吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (5): 1205-1213.doi: 10.13229/j.cnki.jdxbgxb.20231081

汽车漆面缺陷高精度检测系统

陆玉凯1,2( ),袁帅科3,熊树生1,4(

),袁帅科3,熊树生1,4( ),朱绍鹏1,张宁3

),朱绍鹏1,张宁3

- 1.浙江大学 动力机械及车辆工程研究所,杭州 310014

2.浙江吉利汽车有限公司,杭州 310051

3.燕山大学 机械工程学院,河北 秦皇岛 066004

4.龙泉产业创新研究院,浙江 龙泉 323700

High precision detection system for automotive paint defects

Yu-kai LU1,2( ),Shuai-ke YUAN3,Shu-sheng XIONG1,4(

),Shuai-ke YUAN3,Shu-sheng XIONG1,4( ),Shao-peng ZHU1,Ning ZHANG3

),Shao-peng ZHU1,Ning ZHANG3

- 1.Power Machinery & Vehicular Engineering Institute,Zhejiang University,Hangzhou 310014,China

2.Zhejiang Geely Automobile Co. ,Ltd. ,Hangzhou 310051,China

3.College of Mechanical Engineering,Yanshan University,Qinhuangdao 066004,China

4.Longquan Industrial Innovation Research Institute,Longquan 323700,China

摘要:

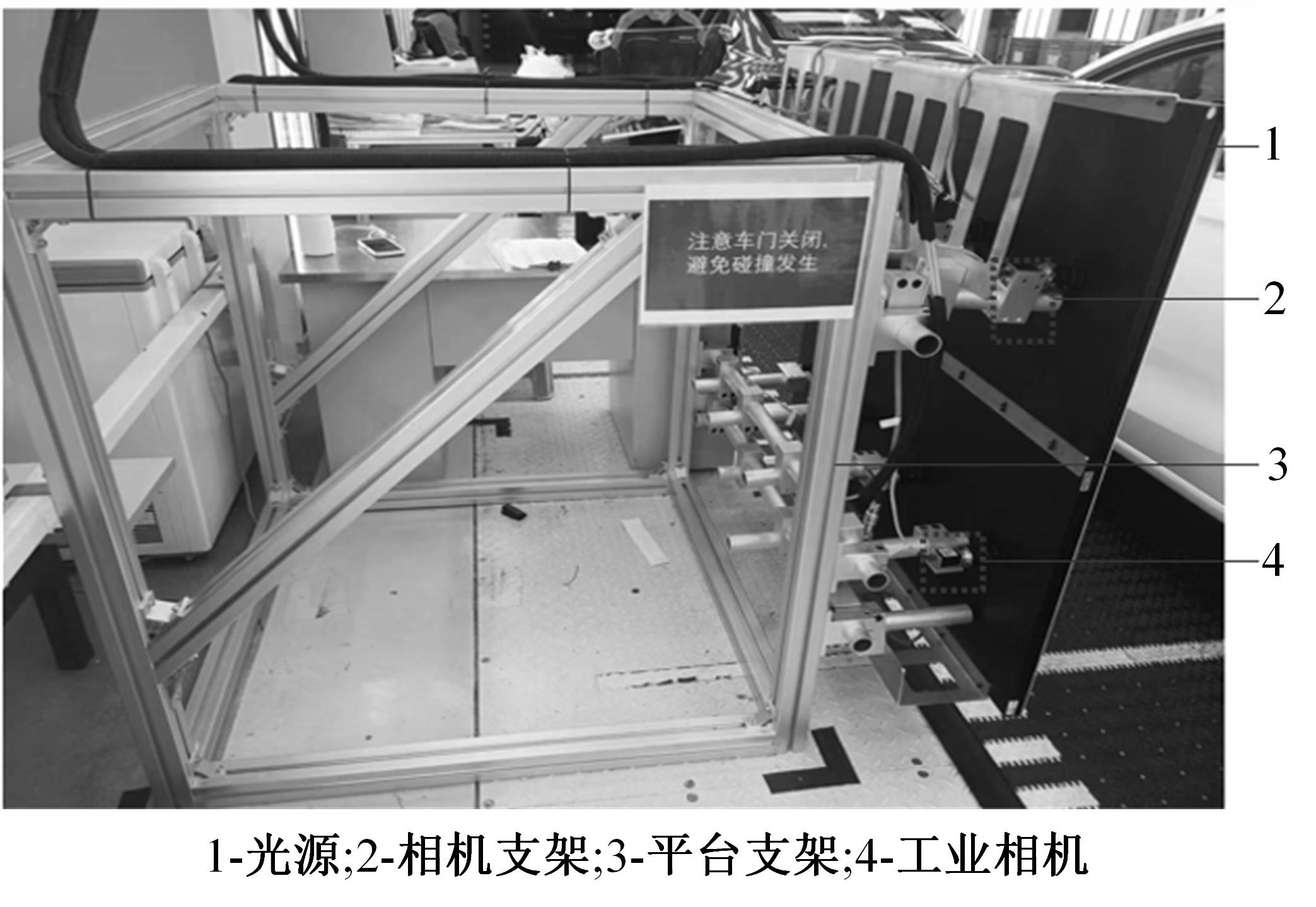

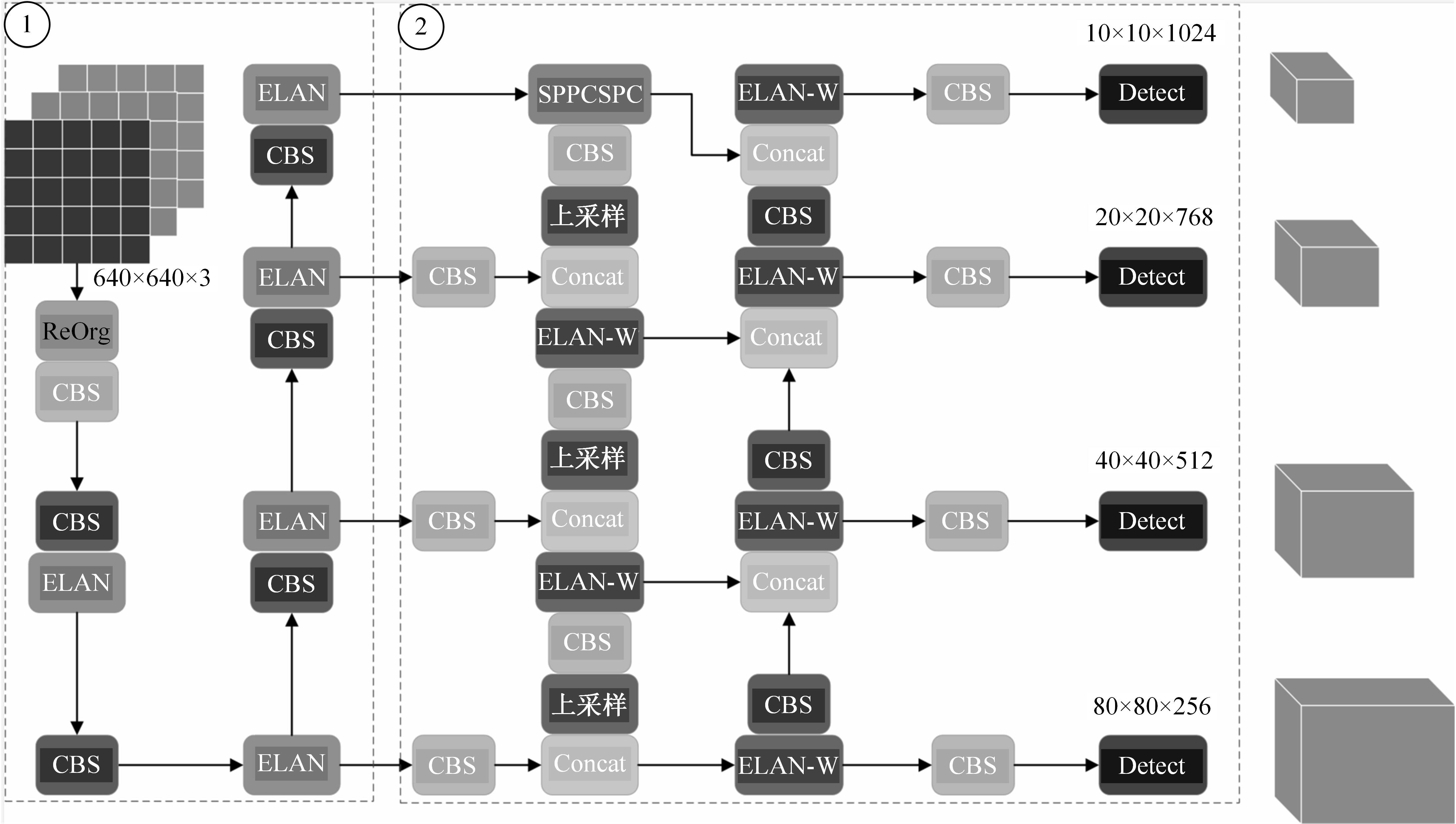

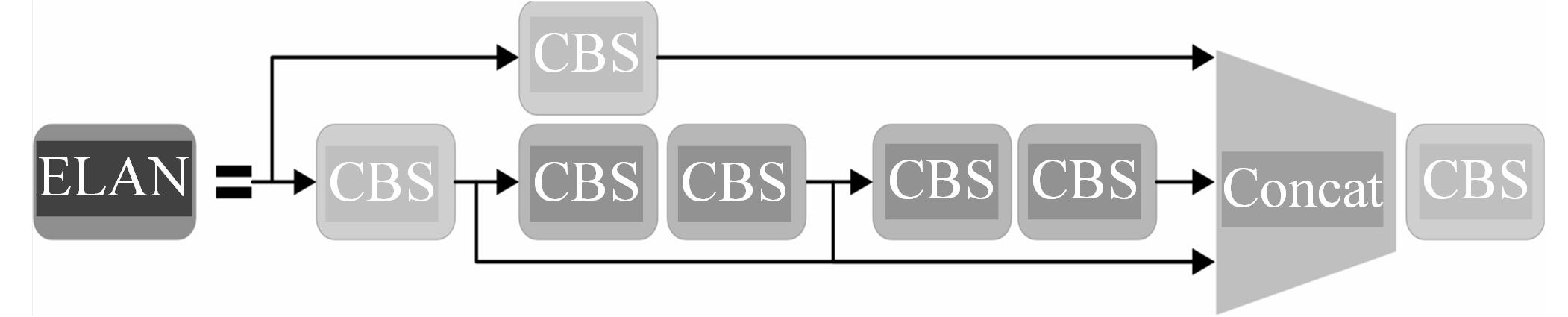

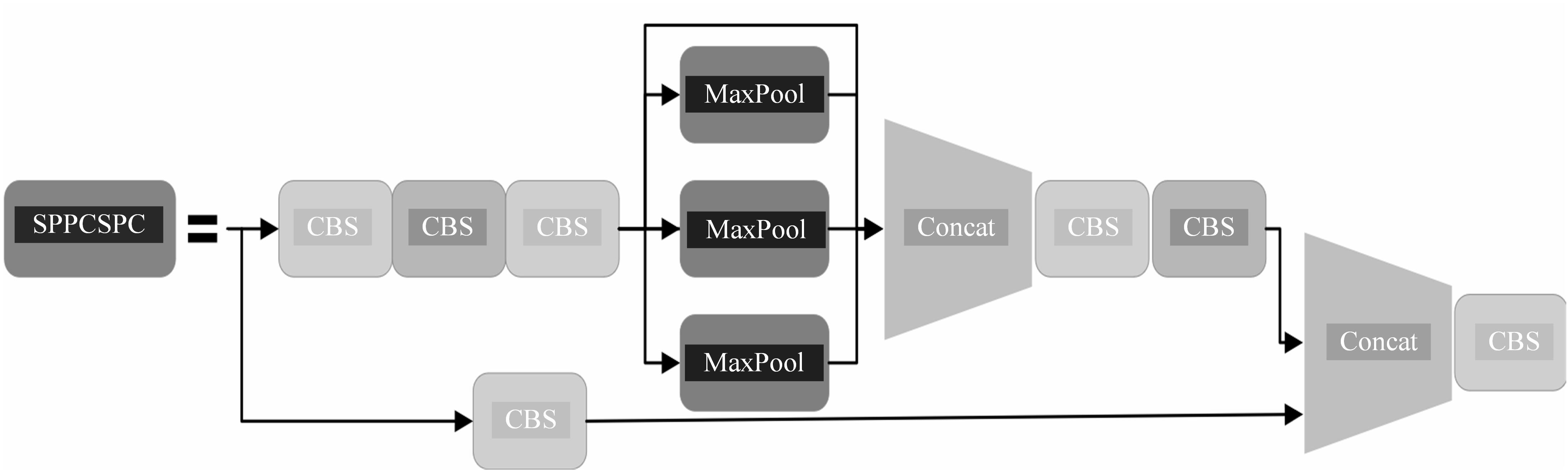

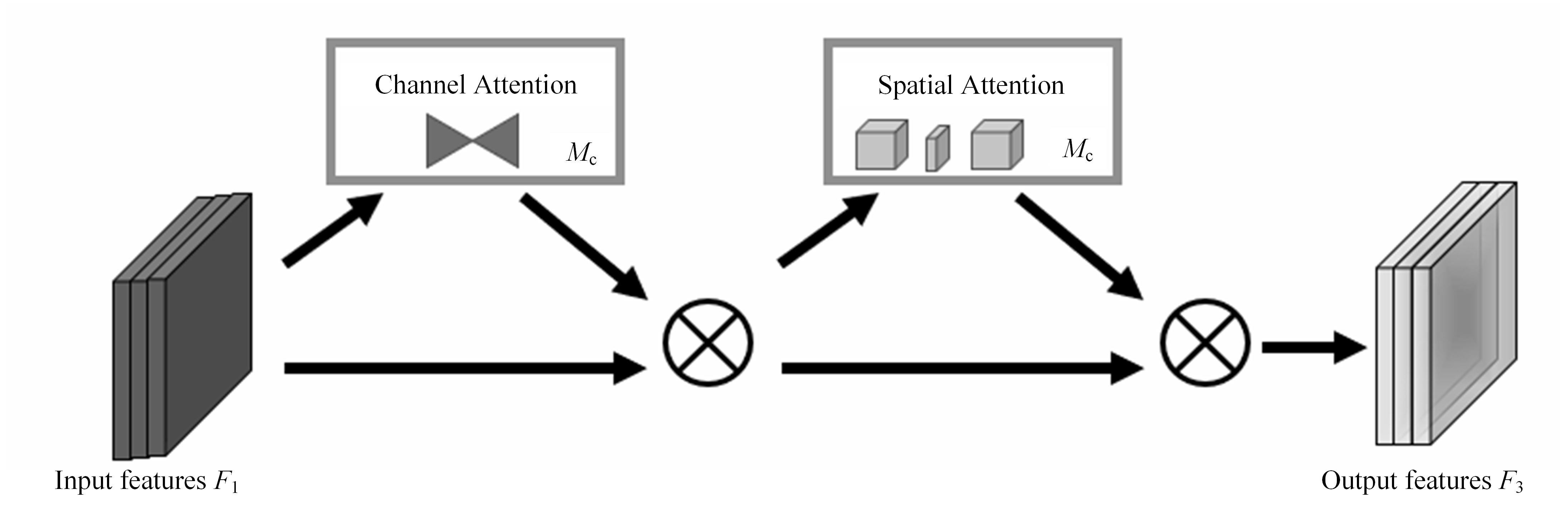

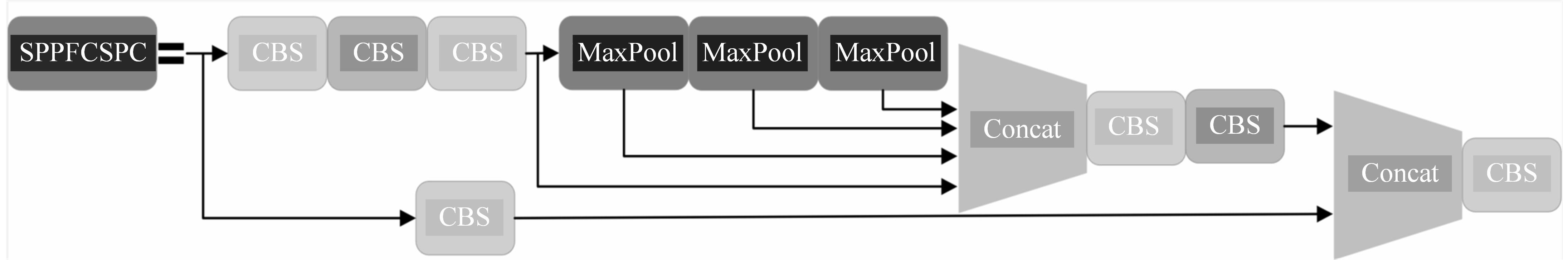

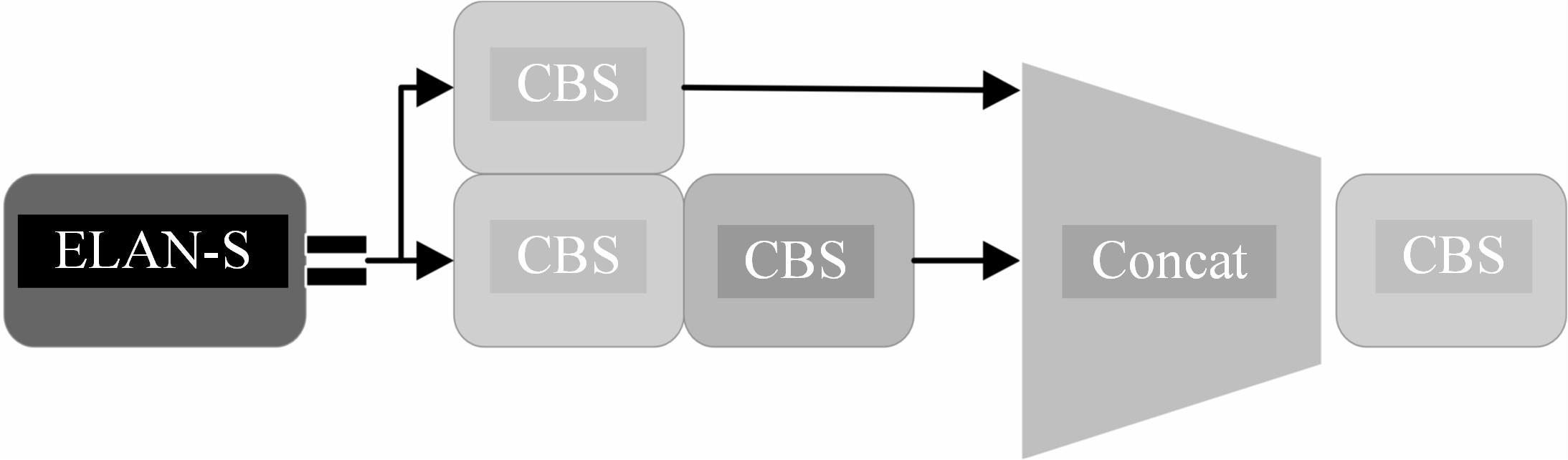

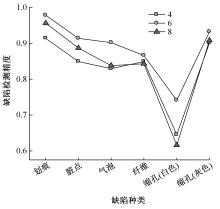

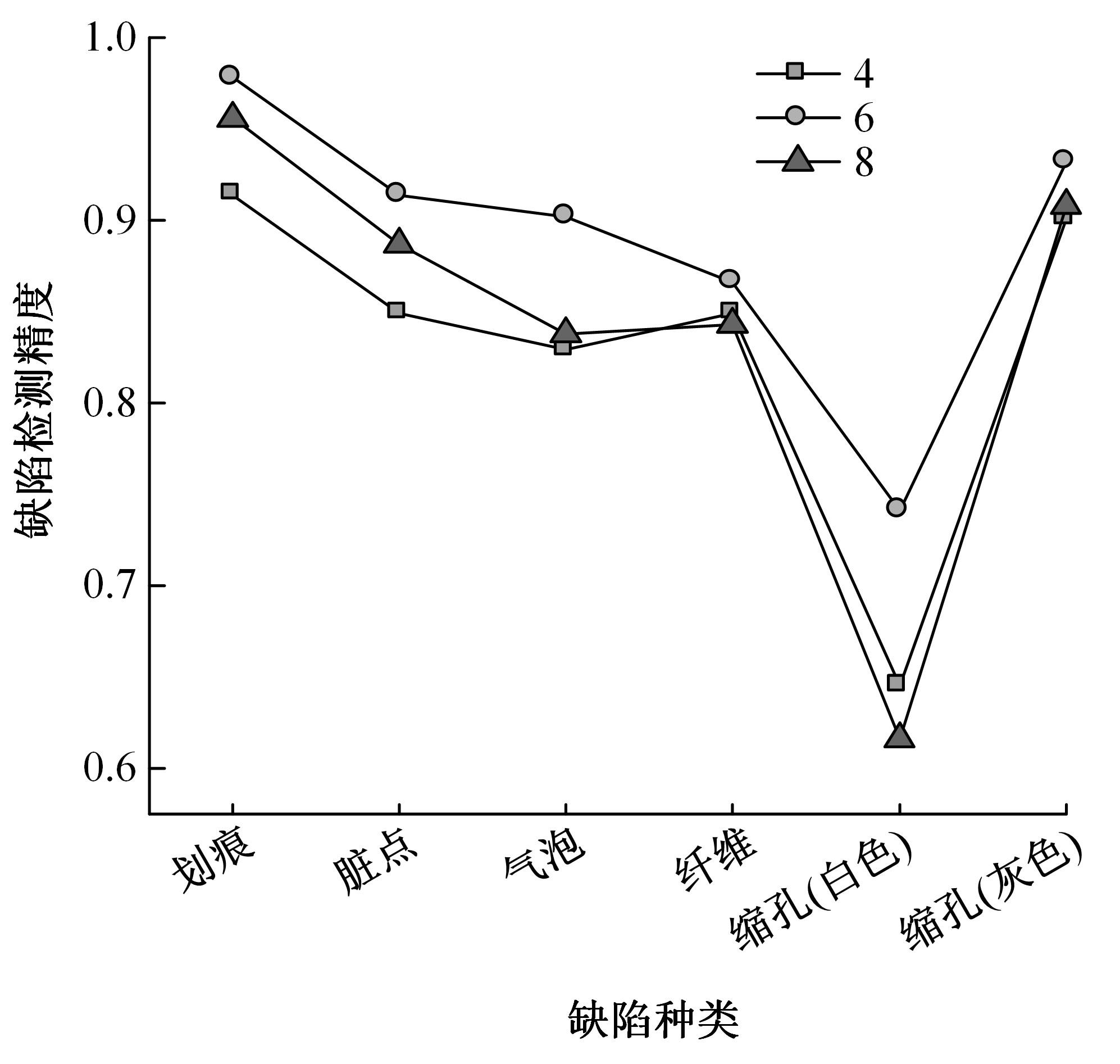

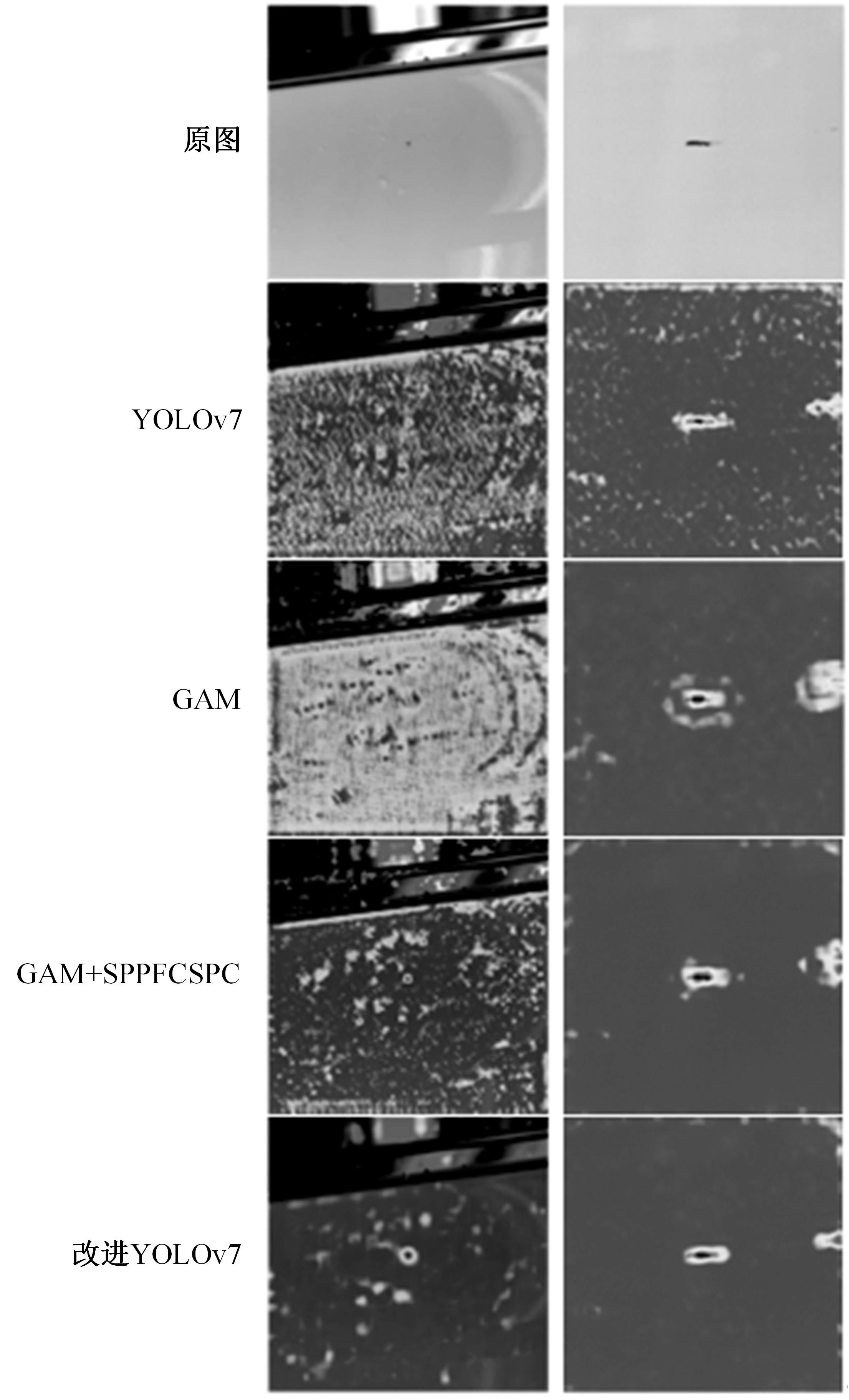

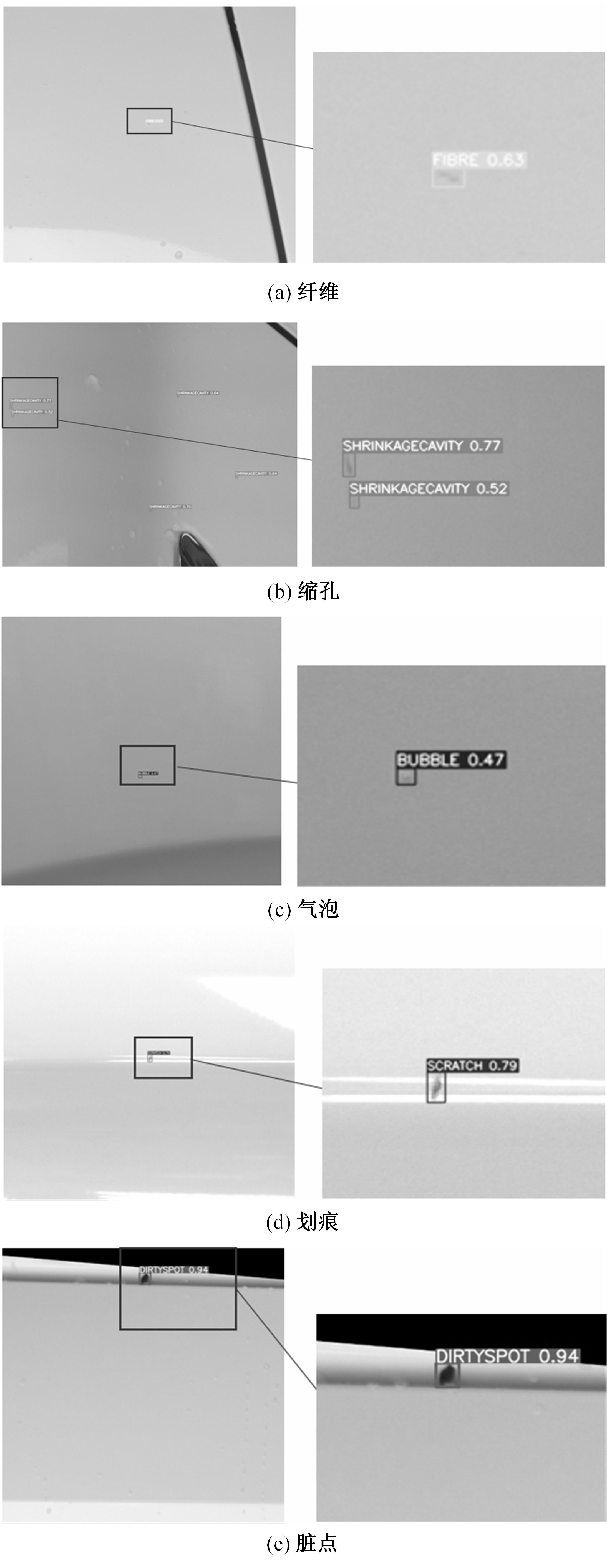

汽车涂装过程中产生的漆面缺陷影响着整车外观质量,针对人工检测存在漏检、低效以及传统检测方案的高实施成本等问题,提出了一种基于改进YOLOv7算法的汽车漆面缺陷检测系统。构建了汽车漆面缺陷数据集,共有4023张图像,其中包含5种常见汽车漆面缺陷;针对YOLOv7算法在微小缺陷上检测精度不足的问题,在原网络中引入了GAM注意力机制和SPPFCSPC模块,用于提高算法对微小缺陷特征的提取能力,同时采用改进的ELAN模块对网络结构进行改