吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (10): 2486-2500.doi: 10.13229/j.cnki.jdxbgxb20210308

• 农业工程·仿生工程 • 上一篇

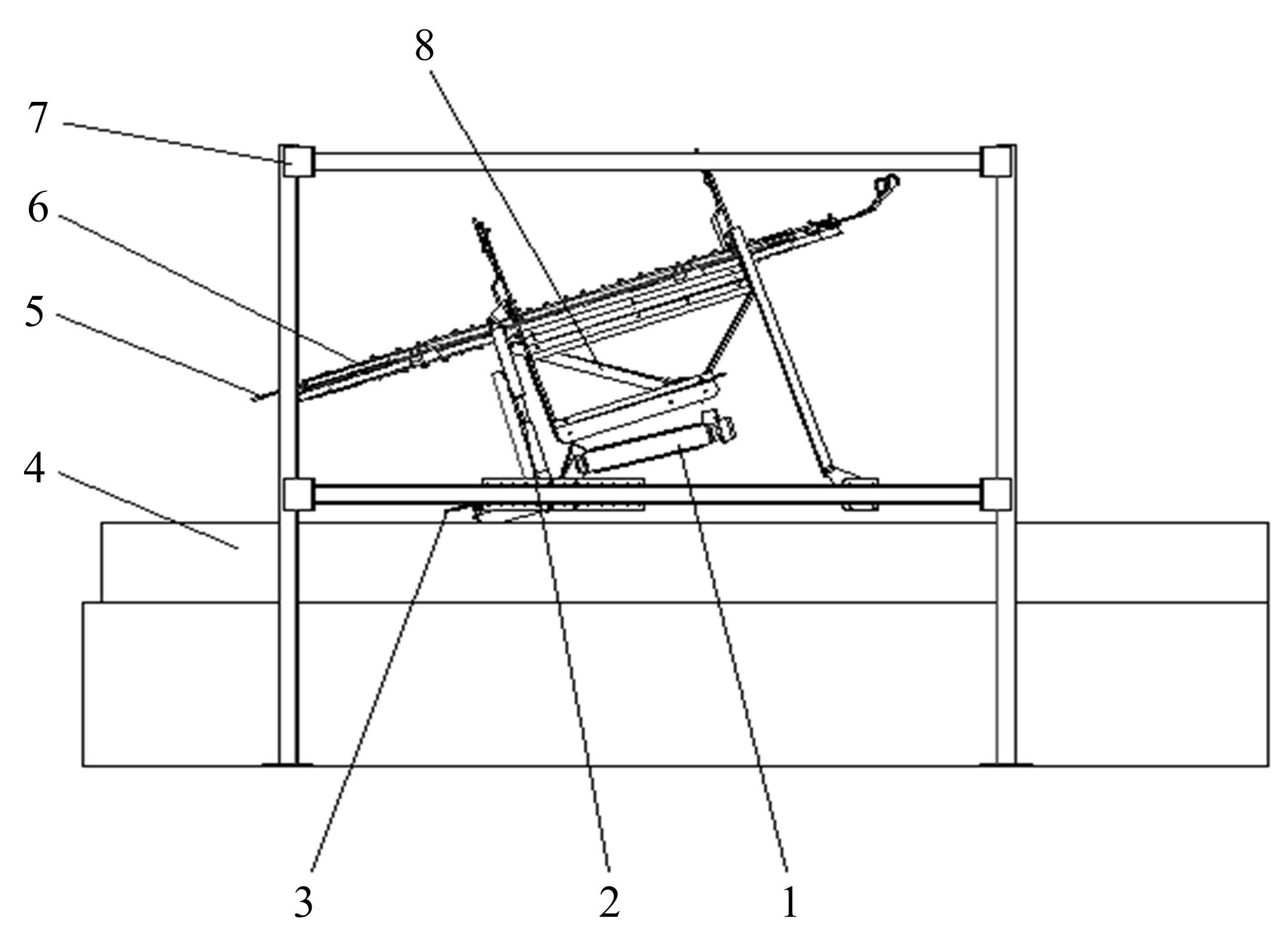

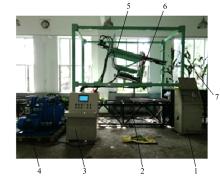

鲜食玉米仿生摘穗柔性夹持输送装置设计与试验

- 1.东北农业大学 工程学院,哈尔滨 150030

2.华北水利水电大学 机械学院,郑州 450046

Design and experiment of flexible clamping and conveying device for bionic ear picking of fresh corn

