吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (1): 181-187.doi: 10.13229/j.cnki.jdxbgxb20190967

• 材料科学与工程 • 上一篇

硅炭黑改性玄武岩纤维增强聚酰胺6复合材料性能

- 吉林大学 材料科学与工程学院,长春 130022

Performance of silica carbon black modified basalt fiber reinforced polyamide 6 composite

Yi LI( ),Dong-di HUANG,Kai-feng YU(

),Dong-di HUANG,Kai-feng YU( ),Ji-cai LIANG,Xiao-ling HE,Xi-tong REN

),Ji-cai LIANG,Xiao-ling HE,Xi-tong REN

- College of Materials Science and Engineering,Jilin University,Changchun 130022,China

摘要:

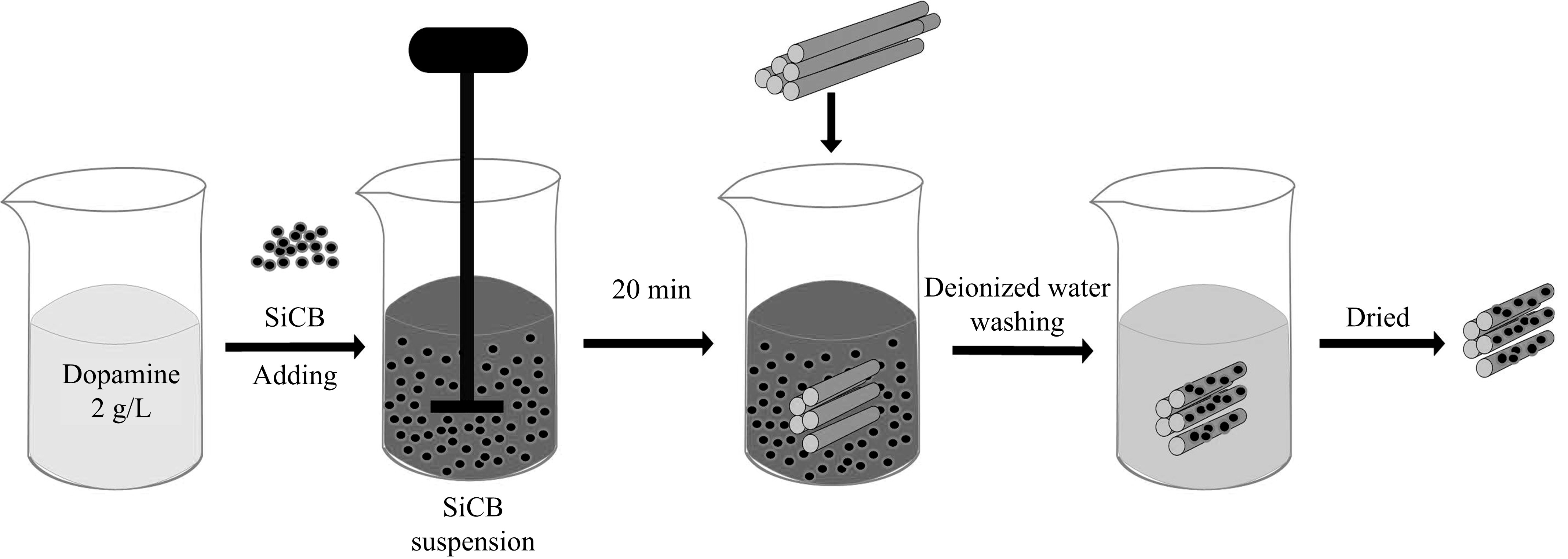

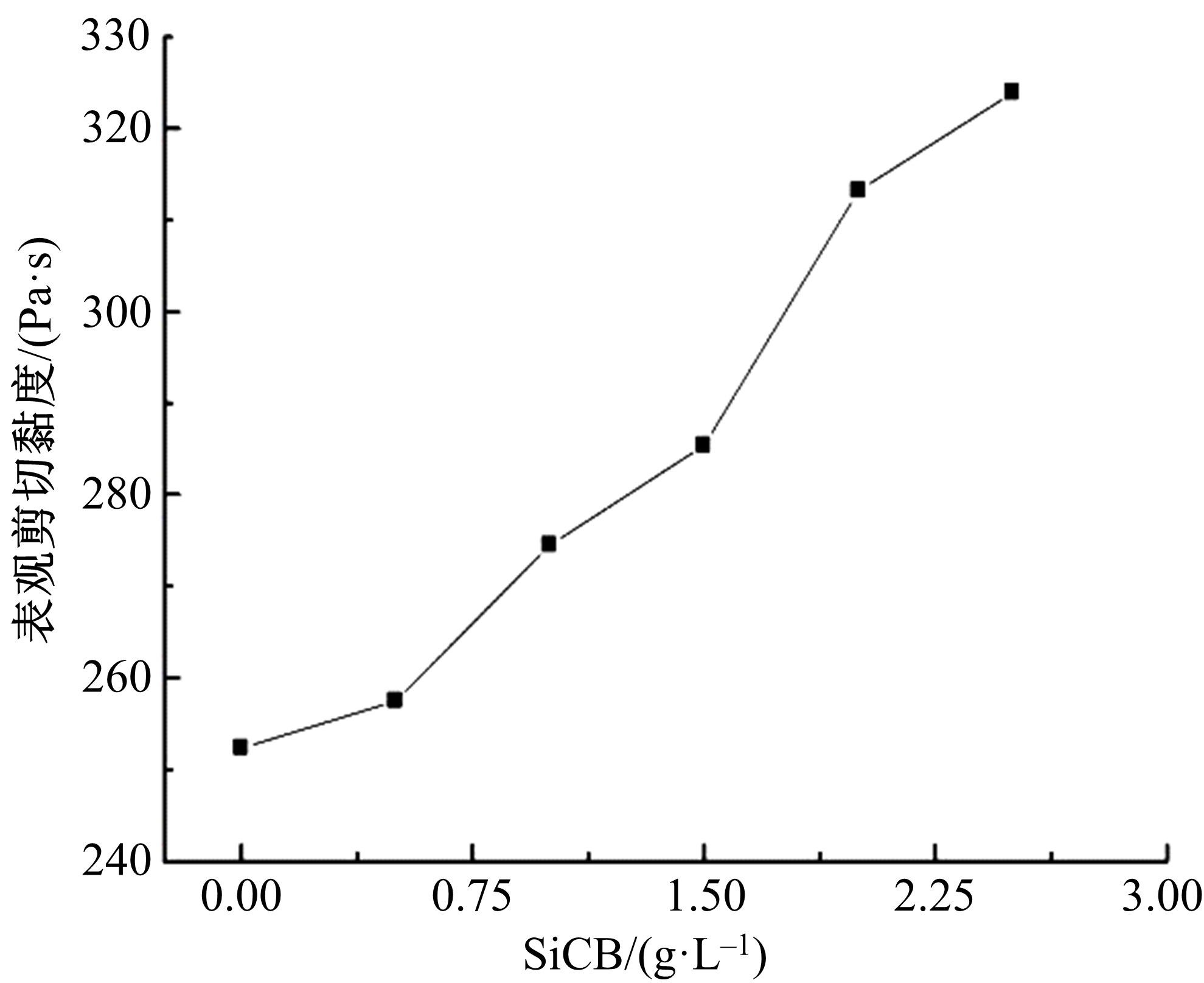

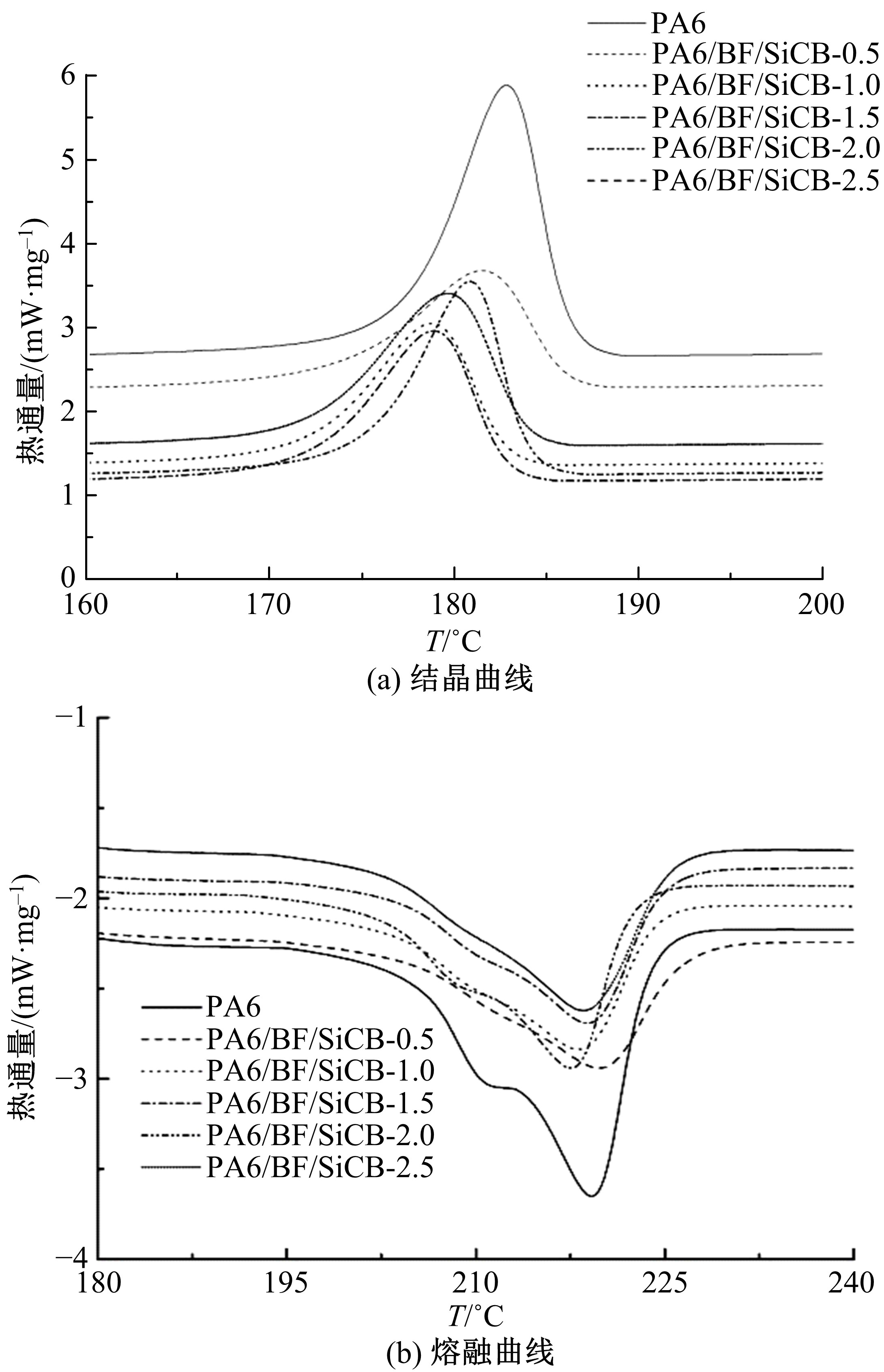

