6082铝合金超厚板搅拌摩擦焊接头组织与性能[J]. 吉林大学学报(工学版), 2020, 50(2): 512-519. |

| [9] | 刘义伦,王卿,刘驰,李松柏,何军,赵先琼. 蠕变和人工时效对2524铝合金疲劳裂纹扩展性能的影响[J]. 吉林大学学报(工学版), 2019, 49(5): 1636-1643. |

| [10] | 徐戊矫,刘承尚,鲁鑫垚. 喷丸处理后6061铝合金工件表面粗糙度的模拟计算及预测[J]. 吉林大学学报(工学版), 2019, 49(4): 1280-1287. |

| [11] | 鲁金忠,周婉婷,张圣洋,邵亦锴,王长雨,罗开玉. 激光冲击强化层数对6061⁃T6铝合金抗腐蚀性能的影响[J]. 吉林大学学报(工学版), 2019, 49(3): 842-849. |

| [12] | 李于朋,孙大千,宫文彪. 6082⁃T6铝合金薄板双轴肩搅拌摩擦焊温度场[J]. 吉林大学学报(工学版), 2019, 49(3): 836-841. |

| [13] | 胡志清, 颜庭旭, 李洪杰, 吕振华, 廖伟, 刘庚. 深冷处理对铝合金薄板冲剪成形性能的影响[J]. 吉林大学学报(工学版), 2018, 48(5): 1524-1530. |

| [14] | 胡志清, 郑会会, 徐亚男, 张春玲, 党停停. 表面微沟槽对Al/CFRP胶结性能的影响[J]. 吉林大学学报(工学版), 2018, 48(1): 229-235. |

| [15] | 付文智, 刘晓东, 王洪波, 闫德俊, 刘晓莉, 李明哲, 董玉其, 曾振华, 刘桂彬. 关于1561铝合金曲面件的多点成形工艺[J]. 吉林大学学报(工学版), 2017, 47(6): 1822-1828. |

|

||