Guang-qiang ZHU1( ),Tian-yu LI1,Fu-jun ZHOU2(

),Tian-yu LI1,Fu-jun ZHOU2( )

)

- 1.College of Engineering,Northeast Agricultural University,Harbin 150030,China

2.College of Mechanical Engineering,North China University of Water Resources and Electric Power,Zhengzhou 450046,China

摘要:

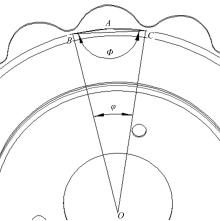

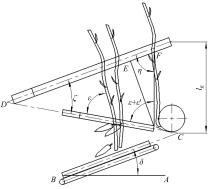

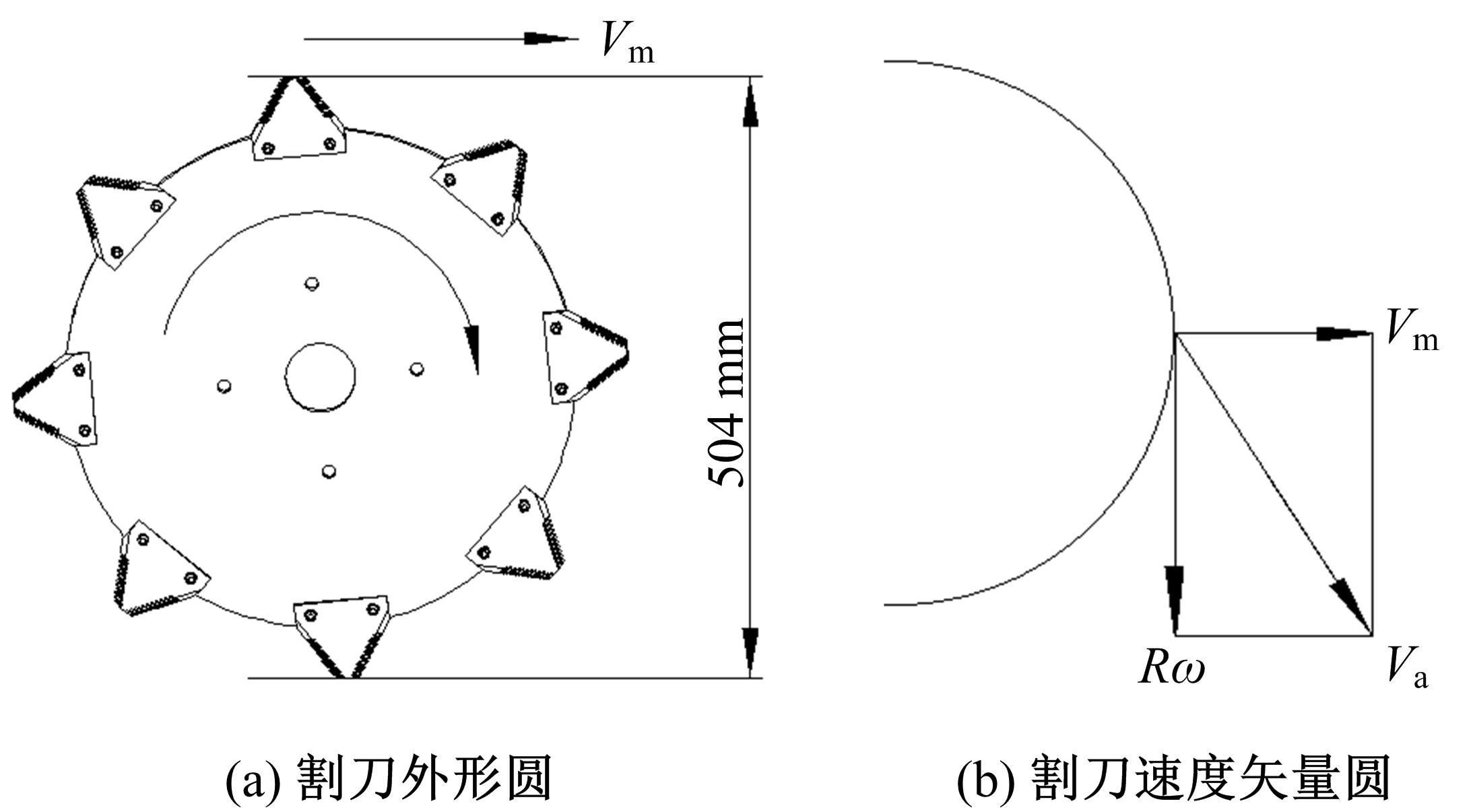

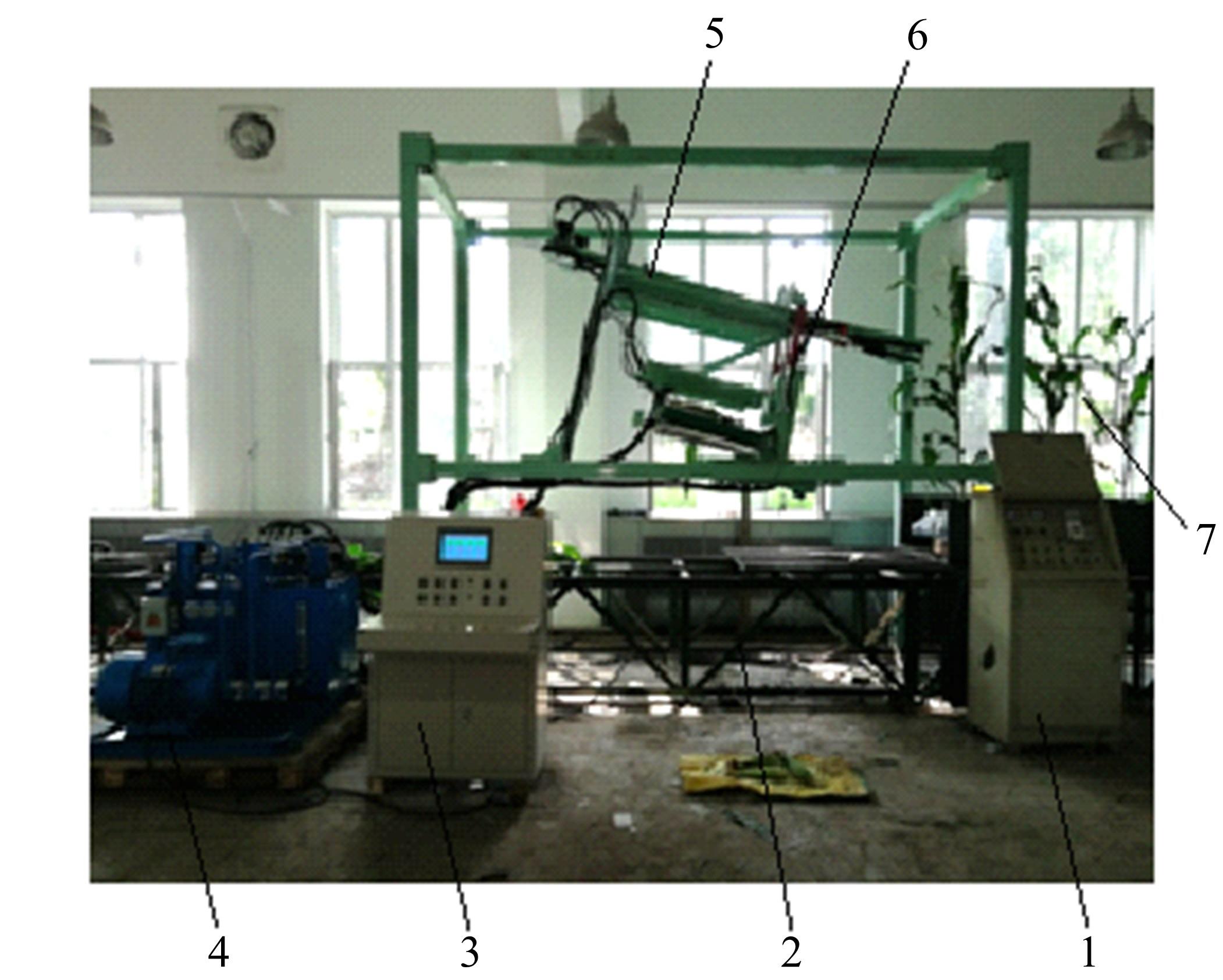

针对鲜食玉米收获过程中茎秆夹持输送断茎、堵塞等问题,设计了一种结构简单、夹持输送稳定的仿生摘穗柔性夹持输送装置。首先,在分析握持茎杆自上而下弯折掰穗的基础上,研究了仿生摘穗原理,重点研究了影响茎秆柔性夹持、输送装置的作业参数,对装置采用分级试验方法,以单因素设计了台架试验,得到装置前进速度为1.2 m/s、割刀转速为420 r/min时作业效率最优;其次,固定两参数不变,以夹持输送带转速、夹持机构倾角和夹持输送带间隙为试验因素,以茎秆断茎率、夹持准确率为试验指标,采用二次回归正交旋转组合试验方法进行台架试验,通过Design-Expert8.0.6软件建立因素与指标的数学模型,增加约束后因素优化,试验结果表明,当夹持输送带转速为342 r/min、夹持机构倾角为19°、夹持输送带间隙为6.0 mm时,茎秆断茎率均值为0.46%、夹持准确率均值为94.0%,作业性能良好。最后,开展了田间验证试验,结果显示茎秆断茎率均值为0.55%、夹持准确率均值为93.0%,与优化结果基本一致,本文所设计的装置降低了茎秆断茎,稳定性较高,满足鲜食玉米果穗收获要求。

中图分类号:

- S233.4

| 1 | 井旭源, 唐春双, 于琳, 等. 鲜食玉米机械化收获发展现状[J]. 现代化农业, 2020, 41(10): 61-62. |

| Jing Xu-yuan, Tang Chun-shuang, Yu Lin, et al. Development status of mechanized harvesting of fresh corn[J]. Modern Agriculture, 2020, 41(10): 61-62. | |

