吉林大学学报(工学版) ›› 2025, Vol. 55 ›› Issue (2): 468-475.doi: 10.13229/j.cnki.jdxbgxb.20230507

• 车辆工程·机械工程 • 上一篇

工艺顺序对车用铝薄板胶-PFSSW接头拉剪性能的影响

- 1.吉林大学 汽车仿真与控制国家重点实验室,长春 130022

2.中国第一汽车股份有限公司 新能源开发院,长春 130000

Effect of process sequence on tensile shear properties of PFSSW joints for automotive aluminum sheets

Xin CHEN1( ),Xiang-yuan ZHANG1,Zi-tao WU1,2,Gui-shen YU1,Li-fei YANG1

),Xiang-yuan ZHANG1,Zi-tao WU1,2,Gui-shen YU1,Li-fei YANG1

- 1.State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

2.New Energy Development Institute,China FAW Group,Changchun 130000,China

摘要:

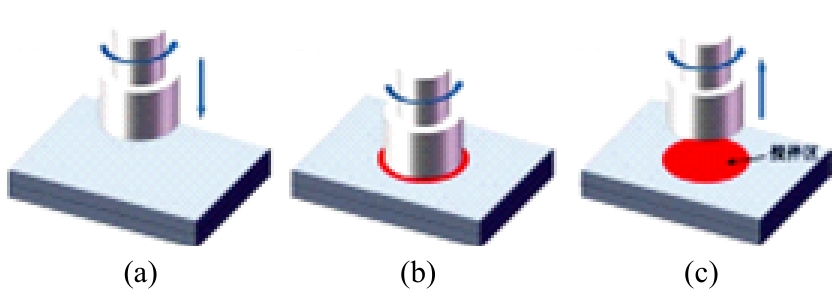

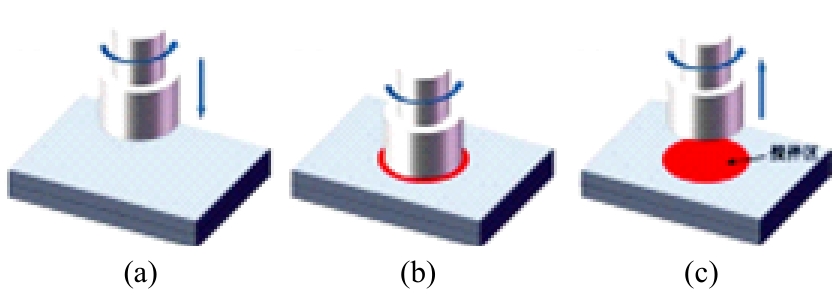

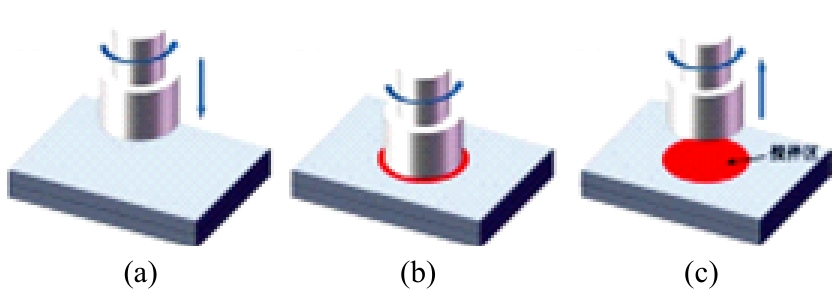

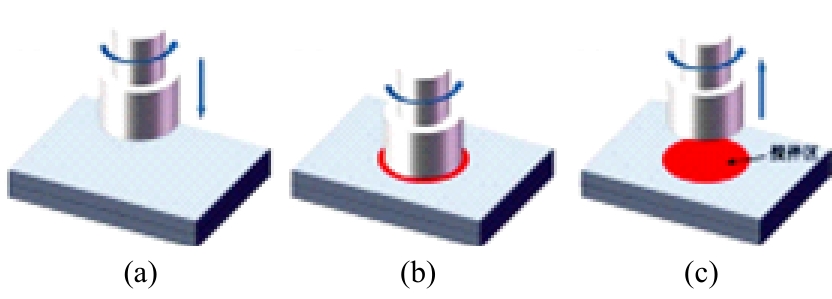

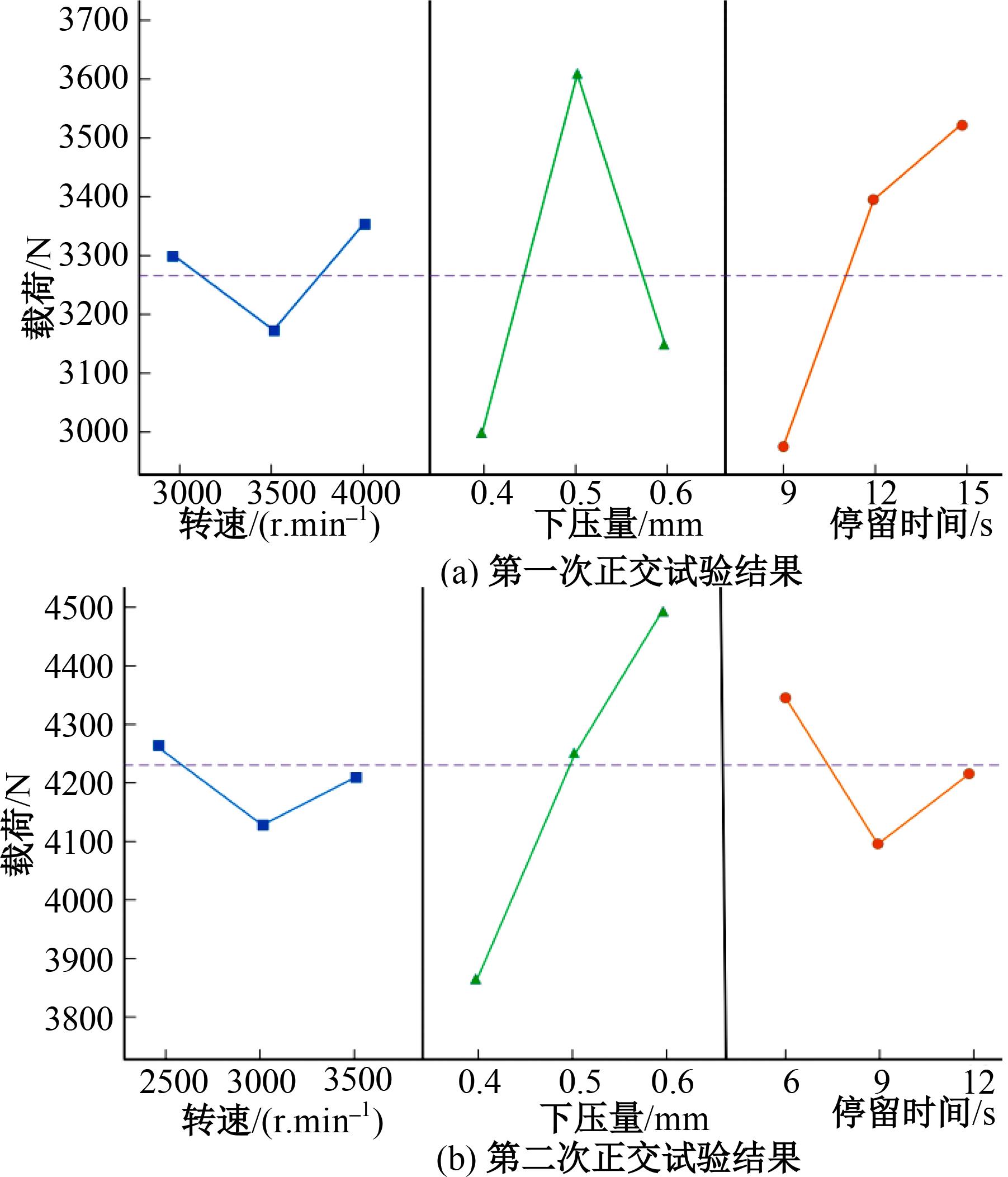

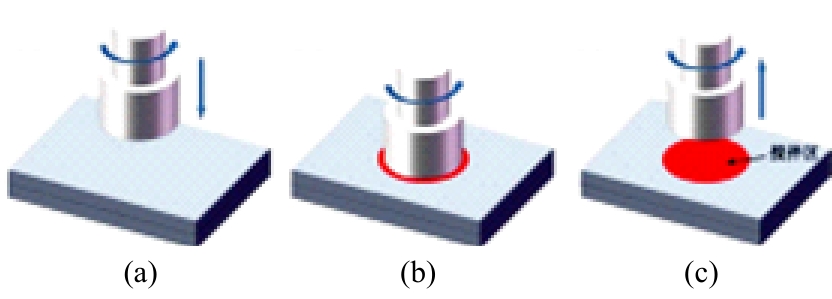