进,减少网络过深造成的小目标信息丢失问题,保证在减轻网络模型的同时提高网络对微小特征的识别精度;实验结果表明:本文方法大幅提升了对微小漆面缺陷的检测性能,缺陷的平均检测精度达到了88.9%,与多种算法相比检测精度最高。

中图分类号:

- TP183

| 1 | Yu J B, Lu X L. Wafer map defect detection and recognition using joint local and nonlocal linear discriminant analysis[J]. IEEE Transactions on Semiconductor Manufacturing,2016,29(1): 33-43. |

| 2 | 刘培勇,董洁,谢罗峰,等. 基于多支路卷积神经网络的磁瓦表面缺陷检测算法[J]. 吉林大学学报: 工学版,2023,53(5): 1449-1457. |

| Liu Pei-yong, Dong Jie, Xie Luo-feng,et al. Surface defect detection algorithm of magnetic tiles based on multi⁃branch convolutional neural network[J]. Journal of Jilin University (Engineering and Technology Edition),2023,53(5): 1449-1457. | |

| 3 | 贺秋伟,王龙山,于忠党,等. 基于图像处理和支持向量机的微型齿轮缺陷检测[J]. 吉林大学学报: 工学版, 2008, 38(3): 565-569. |

| He Qiu-wei, Wang Long-shan, Yu Zhong-dang,et al. Defect detection for microgear based on image processing and support vector machine[J]. Journal of Jilin University (Engineering and Technology Edition),2008, 38(3): 565-569. | |

| 4 | 吴凤和,崔健新,张宁,等. 基于改进YOLOv4算法的轮毂表面缺陷检测[J]. 计量学报,2022,43(11): 1404-1411. |

| Wu Feng-he, Cui Jian-xin, Zhang Ning,et al. Surface defect detection of wheel hub based on improved YOLOv4 algorithm[J]. Acta Metrologica Sinica,2022,43(11): 1404-1411. | |

| 5 | 张飞,单忠德,任永新,等. 缸盖缺陷检测系统线阵相机现场标定方法[J]. 吉林大学学报: 工学版,2017,47(2): 540-545. |