| 2 | Rogovskii I L, Liubarets 1 B S, Voinash S A,et al. Research of diagnostic of combine harvesters at levels of hierarchical structure of systems and units of hydraulic system[J]. Journal of Physics: Conference Series, 2020, 1679(4): No. 042038. |

| 3 | 纪晓琦, 耿端阳, 姚艳春, 等. 玉米收获机激振摘穗装置设计与试验[J]. 农业机械学报, 2020, 51(): 126-133. |

| Ji Xiao-qi, Geng Duan-yang, Yao Yan-chun, et al. Design and test of the corn harvester's excitation vibration ear picking device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(Sup.2): 126-133. | |

| 4 | 刘春鸽, 张喜瑞, 刘桐利, 等. 我国甜玉米收获机的发展现状[J]. 内燃机与配件, 2018, 38(15): 224-225. |

| Liu Chun-ge, Zhang Xi-rui, Liu Tong-li, et al. Developmentstatus of sweet corn harvesting machinery in China[J]. Internal Combustion Engine & Parts, 2018, 38(15): 224-225. | |

| 5 | Vodounnou J H, Ajav E A, Bagan G C, et al. Development and performance evaluation of a small-scale maize harvester for developing countries[J]. Journal of Experimental Agriculture International, 2020, 42(8): 144-156. |

| 6 | 刘传鑫.鲜食玉米收获割台关键技术研究[D]. 长春:吉林大学生物与农业工程学院,2019. |

| Liu Chuan-xin. Study on the key technology of fresh corn harvesting header[D]. Changchun: College of Biology and Agricultural Engineering, Jilin University, 2019. | |

| 7 | 耿端阳,李玉环,何珂,等. 立辊式玉米收获机割台间隙夹持输送装置设计与试验[J]. 农业机械学报,2017, 48(11): 130-136. |

