吉林大学学报(工学版) ›› 2019, Vol. 49 ›› Issue (5): 1521-1530.doi: 10.13229/j.cnki.jdxbgxb20180356

• • 上一篇

沥青混合料劈裂强度影响因素数值模拟

- 1. 浙江大学 交通工程研究所,杭州 310058

2. 中铁二院重庆勘察设计研究院有限责任公司,重庆 400023

Numerical simulation of influence factors of splitting strength of asphalt mixtures

Yong PENG1( ),Hua GAO1,Lei WAN1,Gui-ying LIU2

),Hua GAO1,Lei WAN1,Gui-ying LIU2

- 1. Institute of Transportation Engineering, Zhejiang University, Hangzhou 310058, China

2. China Railway Eryuan Engineering Group (Chongqing) Survey, Design and Research Co. Ltd. , Chongqing 400023, China

摘要:

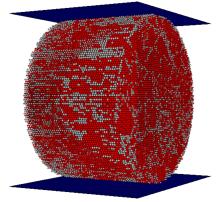

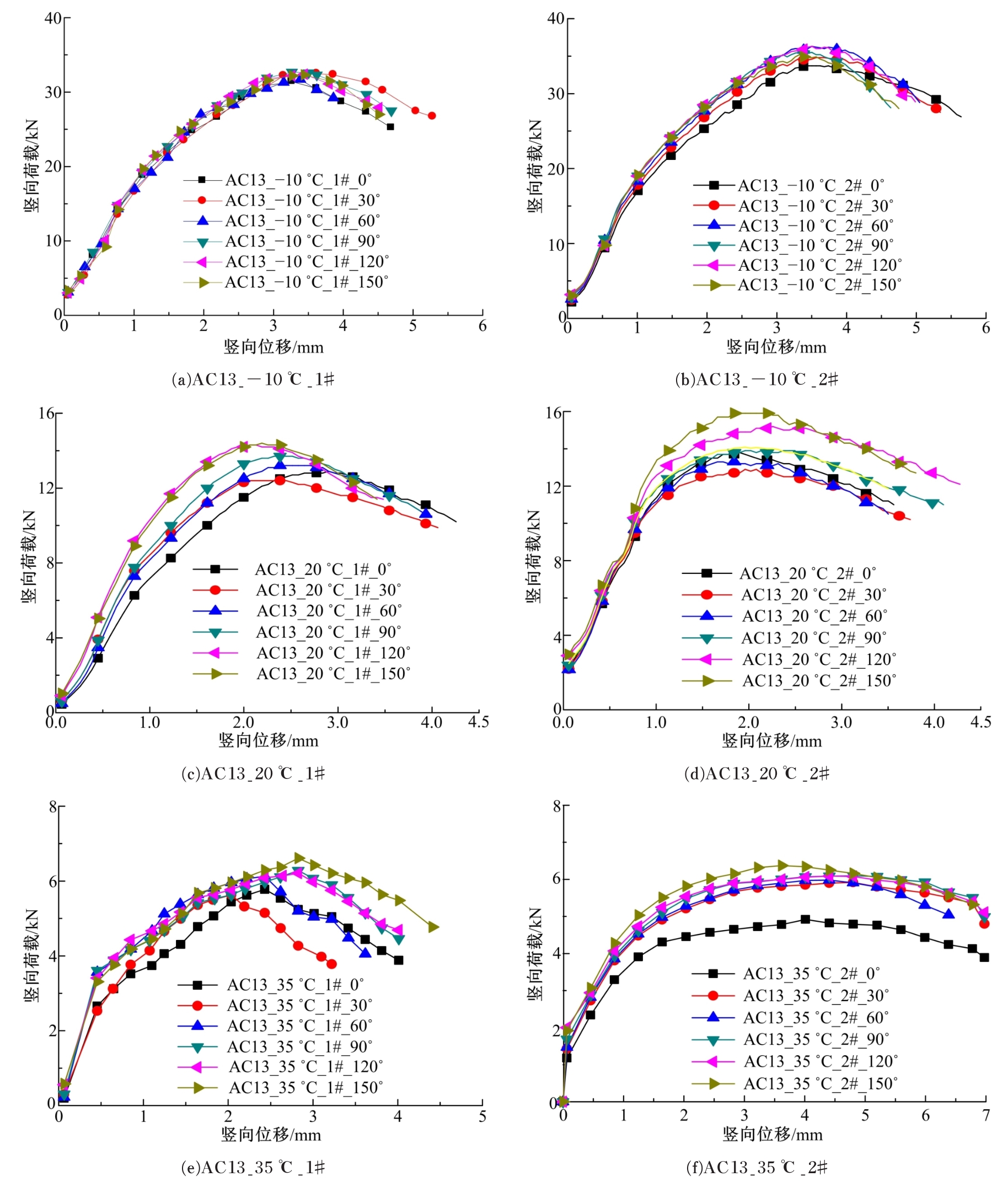

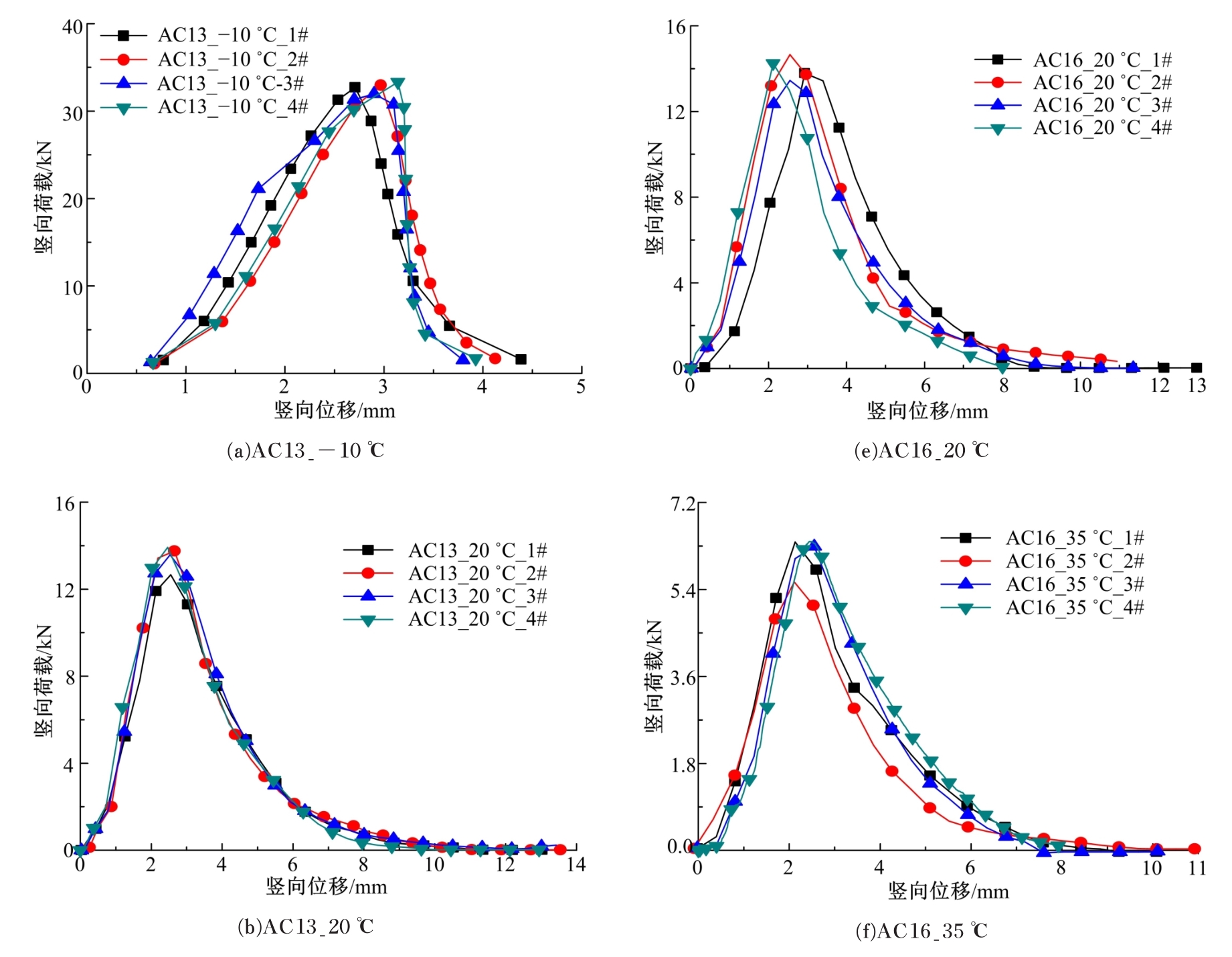

为数值研究沥青混合料劈裂强度影响因素,基于三维离散元法与粘聚带模型,建立了沥青混合料劈裂试验微观力学模型,模拟不同集料级配在不同温度下沥青混合料劈裂强度,并通过室内试验进行验证。研究结果表明:基于粘聚带模型和三维离散元法所建立的沥青混合料劈裂试验微观力学模型可较地好模拟沥青混合料劈裂强度。集料级配和温度对沥青混合料劈裂强度有显著影响。相同温度下,随着集料公称最大粒径变大,集料级配变粗,沥青混合料劈裂强度而逐渐增大;相同集料公称最大粒径时沥青混合料劈裂强度随温度的升高而逐渐降低。

中图分类号:

- U414

| 1 | RotherburgL, BogoboweczA, HaasR, et al. Micromechanical modeling of asphalt concrete in connection with pavement rutting problems[C]∥7th International Conference on Asphalt Pavements, Nottingham, United Kingdom, 1992. |