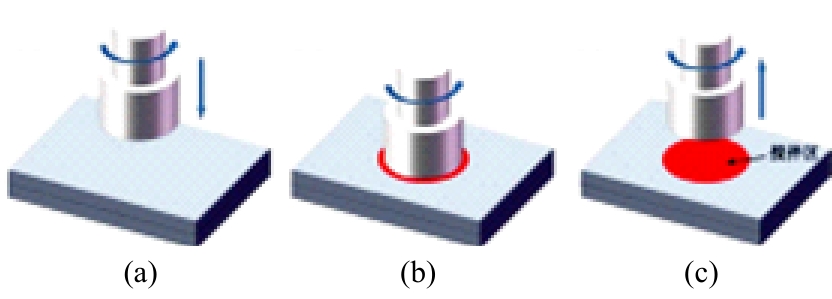

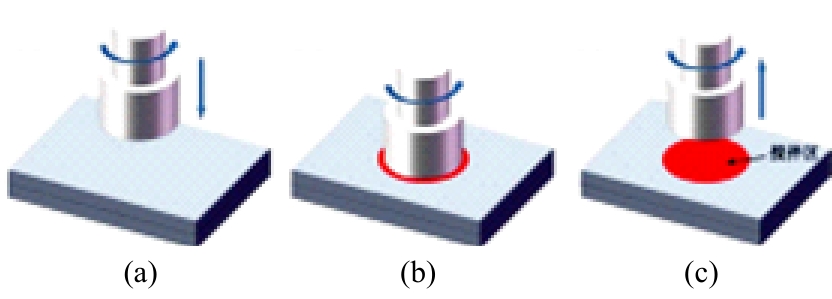

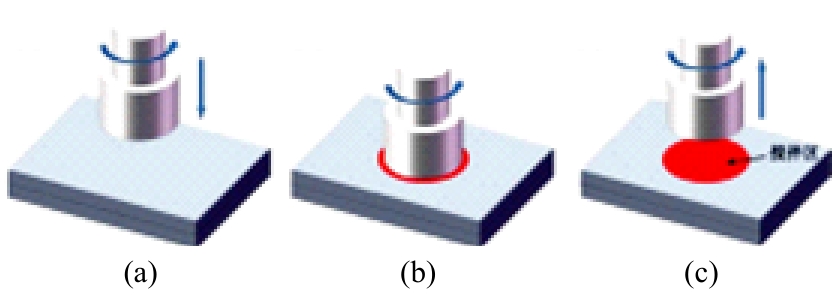

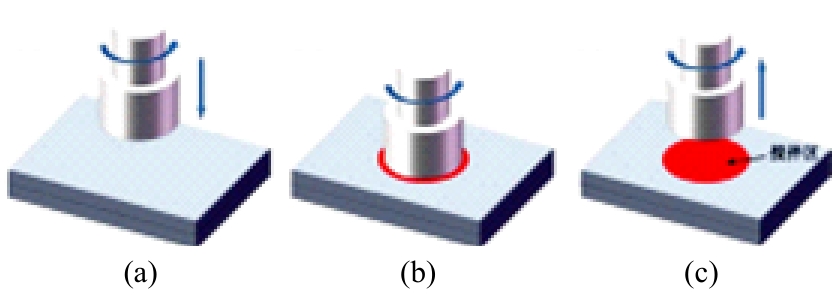

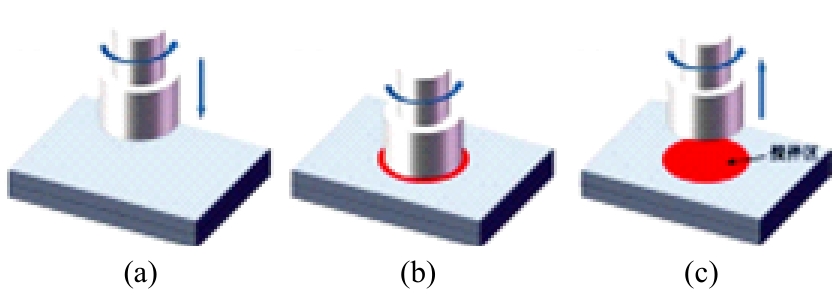

针对车身用1.5 mm的AA6061-T6铝合金薄板,研究采用透胶胶焊法和毛细作用胶焊法两种工艺对PFSSW-胶点焊接头拉剪性能的影响。通过热力耦合法对搭接区域温度场进行分析,然后对比不同工艺顺序接头的拉剪性能及断裂模式。结果表明:相比PFSSW和透胶胶焊法,毛细作用胶焊法能够明显提升铝薄板接头的拉剪性能。本文为车身铝薄板及其他胶焊接头的连接工艺提供了方法支持。

中图分类号:

- U465.2

| 1 | 环鹏程, 王晓南, 朱天才, 等. 800 MPa 级热轧高强钢激光焊接接头的组织和力学性能[J]. 中国激光, 2019, 46(1): 91-99. |

| Huan Peng-cheng, Wang Xiao-nan, Zhu Tian-cai, et al. Microstructure and mechanicl properties of laser welded joint of 800 MPa grade hot-rolled high strength steel[J]. Chinese Journal of Lasers, 2019, 46(1): 91-99. | |

| 2 | 王科学, 王东波, 黄勇, 等. 铝合金材料在汽车轻量化领域应用的研究现状[J]. 铝加工, 2022, 269(6): 3-6. |

