吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (10): 3085-3094.doi: 10.13229/j.cnki.jdxbgxb.20221590

• 农业工程·仿生工程 • 上一篇

新型横辊式玉米摘穗装置设计与试验

- 山东理工大学 农业工程与食品科学学院,山东 淄博 255000

Design and experiment of a new type of cross roll corn ear picking device

Duan-yang GENG( ),Jia-rui MING,Bo-long WANG,Qi-huan WANG,Ce ZHANG,Qing-hao HE

),Jia-rui MING,Bo-long WANG,Qi-huan WANG,Ce ZHANG,Qing-hao HE

- School of Agricultural Engineering and Food Science,Shandong University of Technology,Zibo 255000,China

摘要:

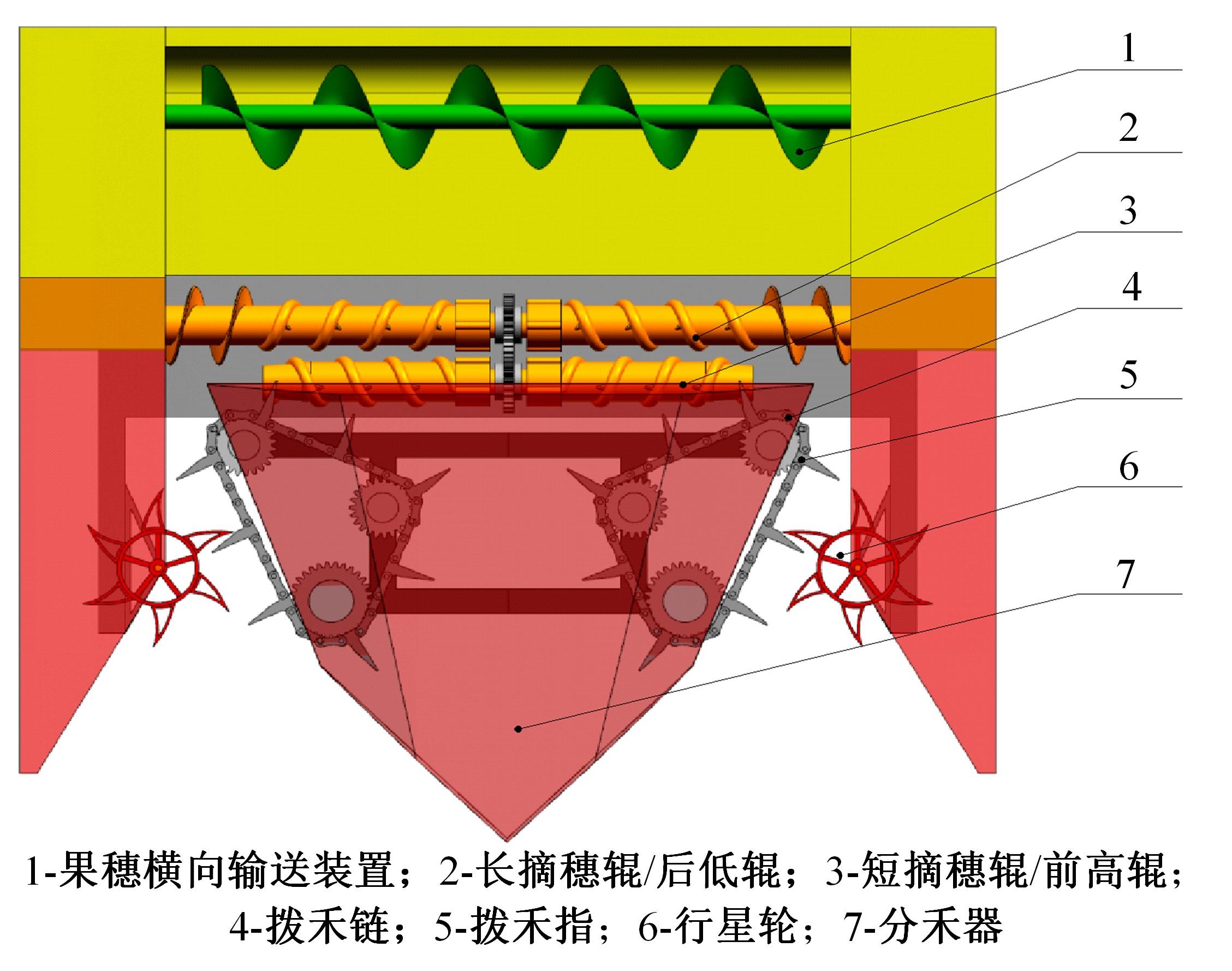

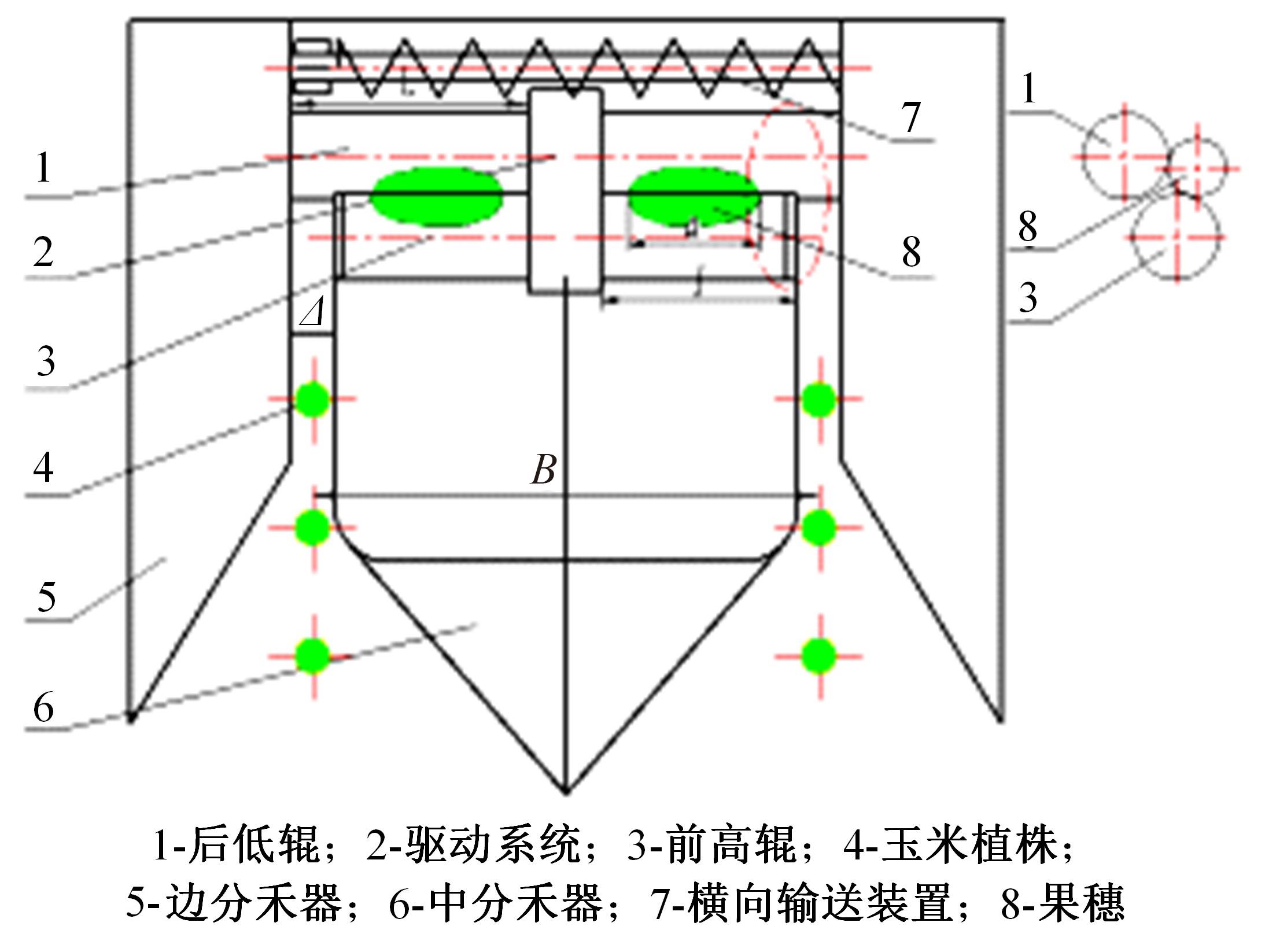

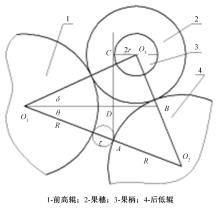

