吉林大学学报(工学版) ›› 2019, Vol. 49 ›› Issue (5): 1593-1599.doi: 10.13229/j.cnki.jdxbgxb20180556

• • 上一篇

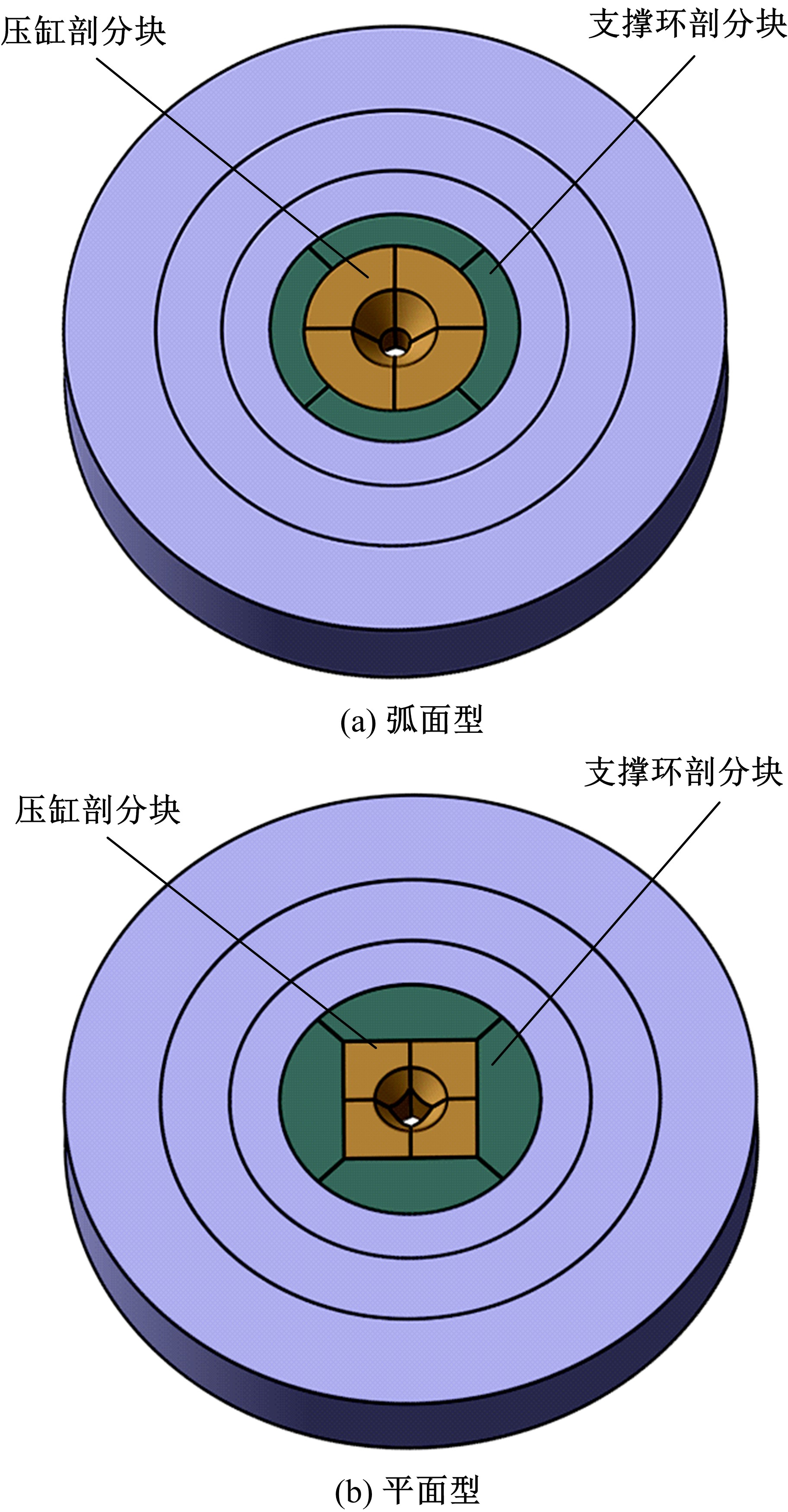

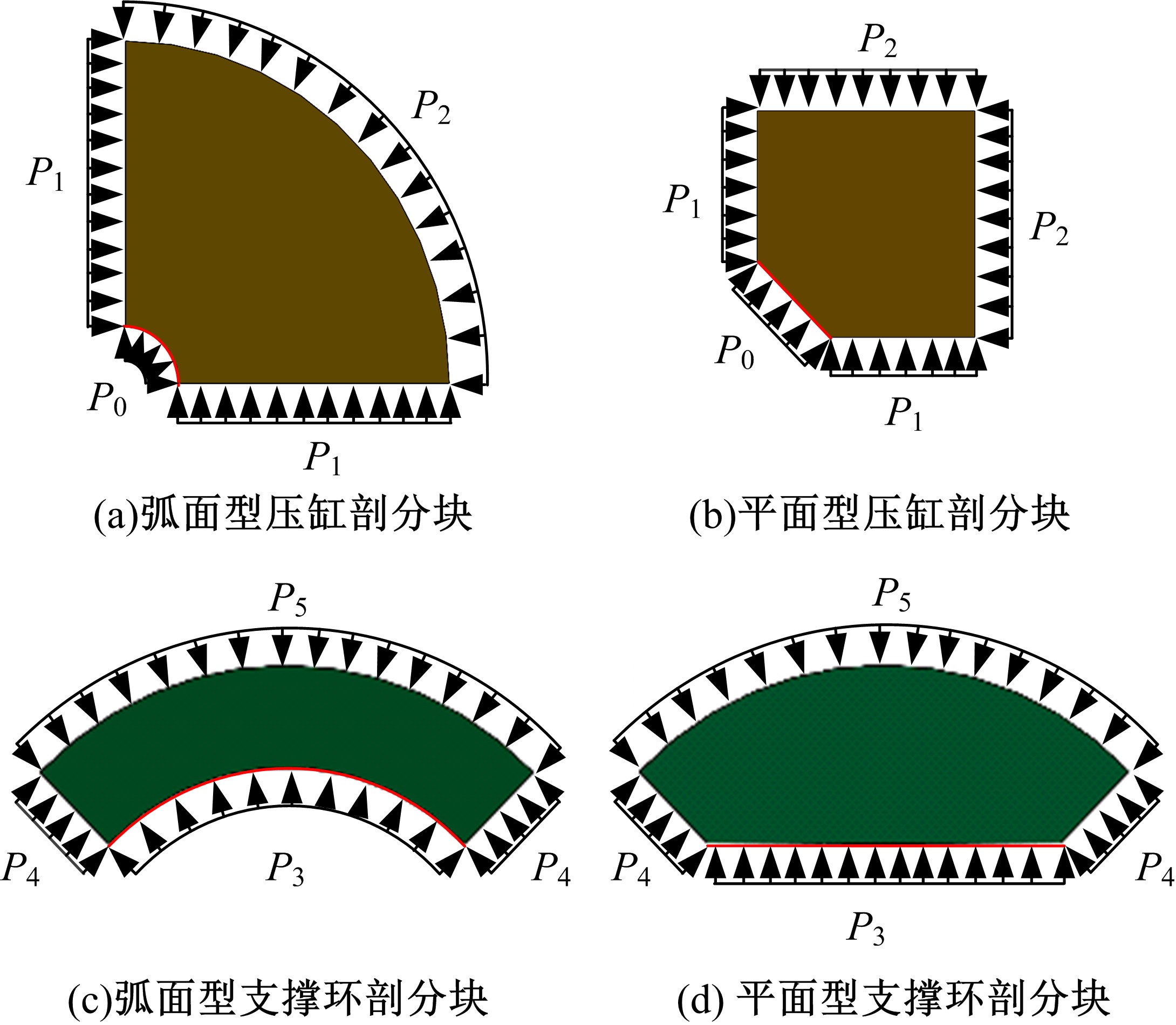

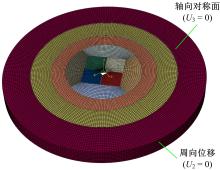

