吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (3): 810-819.doi: 10.13229/j.cnki.jdxbgxb20200070

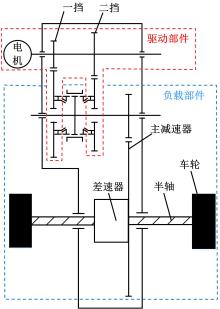

纯电动车机械式自动变速器换挡非线性建模及控制

- 1.北京理工大学 机械与车辆学院,北京 100081

2.北京理工大学 电动车辆国家工程实验室,北京 100081

Shift nonlinear modeling and control of automated mechanical transmission in pure electric vehicle

Qiang SONG1,2( ),Dan-ting SUN1,2,Wei ZHANG1,2

),Dan-ting SUN1,2,Wei ZHANG1,2

- 1.School of Mechanical Engineering,Beijing Institute of Technology,Beijing 100081,China

2.National Engineering Laboratory for Electric Vehicles,Beijing Institute of Technology,Beijing 100081,China

摘要:

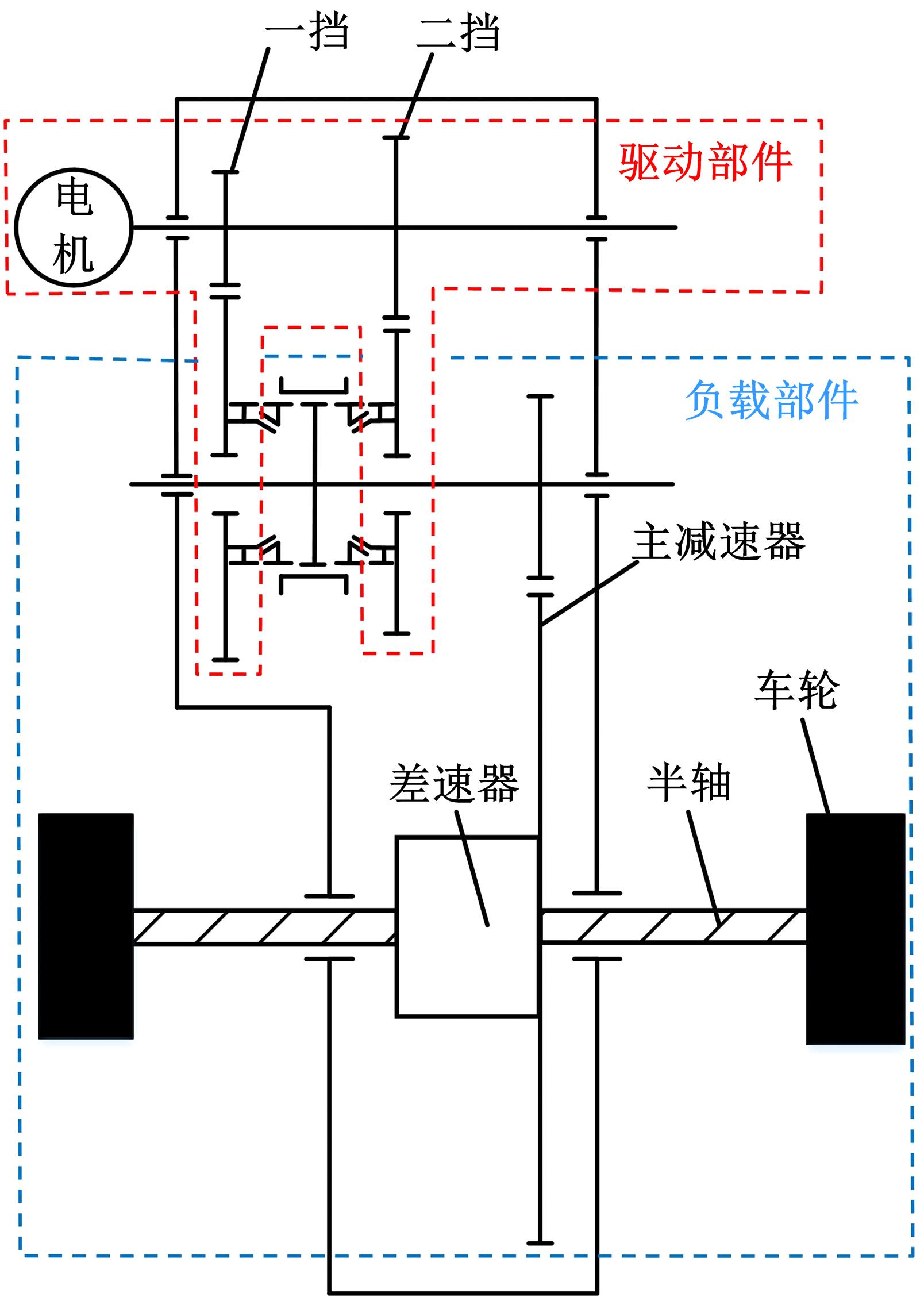

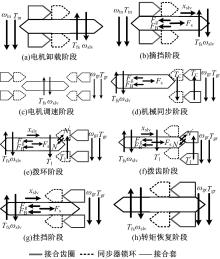

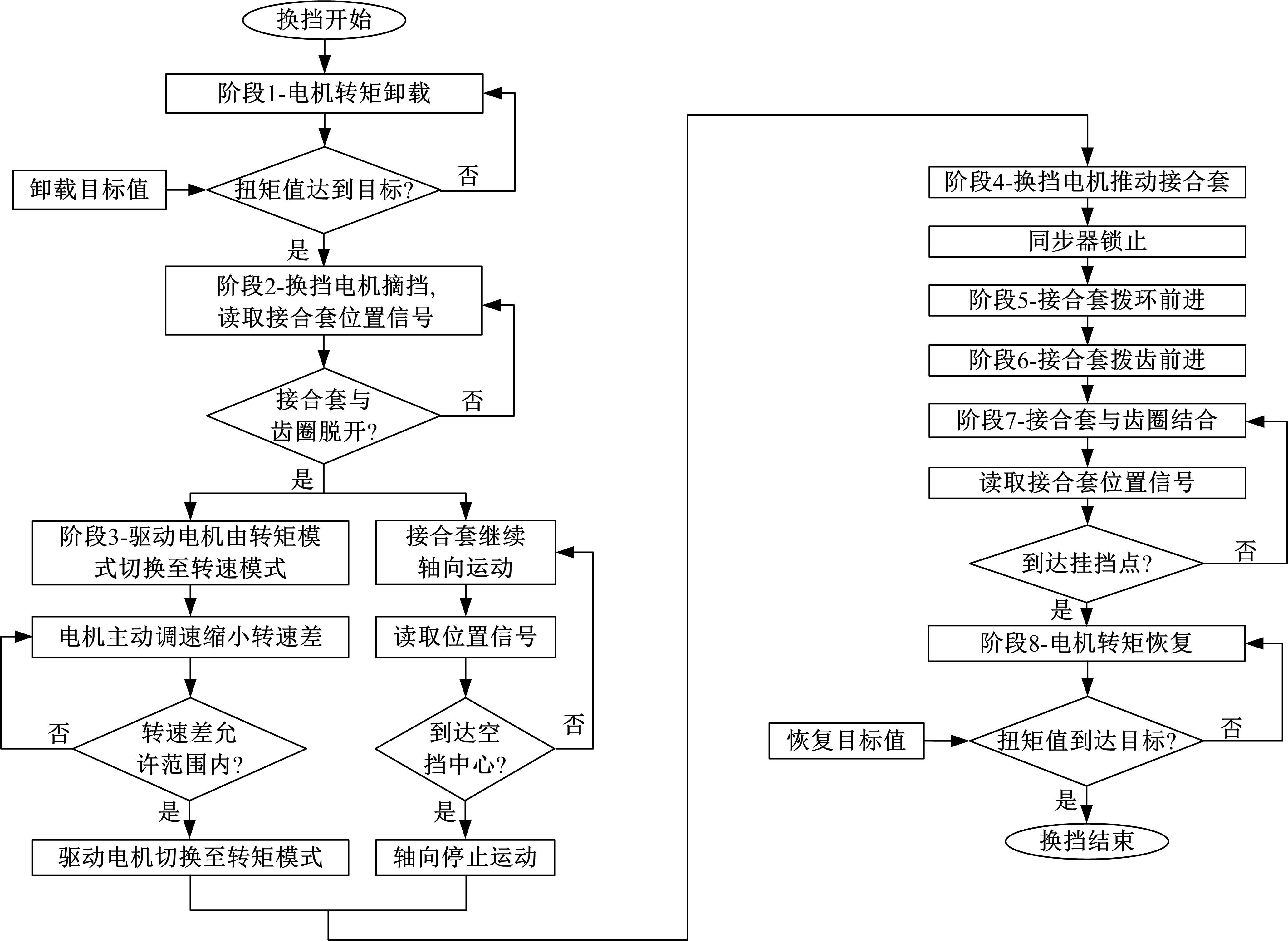

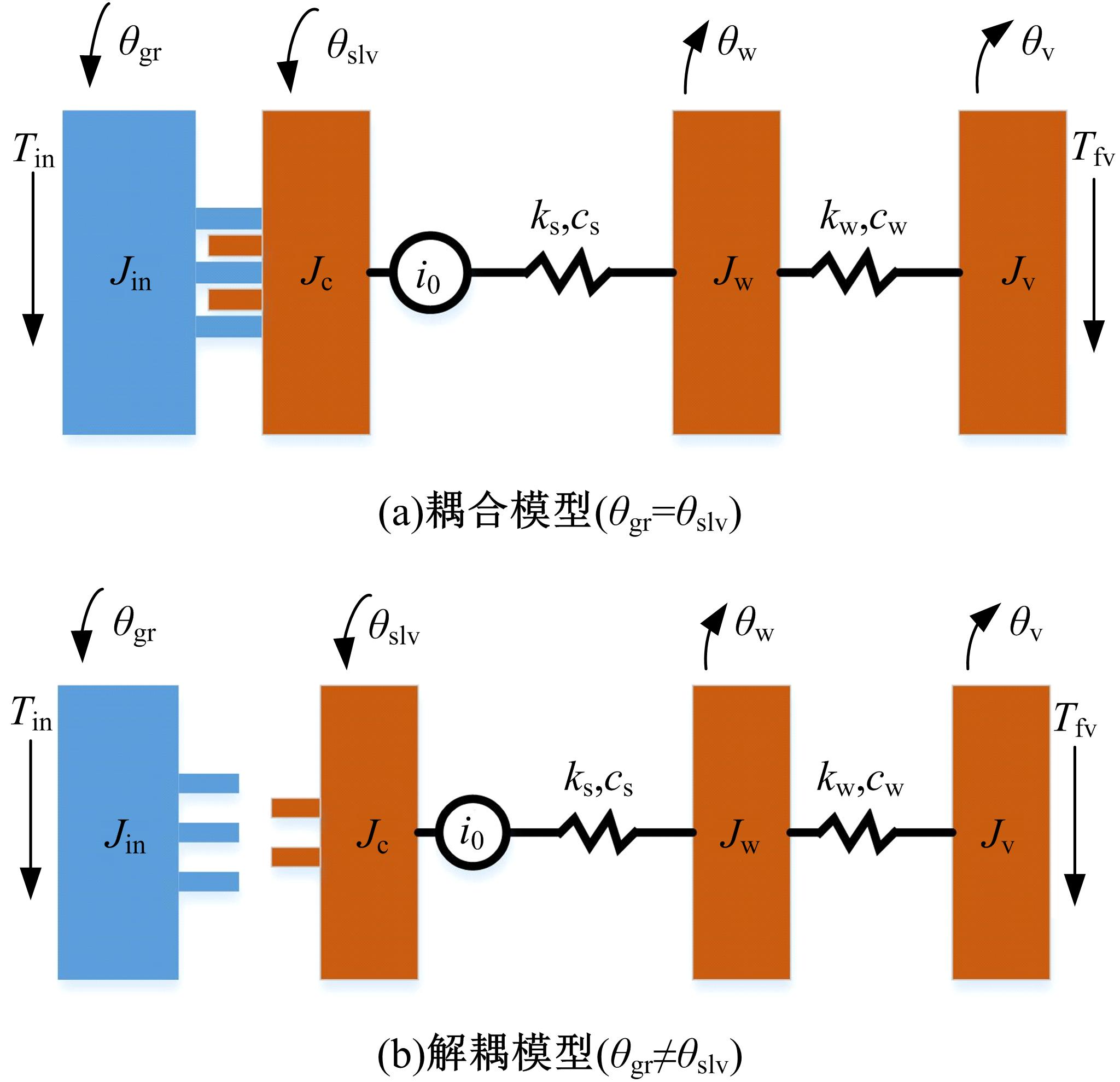

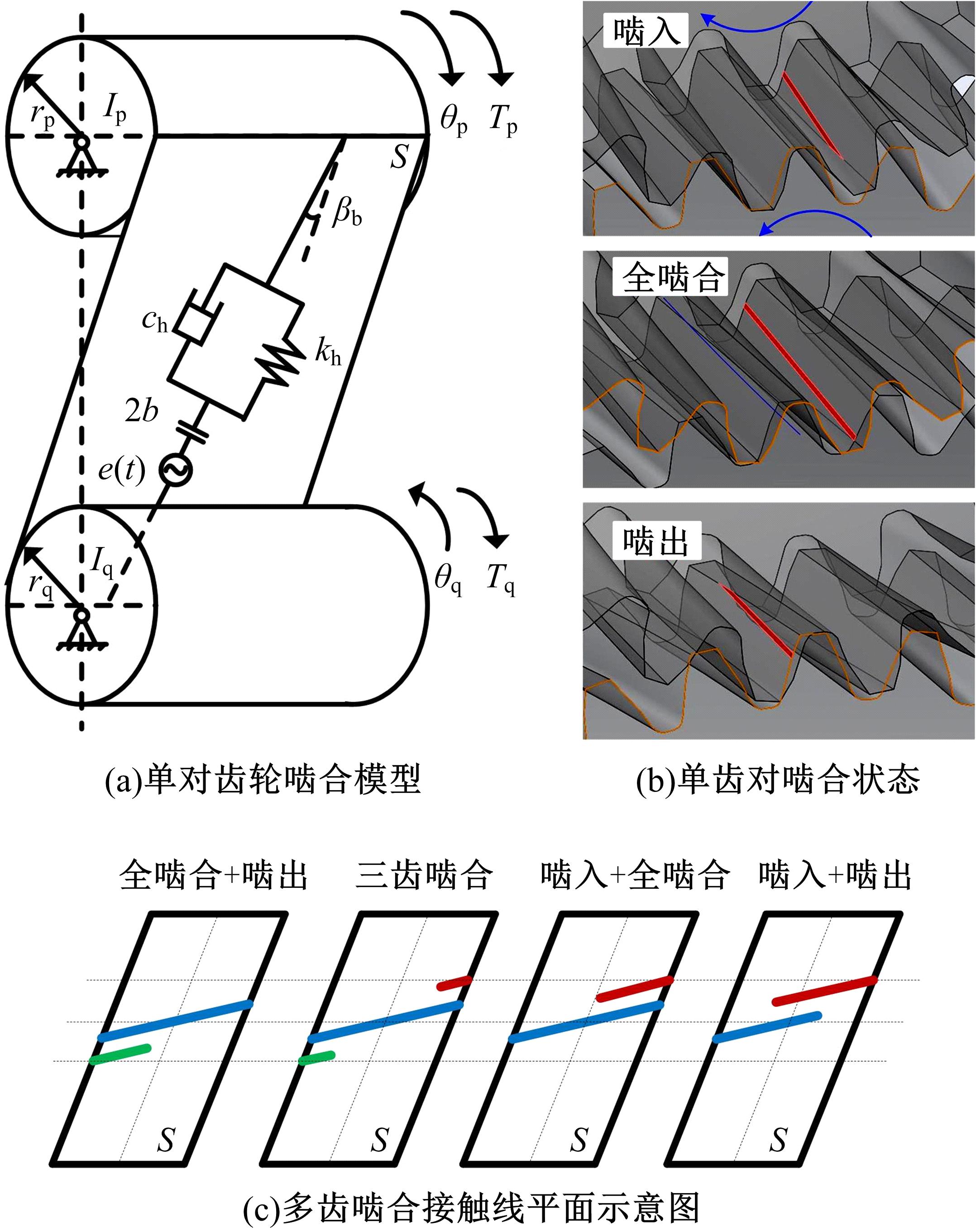