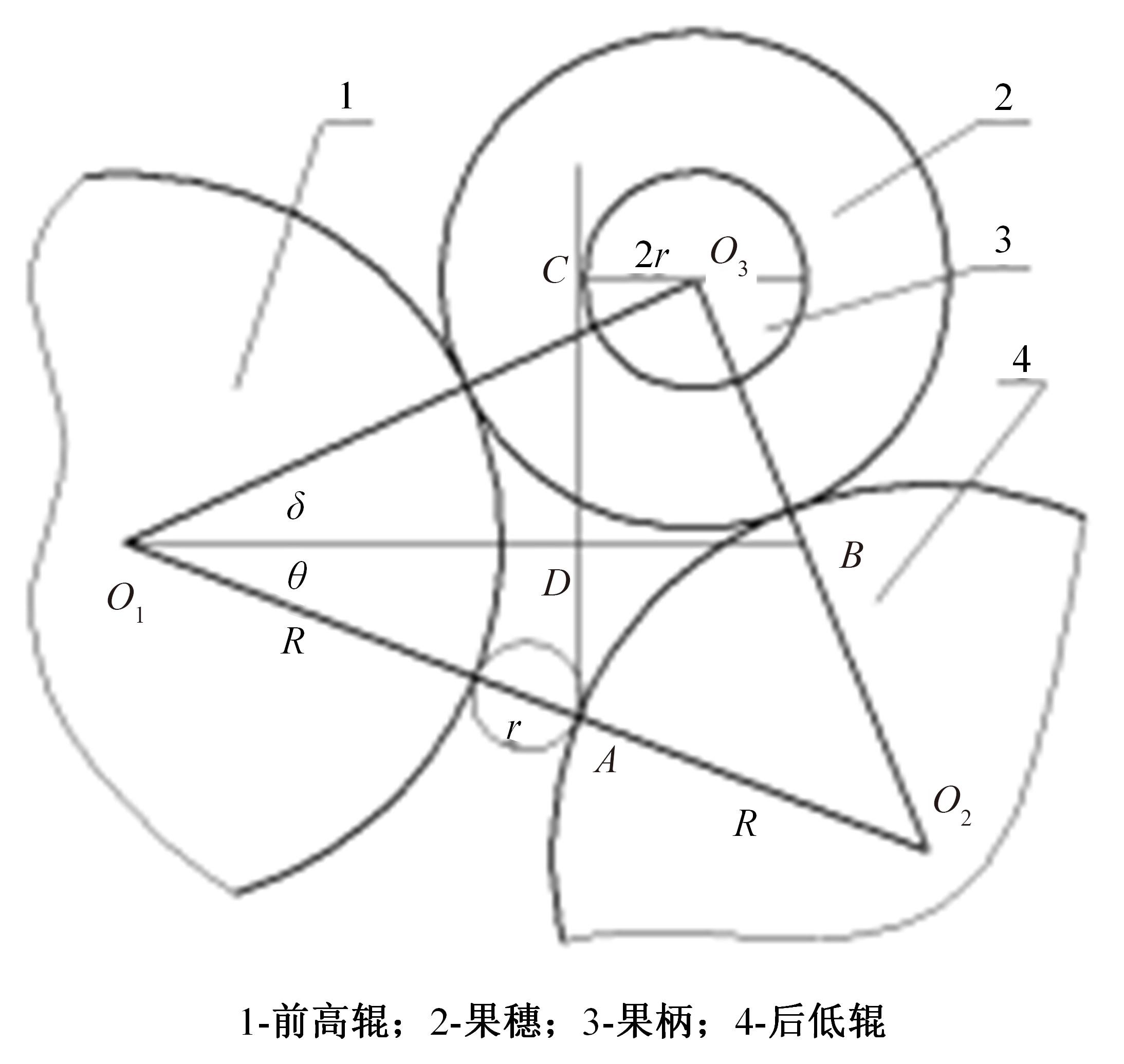

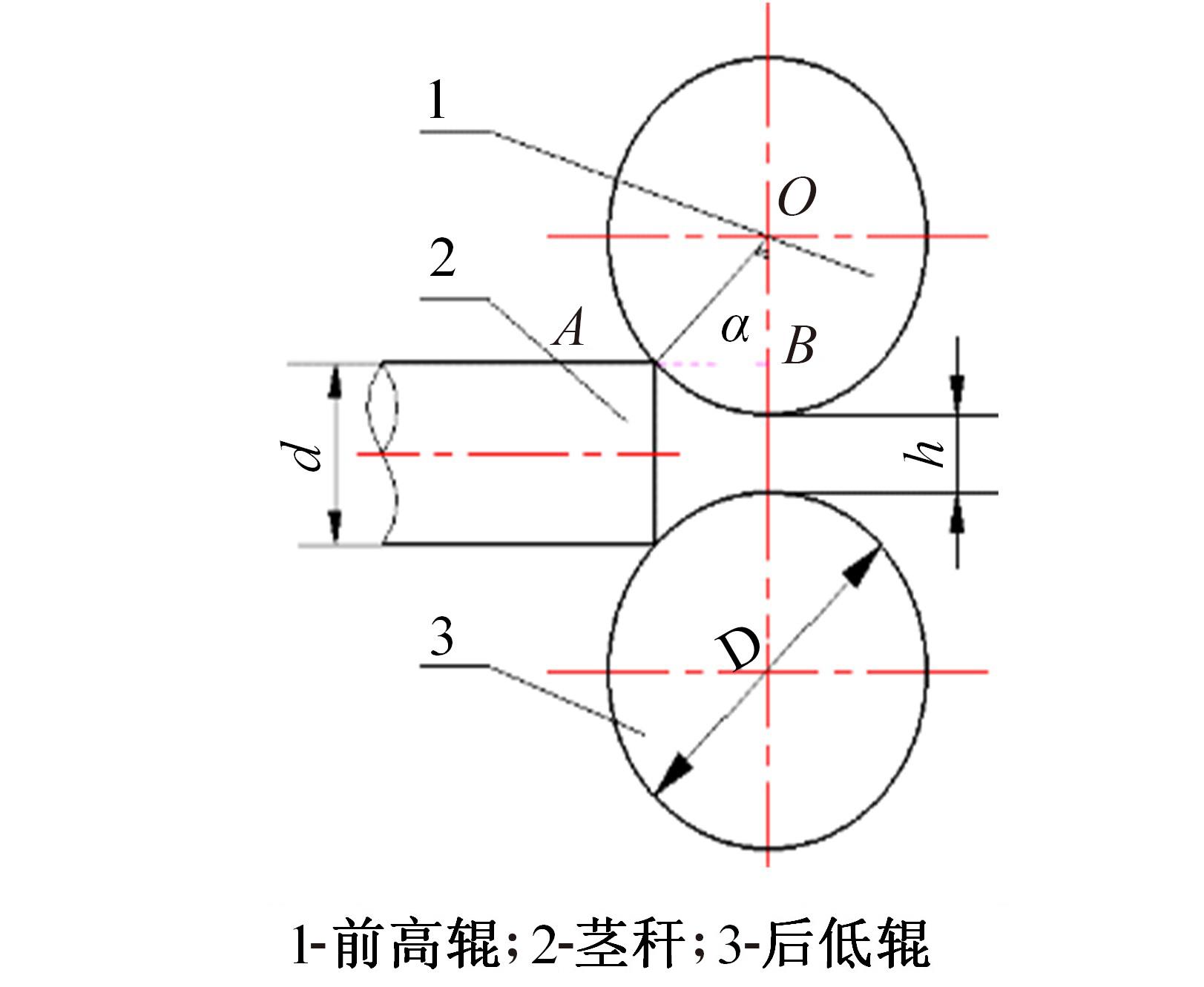

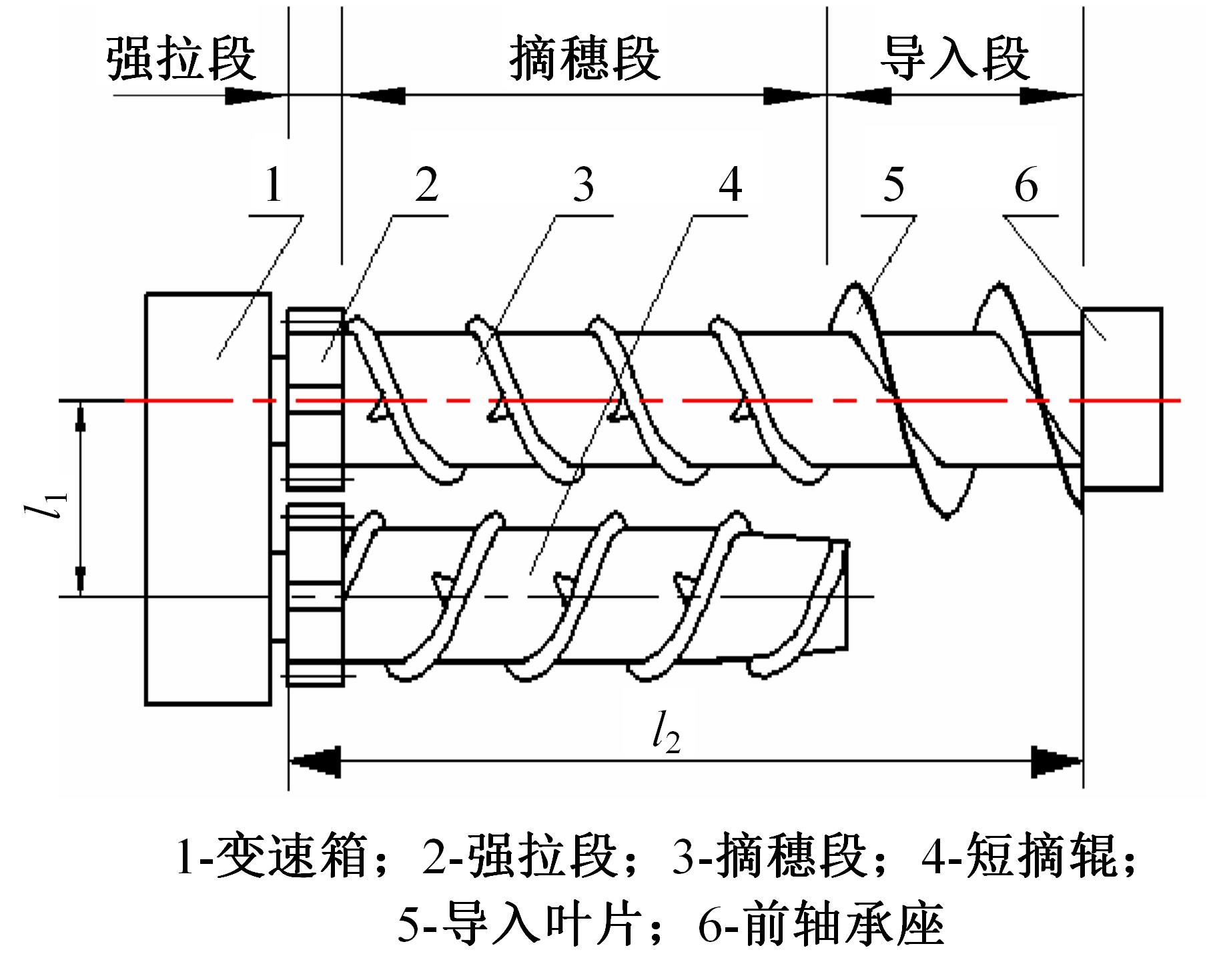

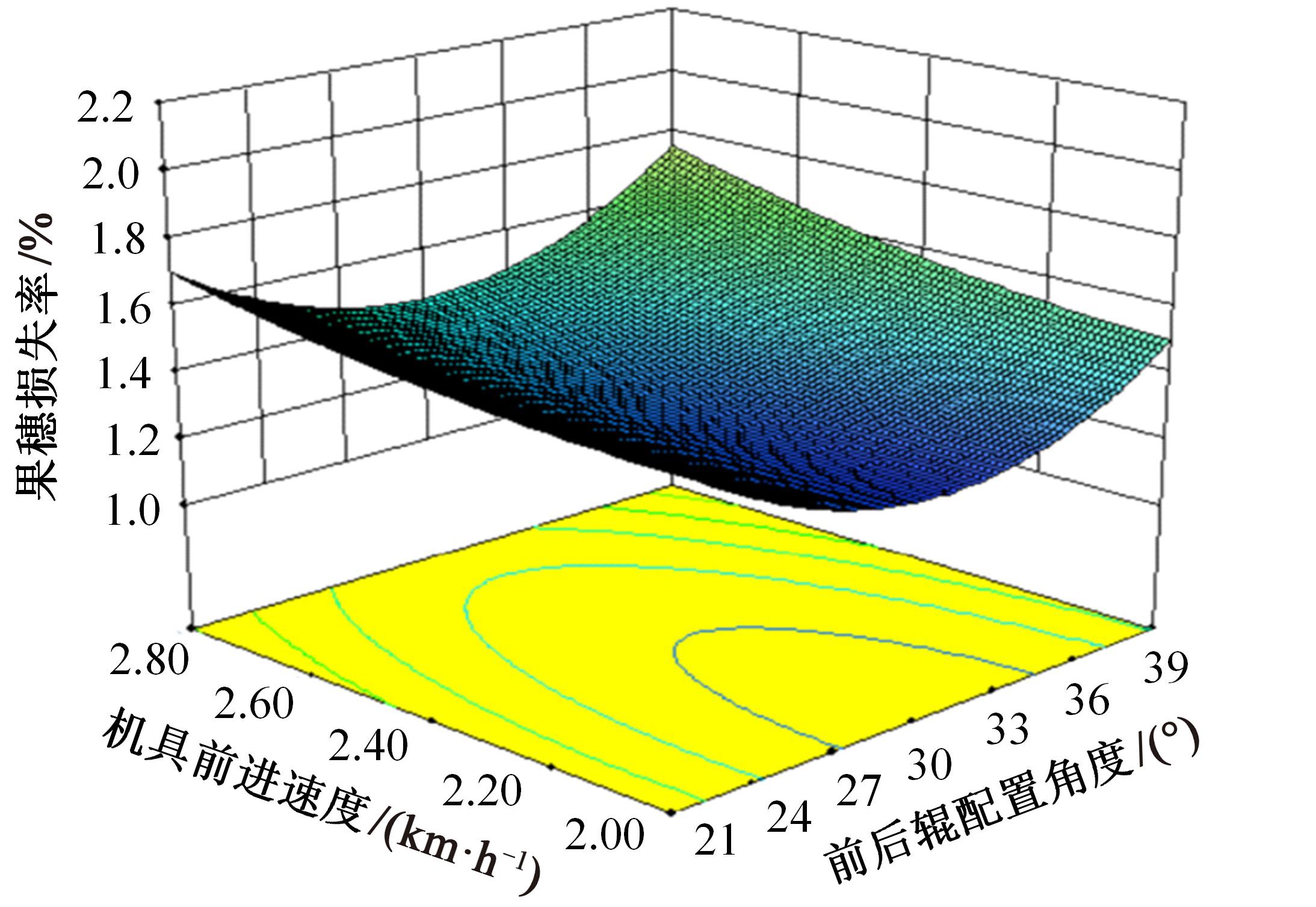

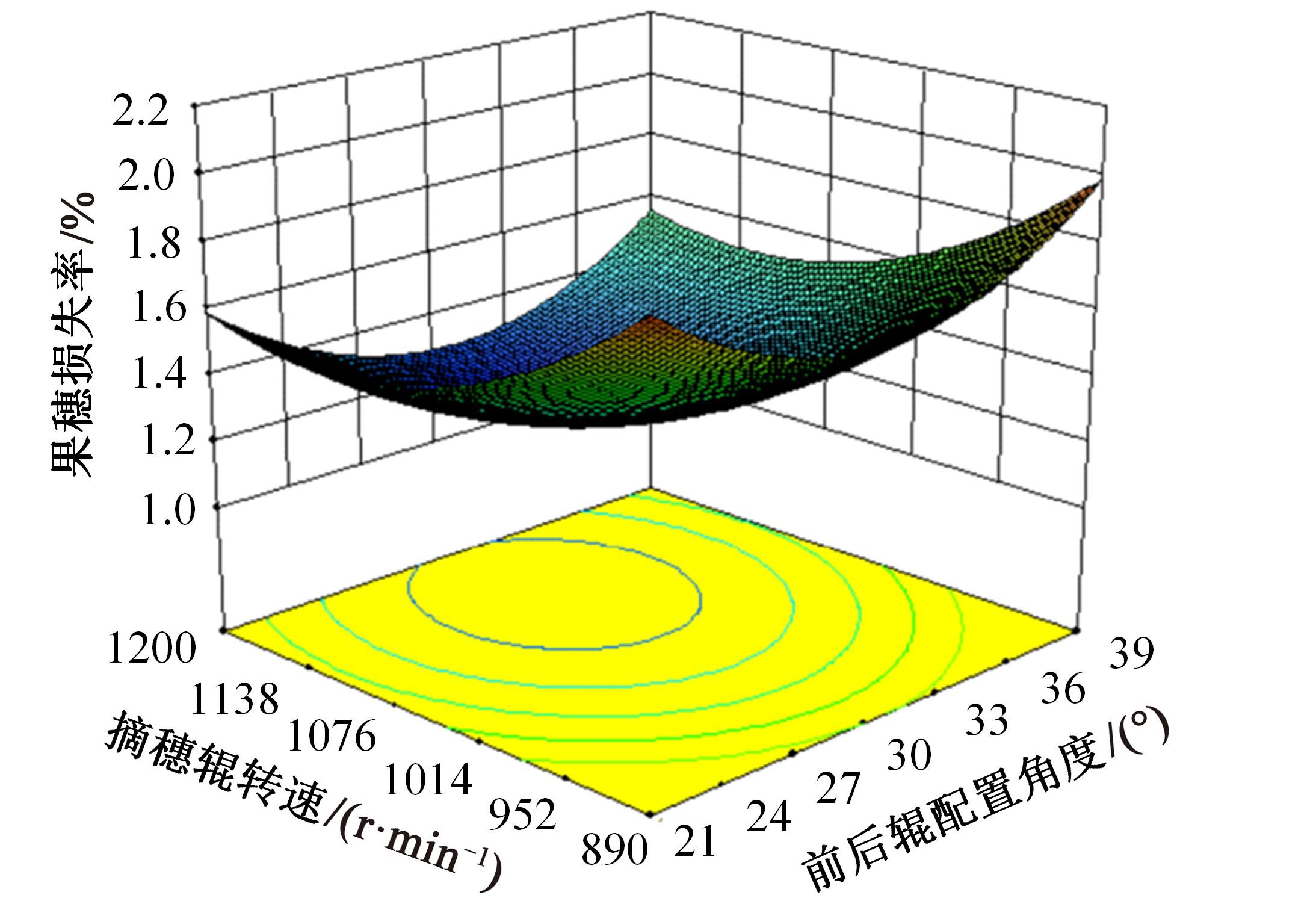