| Zhang Fei, Shan Zhong-de, Ren Yong-xin,et al. Calibration of line array camera for head defect detection system on cylinder cover[J]. Journal of Jilin University (Engineering and Technology Edition),2017,47(2): 540-545. | |

| 6 | Zheng J F, Wu H, Han Z,et al. Insulator-defect detection algorithm based on improved YOLOv7[J]. Sensors,2022,22(22): 22228801. |

| 7 | Sohail A, Adarsh T, Medhat M,et al. A robotics inspection system for detecting defects on semi-specular painted automotive surfaces[C]∥ IEEE International Conference on Robotics and Automation,Paris,France,2020: 8928-8934. |

| 8 | Jing Z, Masaki K, Chao Z,et al. Defect inspection of coated automobile roofs using a single camera[J]. IEEJ Transactions on Electrical and Electronic Engineering,2020,15(4): 616-625. |

| 9 | Jaime M, Solanes J E, Laura A,et al. On the detection of defects on specular car body surfaces[J]. Robotics and Computer-Integrated Manufacturing,2017,48: 263-278. |

| 10 | Edris M Z B, Jawad M S, Zakaria Z. Surface defect detection and neural network recognition of automotive body panels[C]∥ International Conference on Control System,Computing and Engineering,Penang,Malaysia,2015: 117-122. |

| 11 | Yang Y X, Sun Q, Zhang D K,et al. Improved method based on faster R-CNN network optimization for small target surface defects detection of aluminum profile[C]∥ IEEE 15th International Conference on Electronic Measurement & Instruments(ICEMI), Nanjing, China, 2021: 465-470. |

| 12 | Liu M W, Lin Y H, Lo Y C,et al. Defect detection of grinded and polished workpieces using faster R-CNN[C]∥ Advanced Intelligent Mechatronics,Delft,Netherlands,2021: 1290-1296. |

| 13 | Zhang J D, Xu J B, Zhang L Y,et al. An improved mobilenet-ssd algorithm for automatic defect detection on vehicle body paint[J]. Multimedia Tools and Applications,2020,79(31/32): 23367-23385. |

| 14 | Chang F, Liu M, Dong M Y,et al. A mobile vision inspection system for tiny defect detection of smooth car-body surface based on deep ensemble learning[J]. Measurement Science and Technology,2019,30(12): 125905. |