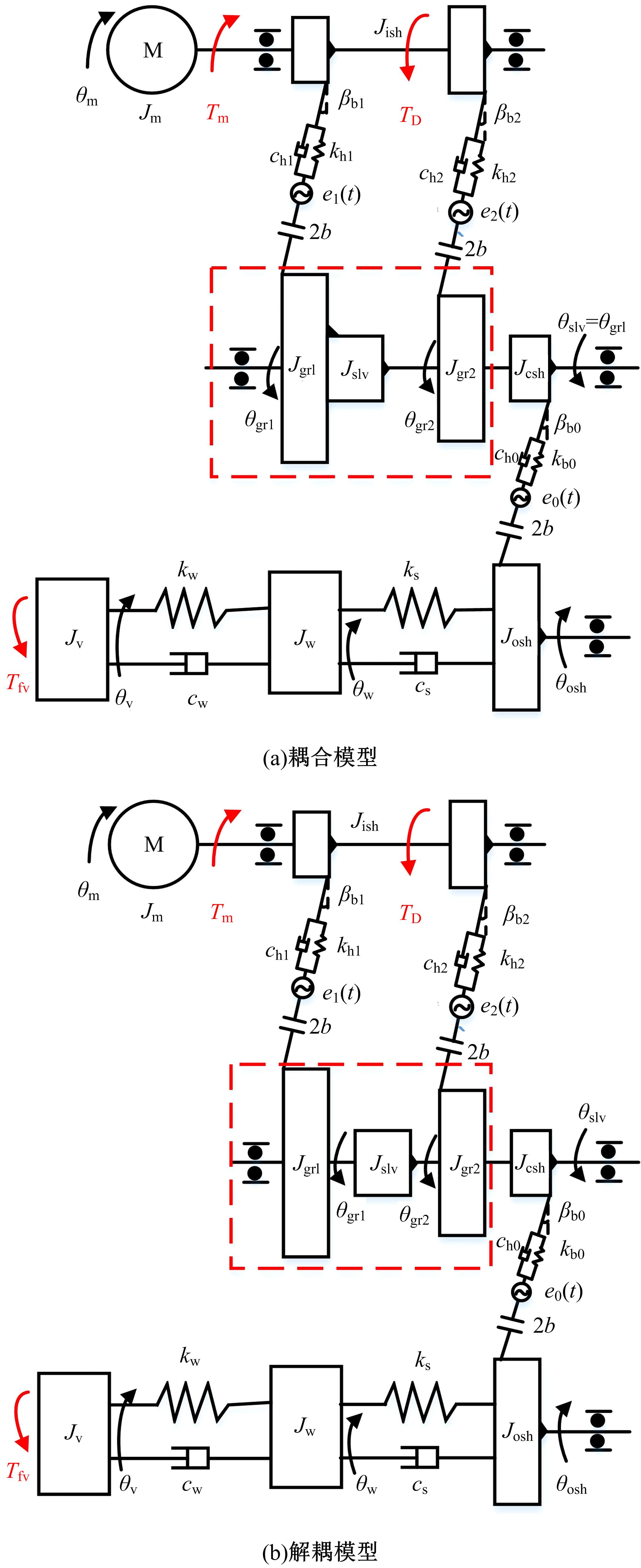

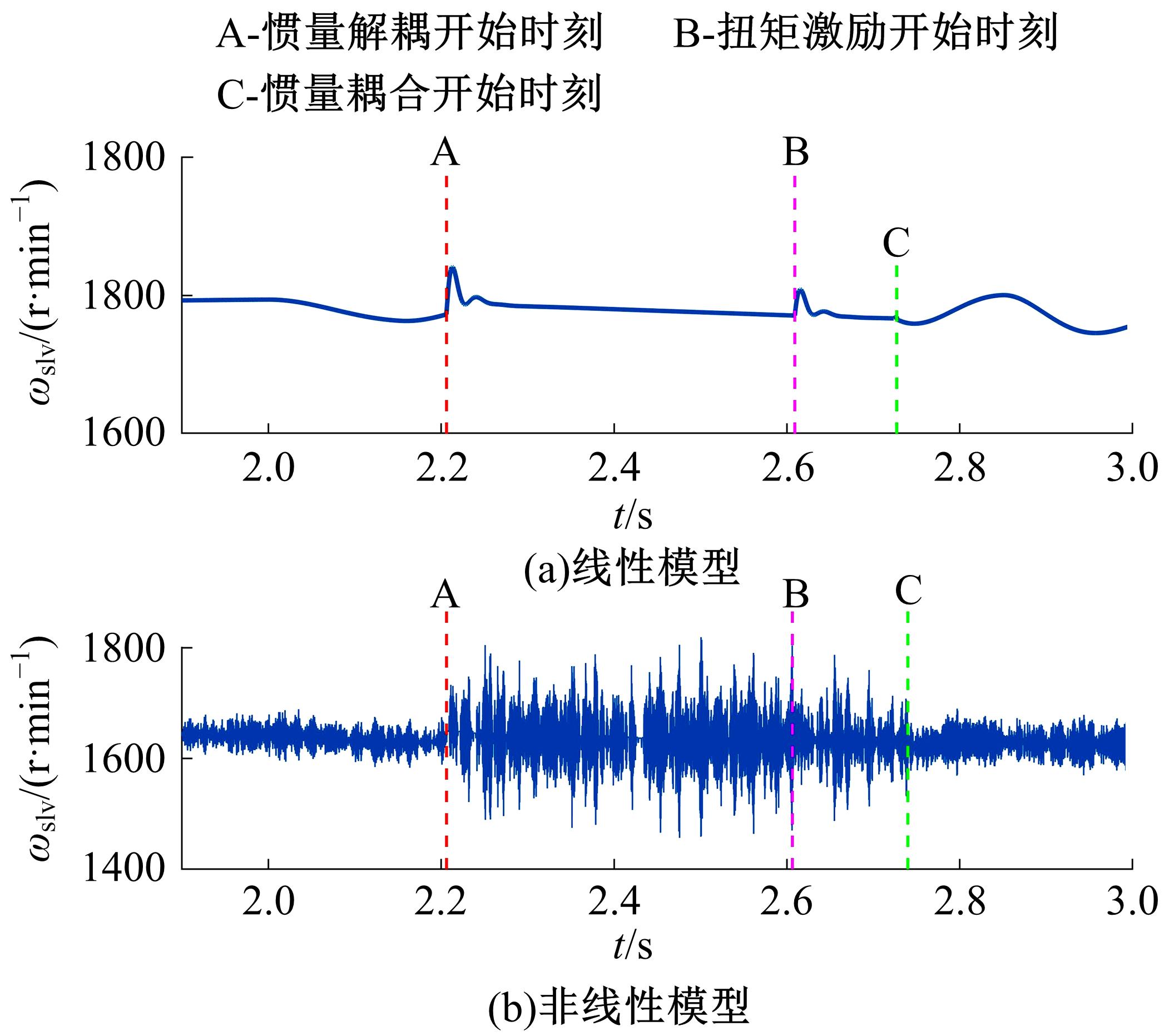

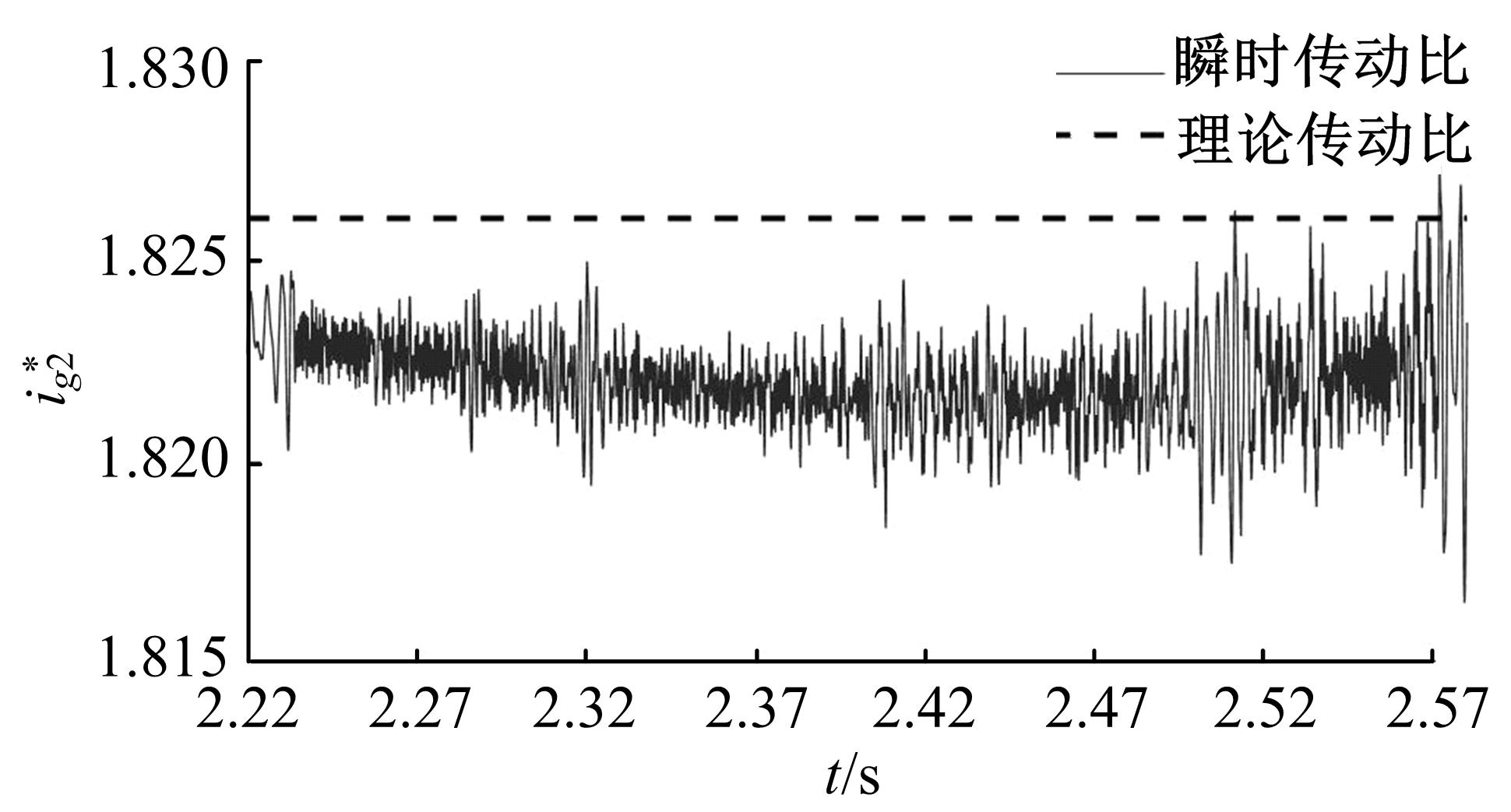

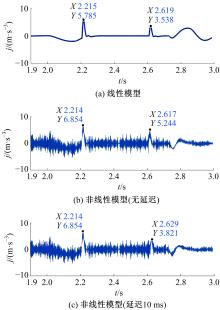

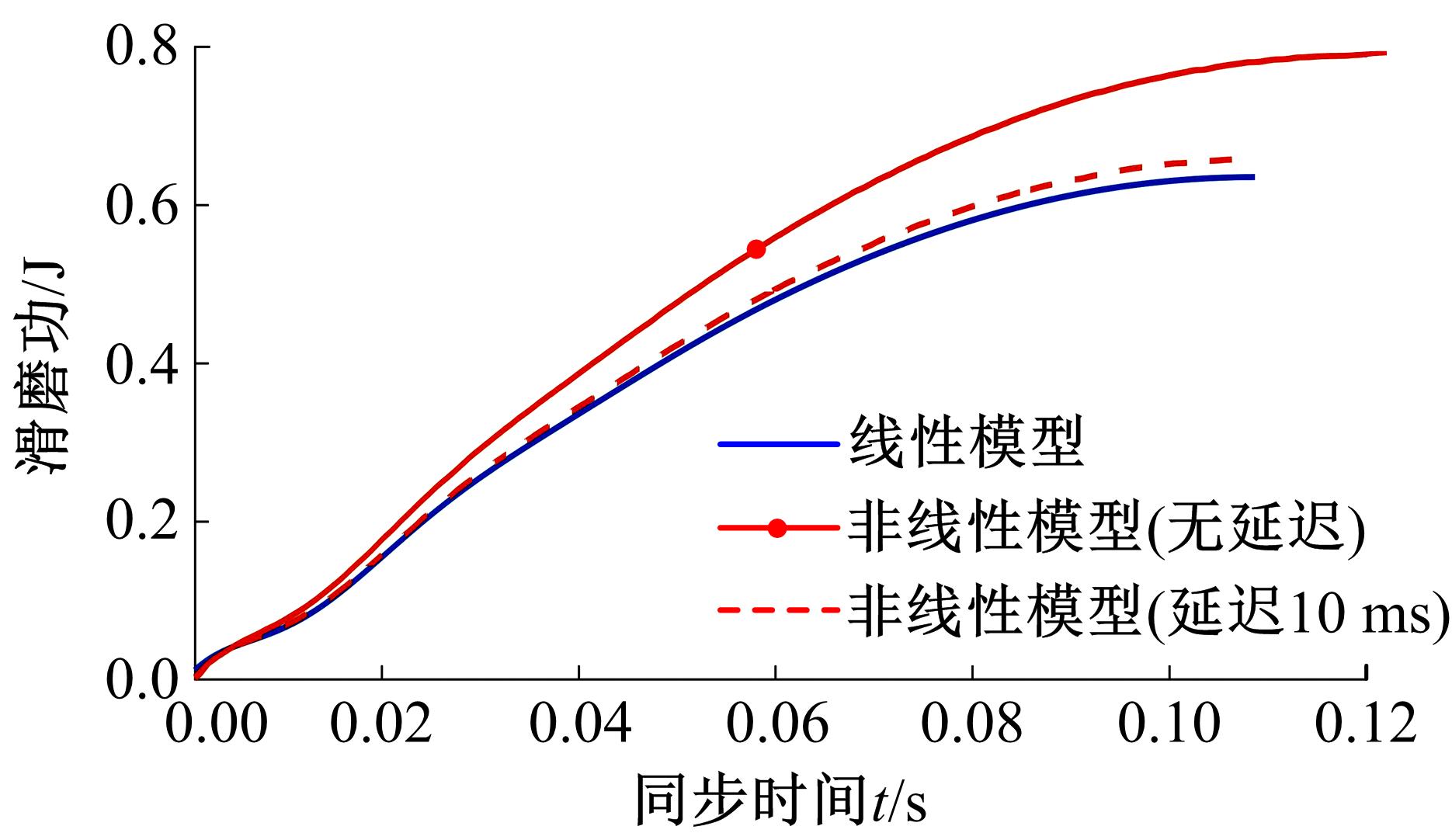

以无离合器机械式自动变速器(AMT)为研究对象,建立了换挡过程线性和非线性多自由度扭转振动模型,分析了线性和非线性条件下换挡过程各阶段接合套转速波动和动力学行为,对比了两种模型下换挡品质评价指标的差异,并通过调速阶段转速差延时PID控制方法来改善换挡品质。结果表明:相比于线性模型,齿轮非线性扭转振动会导致换挡时间延长、换挡冲击度增大且滑磨功增加,而对调速阶段适度延时能够有效缩短换挡时间、减小冲击峰值并减小滑磨功。