| Wang Ke-xue, Wang Dong-bo, Huang Yong, et al. Research status of application of aluminum alloy materials in the dield of automobile lightweight[J]. Aluminium Fabrication, 2022, 269(6): 3-6. | |

| 3 | 朱海, 于明玉, 孙朝伟, 等. 无针搅拌摩擦焊技术研究进展和展望[J]. 热加工工艺, 2019, 48(23): 15-19. |

| Zhu Hai, Yu Ming-yu, Sun Chao-wei, et al. Reserch progress and prospects of pinless friction stir welding technology[J]. Hot Working Technology, 2019, 48(23): 15-19. | |

| 4 | Bakavos D, Prangnell P B. Effect of reduced or zero pin length and anvil insulation on friction stir spot welding thin gauge 6 111 automotive sheet[J]. Science and Technology of Welding and Joining, 2009, 14(5): 443-56. |

| 5 | Chen H L, Na J X, Mu W L, et al. Effect of sealing treatment on the resistance of lap joints to hygrothermal aging[J]. The Journal of Adhesion, 2022, 98(14): 2231-2252. |

| 6 | 王登峰, 陈宏利, 那景新, 等. 单双搭接接头经高温老化后的失效对比[J]. 吉林大学学报: 工学版, 2023, 53(2): 346-354. |

| Wang Deng-feng, Chen Hong-li, Na Jing-xin, et al. Failure comparision of single and double lap joints after high temperature aging[J]. Journal of Jilin University (Engineering and Technology Edition), 2023, 53(2): 346-354. | |

| 7 | Kang J D, Chen Y H, Sigler D, et al. Effect of adhesive on fatigue property of Aural 2 to AA5754 dissimilar aluminum alloy resistance spot welds[J]. Engineering Failure Analysis, 2016, 69: 57-65. |

| 8 | Costa H R M, Souza J M L, Souza J P B, et al. experimental investigation of the mechanical behaviour of spot welding-adhesives joints[J]. Composite Structures, 2015, 133: 847-852. |

| 9 | Marques G P, Campilho R D S G, Moreira R D F, et al. Adhesive selection for hybrid spot-welded/bonded single-lap joints: experimentation and numerical analysis[J]. Composites Part B Engineering, 2016, 84: 248-257. |