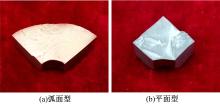

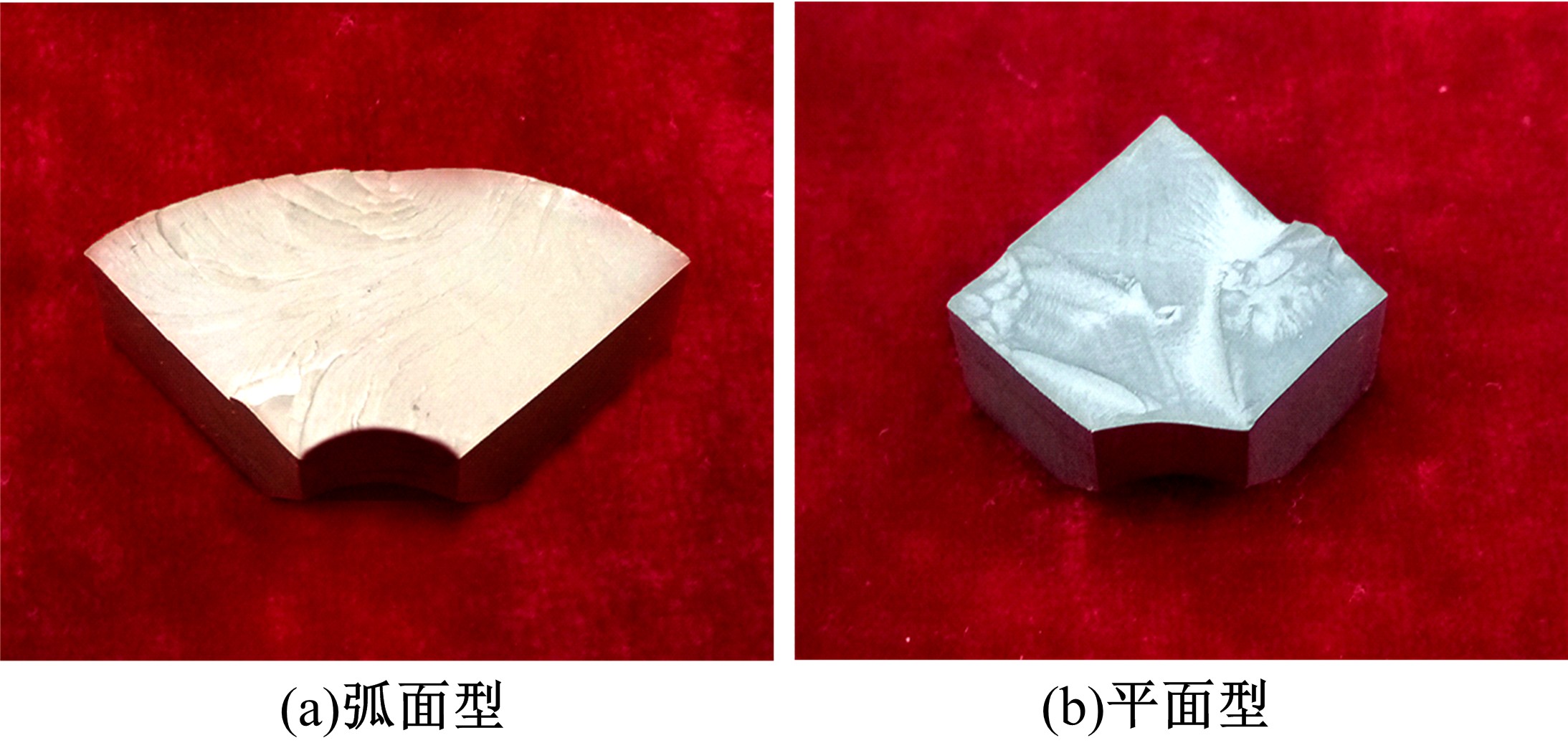

双层剖分式超高压模具数值模拟及实验

- 吉林大学 辊锻工艺研究所,长春 130022

Numerical simulation and experiment on double⁃layered split ultrahigh pressure die