| 15 | Chang F, Dong M Y, Liu M,et al. A lightweight appearance quality assessment system based on parallel deep learning for painted car-body[J]. IEEE Transactions on Instrumentation and Measurement,2020,69(8): 5298-5307. |

| 16 | Xu G, Guo R F, Wang H L. Quality inspection of workpiece camouflage spraying based on improved YOLOv3-tiny[C]∥ IEEE International Conference Computer and Communications,Chengdu,China,2020: 1363-1367. |

| 17 | Venkat A A, Chih H C, Hsu C C,et al. Applying deep learning to defect detection in printed circuit boards via a newest model of you-only-look-once[J]. Mathematical Biosciences and Engineering,2021,18(4): 4411-4428. |

| 18 | Liao D H, Cui Z H, Zhang X,et al. Surface defect detection and classification of Si3N4 turbine blades based on convolutional neural network and YOLOv5[J]. Advances in Mechanical Engineering,2022,14(2): 16878132221081580. |

| 19 | Tu X G, Yuan Z H, Liu B K,et al. An improved YOLOv5 for object detection in visible and thermal infrared images based on contrastive learning[J]. Frontiers in Physics,2023,11: 354-363. |

| 20 | Zhang R, Xie C, Deng L W. A fine-grained object detection model for aerial images based on YOLOv5 deep neural network[J]. Chinese Journal of Electronics,2023,32(1): 51-63. |

| 21 | Wang C Y, Alexey B, Liao H Y. YOLOv7: trainable bag-of-freebies sets new state-of-the-art for real-time object detectors[C]∥ Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition,Vancouver,Canada,2022: 7464-7475. |

| [1] | 黄玲,崔躜,游峰,洪佩鑫,钟浩川,曾译萱. 适用于多车交互场景的车辆轨迹预测模型[J]. 吉林大学学报(工学版), 2024, 54(5): 1188-1195. |

| [2] | 郭洪艳,王连冰,赵旭,戴启坤. 考虑侧向运动的整车质量与道路坡度估计[J]. 吉林大学学报(工学版), 2024, 54(5): 1175-1187. |

| [3] | 汪少华,张启睿,施德华,殷春芳,李春. 双行星排式混合动力传动系统非线性振动响应特性分析[J]. 吉林大学学报(工学版), 2024, 54(4): 890-901. |

| [4] | 高镇海,蔡荣贵,孙天骏,于桐,赵浩源,班浩. 人机共驾下的驾驶行为数据滤波方法[J]. 吉林大学学报(工学版), 2024, 54(3): 589-599. |

| [5] | 谢宪毅,王禹涵,金立生,赵鑫,郭柏苍,廖亚萍,周彬,李克强. 基于改变控制时域时间步长的智能车轨迹跟踪控制[J]. 吉林大学学报(工学版), 2024, 54(3): 620-630. |

| [6] | 邓小林,杨馥模,覃善甘. 新型仿竹六边形梯度层级多胞管耐撞性对比分析[J]. 吉林大学学报(工学版), 2024, 54(2): 333-345. |

| [7] | 王毅刚,王玉鹏,张昊,赵思安. 高速列车转向架区域气动噪声源识别与分析[J]. 吉林大学学报(工学版), 2024, 54(2): 346-355. |

| [8] | 聂建军,侯军凯,解晓琳,鄢鸿桢. 新型巡检机器人移动底盘设计及越障性能分析[J]. 吉林大学学报(工学版), 2024, 54(2): 356-364. |

| [9] | 杨国俊,齐亚辉,石秀名. 基于数字图像技术的桥梁裂缝检测综述[J]. 吉林大学学报(工学版), 2024, 54(2): 313-332. |

| [10] | 胡宏宇,张慧珺,姚荣涵,陈国迎,高菲. L3级自动驾驶接管过程驾驶员情景意识研究[J]. 吉林大学学报(工学版), 2024, 54(2): 410-418. |

| [11] | 李雄飞,宋紫萱,朱芮,张小利. 基于多尺度融合的遥感图像变化检测模型[J]. 吉林大学学报(工学版), 2024, 54(2): 516-523. |

| [12] | 吴骁,史文库,郭年程,赵燕燕,陈志勇,李鑫鹏,孙卓,刘健. 基于Ease off的准双曲面齿轮多目标优化[J]. 吉林大学学报(工学版), 2024, 54(1): 76-85. |

| [13] | 陈岳林,高铸成,蔡晓东. 基于BERT与密集复合网络的长文本语义匹配模型[J]. 吉林大学学报(工学版), 2024, 54(1): 232-239. |

| [14] | 王铁,李旭东,田程,赵宏伟. 基于多轴载荷投影构建轮辋双轴疲劳损伤模型[J]. 吉林大学学报(工学版), 2024, 54(1): 99-104. |

| [15] | 李旭东,王新宇,田程,张新峰,牛治慧,赵志强. 基于用户关联的车辆耐久性载荷谱编制[J]. 吉林大学学报(工学版), 2024, 54(1): 66-75. |

|

||