| Geng Duan-yang, Li Yu-huan, He Ke, et al. Design and experiment on gripping delivery mechanism for vertical-rollers type of corn harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(11): 130-136. | |

| 8 | 张宗玲, 韩增德, 刘立晶, 等. 玉米穗茎兼收割台夹持输送装置参数优化[J]. 农业机械学报, 2018, 49(3): 114-121. |

| Zhang Zong-ling, Han Zeng-de, Liu Li-jing, et al. Parameters optimization for gripping and delivering device of corn harvester for reaping both corn stalk and spike[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(3): 114-121. | |

| 9 | 张莉. 新型仿生玉米摘穗机构理论分析与仿真研究[D]. 长春: 吉林大学生物与农业工程学院,2015. |

| Zhang Li. Theoretical analysis and simulation study of a new bionic corn ear picking mechanism[D]. Changchun: College of Biology and Agricultural Engineering, Jilin University, 2015. | |

| 10 | 辛尚龙. 立辊式玉米摘穗机理与关键技术研究[D]. 兰州: 甘肃农业大学机电工程学院, 2020. |

| Xin Shang-long. Study on mechanism and key technology of vertical roller corn ear picking[D]. Lanzhou: School of Mechanical and Electrical Engineering, Gansu Agricultural University, 2020. | |

| 11 | 范国强, 杨庆璐, 张晓辉, 等. 烟草夹持式智能打顶机设计与试验[J]. 农业机械学报, 2017, 48(7): 121-126. |

| Fan Guo-qiang, Yang Qing-lu, Zhang Xiao-hui, et al. Design and test of intelligent tobacco topping machine with clamping belt[J]. Beijing: Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(7): 121-126. | |