Zhuo YI( ),Wen-zhi FU(

),Wen-zhi FU( ),Ming-zhe LI

),Ming-zhe LI

- Roll Forging Research Institute, Jilin University, Changchun 130022, China

摘要:

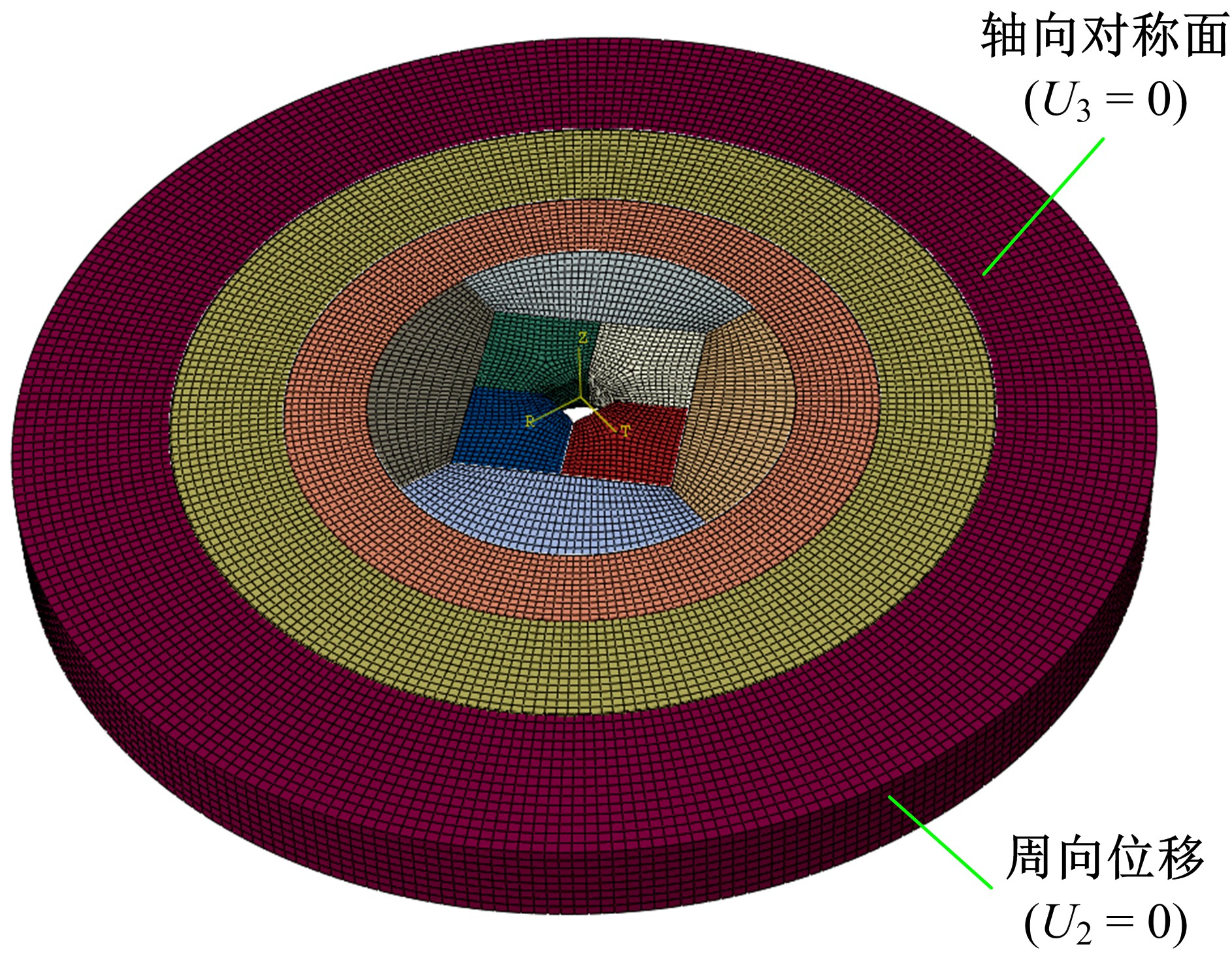