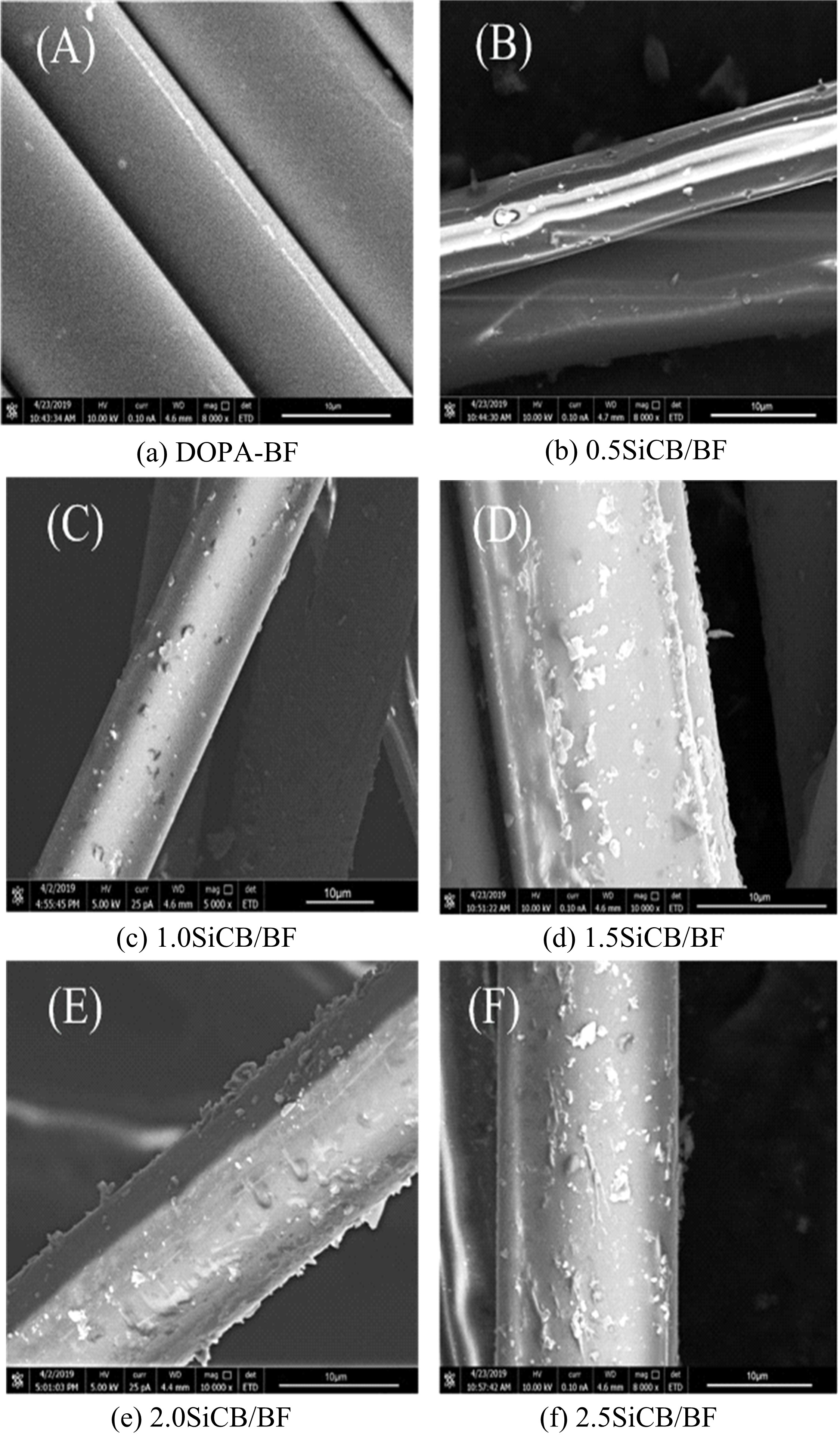

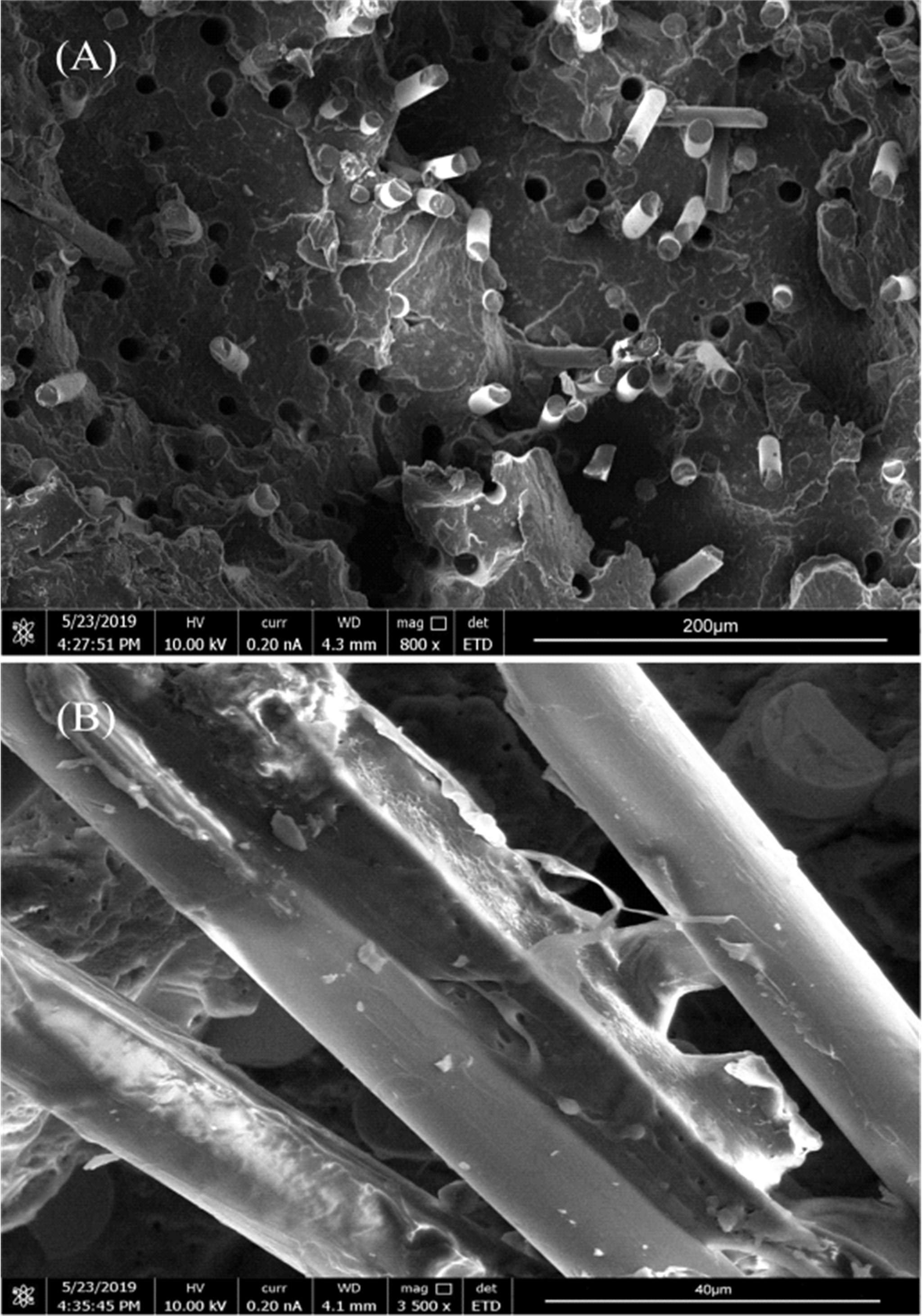

采用多巴胺(DOPA)溶液将硅炭黑(SiCB)分散在玄武岩纤维表面实现改性处理,提高玄武岩纤维(BF)与聚酰胺6(PA6)的界面结合性能。探究了不同SiCB含量对玄武岩纤维/聚酰胺6(BF/PA6)复合材料性能的影响。采用傅里叶红外光谱、差式扫描量热仪(DSC)和扫描电镜(SEM)对改性复合材料的微观形貌与结构进行表征,通过静力学测试对复合材料的断裂行为进行评估。SiCB的含量为2.0 g/L时,复合材料的拉伸强度和冲击强度分别提高了109.4%和89.3%。SEM结果表明,硅炭黑较好地均匀分散在BF表面,同时DCS结果表明,硅炭黑有效地降低了PA6的结晶焓,提高了PA6的结晶度。

中图分类号:

- TQ327.9

| 1 | Colombo C, Vergani L, Burman M. Static and fatigue characterisation of new basalt fibre reinforced composites[J]. Composite Structures, 2012, 94(3): 1165-1174. |

| 2 | 谢尔盖. 玄武岩纤维的特性及其在中国的应用前景[J]. 玻璃纤维, 2005(5): 44-48. |

| Sergei O A. Characteristics of basalt fiber and its application prospect in China[J]. Fiber Glass, 2005(5): 44-48. | |

| 3 | Elsabbagh A, Steuernagel L, Ring J. Natural Fibre/PA6 composites with flame retardance properties: Extrusion and characterisation[J]. Composites Part B: Engineering, 2017, 108: 325-333. |

| 4 | Guo Y M, Li Y, Wang S N, et al. Effect of silanetreatment on adhesion of adhesive-bonded carbon fiber reinforced nylon 6 composite[J]. International Journal of Adhesion and Adhesives, 2019, 91: 102-115. |

| 5 | Dhand V, Mittal G, Rhee K Y, et al. A short review on basalt fiber reinforced polymer composites[J]. Composites Part B: Engineering, 2015, 73: 166-180. |

| 6 | 雷静, 党新安, 李建军. 玄武岩纤维的性能应用及最新进展[J]. 化工新型材料, 2007, 35(3): 9-11. |

| Lei Jing, Dang Xin-an, Li Jian-jun. Characteristic, application and development of basalt fiber[J]. New Chemical Materials, 2007, 35(3): 9-11. | |

| 7 | Karolina M, Stanislaw K, Kamila S. Mechanical, fire, and smoke behaviour of hybrid composites based on polyamide 6 with basalt/carbonfibres[J]. Journal of Composite Materials, 2019, 53(28-30): 3979-3991. |

| 8 | Lee T W, Lee S, Park S M, et al. Mechanical, thermomechanical, and local anisotropy analyses of long basalt fiber reinforced polyamide 6 composites[J]. Composite Structures, 2019, 222: 110917. |

| 9 | Yu S, Oh K H, Hong S H. Effects of silanization and modification treatments on the stiffness and toughness of BF/SEBS/PA6,6 hybrid composites[J]. Composites Part B: Engineering, 2019, 173: 106922. |

| 10 | Kovačević S, Brnada S, Dubrovski P D. Analysis of the mechanical properties of woven fabrics from glass and basalt yarns[J]. Fibres and Textiles in Eastern Europe, 2015, 23(6): 83-91. |

| 11 | Pak S, Park S, Song Y S, et al. Micromechanical and dynamic mechanical analyses for characterizing improved interfacial strength of maleic anhydride compatibilized basalt fiber/polypropylene composites[J]. Composite Structures, 2018, 193: 73-79. |

| 12 | 王辉, 王军杰, 王书展, 等. POE-g-MAH改性PA6/BF复合材料的力学和摩擦磨损性能研究[J]. 塑料工业, 2017, 45(4): 36-39, 76. |

| Wang Hui,Wang Jun-jie, Wang Shu-zhan, et al. Effect of POE-g-MAH on the mechanical and tribological properties of polyamide 6/basalt fiber composites[J]. China Plastics Industry, 2017, 45(4): 36-39, 76. | |

| 13 | Zegaoui A, Derradji M, Ma R, et al. High -performance polymeric materials with greatly improved mechanical and thermal properties from cyanate ester/benzoxazine resin reinforced by silane-treated basalt fibers[J]. Journal of Applied Polymer Science, 2018, 135: 46283. |

| 14 | Wu G M, Hung C H, You J H, et al. Surface modification of reinforcement fibers for composites by acid treatments[J]. Journal of Polymer Research, 2004, 11(1): 31-36. |

| 15 | Wang G J, Liu Y W, Guo Y J, et al. Surface modification and characterizations of basalt fibers with non-thermal plasma[J]. Surface and Coatings Technology, 2007, 201(15): 6565-6568. |

| 16 | Manikandan V, Winowlin Jappes J T, Suresh Kumar S M, et al. Investigation of the effect of surface modifications on the mechanical properties of basalt fibre reinforced polymer composites[J]. Composites Part B: Engineering, 2012, 43(2): 812-818. |

| 17 | Lee J J, Nam I, Kim H. Thermal stability and physical properties of epoxy composite reinforced with silane treated basalt fiber[J]. Fibers and Polymers, 2017, 18: 140-147. |

| 18 | Mondragon G, Santamaria-Echart A, Hormaiztegui M E V, et al. Nanocomposites of waterborne polyurethane reinforced with cellulose nanocrystals fromSisal fibres[J]. Journal of Polymers and the Environment, 2017, 26: 1869-1880. |