| 2 | ButtlarW G, YouZ. Discrete element modeling of asphalt concrete: microfabric approach[J]. Transportation Research Record Journal of the Transportation Research Board, 2001, 1757(1): 111-118. |

| 3 | AbbasA, MasadE A, PapagiannakisT, et al. Modelling asphalt mastic stiffness using discrete element analysis and micromechanics-based models[J]. International Journal of Pavement Engineering, 2005, 6(2): 137-146. |

| 4 | CollopA C, McdowellG R, LeeY W. Modelling dilation in an idealised asphalt mixture using discrete element modelling[J]. Granular Matter, 2006, 8(3): 175-184. |

| 5 | KimH, WagonerM P, ButtlarW G. Simulation of fracture behavior in asphalt concrete using a heterogeneous cohesive zone discrete element model[J]. Journal of Materials in Civil Engineering, 2008, 20(8): 552-563. |

| 6 | YouZ, AdhikariS, DaiQ. Three-dimensional discrete element models for asphalt mixtures[J]. Journal of Engineering Mechanics, 2008, 134(12): 1053-1063. |

| 7 | YouZ, LiuY, DaiQ. Three-dimensional microstructural-based discrete element viscoelastic modeling of creep compliance tests for asphalt mixtures[J]. Journal of Materials in Civil Engineering, 2011, 23(1): 79-87. |

| 8 | LiuY, YouZ. Visualization and simulation of asphalt concrete with randomly generated three-dimensional models[J]. Journal of Computing in Civil Engineering, 2009, 23(6): 340-347. |

| 9 | YuH, ShenS. Impact of aggregate packing on dynamic modulus of hot mix asphalt mixtures using three-dimensional discrete element method[J]. Construction & Building Materials, 2012, 26(1): 302-309. |

| 10 | PengY, HarveyJ T, SunL J. Three-dimensional discrete-element modeling of aggregate homogeneity influence on indirect tensile strength of asphalt mixtures[J/OL]. [2017-08-04]. |

| 11 | 杨宇亮. 沥青混合料细观结构的分析系统[D]. 上海: 同济大学交通运输工程学院, 2003. |

| YangYu-liang. Sub-microstructure analysis system of asphalt concrete[D]. Shanghai: School of Transportation Engineering, Tongji University, 2003. | |

| 12 | 张金喜, 张建华, 王德志. 关于低品质粗集料抗冻性能研究[J]. 混凝土, 2005(8): 11-15. |

| ZhangJin-xi, ZhangJian-hua, WangDe-zhi. Frost resistance of the low quality coarse-aggregate[J]. Concrete, 2005(8): 11-15. | |