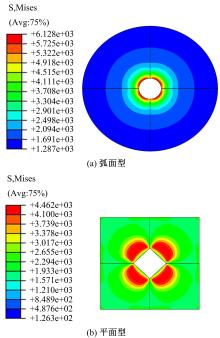

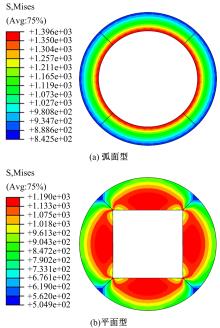

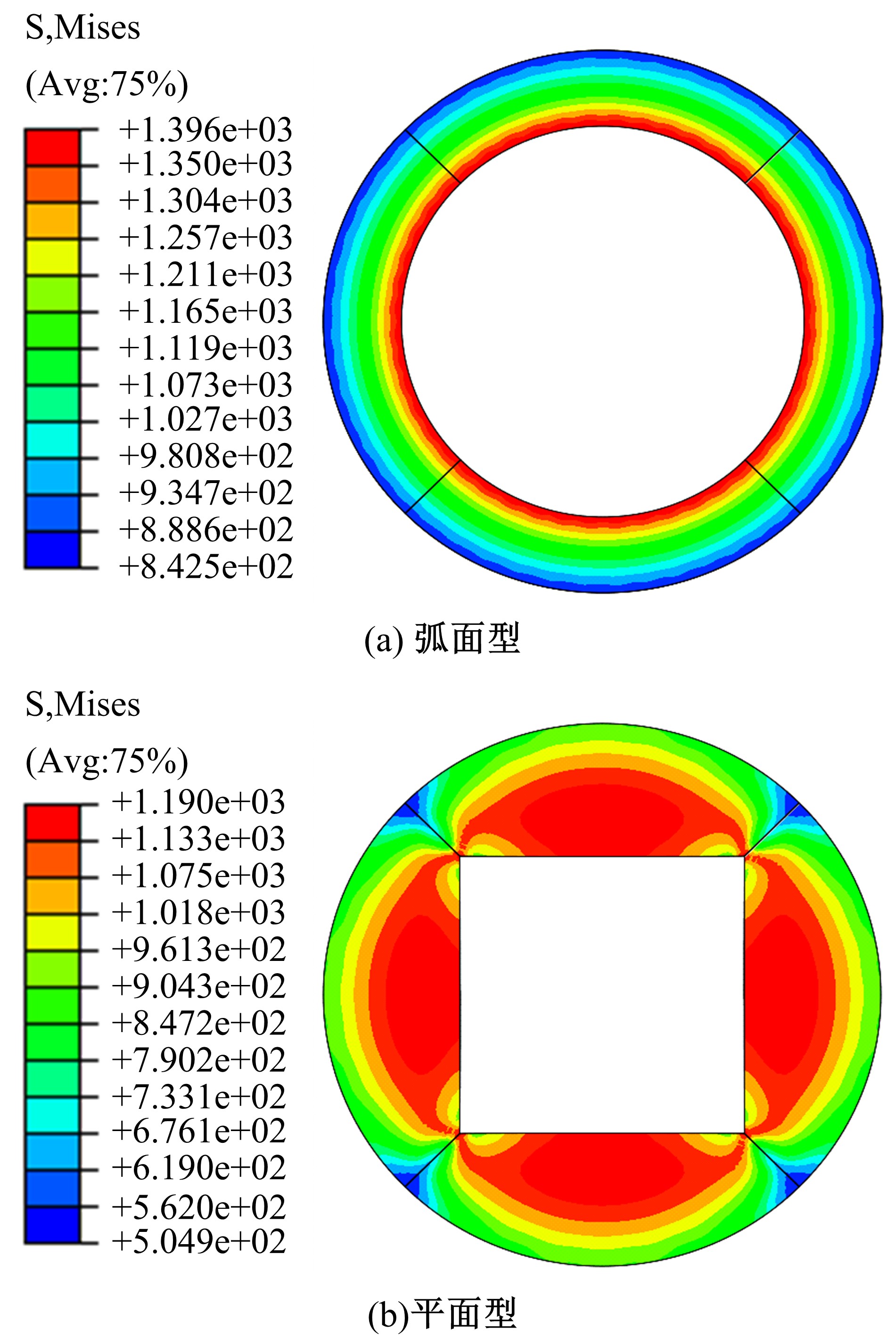

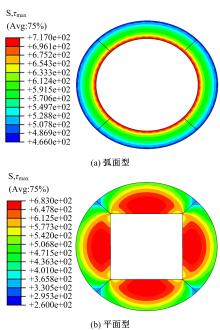