| 12 | 中国农业机械化科学研究院.农业机械设计手册:上册[M]. 北京:中国农业科学技术出版社,2007. |

| 13 | Shinners K J, Boettcher G C, Hoffman D S, et al. Single-pass harvest of corn grain and stover:performance of three harvester configurations[J]. Transactions of the ASABE, 2009, 52(1): 51-60. |

| 14 | Johnson P C, Clementson C L, Mathanker S K, et al. Cutting energy characteristics of Miscanthus giganteus stems with varying oblique angle and cutting speed[J]. Biosystems Engineering, 2012, 112(1): 42-48. |

| 15 | 耿端阳,李玉环,孟凡虎,等.玉米收获机多棱立辊式摘穗装置设计与试验[J]. 农业机械学报,2017, 48(3): 84-91. |

| Geng Duan-yang, Li Yu-huan, Meng Fan-hu, et al. Design and experiment of corn harvester polygonal vertical-rollers snapping means[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017,48(3): 84-91. | |

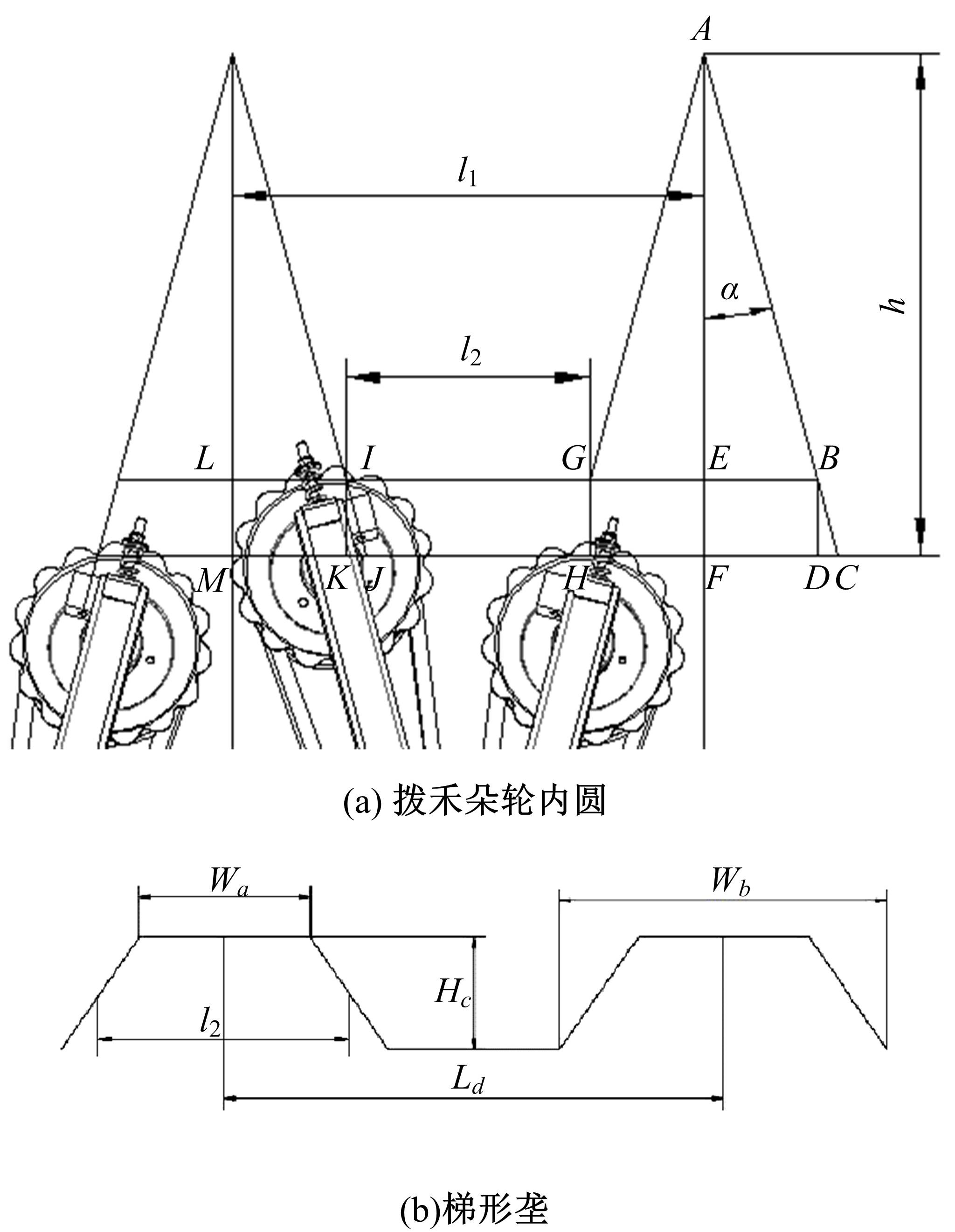

| 16 | 郝付平, 陈志, 张子瑞, 等. 拨禾星轮式玉米收获台设计与试验[J]. 农业机械学报,2014, 45(6): 112-117. |

| Hao Fu-ping, Chen Zhi, Zhang Zi-rui, et al. Design and experiment of corn harvester head with Reel Star wheel[J]. Transactions of the Chinese Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(6): 112-117. | |

| 17 | 张宗玲. 新型玉米穗茎联合收获机割台的研制[D].北京: 中国农业大学工学院,2018. |

| Study on A New Corn Combine Harvester Header for Reaping Both Corn Stalk and Spike[D]. Beijing: College of Engineering,China Agricultural University, 2018. | |

| 18 | 李天宇. 鲜食玉米柔性低损摘穗装置设计与试验[D]. 哈尔滨:东北农业大学工程学院, 2019. |

| Li Tian-yu. Design and experiment of flexible and low loss ear picking device for fresh corn[D]. Harbin: College of Engineering, Northeast Agricultural University, 2019. | |

| 19 | 刘静, 刁培松, 张道林, 等. 玉米收获机分禾器的研究[J]. 农机化研究, 2007, 28(11): 145-146, 149. |

| Liu Jing, Diao Pei-song, Zhang Dao-lin. Research on the nearside divider of corn harvest[J]. Journal of Agricultural Mechanization Research, 2007, 28(11): 145-146, 149. | |