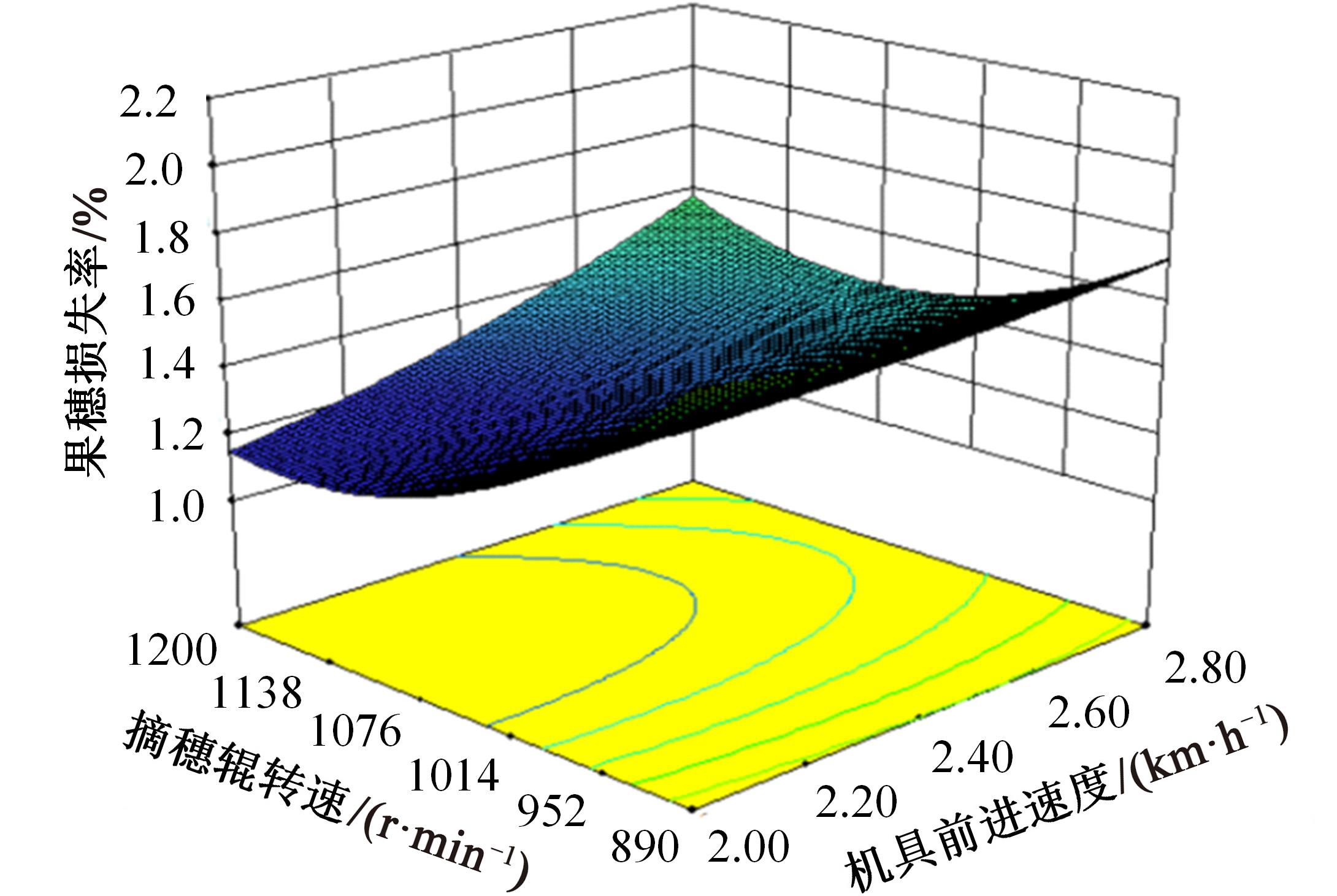

针对我国丘陵山地玉米种植区地块小、回转难、坡地多等制约着我国玉米收获机械化的一系列问题,设计了一款横辊摘穗割台,实现了在丘陵山地复杂地形的玉米机械化收获。该割台采用横辊摘穗技术,整机长度较常规玉米收获割台缩短0.7 m,有效减小了整机的回转半径,提高了收获机对复杂地形的适应性;采用Box-Behnken试验方法,研究了横辊摘穗辊配置角度、机具前进速度、摘穗辊转速对摘穗过程中果穗损失率的影响规律,建立了试验因素与考察指标之间的回归方程,并生成了相应的响应曲面;结果表明:横辊摘穗割台的摘穗辊配置角度、机具前进速度、摘穗辊转速对收获过程的果穗损失率有显著的影响;最终确定了最佳组合为摘穗辊配置角度26°,机具前进速度2 km/h,摘穗辊转速1 050 r/min,在该条件下进行了试验验证,平均果穗损失率为1.227%,低于国家玉米收获机械技术标准要求。

中图分类号:

- S225.5

| 1 | 贾学文. 中国玉米市场供求关系研究[D]. 北京:中国农业科学院,2014. |

| Jia Xue-wen. Research on the supply and demand of corn market in China[D]. Beijing: Chinese Academy of Agricultural Sciences, 2014. | |

| 2 | 程修沛,贾晓东,陈美舟,等. 上拉茎掰穗式玉米收获台架试验与分析[J]. 农业工程学报,2016,32(22):50-55. |

| Cheng Xiu-pei, Jia Xiao-dong, Chen Mei-zhou, et al. Experiment and analysis on test device of corn ear picking by pulling stalk upwards[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(22): 50-55. | |

| 3 | 中国统计局. 中国统计年鉴2020[M]. 北京:中国统计出版社,2020. |

| 4 | 翁凌云. 我国玉米生产现状及发展对策分析[J]. 中国食物与营养,2010(1):22-25. |

| Weng Ling-yun. Analysis on the current situation and development countermeasures of maize production in China[J]. Chinese Journal of Food and Nutrition, 2010(1): 22-25. | |

| 5 | 丛宏斌,姚宗路,赵立欣,等. 中国农作物秸秆资源分布及其产业体系与利用路径[J]. 农业工程学报,2019,35(22):132-140. |

| Cong Hong-bin, Yao Zong-lu, Zhao Li-xin, et al. Distribution of crop straw resources and its industrial system and utilization path in China[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(22): 132-140. | |

| 6 | 姚艳春,刘元义,牛国栋,等. 山东旱作灌溉区小麦-玉米全程机械化技术模式经济效益分析与评价方法[J]. 中国农机化学报,2020,41(12):6-11. |

| Yao Yan-chun, Liu Yuan-yi, Niu Guo-dong, et al. Economic benefit analysis and evaluation method of wheat maize whole mechanization technology mode in dry farming irrigation area of Shandong Province[J]. Journal of Chinese Agricultural Mechanization, 2020, 41(12): 6-11. | |

| 7 | 陈志,郝付平,王锋德,等. 中国玉米收获技术与装备发展研究[J]. 农业机械学报,2012,43(12):44-50. |

| Chen Zhi, Hao Fu-ping, Wang Feng-de, et al. Development of technology and equipment of corn harvester in China[J]. Transactions of the Chinese Society for Agricultural Machinery, 2012, 43(12): 44-50. | |

| 8 | 王晓文,袁寿其,贾卫东.丘陵山区农业机械化现状与发展[J].排灌机械工程学报,2022,40(5):535-540. |

| Wang Xiao-wen, Yuan Shou-qi, Jia Wei-dong. Current situation and development of agricultural mechanizationin hilly and mountainous areas [J]. Journal of Drainage and Irrigation Machinery Engineering, 2022,40(5): 535-540. | |

| 9 | 张健伟,徐曼.丘陵山区农业机械化发展现状与解决对策[J].山西农经,2021(8):155-156. |

| Zhang Jian-wei, Xu Man. Current situation and solutions of agricultural mechanization in hilly and mountainous areas[J]. Shanxi Agricultural Economy, 2021(8): 155-156. | |

| 10 | 郝付平,陈志.国内外玉米收获机械研究现状及思考[J].农机化研究,2007,29(10):206-208. |

| Hao Fu-ping, Chen Zhi.Actuality of domestic and foreign corn harvester[J].Journal of Agricultural MechanizationResearch,2007,29(10):206-208. | |

| 11 | 王优.新型玉米摘穗装置工作机理的基础性研究[D].长春:吉林大学生物与农业工程学院,2011. |

| Wang You.The basic research in the mechanism of the new corn picker[J].Changchun: College of Biological and Agricultural Engineering,Jinlin University,2011. | |

| 12 | 张莉.新型仿生玉米摘穗机构理论分析与仿真研究[D].长春:吉林大学生物与农业工程学院,2015. |

| Zhang Li.The oretical analysis and simulation research on novel bionic corn-ear snapping mechanism[D].Changchun: College of Biological and Agricultural Engineering,Jinlin University,2015. | |

| 13 | 闫洪余,吴文福,韩峰,等.立辊型玉米收获机摘穗辊辊型对工作性能的影响[J].农业机械学报,2009,40(5):76-80. |

| Yan Hong-yu, Wu Wen-fu, Han Feng,et al. Effects of the type of the snapping rolls of vertical corn harvester on harvesting performance[J]. Journal of Agricultural Machinery, 2009, 40(5): 76-80. | |

| 14 | 郭晓晓,张道林,卜令昕,等.立辊式玉米收获机夹持输送装置的设计分析[J].农机化研究,2015,37(2):124-127. |

| Guo Xiao-xiao, Zhang Dao-lin, Bu Ling-xin, et al. Design and analysis on gripping delivery mechanism forvertical-roll type of corn harvester[J]. Research on Agricultural Mechanization, 2015,37(2): 124-127. | |

| 15 | 张道林,刁培松,董锋,等. 拨禾指式不对行玉米收获装置的试验[J]. 农业工程学报,2010,26(5):103-106. |

| Zhang Dao-lin, Diao Pei-song, Dong Feng, et al. Experiment of no-row corn harvesting device with finger wheel[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2010, 26(5): 103-106. | |

| 16 | 王优,张强,于路路.玉米摘穗装置的应用现状与展望[J].农机化研究,2011,33(1):228-231. |

| Wang You, Zhang Qiang, Yu Lu-lu.The present situation of corn snapping device and its exceptation[J].Journal of Agricultural Mechanization Research,2011,33(1):228-231. | |

| 17 | 张亮亮,李其昀,于磊.立式玉米茎秆切碎装置研究[J].山东理工大学学报:自然科学版,2011,25(3):52-55. |

| Zhang Liang-liang, Li Qi-yun, Yu Lei. Study on vertical corn stalk chopper[J]. Journal of Shandong University of Technology (Natural Science Edition), 2011, 25(3): 52-55. | |