| 13 | 刘贵应, 戴俊巍, 刘勇, 等. 集料均匀性对沥青混合料低温劈裂强度影响数值研究[J]. 低温建筑技术, 2018, 40(11): 12-16. |

| LiuGui-ying, DaiJun-wei, LiuYong, et al. Numerical simulation of aggregate uniformity influence on low temperature splitting strength of asphalt mixtures[J]. Low Temperature Architecture Technology, 2018, 40(11): 12-16. | |

| 14 | PengY, WanL, SunL J. Three-dimensional discrete element modelling of influence factors of indirect tensile strength of asphalt mixtures[J]. International Journal of Pavement Engineering, 2019, 20(6): 724-733. |

| [1] | 于天来,李海生,黄巍,王思佳. 预应力钢丝绳加固钢筋混凝土梁桥抗剪性能[J]. 吉林大学学报(工学版), 2019, 49(4): 1134-1143. |

| [2] | 李晓珍,柳俊哲,戴燕华,贺智敏,巴明芳,李玉顺. 碳化作用下水泥浆内亚硝酸根离子的含量分布[J]. 吉林大学学报(工学版), 2019, 49(4): 1162-1168. |

| [3] | 江亮,贺宜. 电动两轮车风险驾驶行为及事故影响因素分析[J]. 吉林大学学报(工学版), 2019, 49(4): 1107-1113. |

| [4] | 黄晓明,曹青青,刘修宇,陈嘉颖,周兴林. 基于路表分形摩擦理论的整车雨天制动性能模拟[J]. 吉林大学学报(工学版), 2019, 49(3): 757-765. |

| [5] | 王静,吕翔,曲肖龙,钟春玲,张云龙. 路基土抗剪强度与化学及矿物成分的关系[J]. 吉林大学学报(工学版), 2019, 49(3): 766-772. |

| [6] | 李伊,刘黎萍,孙立军. 沥青面层不同深度车辙等效温度预估模型[J]. 吉林大学学报(工学版), 2018, 48(6): 1703-1711. |

| [7] | 毕秋实,王国强,黄婷婷,毛瑞,鲁艳鹏. 基于DEM-FEM耦合的双齿辊破碎机辊齿强度分析[J]. 吉林大学学报(工学版), 2018, 48(6): 1770-1776. |

| [8] | 王扬, 王晓梅, 陈泽仁, 于建群. 基于离散元法的玉米籽粒建模[J]. 吉林大学学报(工学版), 2018, 48(5): 1537-1547. |

| [9] | 臧国帅, 孙立军. 基于惰性弯沉点的刚性下卧层深度设置方法[J]. 吉林大学学报(工学版), 2018, 48(4): 1037-1044. |

| [10] | 念腾飞, 李萍, 林梅. 冻融循环下沥青特征官能团含量与流变参数灰熵分析及微观形貌[J]. 吉林大学学报(工学版), 2018, 48(4): 1045-1054. |

| [11] | 宫亚峰, 申杨凡, 谭国金, 韩春鹏, 何钰龙. 不同孔隙率下纤维土无侧限抗压强度[J]. 吉林大学学报(工学版), 2018, 48(3): 712-719. |

| [12] | 王扬, 吕凤妍, 徐天月, 于建群. 大豆籽粒形状和尺寸分析及其建模[J]. 吉林大学学报(工学版), 2018, 48(2): 507-517. |

| [13] | 程永春, 毕海鹏, 马桂荣, 宫亚峰, 田振宏, 吕泽华, 徐志枢. 纳米TiO2/CaCO3-玄武岩纤维复合改性沥青的路用性能[J]. 吉林大学学报(工学版), 2018, 48(2): 460-465. |

| [14] | 季文玉, 李旺旺, 过民龙, 王珏. 预应力RPC-NC叠合梁挠度试验及计算方法[J]. 吉林大学学报(工学版), 2018, 48(1): 129-136. |

| [15] | 张仰鹏, 魏海斌, 贾江坤, 陈昭. 季冻区组合冷阻层应用表现的数值评价[J]. 吉林大学学报(工学版), 2018, 48(1): 121-126. |

|

||