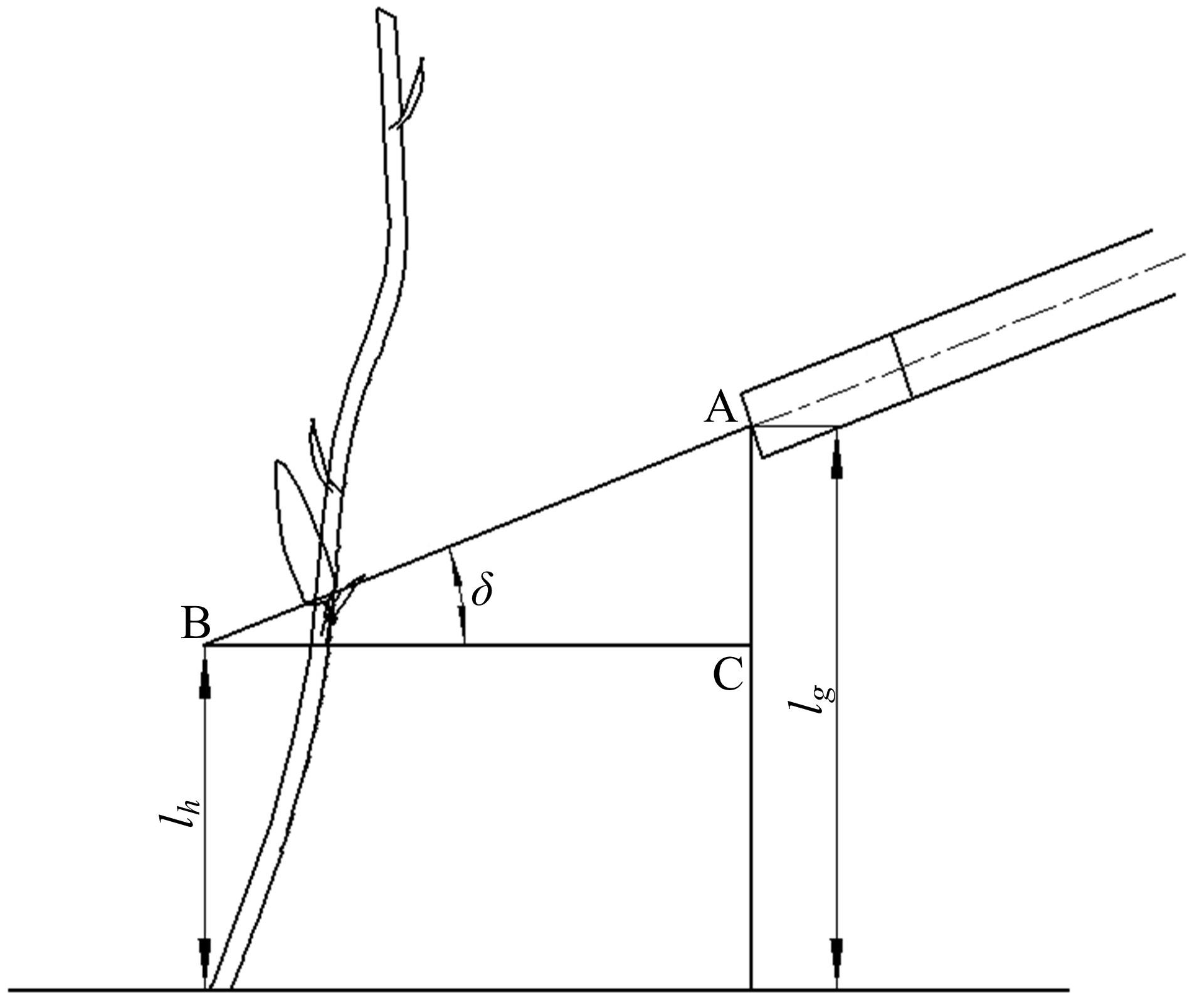

| 20 | 吴鸿欣, 陈志, 韩增德, 等. 玉米植株抗弯特性对分禾器结构的影响分析[J].农业机械学报, 2011, 42(): 6-9. |

| Wu Hong-xin, Chen Zhi, Han Zeng-de, et al.Effect analysis of bending properties of corn plants on divider structure[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(): 6-9. | |

| 21 | 王优, 张强, 于路路. 玉米摘穗装置的应用现状与展望[J]. 农机化研究, 2011, 33(1): 228-231. |

| Wang You, Zhang Qiang, Yu Lu-lu. Application status and prospect of maize maize picking device[J]. Harbin: Journal of Agricultural Mechanization Research, 2011, 33(1): 228-231. | |

| 22 | 张宗玲, 韩增德, 李树君, 等. 玉米穗茎兼收割台切割夹持输送装置仿真与试验[J]. 农业机械学报,2016, 47(): 215-221. |

| Zhang Zong-ling, Han Zeng-de, Li Shu-jun, et al. Simulation and experiment of cutting, clamping and conveying device for corn ear stem and harvester[J]. Transactions of the Chinese Society of Agricultural Machinery, 2016, 47(Sup.1): 215-221. | |

| 23 | 杨庆璐. 烟草夹持式智能打顶机的研制与试验[D]. 泰安:山东农业大学机械与电子工程学院, 2018. |

| Yang Qing-lu. Development and test of tobacco clamping intelligent topping machine[D]. Taian: School of Mechanical and Electronic Engineering, Shandong Agricultural University, 2018. | |

| 24 | 董瑞. 青贮玉米收获割台切割过程仿真及试验研究[D]. 长春:吉林大学生物与农业工程学院,2020. |