中图分类号:

- U463

| 1 | Kim Y K, Kim H W, Lee I S, et al. A speed control for the reduction of the shift shocks in electric vehicles with a two-speed AMT[J]. Journal of Power Electronics, 2016, 16(4):1355-1366. |

| 2 | Chai B B, Zhang J W, Wu S F. Compound optimal control for shift processes of a two-speed automatic mechanical transmission in electric vehicles[J]. Proceedings of the Institution of Mechanical Engineers, 2019, 233(8):2213-2231. |

| 3 | 黄毅,刘辉,项昌乐,等. 车辆传动系统非线性平移扭转耦合振动响应灵敏度研究[J].振动与冲击,2014,33(23):92-99. |

| Huang Yi, Liu Hui, Xiang Chang-le, et al. Response sensitivity of nonlinear translation-torsional vibration coupled model of a vehicle transmission system[J]. Journal of Vibration and Shock, 2014,33(23):92-99. | |

| 4 | 袁旺,田子龙,杨志坚,等. 乘用车加速工况动力传动系扭振分析与改进[J]. 汽车工程,2018,40(1):91-97, 113. |

| Yuan Wang, Tian Zi-long, Yang Zhi-jian, et al. Analysis and improvement of the torsional vibration of car powertrain under acceleration condition[J]. Automotive Engineering, 2018,40(1):91-97, 113. | |

| 5 | 金红光. 纯电动汽车两挡自动变速器箱体动态特性研究[D]. 长沙:湖南大学机械与运载工程学院,2015. |

| Jin Hong-guang. Dynamic characteristics research of a two-speed automatic transmission housing for pure electric vehicle[D]. Changsha: College of Mechanical and Vehicle Engineering, Hunan University,2015. | |

| 6 | Yang Y,Li H,Dai Y P. Nonlinear vibration characteristics of spur gear system subjected to multiple harmonic excitations[J]. Proceedings of the Institution of Mechanical Engineers,2019,233(17):6026-6050. |

| 7 | Yang Y,Cao L Y,Li H,et al. Nonlinear dynamic response of a spur gear pair based on the modeling of periodic mesh stiffness and static transmission error[J]. Applied Mathematical Modelling,2019,72:444-469. |

| 8 | 程功,肖科,王家序,等. 混合润滑状态下齿轮接触刚度[J]. 吉林大学学报:工学版,2020,50(2):494-503. |

| Cheng Gong, Xiao Ke, Wang Jia-xu, et al. Gear contact stiffness under mixed lubrication status[J]. Journal of Jilin University (Engineering and Technology Edition),2020,50(2):494-503. | |

| 9 | 林腾蛟,郭松龄,赵子瑞,等.裂纹故障对斜齿轮时变啮合刚度及振动响应的影响分析[J].振动与冲击,2019,38(16):29-36, 63. |

| Lin Teng-jiao, Guo Song-ling, Zhao Zi-rui, et al. Influence of crack faults on time-varying mesh stiffness and vibration response of helical gears[J]. Journal of Vibration and Shock, 2019,38(16):29-36, 63. | |

| 10 | Mo W,Jiao Y,Chen Z. Dynamic analysis of helical gears with sliding friction and gear errors[J]. IEEE Access,2018,6:60467-60477. |

| 11 | Yi Y, Huang K, Xiong Y S,et al. Nonlinear dynamic modelling and analysis for a spur gear system with time-varying pressure angle and gear backlash[J]. Mechanical Systems and Signal Processing,2019,132(1):18-34. |

| 12 | Geng Z,Xiao K,Wang J,et al. Investigation on nonlinear-dynamic characteristics of a new rigid-flexible gear transmission with wear[J]. Journal of Vibration and Acoustics,2019,141(5):051008. |

| 13 | Fang Y,Liang X,Zuo M J. Effects of friction and stochastic load on transient characteristics of a spur gear pair[J]. Nonlinear Dynamics,2018,93(2):599-609. |

| 14 | 隋立起,田丰,李波,等. 考虑齿轮耦合振动的换挡过程非线性动力学分析[J]. 清华大学学报:自然科学版,2020,60(2):109-116. |

| Li-qi Sui, Tian Feng, Li Bo, et al. Nonlinear dynamics analyses of gear shifting with gear vibrations[J]. Journal of Tsinghua University(Science and Technology),2020,60(2):109-116. | |

| 15 | 马辉,王奇斌,黄婧,等. 不同自由度耦合斜齿轮转子系统的振动特性[J].振动·测试与诊断,2014,34(4):650-657, 775. |

| Ma Hui, Wang Qi-bin, Huang Jing, et al. Vibration characteristics analysis of a helical gear rotor system considering different degrees of freedom coupling[J]. Journal of Vibration, Measurement & Diagnosis, 2014,34(4):650-657, 775. | |

| 16 | 张义民,何永慧,朱丽莎,等. 多平行轴齿轮耦合转子系统的振动响应[J]. 振动、测试与诊断,2012,32(4):527-531, 684. |

| Zhang Yi-min, He Yong-hui, Zhu Li-sha, et al. Vibration response of multi-shaft rotor system with coupled gear mesh[J]. Journal of Vibration, Measurement & Diagnosis, 2012,32(4):527-531, 684. | |