| 10 | Ufferma B, Abke T, Barker M, et al. Mechanical properties of joints in 5052 aluminum made with adhesive bonding and mechanical fasteners[J]. International Journal of Adhesion and Adhesives, 2018, 83: 96-102 |

| 11 | Messler R W, Bohnenstiehl S, Levene J, et al. A pressure-assisted approach for laser-beam weld-bonding Al alloy structure for automobiles[J]. Assembly Automation, 2004, 24(4): 370-378. |

| 12 | Wei T, Na J X, Wang G B, et al. Effect of temperature on the fatigue performance and failure mechanism of a flexible adhesive butt joint[J]. The Journal of Adhesion, 2022, 98(13): 1998-2028. |

| [1] | 朱冰,范天昕,赵文博,李伟男,张培兴. 自动驾驶汽车连续测试场景复杂度评估方法[J]. 吉林大学学报(工学版), 2025, 55(2): 456-467. |

| [2] | 曲俊龙,史文库,玄圣夷,陈志勇. 面向汽车传动系统多挡共振的多级吸振器参数设计方法[J]. 吉林大学学报(工学版), 2025, 55(2): 444-455. |

| [3] | 胡宏宇,张争光,曲优,蔡沐雨,高菲,高镇海. 基于双分支和可变形卷积网络的驾驶员行为识别方法[J]. 吉林大学学报(工学版), 2025, 55(1): 93-104. |

| [4] | 王军年,曹宇靖,罗智仁,李凯旋,赵文伯,孟盈邑. 基于双目视觉的道路水深在线检测算法[J]. 吉林大学学报(工学版), 2025, 55(1): 175-184. |

| [5] | 谭草,任浩鑫,葛文庆,宋亚东,陆佳瑜. 直驱阀控液压振动平台改进自抗扰控制[J]. 吉林大学学报(工学版), 2025, 55(1): 84-92. |

| [6] | 李寿涛,杨路,屈如意,孙鹏鹏,于丁力. 基于模型预测控制的滑移率控制方法[J]. 吉林大学学报(工学版), 2024, 54(9): 2687-2696. |

| [7] | 吴量,顾义凡,邢彪,马芳武,倪利伟,贾微微. 基于线性二次型调节器的四轮转向与分布式集成控制方法[J]. 吉林大学学报(工学版), 2024, 54(9): 2414-2422. |

| [8] | 王玉海,李晓之,李兴坤. 面向高速工况的混合动力卡车预见性节能算法[J]. 吉林大学学报(工学版), 2024, 54(8): 2121-2129. |

| [9] | 常胜,刘宏飞,邹乃威. 汽车变曲率路径循迹H∞回路成形鲁棒控制[J]. 吉林大学学报(工学版), 2024, 54(8): 2141-2148. |

| [10] | 刘建泽,柳江,李敏,章新杰. 基于最小二乘的车速解耦路面辨识方法[J]. 吉林大学学报(工学版), 2024, 54(7): 1821-1830. |

| [11] | 谢宪毅,张明君,金立生,周彬,胡涛,白宇飞. 考虑舒适度的智能汽车人工蜂群轨迹规划方法[J]. 吉林大学学报(工学版), 2024, 54(6): 1570-1581. |

| [12] | 刘从臻,陈高,刘洪柱,马强,徐成伟,孟辉,王国林. 湿滑路面轮胎接地力学特性模型[J]. 吉林大学学报(工学版), 2024, 54(6): 1501-1511. |

| [13] | 黄玲,崔躜,游峰,洪佩鑫,钟浩川,曾译萱. 适用于多车交互场景的车辆轨迹预测模型[J]. 吉林大学学报(工学版), 2024, 54(5): 1188-1195. |

| [14] | 郭洪艳,王连冰,赵旭,戴启坤. 考虑侧向运动的整车质量与道路坡度估计[J]. 吉林大学学报(工学版), 2024, 54(5): 1175-1187. |

| [15] | 陆玉凯,袁帅科,熊树生,朱绍鹏,张宁. 汽车漆面缺陷高精度检测系统[J]. 吉林大学学报(工学版), 2024, 54(5): 1205-1213. |

|

||