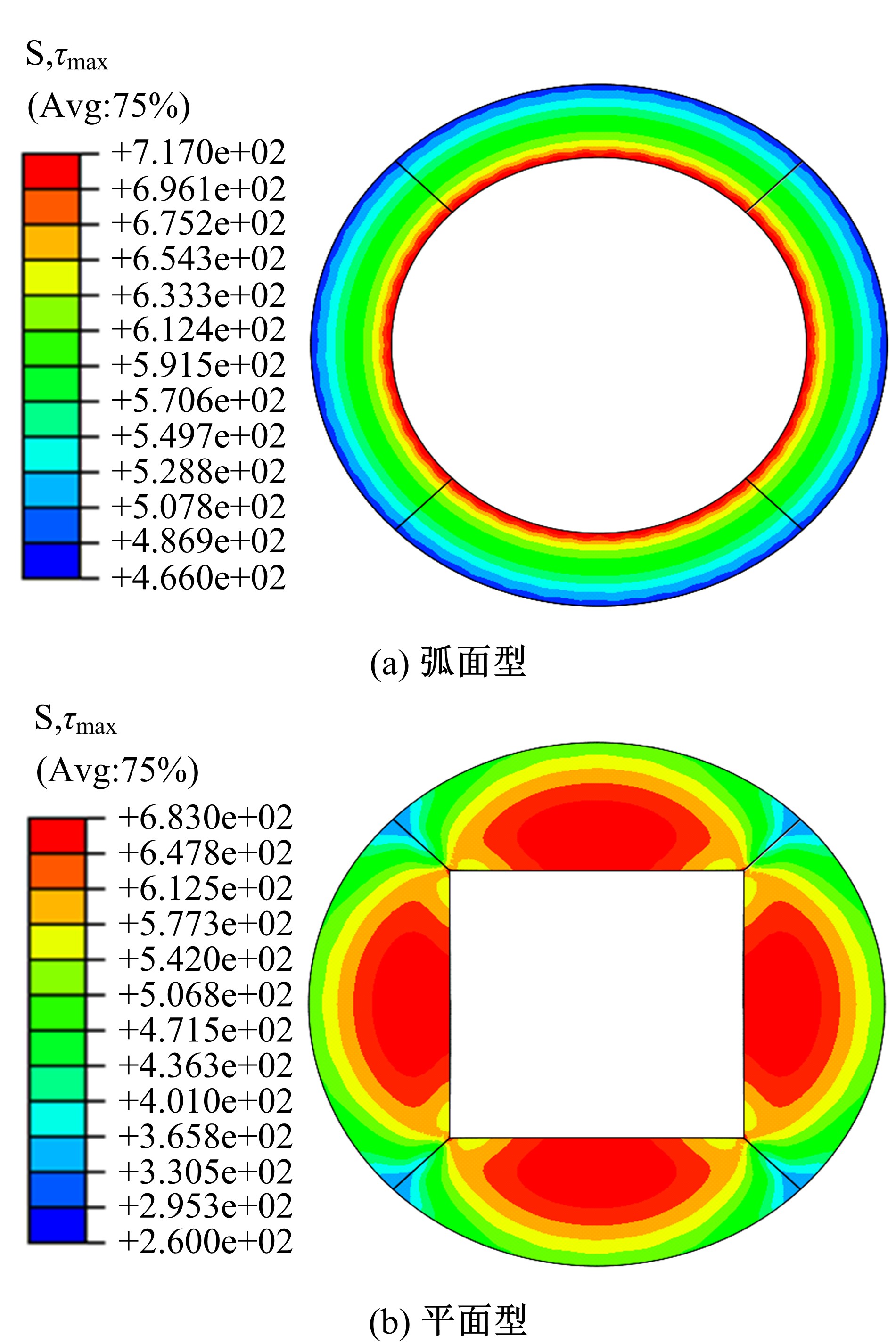

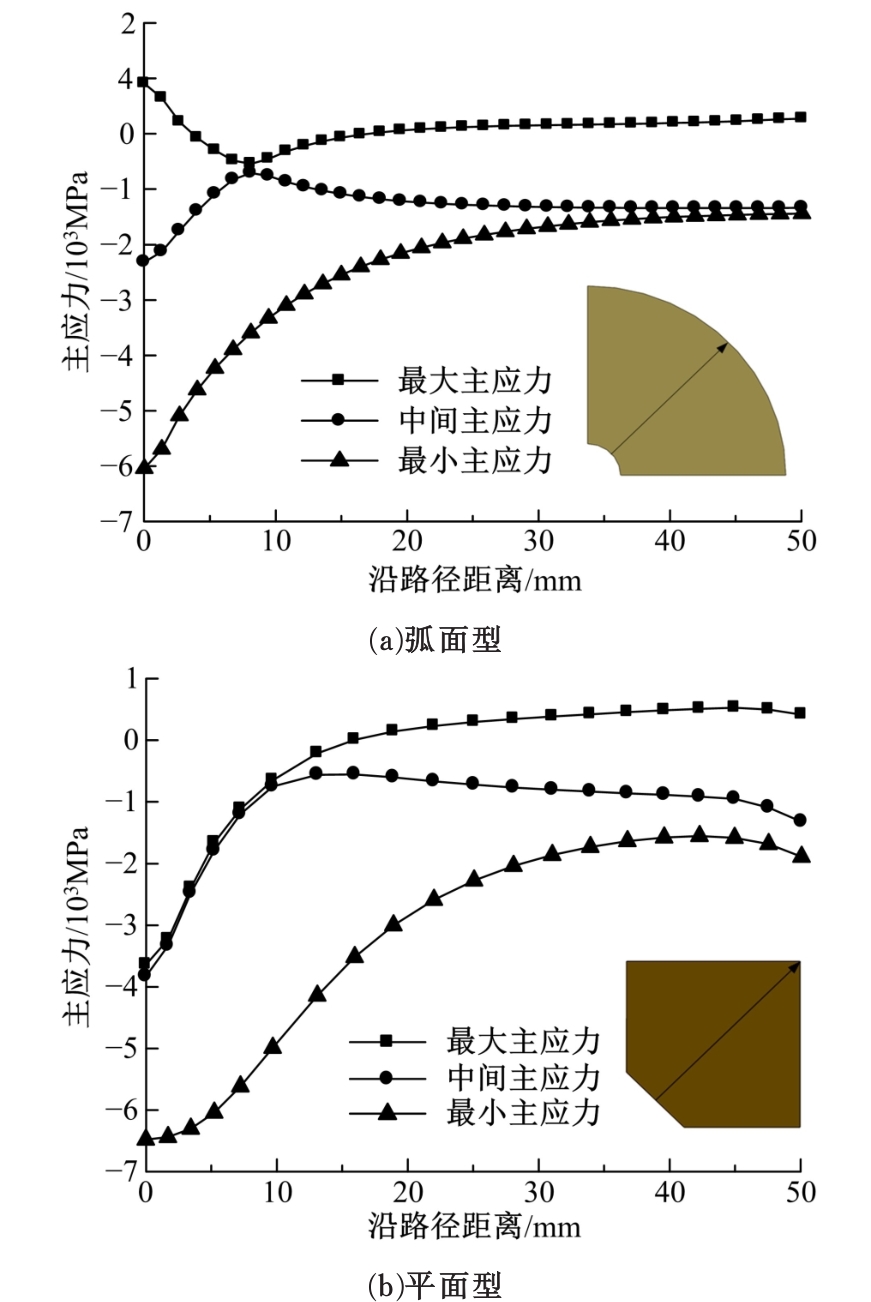

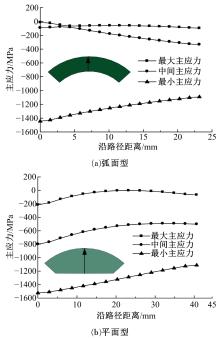

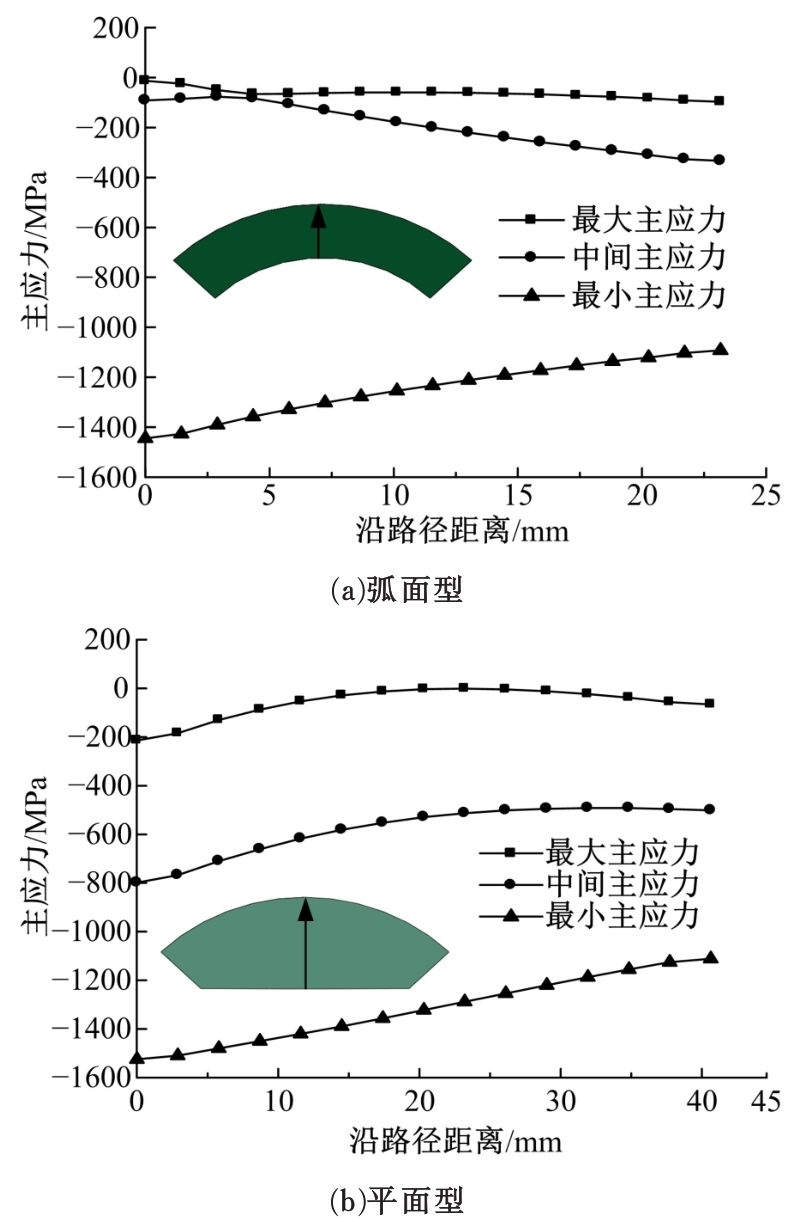

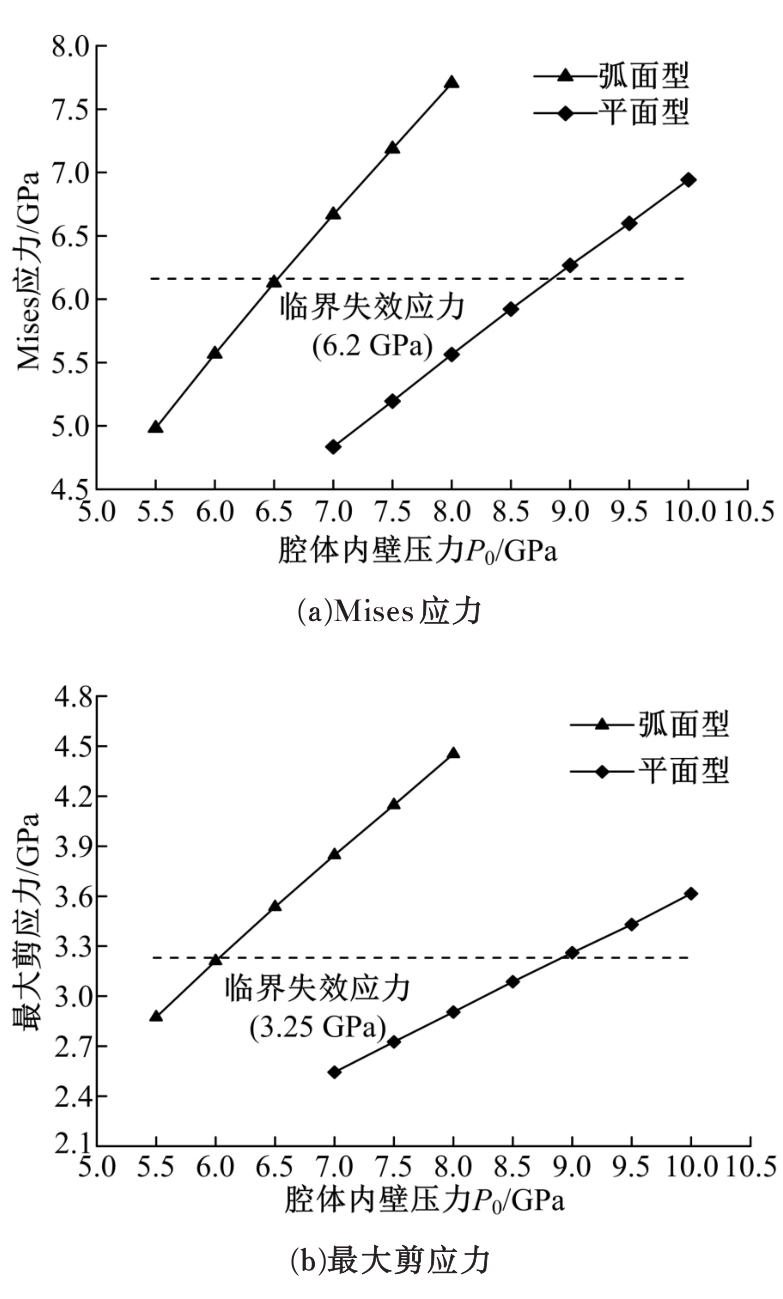