| 17 | Wang J G, Zhang J,Yuan Z, et al. Nonlinear characteristics of a multi-degree-of-freedom spur gear system with bending-torsional coupling vibration[J]. Mechanical Systems and Signal Processing,2019,121:810-827. |

| 18 | 符升平,项昌乐,姚寿文, 等. 基于刚柔耦合动力学的齿轮传动系统动态特性[J]. 吉林大学学报:工学版, 2011, 41(2): 382-386. |

| Fu Sheng-ping, Xiang Chang-le, Yao Shou-wen, et al. Dynamic characteristic of gear transmission system based on rigid and flexible coupled dynamics[J]. Journal of Jilin University (Engineering and Technology Edition), 2011, 41(2):382-386. | |

| 19 | 程潇骁. 电机变速器耦合系统换挡过程动力学建模与控制策略研究[D]. 北京:清华大学汽车工程系,2014. |

| Cheng Xiao-xiao. Dynamics modeling and control strategy for the shifting process of coupled motor-transmission system[D]. Beijing: Department of Automotive Engineering, Tsinghua University, 2014. | |

| 20 | 隋平阳. 电动车辆齿轮传动系统非线性动力学特性研究[D]. 北京:北京理工大学机械与车辆学院,2016. |

| Ping-yang Sui. Study on nonlinear dynamic characteristics of gear system for electric vehicle's transmission[D]. Beijing:School of Mechanical Engineering, Beijing Institute of Technology,2016. | |

| 21 | Song Q, Sui P Y. Nonlinear dynamics coupling analysis on gear system of automated mechanical transmission[C]∥The 3rd International Conference on Material Engineering and Application, Shanghai, China, 2016:518-523. |

| 22 | 柴本本. 电驱动两挡机械式自动变速器换挡过程控制研究[D]. 上海:上海交通大学机械与动力工程学院,2019. |

| Chai Ben-ben. Study on shifting process control for two-speed automatic mechanical transmissions on electric vehicles[D]. Shanghai:School of Mechanical Engineering,Shanghai Jiao Tong University, 2019. |

| [1] | 宋大凤,杨丽丽,曾小华,王星琦,梁伟智,杨南南. 基于行驶工况合成的混合动力汽车电池寿命优化[J]. 吉林大学学报(工学版), 2021, 51(3): 781-791. |

| [2] | 张家旭,王欣志,赵健,施正堂. 汽车高速换道避让路径规划及离散滑模跟踪控制[J]. 吉林大学学报(工学版), 2021, 51(3): 1081-1090. |

| [3] | 何仁,赵晓聪,杨奕彬,王建强. 基于驾驶人风险响应机制的人机共驾模型[J]. 吉林大学学报(工学版), 2021, 51(3): 799-809. |

| [4] | 王波,何洋扬,聂冰冰,许述财,张金换. 底部爆炸条件下车内乘员的腹部损伤[J]. 吉林大学学报(工学版), 2021, 51(3): 792-798. |

| [5] | 李寿涛,王蕊,徐靖淳,王德军,田彦涛,于丁力. 一种基于模型预测复合控制的车辆避碰控制方法[J]. 吉林大学学报(工学版), 2021, 51(2): 738-746. |

| [6] | 王伟达,武燕杰,史家磊,李亮. 基于驾驶员意图识别的电子液压制动助力系统控制策略[J]. 吉林大学学报(工学版), 2021, 51(2): 406-413. |

| [7] | 陈国迎,姚军,王鹏,夏其坤. 适用于后轮轮毂驱动车辆的稳定性控制策略[J]. 吉林大学学报(工学版), 2021, 51(2): 397-405. |

| [8] | 马芳武,梁鸿宇,王强,蒲永锋. 双材料负泊松比结构的面内冲击动力学性能[J]. 吉林大学学报(工学版), 2021, 51(1): 114-121. |

| [9] | 吴岛,张立斌,张云翔,单洪颖,单红梅. 基于滑移率辨识的汽车制动时序视觉检测方法[J]. 吉林大学学报(工学版), 2021, 51(1): 206-216. |

| [10] | 张恩慧,何仁,苏卫东. 不同挡板结构对油箱内油液晃动特性的数值分析[J]. 吉林大学学报(工学版), 2021, 51(1): 83-95. |

| [11] | 熊璐,魏琰超,高乐天. 基于惯性测量单元/轮速融合的车辆零速检测方法[J]. 吉林大学学报(工学版), 2021, 51(1): 134-138. |

| [12] | 陈吉清,蓝庆生,兰凤崇,刘照麟. 基于轮胎力预判与拟合的轨迹跟踪控制[J]. 吉林大学学报(工学版), 2020, 50(5): 1565-1573. |

| [13] | 杨志刚,范亚军,夏超,储世俊,单希壮. 基于双稳态尾迹的方背Ahmed模型减阻[J]. 吉林大学学报(工学版), 2020, 50(5): 1635-1644. |

| [14] | 沈哲,王毅刚,杨志刚,贺银芝. 风洞中未知声源漂移误差的逼近修正[J]. 吉林大学学报(工学版), 2020, 50(5): 1584-1589. |

| [15] | 刘钊,程江琳,朱玉田,郑立辉. 轨道车辆垂向振动建模及运动关联分析[J]. 吉林大学学报(工学版), 2020, 50(5): 1600-1607. |

|

||