| Dong Rui. Simulation and experimental study on cutting process of silage corn harvesting header [D]. Changchun: College of Biology and Agricultural Engineering, Jilin University, 2020. | |

| 25 | Wang Chen, Cao Shun-kun, Gao Kui-zeng, et al. Intelligent control system for corn harvester[J]. Journal of Physics: Conference Series, 2021, 1798(1): No. 012011. |

| 26 | 贾洪雷, 王刚, 赵佳乐, 等. 间距自适应差速玉米摘穗辊设计与试验[J]. 农业机械学报,2015, 46(3): 97-102. |

| Jia Hong-lei, Wang Gang, Zhao Jia-le, et al.Design and experiment of spacing-adaptive differential snapping rollers for corn harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(3): 97-102. | |

| 27 | 王刚, 贾洪雷, 赵佳乐, 等. 玉米留高茬切割器的设计及留茬效果试验[J]. 农业工程学报, 2014, 30(23):43-49. |

| Wang Gang, Jia Hong-lei, Zhao Jia-le, et al. Design of corn high-stubble cutter and experiments of stubble retaining effects[J]. Beijing: Transactions of the Chinese Society of Agricultural Engineering, 2014, 30(23): 43-49. | |

| 28 | 赵淑红, 谭贺文, 王加一, 等. 多功能集成式播种开沟器的设计与试验[J]. 农业工程学报, 2018, 34(11):58-67. |

| Zhao Shu-hong, Tan He-wen, Wang Jia-yi, et al. Design and experiment of multifunctional integrated seeding opener[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(11): 58-67. | |