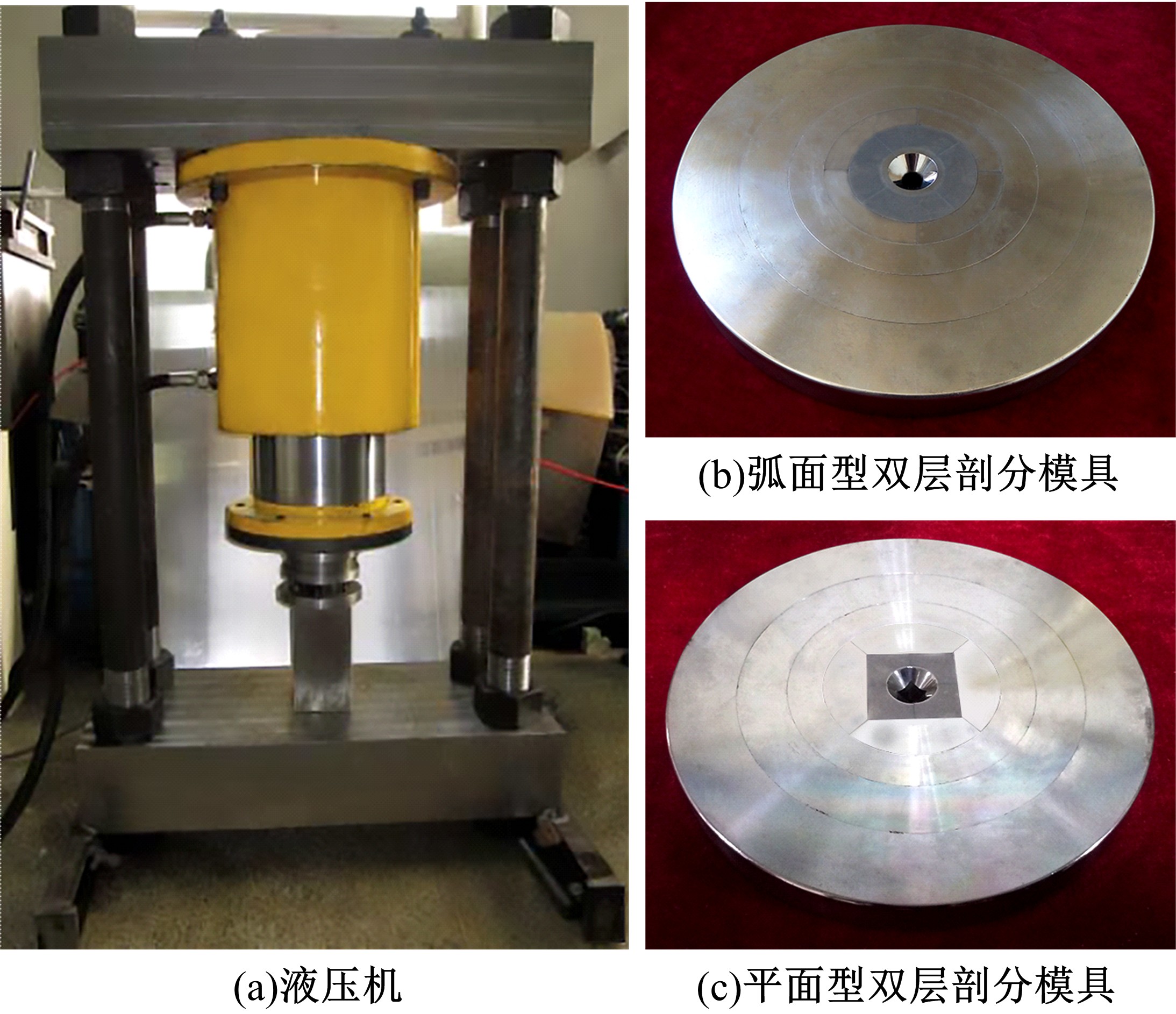

为获得更高的承压能力,研究了弧面型和平面型两种双层剖分式超高压模具,通过有限元方法对比分析了两种双层剖分式超高压模具的应力分布和承压能力。结果表明:平面型双层剖分式超高压模具能有效降低压缸和第一层支撑环应力,模具承压能力得到显著提高。与弧面型双层剖分式超高压模具相比,平面型双层剖分式超高压模具压缸的Mises应力和最大剪应力分别降低了27.2%、33.2%;第一层支撑环的Mises应力和最大剪应力分别降低了14.8%、4.7%。根据最大畸变能理论和最大剪应力理论,平面型双层剖分式超高压模具的承压能力分别提高了35.6%、47.1%。实验结果表明:平面型压缸双层剖分式超高压模具具有更高的承压能力。

中图分类号:

- TG375

| 1 | MiyakawaM, TaniguchiT. Homogeneous heating of a sample space by a modified heating assembly in a belt-type high-pressure apparatus[J/OL]. [2018-06-04]. https:⫽aip.scitation.org/doi/10.1063/1.4906818 |

| 2 | KawamuraF, WatanabeK, TakedaT, et al. Synthesis of high-crystallinity cubic-GaN nanoparticles using the Na flux method-a proposed new usage for a belt-type high-pressure apparatus[J]. Journal of Crystal Growth, 2011, 321(1): 100-105. |

| 3 | 臧传义, 马红安, 田宇, 等. 利用不同籽晶面生长优质宝石级金刚石单晶[J]. 吉林大学学报: 工学版, 2006, 36(1): 10-13. |

| ZangChuan-yi, MaHong-an, TianYu, et al. Growth of high-quality gem diamonds with different seed facets[J]. Journal of Jilin University (Engineering and Technology Edition), 2006, 36(1): 10-13. | |

| 4 | BocquillonG, LégerJ M, BogicevicC. Optimization of stress in the anvils of an opposed-movement multianvil device[J]. Measurement Science and Technology, 2002, 13(6): 885-894. |

| 5 | LiuZ W, LiM Z, YangY F, et al. Study on pressure capacity of multilayer stagger-split die, using simulation-based optimization[J]. High Pressure Research, 2013, 33(4): 787-794. |

| 6 | WangB L, LiM Z, YangY F, et al. Note: double-beveled multilayer stagger-split die for a large volume high-pressure apparatus[J/OL]. [2018-05-11]. https:⫽aip.scitation.org/doi/10.1063/1.4929712 |

| 7 | YangY F, LiM Z, LiuZ W, et al. Numerical simulation and experiment on split tungsten carbide cylinder of high pressure apparatus[J/OL]. [2018-04-06]. https:⫽aip.scitation.org/doi/full/10.1063/1.4939033 |

| 8 | 王光祖. 超硬材料制造与应用技术[M]. 郑州: 郑州大学出版社, 2013. |

| 9 | GettingI C, ChenG, BrownJ A. The strength and rheology of commercial tungsten carbide cermets used in high-pressure apparatus[J]. Pure and Applied Geophysics, 1993, 141(2-4): 545-577. |

| 10 | LiuZ W, LiM Z, HanQ G, et al. Numerical simulation and experiment on multilayer stagger-split die[J]. Review of Scientific Instruments, 2013, 84(5): 3-6. |

| 11 | HanQ G, LiM Z, JiaX P, et al. Finite element analysis and design of cubic high-pressure anvils based on the principle of lateral support[J]. Review of Scientific Instruments, 2010, 81(12): 1-4. |

| 12 | ZhaoL, LiM Z, YangY F, et al. Finite element analysis and experiment on high pressure apparatus with split cylinder[J]. High Pressure Research, 2017, 37(3): 1-12. |

| [1] | 李欣,王丹,陈军绪,孙延朋,谷诤巍,徐虹. 手刹固定板冲压成形数值模拟[J]. 吉林大学学报(工学版), 2019, 49(4): 1258-1265. |

| [2] | 刘文权,盈亮,荣海,胡平. 基于损伤修正M⁃K模型的高强度钢成形极限预测[J]. 吉林大学学报(工学版), 2019, 49(4): 1266-1271. |

| [3] | 张学广,贾明萌,刘纯国,何广忠. 基于增量控制的型材拉弯轨迹设计及有限元仿真[J]. 吉林大学学报(工学版), 2019, 49(4): 1272-1279. |

| [4] | 郭昊添,徐涛,梁逍,于征磊,刘欢,马龙. 仿鲨鳃扰流结构的过渡段换热表面优化设计[J]. 吉林大学学报(工学版), 2018, 48(6): 1793-1798. |

| [5] | 姜秋月,杨海峰,檀财旺. 22MnB5超高强钢焊接接头强化性能[J]. 吉林大学学报(工学版), 2018, 48(6): 1806-1810. |

| [6] | 宫亚峰, 王博, 魏海斌, 何自珩, 何钰龙, 申杨凡. 基于Peck公式的双线盾构隧道地表沉降规律[J]. 吉林大学学报(工学版), 2018, 48(5): 1411-1417. |

| [7] | 胡志清, 颜庭旭, 李洪杰, 吕振华, 廖伟, 刘庚. 深冷处理对铝合金薄板冲剪成形性能的影响[J]. 吉林大学学报(工学版), 2018, 48(5): 1524-1530. |

| [8] | 邱小明, 王银雪, 姚汉伟, 房雪晴, 邢飞. 基于灰色关联的DP1180/DP590异质点焊接头工艺参数优化[J]. 吉林大学学报(工学版), 2018, 48(4): 1147-1152. |

| [9] | 陈俊甫, 管志平, 杨昌海, 牛晓玲, 姜振涛, 宋玉泉. 金属棒试样拉伸和扭转试验应变范围和力学特性对比[J]. 吉林大学学报(工学版), 2018, 48(4): 1153-1160. |

| [10] | 刘子武, 李剑峰. 叶片材料FV520B再制造熔覆层冲蚀损伤行为及评价[J]. 吉林大学学报(工学版), 2018, 48(3): 835-844. |

| [11] | 梁晓波, 蔡中义, 高鹏飞. 夹芯复合板柱面成形的数值模拟及试验[J]. 吉林大学学报(工学版), 2018, 48(3): 828-834. |

| [12] | 刘纯国, 刘伟东, 邓玉山. 多点冲头主动加载路径对薄板拉形的影响[J]. 吉林大学学报(工学版), 2018, 48(1): 221-228. |

| [13] | 吕萌萌, 谷诤巍, 徐虹, 李欣. 超高强度防撞梁热冲压成形工艺优化[J]. 吉林大学学报(工学版), 2017, 47(6): 1834-1841. |

| [14] | 王辉, 周杰, 熊煜, 陶亚平, 向荣. 基于逆向工程的复杂曲面冲压件回弹补偿[J]. 吉林大学学报(工学版), 2017, 47(6): 1842-1847. |

| [15] | 张志强, 刘从豪, 何东野, 李湘吉, 李纪萱. 基于性能梯度分布的硼钢热冲压工艺对形状精度的影响[J]. 吉林大学学报(工学版), 2017, 47(6): 1829-1833. |

|

||