| 19 | 周玉. 硅炭黑/高分子聚合物复合材料的制备及性能研究[D]. 长春:吉林大学化学学院,2017. |

| Zhou Yu. A study about the preparation and performance of silica carbon black/polymer composites[D]. Changchun: College of Chemistry, Jilin University, 2017. | |

| 20 | Sa R, Yan Y, Wei Z H, et al. Surface modification of aramid fibers by bio-inspired poly(dopamine) and epoxy functionalized silane grafting[J]. Applied Materials & Interfaces(ACS), 2014, 6(23): 21730-21738. |

| [1] | 杨帆,张旭东,赵蒙,折波,邓俊楷. 基于有限元计算的形状记忆合金⁃金属玻璃复合材料变形行为[J]. 吉林大学学报(工学版), 2021, 51(1): 172-180. |

| [2] | 慕文龙,那景新,谭伟,王广彬,申浩,栾建泽. 基于FTIR分析的CFRP-铝合金粘接接头剩余强度预测[J]. 吉林大学学报(工学版), 2021, 51(1): 139-146. |

| [3] | 叶辉,刘畅,闫康康. 纤维增强复合材料在汽车覆盖件中的应用[J]. 吉林大学学报(工学版), 2020, 50(2): 417-425. |

| [4] | 朱春凤,程永春,梁春雨,肖波. 硅藻土⁃玄武岩纤维复合改性沥青混合料路用性能试验[J]. 吉林大学学报(工学版), 2020, 50(1): 165-173. |

| [5] | 叶辉,朱艳荣,蒲永锋. 纤维增强复合材料应变率效应的数值仿真[J]. 吉林大学学报(工学版), 2019, 49(5): 1622-1629. |

| [6] | 马芳武,韩露,周阳,王世英,蒲永锋. 采用聚乳酸复合材料的汽车零件多材料优化设计[J]. 吉林大学学报(工学版), 2019, 49(5): 1385-1391. |

| [7] | 李碧雄,廖桥,章一萍,周练,隗萍,刘侃. 超高强钢筋工程用水泥基复合材料梁受弯计算理论[J]. 吉林大学学报(工学版), 2019, 49(4): 1153-1161. |

| [8] | 那景新,刘浩垒,范以撒,秦国锋,浦磊鑫. 湿热环境对车用粘接剂拉伸强度的影响[J]. 吉林大学学报(工学版), 2019, 49(3): 822-828. |

| [9] | 程永春, 毕海鹏, 马桂荣, 宫亚峰, 田振宏, 吕泽华, 徐志枢. 纳米TiO2/CaCO3-玄武岩纤维复合改性沥青的路用性能[J]. 吉林大学学报(工学版), 2018, 48(2): 460-465. |

| [10] | 胡志清, 郑会会, 徐亚男, 张春玲, 党停停. 表面微沟槽对Al/CFRP胶结性能的影响[J]. 吉林大学学报(工学版), 2018, 48(1): 229-235. |

| [11] | 刘耀辉, 陈乔旭, 宋雨来, 沈艳东. 火山灰-SBS、胶粉-SBS和SBS改性沥青压缩变形行为及机理[J]. 吉林大学学报(工学版), 2017, 47(6): 1861-1867. |

| [12] | 李静, 王哲. 真三轴加载条件下混凝土的力学特性[J]. 吉林大学学报(工学版), 2017, 47(3): 771-777. |

| [13] | 杨悦, 李雪, 徐晓丹. Ti-B-C-N粉末烧结的微观组织及其性能[J]. 吉林大学学报(工学版), 2017, 47(2): 552-556. |

| [14] | 陈江义, 刘保元. 纤维断裂损伤对复合材料板中导波频散特性的影响[J]. 吉林大学学报(工学版), 2017, 47(1): 180-184. |

| [15] | 关庆丰, 黄尉, 李怀福, 龚晓花, 张从林, 吕鹏. 强流脉冲电子束诱发的Cu-C扩散合金化[J]. 吉林大学学报(工学版), 2016, 46(6): 1967-1973. |

|

||