| 18 | 耿端阳,王骞,鹿秀凤,等. 基于激振理论的玉米多棱摘穗辊设计与试验[J]. 农业机械学报, 2019,50(5):124-132. |

| Geng Duan-yang, Wang Qian, Lu Xiu-feng, et al. Design and experiment on vertical polygonal roller snapping ears of corn harvester based on excitation theory[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(5): 124-132. | |

| 19 | 张宗毅.“十四五”期间丘陵山区农田宜机化改造若干重大问题与举措[J].中国农村经济,2020(11):13-28. |

| Zhang Zong-yi. Some important problems and measures of farmland construction suitable for mechanization in hilly and mountainous areas during the 14th Five-year Plan period[J]. China Rural Economy, 2020(11): 13-28. | |

| 20 | Willcutt H. Corn harvesting, drying, and storage: extension service of Mississippi[J]. Cooperating with U.S. Department of Agriculture, 2001, 41(5): 37-41. |

| 21 | 耿端阳,何珂,王骞,等. 横轴流式玉米柔性脱粒装置设计与试验[J]. 农业机械学报,2019,50(3):101-108. |

| Geng Duan-yang, He Ke, Wang Qian, et al. Design and experiment on transverse axial flow flexible threshing device for corn[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(3): 101-108. | |

| 22 | 耿端阳,李玉环,何珂,等. 立辊式玉米收获机割台间隙夹持输送装置设计与试验[J]. 农业机械学报,2017,48(11):130-136. |

| Geng Duan-yang, Li Yu-huan, He Ke, et al. Design and experiment on gripping delivery mechanism for vertical-rollers type of corn harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(11): 130-136. | |

| 23 | 耿端阳,孙延成,李华彪,等.履带式坡地玉米收获机设计与试验[J].农业工程学报,2021,37(13):11-19. |

| Geng Duan-yang, Sun Yan-cheng, Li Hua-biao, et al. Design and experiment of crawler corn harvester for sloping fields[J]. Journal of Agricultural Engineering, 2021,37(13): 11-19. | |

| 24 | 葛宜元. 试验设计方法与Design-Expert软件应用[M]. 哈尔滨:哈尔滨工业大学出版社,2014. |

| 25 | 徐中儒. 回归分析与试验分析[M]. 北京:中国农业出版社,1998. |

| [1] | 朱光强,李天宇,周福君,王文明. 鲜食玉米仿生摘穗装置设计与试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1231-1244. |

| [2] | 耿端阳,孙延成,王宗源,王其欢,明家锐,杨昊霖,徐海港. 玉米籽粒直收机板齿式脱粒装置设计与试验[J]. 吉林大学学报(工学版), 2023, 53(11): 3281-3292. |

| [3] | 耿端阳,孙延成,牟孝栋,张国栋,姜慧新,朱俊科. 基于差速辊的青贮玉米籽粒破碎仿真试验及优化[J]. 吉林大学学报(工学版), 2022, 52(3): 693-702. |

| [4] | 朱光强,李天宇,周福君. 鲜食玉米仿生摘穗柔性夹持输送装置设计与试验[J]. 吉林大学学报(工学版), 2022, 52(10): 2486-2500. |

| [5] | 程超,付君,陈志,任露泉. 玉米籽粒收获机清选筛堵塞规律及脱附试验[J]. 吉林大学学报(工学版), 2021, 51(2): 761-771. |

| [6] | 耿端阳,谭德蕾,于兴瑞,苏国粱,王骞,鹿秀凤,金诚谦. 玉米柔性脱粒滚筒脱粒元件设计与试验[J]. 吉林大学学报(工学版), 2020, 50(5): 1923-1933. |

| [7] | 薛钊,付君,陈志,王锋德,韩少平,任露泉. 青饲玉米收获机械切碎装置参数优化试验[J]. 吉林大学学报(工学版), 2020, 50(2): 739-748. |

| [8] | 程超,付君,郝付平,陈志,周德义,任露泉. 清选筛运动参数对玉米芯轴堵筛规律的影响[J]. 吉林大学学报(工学版), 2020, 50(1): 351-360. |

| [9] | 王扬, 王晓梅, 陈泽仁, 于建群. 基于离散元法的玉米籽粒建模[J]. 吉林大学学报(工学版), 2018, 48(5): 1537-1547. |

| [10] | 徐艳阳, 蔡森森, 吴海成. 玉米热风与微波联合干燥特性[J]. 吉林大学学报(工学版), 2014, 44(2): 579-584. |

| [11] | 刘晶晶, 孙永海, 丁健峰, 孙钟雷. 玉米汁辨识中的传感器阵列优化[J]. 吉林大学学报(工学版), 2013, 43(02): 538-543. |

| [12] | 周德义, 王子佳, 张丹丹, 吴冠军, 周晗宇. 新型玉米收获机的秸秆处理装置[J]. 吉林大学学报(工学版), 2012, 42(增刊1): 113-116. |

| [13] | 付宏, 吕游, 李艳双, 于建群. 基于离散元法的玉米脱粒过程分析[J]. , 2012, 42(04): 997-1002. |

| [14] | 赵文竹, 殷涌光, 于志鹏, 于一丁, 刘静波. 玉米须多糖微波提取工艺及其红外光谱结构分析[J]. 吉林大学学报(工学版), 2012, 42(02): 515-520. |

| [15] | 刘静波, 王翠娜, 刘军, 路爽, 张城, 蔡玥. 玉米须急性毒性及致突变性[J]. 吉林大学学报(工学版), 2011, 41(增刊2): 359-363. |

|

||