| 29 | 赵艳忠, 王运兴, 刘海涛, 等. 带状深松灭茬机灭茬部件设计与试验[J]. 农业机械学报, 2018, 49(3):94-103. |

| Zhao Yan-zhong, Wang Yun-xing, Liu Hai-tao, et al. Design and test of stubble-breaking components on strip subsoiling and stubble-breaking machine[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 49(3): 94-103. | |

| 30 | 陈洋,连永祥,李新. 二次回归正交旋转组合设计优化废橡胶辊筒粉碎机效率[J]. 沈阳化工大学学报,2012, 26(3):251-254. |

| Chen Yang, Lian Yong-xiang, Li Xin.Rubber roller mill efficiency with the method of quadratic regression orthogonal rotation[J]. Journal of Shenyang University of Chemical Technology, 2012, 26(3): 251-254. | |

| 31 | 肖宝兰,俞小莉,韩松,等. 翅片参数对车用中冷器流动传热性能的影响[J]. 浙江大学学报: 工学版, 2010, 44(11): 2164-2168, 2178. |

| Xiao Bao-lan, Yu Xiao-li, Han Song,et al.The study of effects of fin parameters on thermal hydraulic performance of a vehicular charged air cooler[J]. Journal of Zhejiang University (Engineering Science), 2010, 44(11): 2164-2168, 2178. | |

| 32 | 葛宜元, 梁秋艳, 王桂莲. 试验设计方法与Design-Expert软件应用[M]. 哈尔滨: 哈尔滨工业大学出版社,2015. |

| 33 | 谭贺文. 一种组合式播种开沟器的设计与试验[D].哈尔滨:东北农业大学工程学院,2018. |

| Tan He-wen. Design and test of a combined sowing furrow opener[D]. Harbin: College of Engineering,Northeast Agricultural University, 2018. | |

| 34 | 玉米收获机械技术条件 [S]. |

| [1] | 曾山,黄登攀,杨文武,刘伟健,文智强,曾力. 三角履带式再生稻收割机底盘的设计与试验[J]. 吉林大学学报(工学版), 2022, 52(8): 1943-1950. |

| [2] | 魏国粱,张青松,王彪,何坤,廖庆喜. 油菜直播机扣垡犁体参数分析与试验[J]. 吉林大学学报(工学版), 2022, 52(7): 1709-1718. |

| [3] | 梁荣庆,钟波,蒙贺伟,孙志民,坎杂. 4QJ⁃3型青贮燕麦捡拾割台的研制[J]. 吉林大学学报(工学版), 2021, 51(5): 1887-1896. |

| [4] | 袁佳诚,王昌,何坤,万星宇,廖庆喜. 油菜联合收获机筛下物组分质量比对清选性能的影响[J]. 吉林大学学报(工学版), 2021, 51(5): 1897-1907. |

| [5] | 王刚,刘慧力,贾洪雷,郭春江,丛永健,屈明浩. 触碰定位式玉米行间除草装置的设计与试验[J]. 吉林大学学报(工学版), 2021, 51(4): 1518-1527. |

| [6] | 付君,张屹晨,程超,陈志,唐心龙,任露泉. 刚柔耦合式小麦脱粒弓齿设计及试验[J]. 吉林大学学报(工学版), 2020, 50(2): 730-738. |

| [7] | 薛钊,付君,陈志,王锋德,韩少平,任露泉. 青饲玉米收获机械切碎装置参数优化试验[J]. 吉林大学学报(工学版), 2020, 50(2): 739-748. |

| [8] | 程超,付君,郝付平,陈志,周德义,任露泉. 清选筛运动参数对玉米芯轴堵筛规律的影响[J]. 吉林大学学报(工学版), 2020, 50(1): 351-360. |

| [9] | 程超,付君,唐心龙,陈志,任露泉. 振动形式对水稻脱出物界面粘附规律的影响[J]. 吉林大学学报(工学版), 2019, 49(4): 1228-1235. |

| [10] | 付君,钱志辉,尹维,王甲甲,任露泉. 小麦摩擦与拉伸性能[J]. 吉林大学学报(工学版), 2015, 45(2): 501-507. |

| [11] | 王丽丽1,2, 杨印生1,3, 王忠江2. 北方大型沼气工程加热保温系统优化[J]. 吉林大学学报(工学版), 2011, 41(4): 1183-1188. |

|

||